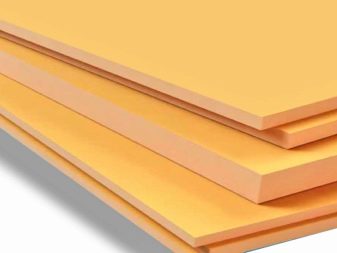

Polyurethane sheet foam: technical characteristics and application features

For a long time, polyurethane sheet foam is considered to be one of the most popular building materials. The huge variety in the application of this unique material allows you to use it not only in the form of insulation in the construction of buildings, but also in the manufacture of fabrics and furniture.

Special features

Polyurethane foam is a synthetic foam in the form of a rectangular canvas, which has a different thickness and is easy to use. In fact, polyurethane foam can be described as a kind of plastic. Back in 1937, German scientists led by chemist Otto Bayer invented PPU. At that time, the material was not yet so popularhowever, it was clear that he possesses unique properties, and that many possibilities await him for further use in production.

Nowadays, polyurethane foam is very popular. Production of polyurethane foam is a feasible task. This is easy to do right on the construction site, all you need to do is to observe the necessary proportions of special ingredients. The seams are made by pouring the components of petrochemical processing into a special form. After thorough mixing, the mixture is distributed into prepared molds with a press, where the material hardens and takes on the required shape and size.

According to its structure, the material is obtained porous, with the presence of cells that are filled with gaseous substance. Cell sizes affect material density.

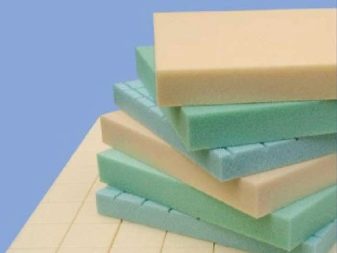

According to the type of stiffness, there are several types of sheet polyurethane foam:

- standard version;

- hard material;

- polyurethane foam of increased rigidity;

- highly elastic;

- elastic, non-combustible.

Hard elastic flame-resistant insulation brand PPU-ER has high thermal insulation properties.Its technical characteristics make the material indispensable for arranging buildings and industrial enterprises. This material is used in production areas with a high degree of responsibility, such as the automotive industry and aviation.

Hard sheet polyurethane foam has proven itself in wall insulation. This material is produced in the form of slabs and has noise-suppressing properties. Installation of walls in the building is made both from the outside and from the inside. Rigid polyurethane foam is excellent for insulating pipelines. Often used special forms, attached to the pipe with clamps or wire, which, in turn, helps to keep warm and protects them from damage and low air temperatures.

Advantages and disadvantages

Polyurethane foam is a modern building material, which has a solid structure and thermal insulation properties. The scope of polyurethane foam is quite diverse and includes many industries, such as building construction, aviation, automobile industry, the manufacture of toys and upholstered furniture.

The main positive aspects of the material can be identified as follows:

- material does not cause allergic reactions;

- it does not form fungus and mold;

- resistant to temperature changes;

- convenient in work;

- wide range of activities;

- high sound insulation performance.

PPU for the production of furniture does not constitute a favorable habitat for insects. And also its main advantage is the ability to take various necessary forms, which is important in the manufacture of upholstery for furniture, seats and mattresses.

Despite significant advantages, polyurethane foam has negative sides.

- The negative effect of ultraviolet radiation contributes to rapid wear. As protection, you can use plaster or paint.

- Polyurethane foam is a non-combustible material. Higher temperatures will not cause a fire, but the insulation may start to smolder. This process can be stopped by cooling the material. Therefore, where the surface can begin to warm, it is better to abandon the use of foam.

Specifications

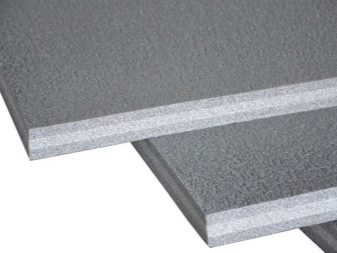

As a heater, polyurethane foam has a significant superiority over other building materials.Usually in construction rigid polyurethane foam is used, which has excellent energy-saving qualities in the form of high density up to 70 kg / m3 and low thermal conductivity from 0.02 to 0.03 W / m.

In general, the following features are characteristic of rigid type PUF:

- low permeability;

- high strength;

- various methods of manufacturing material;

- large temperature range;

- resistance to precipitation, chemical elements, radiation and corrosion.

In general, polyurethane foam sheet is a modern building material, which has found wide application in various industries, including construction, furniture and clothing industry.

This universal polymer in the form of foam is not affected by moisture and temperature. Polyurethane foam is durable in operation and has high sanitary and hygienic standards, which makes it safe for human health and life.

You will learn more about the benefits of polyurethane foam in the next video.