Warming of the house from a bar: the choice of materials and technology

Houses built of timber are very popular in our country. Such buildings not only look aesthetically pleasing, but are also warm. However, this does not negate the fact that they need to be additionally warmed with various special means.

Features of the procedure

Houses from a bar are chosen by many users. The popularity of such buildings is due to their attractive and natural appearance, the use of natural materials in the construction, as well as the comfortable microclimate that persists in such environments. By itself, a timber is a warm material, so the houses from it are considered to be cozy and welcoming. They are not cold in winter, but not hot in summer.However, such structures still need additional warming, otherwise during the frosty seasons they will not be so comfortable.

Warming is primarily required log houses, in which the building material does not have sufficient thickness. If the cross section inside the wooden house is incorrect, complete freezing can occur. This fact suggests that the overlap in such a structure is not able to retain heat qualitatively and can not do without insulation. If the timber in the house has a cross section of 150x150 mm, then it is not necessary for it to provide additional finishing, especially if the building is located in areas with a warm and temperate climate. And also the timber with a section of 180x180 mm is popular - very warm and reliable houses are built from it, for which additional finishing is also optional. However, it is worth considering that if the cross-section of the timber at home is correct, all the same, over time, the building material will crack, and this will also cause significant heat loss.

If the decision is made to warm the log house, then you should pay attention that this can be done both outside and inside.

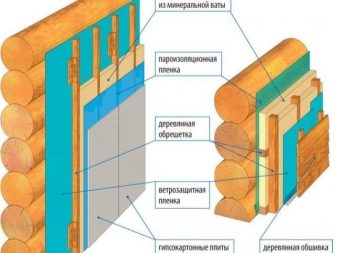

The following features are characteristic for the insulation of the house from the inside:

- with such work, a certain part of the useful living space will inevitably be lost due to the installation of the frame structure under the insulation;

- a layer of thermal insulation material hides under the wooden floors, which affects the design of rooms in the house;

- due to the inevitable winter cooling of wooden walls, the dew point moves directly to the internal insulation. After this, condensation and mold appear. It should be borne in mind that monitoring the condition of the timber in such circumstances is not an easy task.

It is considered more common to warm the log house outside. It includes the following features:

- with such insulation, the living space of the living space does not undergo major changes and does not become less;

- external works are good because they do not affect the internal order of the household;

- with this method of insulation, the facade of a wooden house is reliably protected from destructive temperature shocks, and this significantly prolongs the life of the building;

- if you correctly select the suitable and high-quality insulation, then in the inner part of the house a comfortable microclimate will not be disturbed;

- Most owners turn to this method of warming so that it is comfortable in the house and that it “breathes”;

- with external insulation, you can upgrade the facade in case of natural darkening;

- Using external insulating materials, you can protect the timber from damage.

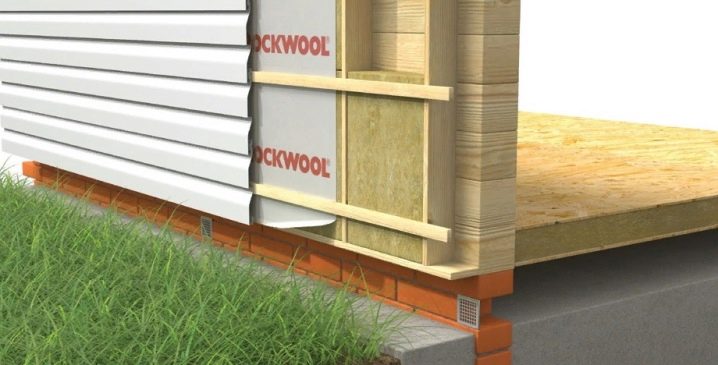

At the moment there are several basic options for wall insulation in the house of the bar. Ventilated facade is a technology developed as an additional decoration of the facade of the building.

It is worth considering in more detail what advantages are characteristic of this option of warming a log house:

- ventilated facades are characterized by a long service life, which is capable of reaching 50 years;

- This type of insulation is characterized by excellent heat and sound insulation, which is noted by many users;

- Installation of ventilated facades is considered simple and affordable;

- a similar method of insulation allows the use of a variety of facing materials;

- With this warming, the dew point moves outwards, thus avoiding the accumulation of condensate in the material.

The technology of warming a log house under the siding largely repeats the hinged ventilatedfacade. In this case, the insulation is also mounted on the outside, and on top is supplemented by a decorative coating. Polyurethane technology will be clear to every craftsman who has come across at least once work related to assembly foam. The main difference of this method is only in the amount of materials required for the formation of a heat-insulating cushion, because they need much more. That is why when choosing such a technology, it is necessary to stock up with a high-quality spray gun.

Selection of materials

Modern manufacturers offer the choice of consumers several options for insulating materials.

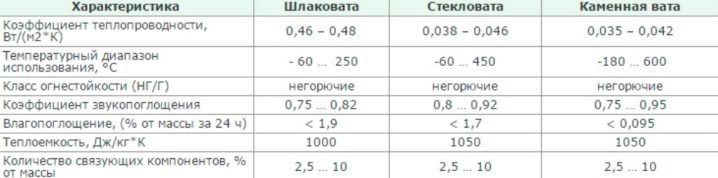

Mineral wool

Currently, mineral wool is recognized as one of the most popular insulation materials.

It is of the following types:

- stone or basalt;

- glass;

- slag.

All types of mineral wool have approximately the same properties and characteristics.

This insulation and all its subtypes are characterized by the following qualities:

- mineral wool is flame retardant and non-flammable;

- different biological and chemical resistance;

- vapor permeable;

- ecologically safe;

- possesses sound insulation properties.

The main disadvantage of mineral wool is that it is very attractive for rodents. In addition, in the case of wetting this insulation does not dry out completely, which is detrimental to its qualities. Most experts in the insulation of the outer part of the house use Minvata in mats. Rolls in this case are considered less practical and convenient, since they are inconvenient to deploy on vertical bases. Before installing such insulation, you should make sure that the walls and foundation of the house are steam- and waterproofed with high-quality materials.

Styrene plates

The cheapest insulation is the good old foam. It can afford a buyer with any budget. Such material differs in the minimum weight and hygroscopicity. In addition, the foam has good thermal insulation qualities.

However, this cheap insulation has its weaknesses.

- Polyfoam is a combustible material. Moreover, during combustion, it actively releases toxic substances hazardous to human health.

- This insulating material is fragile.

- Do not tolerate contact with ultraviolet.

Insulation of polyurethane foam is more expensive. It is one of the varieties of plastic. This material has a characteristic cellular and foamy structure. The main component of polyurethane is a gaseous substance, which accounts for 85–90% of the total composition. Hard polyurethane foam is more popular than foam, despite the high cost.

The relevance of this insulation is due to the following advantages:

- polyurethane easily "sticks" to the bases from a variety of materials, from wood to metal;

- a similar insulation is made right on the site of all the work with a minimum number of components. This fact suggests that in matters of transportation polyurethane foam is economical;

- This material is lightweight, so working with it is not so difficult;

- floors, supplemented with polyurethane, are not only warmer, but also durable;

- this material is not afraid of temperature drops.

Of course, this warming material has its drawbacks, namely:

- contact with ultraviolet rays often leads to rapid deterioration of the insulation, so it is recommended to “cover” it with other materials, for example, plaster or panels;

- in contact with high temperatures, the foam insulation from the foam will not burn, but it will actively fester;

- such material cannot be used for warming the roofs of professional sheets in wooden houses;

- PPU is quite expensive, as well as work on its deposition on the foundations of the beam.

Ecowool

Many consumers turn to the warming of log houses with ecowool. This material consists of cellulose, boric acid, antiseptic components and sodium tetraborate.

This insulation has the following advantages:

- has excellent sound insulation properties;

- to warm the room, you need a small amount of such a warming material, which indicates its efficiency;

- as part of no hazardous and harmful substances that harm human health;

- very easy to blow out even the most inaccessible areas;

- is a seamless material, so in the winter season with it you can significantly save on heating;

- It is inexpensive with good quality;

- does not cause allergic reactions.

Unfortunately, ecowool has its weaknesses, such as:

- Over time, the excellent thermal insulation characteristics of ecowool inevitably decrease.At this time, the thermal conductivity of the living space increases;

- the installation of this insulation can be made only with the use of special, complex equipment, so that without the involvement of a team of masters is hardly possible;

- so that the thermal insulation of the space does not decrease, it is necessary to contact only highly qualified specialists with rich experience;

- with a dry installation of such a heater, quite a lot of dust will remain, and with a wet version, the material will dry for quite a long time;

- Ecowool stiffness is much lower than that of polystyrene materials; therefore, it cannot be installed without first constructing a reliable framework;

- ecowool is subject to a shrinkage process if it is installed on a vertical base with a density below the norm;

- Experts do not recommend placing this insulation material near open flame sources, as well as chimneys and chimneys, because the coating may begin to smolder.

Warm plaster

Relatively recently, another interesting insulating material appeared on the market - it is a warm plaster. This insulation is good because it is non-flammable, is not afraid of sunlight, is easy to install and protects wooden houses from the ingress of damp and moisture.

It has a complex composition, which includes the following ingredients:

- glass;

- cement;

- hydrophobic components.

Polyethylene foam

Currently, this material is often used for insulation of houses from profiled or glued timber.

Polyethylene foam has such positive qualities as:

- low thermal conductivity;

- elasticity and flexibility in work;

- small weight;

- affordable cost.

Choosing such a foil material, you should know that it is available in two versions:

- PVD - high pressure feedstock;

- HDPE - low pressure polyethylene.

In addition, these insulants come in single or double sided foiling.

Sawdust

If you want to insulate the house as environmentally friendly and natural materials, then you should turn to sawdust.

This insulation has the following characteristics:

- are inexpensive;

- do not emit harmful and hazardous substances, as they simply are absent in their composition.

However, there is such a warming material and a number of significant drawbacks, namely:

- Easy flammability. In addition, these materials are prone to spontaneous combustion,that in a log house is a serious problem;

- "Tidbits" for all sorts of parasites and pests, for example, rodents and insects.

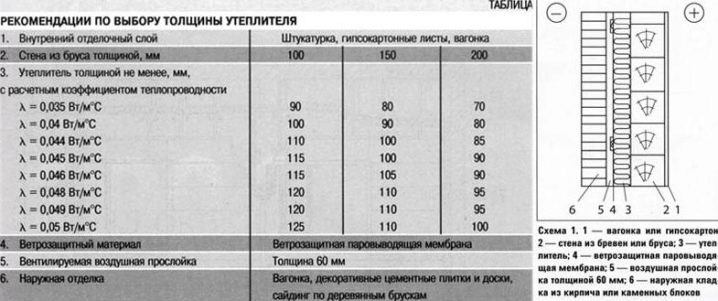

How to make the necessary calculations?

To insulate a wooden house you need to calculate the volume of materials. For this, it is permissible to use a special online calculator. But before that you need to know the thickness of the bases (for example, walls), the area of space, as well as the type of exterior and interior decoration.

Variety of methods

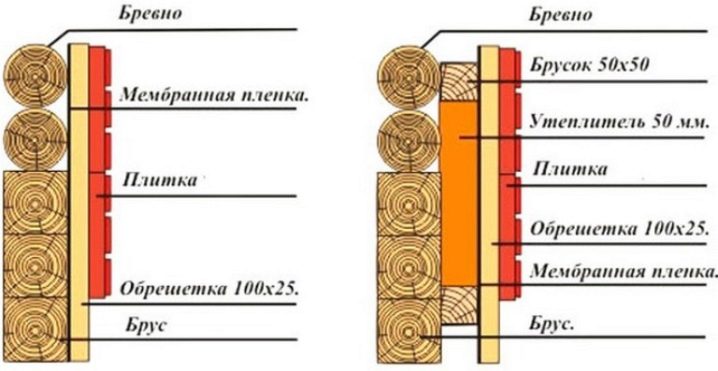

Using the hinged method, the following heater installation technology is applied:

- First, all sawn timber is treated with special compounds to protect them from rotting and insect attacks;

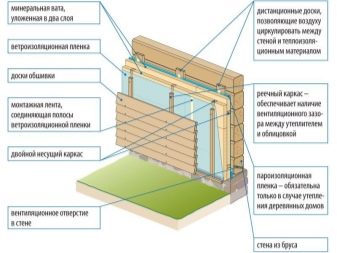

- a reliable lattice is attached to the outside of the wooden house. Hydro and windproof materials are nailed to it. Air will circulate in the spaces between the plates and the crate, so condensate will not accumulate in the insulation;

- the crate is leveled with a plumb using the level;

- insulation in this case is carried out between the slats using dowels;

- bars are put on the slats, their thickness should be not less than 5 cm, so that there is a small gap between the insulation material and the cladding;

- It is necessary to proceed to the installation of cladding, for example, siding.

When installing the insulation layer under the siding, the following work should be done:

- it is necessary to specify the gap between the slats, which will correspond to the width of the slabs, if polystyrene or polystyrene is used;

- there should be a distance of 10–15 mm between the laths less than the width of the mat, if the base is insulated with miniplates. This should be taken into account when calculating the volume of insulation;

- insulation must be installed on the insulation;

- when laying mineral wool on top, install a waterproofing layer. For this, it is permissible to purchase a diffuse membrane. However, this material is not useful if fiberglass or polystyrene is used.

The spraying method is simple. When using it, the insulating material is applied using a special sprayer. A wet method of warming a wooden house is considered cheap, but rather time-consuming.

It includes the following steps:

- First, warming plates are attached to the bases with the help of polymer glue;

- a reinforcing mesh is installed on the dowels, and plaster is laid on it (it is called “light”).

- follows a layer of "heavy" plaster.Its application begins with the installation of dowels on insulated plates. Then special blocking plates are used, and the armo mesh is fixed;

- plaster is applied and seams are processed;

- spraying of liquid insulation is carried out.

Of course, you can use the internal method of installation of insulation. And it can be carried out not only for walls, but also for the floor, and for the roof. However, such methods are not used as often as they are less convenient. In this case, apply methods using decorative plaster, wall paneling or panels.

Independent installation

Fixation of insulating coatings can be made by hand. The main thing is to stock up on reliable tools and quality materials.

To get started is to familiarize yourself with a list of fixtures and materials, namely:

- plummet or level (a bubble or laser instrument is recommended);

- roulette;

- angle;

- metal ruler;

- special dowels for the facade;

- Scotch;

- a piece of chalk;

- polyurethane foam;

- antiseptics;

- absolutely dry slats;

- insulation itself;

- steam and waterproofing coatings;

- facing materials for finishing;

- sprayers for treating timber with protective mixtures.

When choosing any method of installation of insulation, all work steps will be approximately the same.

The general step-by-step course of the installation of thermal insulation in a house from a bar includes such actions as:

- for ventilation of the first insulation layer, first, as a rule, a crate of wooden slats or metal guides is installed;

- frame structure is nailed to the crate in order to fix the insulation;

- installation of the warming material is made;

- if necessary, install the second frame and crate (in the case of double insulation);

- fit extra layer of heat insulator;

- a diffuse membrane is attached to protect materials from moisture and wind;

- You can proceed to the installation of decorative cladding. It is necessary to leave small gaps for sufficient air circulation.

Homeowner Reviews

The owners, who insulated their houses from timber, argue that this should be done exclusively from the outside. But not all people agree with such statements. According to some home craftsmen, the internal warming of a log house is easier and faster.However, those who advocate only for external processing are much more. Consumers who have acquired high-quality and durable insulation, for example, mineral wool, do not cease to admire their qualities and characteristics. With reliable insulation in a wooden house it becomes very cozy and comfortable.

According to consumers, you can save a lot by choosing sawdust or foam to insulate the house. However, the excitement of the cheapness of these materials will not be long. Many people are faced with the problem of the appearance of rodents and insects, putting sawdust. Polyfoam also disappoints with its fragility and toxic composition.

Useful tips from professionals

The following tips from professionals should be followed:

- outdoor insulation should be carried out only in good weather;

- insulation will hide the beauty of the bar. In such cases, the insulating layer can be sheathed from above with a block house;

- choosing a heater, it is necessary to consider the dew point. The material should not “lead” it to the depth of the ceiling;

- when working with mineral wool, protective equipment should be worn - glasses, gloves, a respirator;

- it is worth monitoring the roof weatherization, since warm air comes out of the room when rising.Due to poor quality insulation of such spaces, you can feel the greatest heat loss.

Features heat calculation of the walls of log houses are disclosed in the video.