Warming of the house of aerated concrete: types of insulation and installation stages

Buildings made of aerated concrete or foam blocks, built in temperate and northern climates, require additional insulation. Some believe that the material itself is a good heat insulator, but it is not. Therefore it is worth considering in more detail the insulation of a house of aerated concrete, types of thermal materials and installation steps.

The need for insulation

The popularity of gas-silicate blocks is due to a number of reasons: they are light, with a clear rectangular shape, do not require the construction of a strong foundation for a house, and even a novice specialist can cope with their installation. Installation of a building of such material does not require such qualifications of a bricklayer as a brick house. It is easy to cut blocks of foam concrete - a regular hacksaw.

The composition of the aerated concrete block includes a cement-lime mixture, a foaming agent, which is most commonly used aluminum powder.To increase the strength of this cellular material, the finished blocks are held under high pressure and temperature. Air bubbles inside give a certain level of insulation, but you still have to insulate the building at least outside.

Many believe that to protect against the cold and moisture of the outer walls, it is enough just to plaster them. The plaster will perform not only a decorative, but also a protective function, it actually retains heat a little. In the future, many are faced with problems.

In order to answer whether it is necessary to warm buildings from foam concrete, you first need to take a closer look at the structure of the material. It contains cells filled with air, but their pores are open, that is, it is vapor-permeable and absorbs moisture. So for comfortable housing and efficient use of heating it is necessary to use heat, hydro and vapor insulation.

Builders recommend building such buildings with a wall thickness of 300–500 mm. But these are only norms for the sustainability of the building; we are not talking about thermal insulation here. For such a house, an external protection from cold in at least one layer is necessary.It should be borne in mind that according to its thermal insulation characteristics of a stone wool or foam plastic plate with a thickness of 100 mm, they replace 300 mm of a gas-concrete wall.

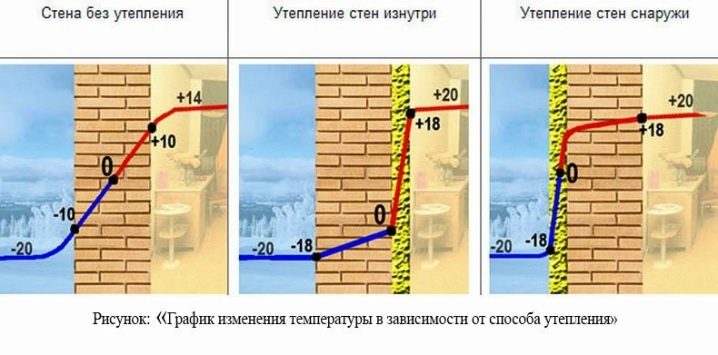

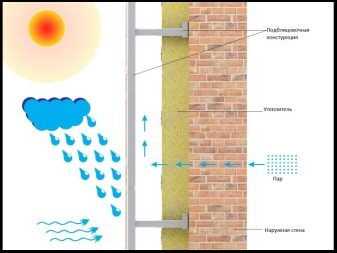

Another important point is the “dew point”, that is, the place in the wall where the positive temperature becomes negative. In the strip, where zero degrees, condensate accumulates, this is due to the fact that aerated concrete is hygroscopic, that is, it easily passes moisture. Over time, under the influence of temperature, this liquid will destroy the structure of the block.

Therefore, due to external insulation, it is best to transfer the “dew point” to the outer insulating layer, especially since foam plastic, mineral wool, polystyrene foam and other materials are less susceptible to destruction.

Even if, under the action of cold and moisture, the outer insulation collapses with time, then it is much easier to replace it than destroyed and deformed blocks. By the way, this is why it is recommended to install insulation outside, not inside the building.

If you plan to build a cozy house in which the family can live comfortably all year round, and the walls of relatively fragile material will not collapse, then you should definitely take care of the insulation.Moreover, the cost of it will not be so significant, several times less than the installation of the gas silicate walls themselves.

Ways

Houses made of aerated concrete are warmed outside on the facade, inside under the finishing interior. Do not forget about the insulation of the floor and ceiling. First, consider the ways of wall insulation outside.

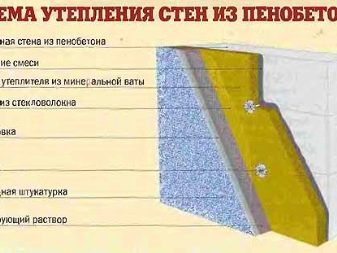

Wet facade

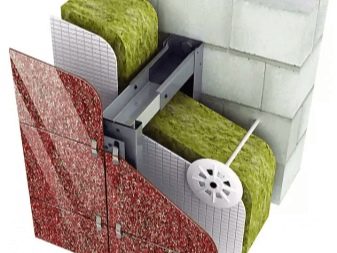

The so-called wet facade is a simple and cheap way to insulate a building from foam blocks, but it is also quite effective. The method consists in fixing plates of mineral wool on glue and plastic dowels. Instead of wool, you can use foam or other similar materials. Outside, a reinforcing mesh is hung on the insulation, then the surface is plastered.

Before starting work, the surface of the walls is cleaned from dust and primed with a special composition for deep penetration foam blocks. After the primer is completely dry, glue is applied, for this it is best to use a notched trowel. Adhesive compositions for the installation of plates of insulation are many, they are produced in the form of dry mixtures, which are diluted with water and kneaded with a mixer. As an example, glue for exterior work Ceresit CT83.

Until the glue has dried, a serpyanka is applied to it so that it covers the entire wall without gaps. Then proceed to the gluing of insulating plates, this work should not cause problems even for an amateur. Mineral wool is applied to the surface covered with glue, and tightly pressed. At the same time it is necessary to ensure that the plates are located exactly, there is no gap between them. Optimally, each subsequent row is laid with a shift by half the slab.

Installation of insulating plates comes from the bottom up. Optimally, after laying each row, hammer in the dowels until the glue has dried. For the “wet” facade there are special plastic dowels-umbrellas 120–160 mm long on the market, inside there is a metal screw. They are hammered into gas-silicate blocks with little effort with an ordinary hammer. It is necessary to fasten them so that the cap is slightly recessed into the insulator.

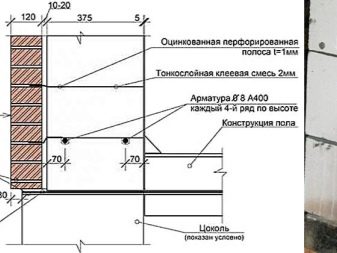

When all the plates are installed and the dowel-umbrellas are clogged, you need to wait until the inner layer is completely dry, then apply a second layer of glue on the entire surface. After these procedures, with full drying, you can apply decorative plaster.With a wall thickness of 300–375 mm, together with insulation, 400–500 mm are obtained.

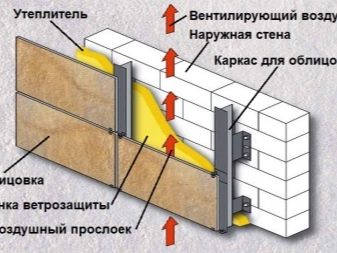

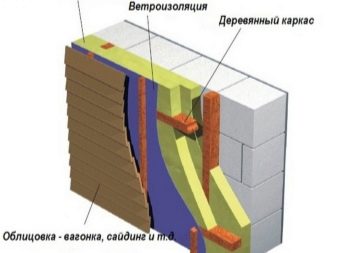

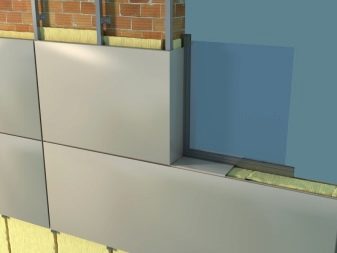

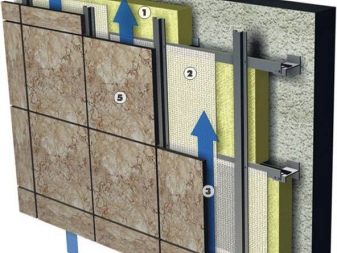

Ventilated facade

This is a more complicated version of wall insulation with gas blocks. It requires the installation of crates from wooden bars or metal profiles. This method allows you to use a more diverse finish under siding, decorative stone or wood. For the ventilated facade use the same insulating materials as for the "wet": mineral wool, foam, penoplex, polystyrene foam.

Advantages and disadvantages

The following advantages of the ventilated facade can be noted:

- longer service life of insulation materials;

- effective moisture protection;

- additional sound insulation;

- protection against deformation of the walls of aerated concrete blocks;

- fire safety.

Immediately worth noting its disadvantages:

- relatively short lifetime;

- requires a great skill in installation, otherwise there will be no air cushion;

- due to ingestion of condensate and freezing in winter, swelling may occur.

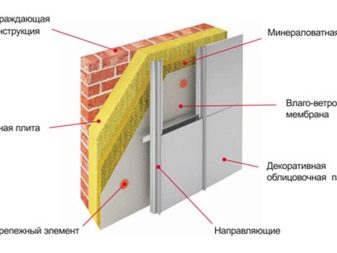

Installation steps

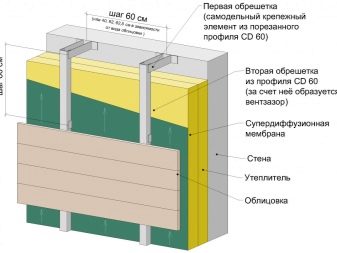

The process of installation of the ventilated facade begins with the installation of a warming layer.Here, as in the previous version, any tile insulation materials are used, for example, all the same mineral wool. The wall is cleaned, primed in 2–3 layers, after the primer has dried, a glue for foam blocks is applied with a notched trowel. Then, as well as on the “wet facade”, insulator sheets are laid on the serpyanka, dowels and umbrellas are attached. The difference from the first method is that not glue is applied over the mineral wool, but a moisture-windproof membrane or wind barrier is strengthened.

After the glue dries, the preparation for the installation of the batten begins. For example, consider its construction of a tree. It is best to take vertical bars 100 to 50 or 100 to 40 mm, and for horizontal lintels - 30 x 30 or 30 x 40 mm.

Before work, they must be treated with antiseptic. Bars are fastened to the wall with anchors on aerated concrete, and between themselves with wood screws, preferably galvanized.

Initially, the installation of vertical bars over the wind barrier in the entire length of the wall. Step should not be done more than 500 mm. After that, vertical jumpers are installed in the same way. It is worth remembering that everywhere the level should be observed under a single plane. At the final stage, siding or another type of decorative trim is attached to the crate.

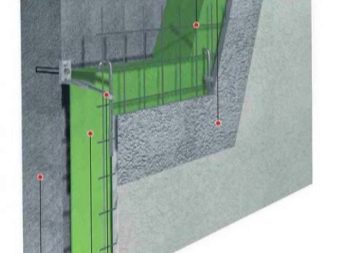

More rarely, in the construction of private houses, the heavy method of the “wet facade” is used. For him, the foundation of the building expands, the insulation rests on it and is attached to powerful metal hooks. A reinforcing mesh is placed over the insulating layer and then plaster is applied, which can be covered with decorative stone.

Another option for external insulation of the house of gas silicate blocks can be noted outside trim facing bricks. A protective layer of air is formed between the brick wall and the gas concrete. This method allows you to create a beautiful exterior of the facade of the building, but it is quite expensive, and the laying of facing bricks requires special professionalism.

After the external insulation of the walls of the foam blocks is to start installing internal insulation. Here it is better not to use completely vapor-proof materials, as the wall seems to be clogged, and the building does not breathe. It is best to use ordinary plaster for interior work. The dry mixture is diluted with water, mixed with a mixer and applied on a vertical surface, then leveled. Before plastering you should not forget about priming the walls and fixing the serpyanka.

Inside such a house you should definitely insulate the floor, ceiling and roof. To do this, you can use various methods and materials, for example, to mount a crate in which to place stone wool or polystyrene plates, to create a “warm floor” system with heating, to use a tie with an additional protective layer, to lay rolled insulation materials in the attic.

When warming the floor and ceiling in a private house, you should not forget about their protection from moisture and steam.

Varieties of materials

To decide which insulation is better to choose for your home, you must not only take into account the price of the material and installation, but also know their properties.

Stone wool is traditionally insulated walls of houses, floors and roofs, sewage pipes, plumbing and heating. It is widely used for thermal insulation of buildings made of aerated concrete, it is the most popular material with the technologies “wet facade”, ventilated facade. It is made from mineral raw materials, mainly basalt under the action of high temperatures by pressing and squeezing the fibers.

Stone wool can be used to protect against frost when building a building from scratch or in a house that has been built for a long time.Due to its structure, it contributes to good air circulation, so that, together with porous foam blocks, will allow the house to “breathe”. This material is not subject to burning: at high temperatures and an open flame, its fibers will only melt and stick together, so this is a completely fireproof variant.

The coefficient of thermal conductivity of mineral wool is the highest among all materials. In addition, it is made from natural raw materials, without harmful impurities, it is an environmentally friendly material. It is absolutely impossible to get wet with it, it immediately becomes useless, therefore, during its installation, it is necessary to properly use waterproofing.

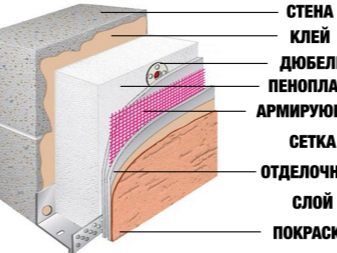

It is possible to warm a facade of the house from a gas concrete polyfoam. In terms of its popularity, it is practically not inferior to mineral wool, while it has high thermal insulation characteristics and low cost. Material consumption in comparison with mineral wool with the same layer is almost one and a half times less. It is easily cut and fixed to the wall of foam blocks using plastic dowels, umbrellas. An important advantage of foam plastic is that its plates have a flat surface, they are rigid and do not require a batten or guides during installation.

The density of the foam from 8 to 35 kg per cubic meter.m, thermal conductivity of 0.041–0.043 W per micron, fracture resistance 0.06–0.3 MPa. These characteristics depend on the type of material chosen. The cells of the foam have no pores, so it practically does not allow moisture and steam to pass through, which is also a good indicator. It has good sound insulation, does not emit harmful substances and is resistant to various chemical reagents. Conventional foam is quite combustible material, but with the addition of fire retardants, its fire risk is reduced.

A good option would be to warm the house of aerated concrete basalt plate. This material is very similar to mineral wool, but more solid, it can be installed without guides, just gluing in even rows to the wall. A basalt slab is made from rocks: basalt, dolomite, limestone, some types of clay by melting at temperatures above 1500 degrees and producing fibers. In terms of density, it is almost the same as foam, easily cut into fragments, attached to the wall retains sufficient rigidity.

Modern varieties of basalt plates have a high hydrophobicity, that is, their surface practically does not absorb water.In addition, they are environmentally friendly, when heated, do not emit harmful substances, vapor-permeable, have excellent sound insulation.

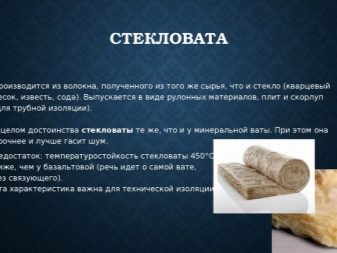

Glass wool has been used for a long time, but has recently been superseded by other more practical and efficient materials. Its main disadvantage is still considered by many to be harmful to the skin and respiratory tract during work. Its small particles are easily separated and hover in the air. An important advantage compared to all other common heat insulators is the low cost of glass wool.

Glass wool is easy to transport as it folds into compact rolls. This is a non-combustible material with good sound insulation.

To install thermal protection of glass wool is best with the installation of crates. Another advantage is that rodents are afraid of this material and do not create their own burrows in the thickness of the insulation.

Ecowool is a fairly new thermal insulation material made from cellulose, various residues of paper and cardboard. Fire retardant is added to protect it from fire, and antiseptics are added to prevent rotting. It has a low cost, environmentally friendly and has a low thermal conductivity.It is installed in the crate on the wall of the building. Among the drawbacks, it is worth noting that ecowool intensively absorbs moisture and decreases in volume over time.

Penoplex or polystyrene foam is a fairly effective material for insulating foam block walls. It is a fairly solid and rigid plates with grooves at the edges. It has durability, moisture protection, durability and low vapor permeability.

Polyurethane foam is applied to the surface by spraying from the cans, this is its main plus, it does not require any glue, nor fasteners, or crates. On top of that, if there are metal elements in the wall of foam blocks, it covers them with a protective anti-corrosion grid.

A standard facing brick can serve not only as an excellent exterior finish of a facade, but also to be an external heat insulator if you cover it with a wall of foam blocks. But it is best to use two layers to keep the heat in the house, putting foam sheets between them.

To simplify all the work on the insulation and exterior decoration of the building, you can sheathe its walls with thermopanels. It is a versatile material that combines insulating and decorative properties.The inner layer is made of various non-combustible heat insulators, and the outer one represents a variety of textures, patterns, colors. There is an imitation of a brick, natural stone, rubble, wood. It is successfully possible to combine thermopanels with a brick tile.

Subtleties of installation

Installation of insulation of the building of aerated concrete and the subsequent decorative decoration with their own hands have a number of subtleties. For convenience and safety, be sure to use hard, securely fastened to the wall of the forest with scaffolds. They can be fastened to the wire and anchors screwed into the facade. It is best to use lightweight and durable aluminum, rather than heavy steel.

For any kind of facade, it is necessary to properly follow the cake sequence: first comes a layer of glue with a serpyanka, then insulating panels, the next layer of glue or a windscreen with a crate. Decorative facing of the facade in the "wet" version is applied only on a hard surface.

Above the foundation of the house of gas silicate can fix a corner of the metal profile, which will additionally support the insulation layer, and at the same time separate the base from the wall. It is attached to ordinary metal dowels or anchors on aerated concrete.

For all its merits, polyfoam does not provide air circulation, that is, fixing it from two sides to a wall of gas-silicate blocks virtually eliminates its remarkable properties. Therefore, many people prefer to use traditional mineral wool or more modern and efficient basalt slabs.

Ventilated or hinged facade can be installed on a metal or wooden crate. The tree under the influence of temperature, humidity can be deformed, therefore there is a probability of deformation of the decorative facing of the building.

How to insulate a house of aerated concrete with mineral wool, see the following video.