Warming of the facade of a brick house with modern methods

Brick is a traditional material for private construction. But unlike wood, it necessarily requires high-quality insulation. If this is not done, then life in the house is unlikely to be pleasant and comfortable, especially in cold weather.

Special features

Warming brick house is a large complex of works. It is not enough to perform them only on the walls of the facade, it will be necessary to carry out certain manipulations with the roof, the rest of the walls, the base and the floor. Be sure to take into account what type of brick is used, how the masonry was made, in what climatic region construction or repair is carried out.

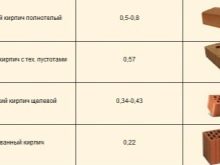

It is impossible to insulate the corpulent blocks from the outside using the same method that is suitable for parts with air cavities. The method of laying (continuous or providing for an internal air gap) is also important.

In assessing thermal conductivity, one cannot rely only on tabular indicators that can be found on the Internet or in special literature. Technologies are changing rapidly, and each manufacturer is trying to put into circulation its own know-how, to vary the recipe and processing modes. Therefore, you should focus only on official information from suppliers.

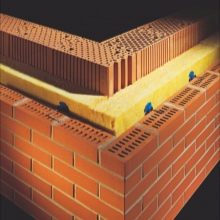

If you plan to lay a brick in a continuous layer, the insulation can be placed on one side, and immediately with two. The use of facade panels and in-wall insulation of hollow masonry has its own subtleties.

Top materials

The coefficient of thermal conductivity is a decisive indicator for any insulating material.It is equal to the heat energy that passes through 100 cm of coating in 60 minutes. If we proceed only from this parameter, then it is best to cover the brick wall with expanded polystyrene and mineral wool.

But you need to take into account other nuances, because if the material keeps heat well, then this does not mean that it is suitable for all possible cases. It is very important to pay attention to the intensity of moisture absorption - depending on this indicator, no material can be compared with extruded polystyrene foam.

The same method of protection is the most dense among all. If we take into account the flammability (class G1 - stop burning after the cessation of the fire), then EPSP and foam plastic are in approximately equal positions. It is not always possible to use claydite, it is suitable only for houses with well laying.

Such heat protection is created very simply, but over time can become non-uniform, which adversely affects the characteristics. It is possible to use drywall for insulation only indoors, because the manufacturers' statements on the resistance of some variants to high humidity should not be considered seriously.

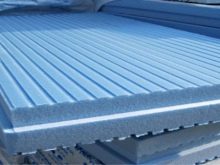

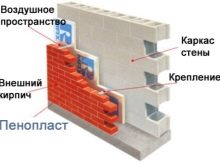

Using polystyrene, including penoplex, is relatively simple. Large plates are sometimes equipped with a thorn-groove system, they can be glued from the basement profile. This solution is suitable for siding, but the level of permeability of the finishing layer for a couple will satisfy very few people. If you still have the desire to choose just such insulation, you should equip the top with a full ventilated facade.

Put penoplex can be a variety of ways. A typical sheet has a width of 600 mm and a length of 1.2 or 2.4 m. In various versions, the sheet thickness varies from 20 to 100 mm. Among all versions in the first place is deservedly a modification of the "Facade", specifically designed for the decoration and thermal protection of the external capital walls.

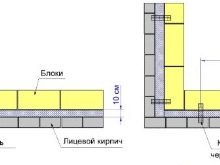

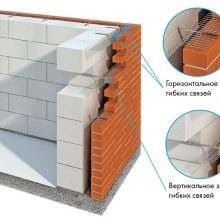

Part of amateur builders chooses the facing of brick walls with blocks of aerated concrete for warming. Such a measure is recommended if there is a suitable point of support, and the whole structure is thought out very well. It is necessary in advance, in the process of preparing the bearing wall, to put fiberglass reinforcement in the form of releases.

Use claydite for thermal protection of brick structures is not worth it, because its thermal quality is not good enough.It is justified to insulate a wall of silicate brick with basalt cotton wool because it serves for a long time and is a completely natural solution. Instead of loose or rolled version, it is more correct to take cotton wool plates, they are considered the most reliable.

Warm up granulated foam glass at home began in the 1930s, but then it was very expensive, and was not very practical. The porosity of such material obtained by modern technology ranges from 80 to 95%. Coloring depends on what specific raw materials were used. Despite the ease of resistance to compression of this material is very high, and the departure of heat to the outside noticeably ahead of even wood.

The advantage of foamed glass is excellent damping of external noise; but we must not forget that it is quite expensive and can be destroyed by mechanical action.

Specifications

The standard thickness of insulation for brick walls is determined by the simplest formulas. It is better to focus on the rate of thermal resistance established for a particular region of the country. The second indispensable parameter for accurate calculation is the thermal resistance of the main bearing surfaces, and the third is the same, but for thermal protection.

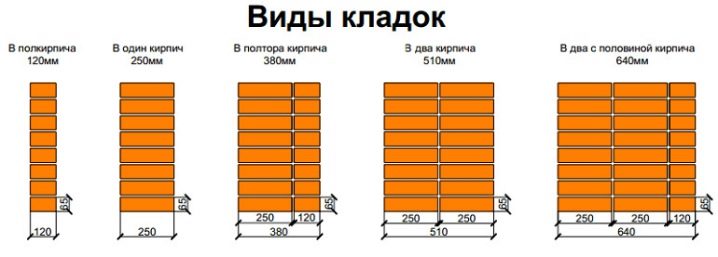

A half brick wall is assumed to be 12 cm, one brick is 24 cm, and for a three-layer structure, the calculation is carried out at a thickness of 0.8 m. A three-layer structure is a very rare and rather expensive option. The main part of the structures is made into one or one and a half bricks, and if there are fewer than three blocks, then we cannot do without insulation in the entire post-Soviet territory. This rule also applies to the Black and Azov Seas.

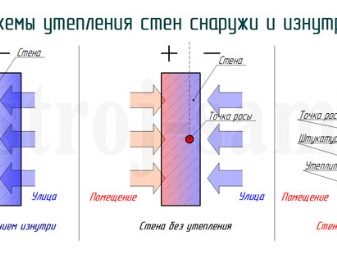

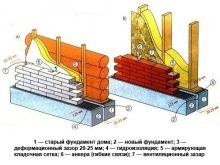

A common mistake is to warm the walls from the inside, it leads to condensation and other negative phenomena. Under siding or ventilated facade most often mineral or glass wool with a density of at least 40 kg and 17 kg per 1 cubic meter is used. m. respectively. When it is planned to insulate the walls with decorative brick, it will be necessary to strengthen the foundation by adding mortar.

Whether the wall will be permeable to water vapor after finishing with insulation or not depends on the personal preferences of the owners. An exception is made only for the steam room, where the evaporation outside is required.

Which to choose?

After reviewing the basic information on insulation materials, it is easy to understand that their choice cannot be dictated solely by financial considerations.Attempting to save money on the insulation only turns into an additional expense in the operation of the building. Note that depending on the chosen option changes:

- composition of the desired hand tools;

- the types of machinery used;

- list of components;

- sequence of work;

- execution of the base.

A very light base will easily withstand the load created by the foamed polymer, but if ceramic granules are used, it will already be unreliable. And it is also required to pay attention to whether an exterior decorative finish will be needed or the heat protection details themselves will be quite attractive in performance.

If you need to mount siding, facing brick or plaster, you will need more adhesives, fasteners, geotextiles, and so on. This circumstance significantly complicate the work. It is necessary to carefully separate the materials for internal and external insulation.

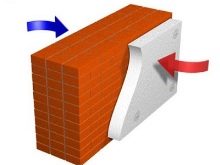

In the second case, the requirements for environmental safety are much less, but the risk of the destructive effect of moisture and wind increases.External insulators are preferable for another reason: they allow you to leave the entire supporting wall in the positive temperature area and completely eliminate its freezing.

The use of internal insulation materials becomes mandatory in the following cases:

- according to the decision of state supervisors, this is the only way to do it

- Immediately behind the wall was placed an unheated technical room (this is irrelevant for the facade of the house);

- very hard frosts are likely that require the most intensive protection of the inhabited space.

Mineral wool, being quite good in itself, is quickly soaked with water. Therefore, you will need to cover it outside with waterproof films. If you want to make as thin as possible “pie”, you should pay attention to extruded polymer blends, because they are almost impermeable to moisture and have a high strength. When evaluating the flammability, it is recommended to compare the actual performance of the material with the requirements established by the fire department.

The advantage of roll and sheet coatings over the liquid versions is that they are easily assembled even by non-professionals who do not have a specialized tool.

Current technology

The best solution is not to look for a suitable option among all possible approaches to insulation, but to focus on modern methods. They fully meet all the requirements of standards and in addition have absorbed a concentrated centuries-old experience. There are two key areas that are most in demand now:

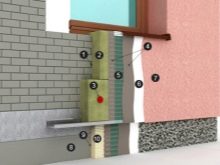

- Sandwich format. On a fully finished wall mount frame (made of wood or metal), in which they put insulation. Outside on the frame superimposed decorative material. The advantage of this method lies in its high strength and reliability, but the foundation of the building must also be strong and solid.

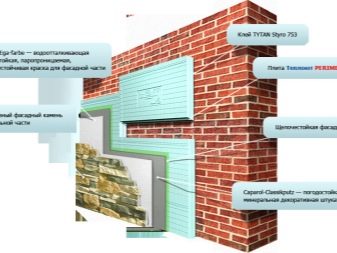

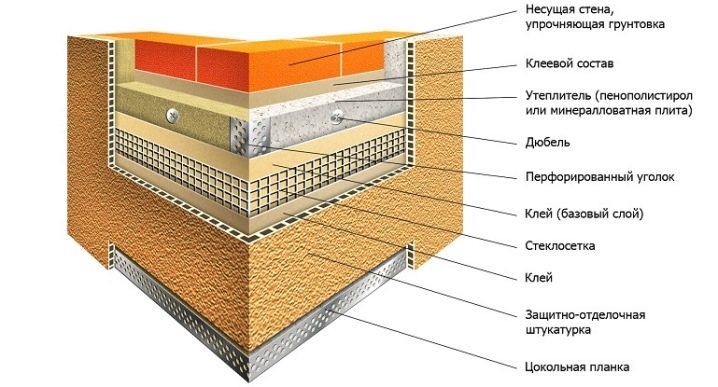

- "Wet facade." Insulation is glued with special mixtures, then it is overlaid with a reinforcing mesh and finishing finish. It is worth paying attention that foam polystyrene will be correctly mounted as a substrate for vinyl siding and other finishing materials.

The method of attachment when choosing a "wet facade" is about the same as when working with foam, namely:

- the first step is to clean the walls of dirt, dust and plaster;

- large cracks overlap putty, and the surface as a whole should be covered with a layer of primer;

- the starting profile is put, it is fixed along the perimeter with the help of dowel-nails. Be sure to check the horizontal lines of the building level;

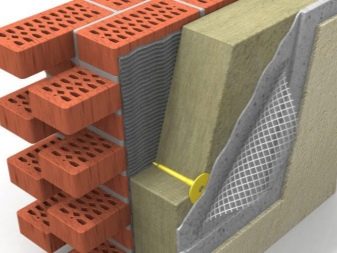

- in addition to sticking polystyrene foam, sometimes it is attached with anchors or special pastes;

- fastening in the central part of the panels with the help of dowel-nails increases the rigidity of the structure;

- it is required to seal the joints of the plates with assembly foam, and take a reinforcing mesh that is not destroyed by acids and alkalis.

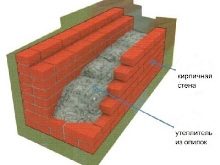

If a brickwork is being made, rolled materials can be used for waterproofing it from the inside. The actual insulation is made by filling in special reagents - lightweight concrete, slag, expanded clay and some others. Ramming material is required every 50 cm.

Great attention should be paid to the warming of the corners, while you should achieve a thermos effect. It is recommended to carefully study the chemical composition of the mounted coating or the mixture poured inside to be completely confident in their safety and reliability.

How to make an independent installation?

Calculations

Even the most modern methods of warming brick walls are available to ordinary people. The main condition for their use is an accurate and competent design calculation. Only it allows you to simultaneously guarantee the retention of heat inside and the minimum cost of the work. The simplest and most effective solution in many cases is wall insulation with extruded polystyrene foam. Calculate the required performance is quite simple.

For example, the wall is lined with full bricks with a thickness of 30 cm each. Heat transfer resistance is determined by dividing this thickness by the thermal conductivity of the material. It turns out the difference between the normatively prescribed and real thermal resistance.

Now you need to multiply this difference by the thermal conductivity coefficient of the selected heater. The calculated result should, if necessary, be rounded to an integer value (since the roll and slab thermal protection is available in a multiple of 1 cm thick).

When several layers are used at once, their energy characteristics must be added together to avoid errors.

The insulation of the end wall in a house or apartment also has its subtleties.In apartment buildings, such manipulation is rarely carried out outside, since it is very expensive and impractical. Be sure to precede this thorough search for probable bridges of cold. As in other cases, it is recommended to use polystyrene foam, foam plastic or materials based on basalt.

Sequence of work

Ceramic brick not only warms the facade, but also looks attractive and serves reliably. But this is carried out only under the condition that the laying is made according to the rules, its seams are completely flat and not dirty. The slightest cracks or mortar stains on the blocks are unacceptable. The mixture for fixing the masonry is formed with M-400 cement and sand in a 1: 3 ratio.

It is worth noting that river sand cannot be taken, because it leads to a rapid shrinkage of the solution, if you do not add a plasticizer. It is not necessary to create a classic gray seam: the set of facing bricks willingly sell a variety of pigments.

The first step in the work will be the preparation of waterproofing. For her take either roofing material, or thick polyethylene. Begin laying with corners, leaving an air gap to the main wall (40–50 mm).The prepared solution should be relatively dense, but not too heavy to work with a trowel. A metal bar with a section from 8x8 to 12x12 mm is placed on the front edges of the masonry.

Next to it, the solution should be flush, and from the back side - about 1 cm above. Similarly, a vertical seam is created. All strips will need to be wiped with a small brush in 120–180 minutes, to block the holes or scoring. Then the ingress of water from the external environment will be excluded.

Reviews

Warming brick country house with their own hands using opilkobetona quite possible. Judging by the experience of people, this requires the formation of formwork and backfilling or pouring insulation between the wall and the outer perimeter of this formwork. According to professionals, opilkobeton must be mixed with lime, which will make it stronger and more stable. This insulation is more durable foam, not subject to invasions of mice. Some complexity of work is completely covered by these advantages.

Useful tips from professionals

Warming of hollow walls is recommended to be made by means of the following materials:

- foam balls;

- sawdust;

- mixtures of these two reagents.

If we are not talking about a completely new construction, you can use Penoizol. After a few specially drilled holes, the cavity will be filled with it, and this will complete the work. Well masonry can also be insulated with polyurethane foam, which is 50–300% warmer than other options. Formed monolithic coating without seams and frost bridges.

The insulating layer during the movement of the building will not crack. To insulate the outer wall of brick on the outer perimeter can be such materials as:

- polystyrene foam;

- Styrofoam;

- mineral wool.

You should not be afraid that these materials will worsen the appearance, because they can be sheathed in addition with sheets of gypsum boards or siding. In addition, every 100 mm of insulation should be equal to 100 cm of brickwork.

Before exterior walls should be removed the slightest defects from the plaster. Installation of foam plates should be made on a special glue, and additional fixing is achieved by umbrella dowels. A completely finished exterior surface is sometimes covered with facade paint for an optimal look, but here you have to decide on your own.

Forming a ventilated facade, you should give preference to the metal frame. Of course, it is more difficult to create it, but this design will be more durable and stable. It is recommended to place insulation with tension, as well as to lay materials impermeable to liquids over it. Significant defects are eliminated with a primer that penetrates deep into the material. Cement-sand compositions do not provide an effective connection between the main wall and the thermal protection layer.

Warming of an old wooden house, lined with bricks, is quite affordable for ordinary builders. It is recommended in this case to take mineral wool, because it will pass air and is characterized by an increased level of fire safety. But if there is a need or desire, there will also be no particular harm from the choice of penoplex and other modern materials. It is advisable to carry out external insulation in two layers, then there definitely will not appear cold bridges. Ventilation holes in the brickwork will help to avoid getting wet insulation layer.

People often ask how to insulate a corner room in a brick house.The first step is to apply a coat of plaster (if it is not there initially). Of course, all the old wall finish, including putty, must be completely removed. Internal insulation is most often done by gluing sheets of expanded polystyrene. It is important not to forget that after applying the adhesive to the sheet, there is only a minute to work, so all fittings and trimming must be completed in advance.

In this video you will find a comparative review of insulation for the facade of the house.