Nurse on a polyethylene pipe: features and purpose

The saddle is the name of the part of the pipeline that is intended to perform a secondary branch from the main pipe consisting of several parts. In other words, this part is a type of fitting. It is made from various materials, such as plastic, cast iron, steel or brass. This element can be used in pipelines for various purposes. Its use will not only simplify installation, but also make it much cheaper.

The saddle on a polyethylene pipe is used both for sewer system, and for a branching water supply system. Currently, saddle bends are being manufactured for pipes of a specific size and universal, in which you can slightly change the coverage.

Specifications

These devices are very popular on both industrial and domestic highways due to their versatility and simple installation. The saddle is used to tie in the main pipe without cutting it, thereby not spending on transition tees.

There are two main subspecies of the nurse: clamp and pad. They are considered universal elements, as they have different diameters, which depend on the type of pipes.

Saddle withdrawal has a lot of advantages, for example:

- installation can be done easily in small rooms - bathrooms, mines, etc .;

- no need to turn off the water during installation;

- low cost;

- installation can be carried out without special equipment.

If we compare modern methods of tie-ins and lines with metal pipes, the first will help to avoid a number of problems. For example, discontinuing people may arise when stopping the flow of water or gas in a residential building. And in some institutions the shutdown of water is generally unacceptable.

Main types

As already mentioned, there are two types of saddles:

- blooming saddle clamps;

- saddles lining.

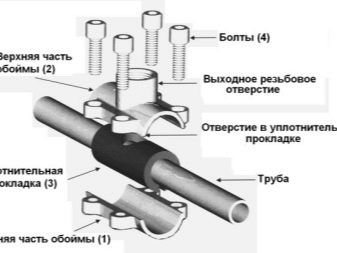

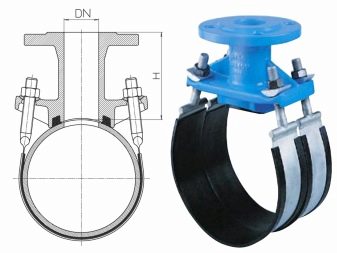

The first device is bolted. Its use is possible for various types of pipes: sewer, drainage, polypropylene or asbestos cement. The product contains two halves, which are attached to each other. On one of them is threaded waste, there is a transitional part, which is needed for tie-in. The collar is sealed due to the rubber ring (gasket), it can be mounted on pipes of different diameters. Also, thanks to the bolted connection, installation can be done quickly and easily. They are available with threaded outlets from 0.5 to 4 inches and are suitable for pipes with diameters from 20 to 315 mm.

It should be noted that this species can withstand pressures up to 10 atmospheres.

Nurse-pad is available without cutter or with it and is designed specifically for polyethylene pipes that operate at low pressure. And to install it, you need special equipment - electrodiffusion welding. This unit is connected to a special heating element, which is located at the bottom of the saddle. A device of this type withstands water pressure up to 16 atmospheres, and gas up to 10. There is also a belt that serves to secure the device.

Of the advantages of the lining are the following:

- possibility of use for the gas pipeline;

- strength and durability;

- use on pipes with an internal arrangement;

- installation is easy;

- it can be installed on any part of the system;

- can be used in systems with a carrier temperature up to 40 degrees Celsius.

There is another type of clamp - cast iron flange modifiers. Their main part is flexible, and the second is made of metal. On one half of the yoke clamp, a threaded branch is installed, a coupling with an external thread is easily screwed onto it and a pipeline assembly is mounted.

Subspecies nurses come with swivel and non-swiveling head. The first is prefabricated and can be used without the head, and the second allows you to make a 90 degree elbow relative to the main highway.

Electrowelded saddle with a cutter is often used for gas and water pipes. This connection is very reliable, hermetic and durable, so it can be used in pipes with particularly high quality requirements.

There are also special saddles for large diameter lines, their size is appropriate.Section of pipes in which they are used is 110-630 mm. These clamps are slightly different principle of fastening. If in models for pipes of smaller diameter coverage occurs with the help of two halves, then in this case the part consists of only one part - a metal flexible tape.

Installation

The installation of an electrically welded saddles without disturbing the integrity of the pipe and can even be performed under pressure. But getting permission for these works from Vodokanal is still required. The part has a heating coil, on which current flows, and is heated to the melting point.

Installation of electrically welded saddles occurs according to the following algorithm:

- it is necessary to shut off the pipeline;

- clean the surface and degrease it; This can be done with the help of specialized napkins or ordinary rags and alcohol;

- using a scraper to get rid of the epoxy layer from the welding zone;

- install the saddle with belts or bolts (in the case of bolts, fastening is uniform and does not warp);

- connect an electrofusion welding machine and perform welding;

- after its completion, it is necessary to mill the pipe wall.

In case of deficiencies, welding is rejected, and a new tap is welded next to it. It is worth noting that the equipment for welding may have a different operating temperature, so this information should be clarified by the bar code, which is located on the connecting elements. If there are any doubts about the quality of the gasket or tightness, it is better to additionally use a special sealant.

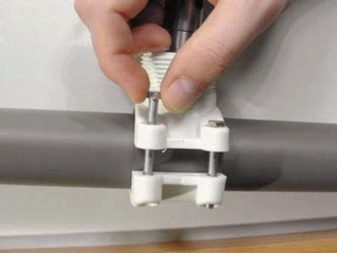

The installation of crimped crimp type is not at all difficult:

- if necessary, blocking of the pipeline section occurs;

- then the surface, as well as in the previous case, is cleaned of dirt;

- the nurse is installed in the chosen place and bolted;

- a check is carried out and if everything is installed correctly, the bolts are fully tightened.

It is worth noting that the task of inserting into the gas pipeline is better to be entrusted to professionals in the field of the gas industry.

Selection rules

Different types of nurses do not differ much from each other, so it’s easy to choose the right one. If the installation will be made on polyethylene pipes, it would be better to choose a part with an overlay, which is made of the same material.The most reliable are crimping models without sealed rings, but they are more difficult to install, so you need to be sure that the installation will be carried out correctly.

Despite the fact that modern production offers a large number of accessories for tapping, the saddle remains the most practical and simplest option for this.

How to mount the saddle on a polyethylene pipe, see the following video.