Finishing basement thermopanels: the pros and cons

Most owners of country houses want to make an additional facing basement of the facade. A similar finish is required not only for decorative purposes, but also for warming and giving greater strength to external walls. The modern construction market offers a huge amount of materials to strengthen the base, made with the latest technologies, thanks to which the materials have optimal characteristics and simplify the process of laying.

One of such steel basement thermopanels with clinker tiles. In the article we will look at the pros and cons of products, the method of their installation and customer reviews.

What it is?

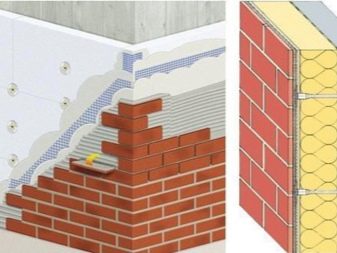

Products are the warmed panels with a brick tile which, besides thermal function, have also decorative.The basis of the material is a heat insulator of polyfoam, polyurethane foam or polystyrene foam. Each of the above types is intended for a specific surface. The facing part is a clinker, which is known for its durability and long operational life. Similar characteristics are inherent in this tile, since the clay from which it is produced undergoes a special heat treatment.

Many experts put clinker on a par with such materials as granite or marble, due to their increased strength, but unlike them, tiles do not have a radiation background.

For finishing the basement part of the house, panels of 6-10 centimeters thick are used, the level of basement insulation will depend on the model chosen. The choice of the width of the product should be done, focusing on the type of base on which the installation will be made. Brands-manufacturers promise buyers that their panels will last 50-100 years, depending on external conditions. And companies that produce clinker tiles, give a forty-year guarantee of preservation of the color of the facing material.

Features and benefits

Thermopanels for facing the ground floor have a large number of advantages that distinguish them from the rest of facade finishing materials with insulation. Products have high reliability due to the special manufacturing technology, which provides a tight connection of the tile with the polystyrene foam base at a certain temperature mode in a locking manner.

This means that between the two materials there is no adhesive composition, which could have collapsed within a certain period of time and thus lower the life of the panels. Due to the location of the dew point inside the material itself, moisture does not condense on the wall, which guarantees even greater safety of the products.

A plus of such thermopanels is the special fabrication of every detail, which ensures the perfect connection of tongue-and-groove parts. Upon completion of the installation process, they merge into one whole and contribute to the creation of not only a uniform coating, but also a high-quality thermal insulation system. This plus is a guarantee of full waterproofing of the lining even in case of a slanting rain.

The moisture resistance of the material is an advantage, because thanks to this, the installation of panels is much easier to produce. And since the products do not absorb water, the walls of the building themselves are protected from moisture. Panels with thermal insulation are mounted using plastic profiles, which prevents the occurrence of internal stresses that adversely affect the internal layer. The fire safety of thermopanels is due to the fact that the raw material for the manufacture of insulating base falls into the category “G1”, which indicates that the product is not flammable. Low thermal conductivity of panels with a width of 6-10 centimeters contributes to heat-saving properties, similar to concrete, whose thickness is at least 1 m.

Clinker tile panels do not require special care, they are easy to wash and clean, they will retain their original appearance for many years. Products are biostable, prevent the occurrence of mold and mildew. Among other things, the plates perform and waterproofing pile foundation, thereby strengthening it. A wide range of color palettes and a large selection of textures will allow each customer to find a product for their home.

However, these products have some features that should also be considered when buying. One of the main drawbacks is the absence of rubbed seams on the finished panels. This process is long and complicated, so it will be expensive for the owner of the house.

But even with the implementation of independent work will have to spend a lot, since the amount of the mixture per 1 m2 is more than 200 rubles. Some manufacturers produce panels with already rubbed seams, but their price is high.

Another disadvantage is a certain unevenness of the surface of the plates, which is provided by the production technology.

Assembly process

Installation of thermopanels is pretty quick and easy. For self-facing of the basement part of the house with clinker plates with insulation, you should take care to purchase the necessary tools in advance. For work you will need a grinder, a hammer drill, a building level, a screwdriver and a special spatula for grouting. In addition, you will have to buy mounting foam, dowels and screws.

Installation of plates should be made strictly according to the instructions to ensure increased durability of products and their durability.. The first is the level of the height of the basement part around the perimeter of the external walls of the house. In case of detection of protrusions, they will have to be eliminated, and if geometry is violated, you will need to upholster the base with wooden planks or with a metal profile for leveling. Further it should be noted the line of the beginning of furnish and to build in the starting rail made of aluminum.

Be sure to have a small gap between the galvanized profile of the slats and the blind area, so as not to damage the wall finish.

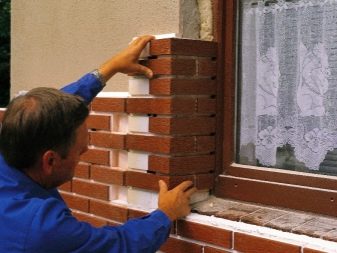

It is recommended to start the process of laying clinker plates with insulation from the left corner of the building. The panels are fixed with screws through the plastic guides. When the first product is laid, the space between the slab and the wall is filled with polyurethane foam to prevent air circulation under the material. Then the following plates are sorted by turns, which are connected to each other by the tongue-and-groove method. Thermopanels can be cut with a grinder.

The final step will be grouting a special mixture with a frost-resistant composition. This process can be carried out directly after the installation of thermopanels with clinker, and after some time.A prerequisite for grouting is a positive temperature, which will not fall below five degrees for several days until the mixture is completely dry.

If all actions are carried out correctly, the thermopanels with clinker tiles will look like natural brickwork.

Professional Tips

Masters of laying clinker thermopanels recommend that you follow certain actions while working with products. For example, before starting the lining process, it is advisable to treat the base with antibacterial primer to prevent mold and fungus. Panels can finish the whole house, and not just its lower part, while the basement, as a rule, is distinguished with plates of a different color to give a more interesting look.

When buying a product, you should pay attention to the presence of small peaks to protect against rain, if there are none, they can be ordered separately.

A wide range allows you to play with the color and texture of clinker, to give the house originality and bring a little zest to the outer facade. Certain types of thermopanels have special requirements for the installation process. In order not to be mistaken, you should carefully read the instructions and follow it.

Reviews

In general, owners of country houses are satisfied with the choice of basement thermopanels with clinker tiles. The material looks expensive and gives the building an interesting look. Easy installation and ease of maintenance are also noted among the main advantages of products. Many people write about the increased technical characteristics of tiles, which provide durability, reliability and durability of cladding. The tight junction of the base and the clinker plate to each other allows you not to worry about the detachment of the upper part, so the integrity of the lining will not be broken.

The only drawback, which is indicated in the online reviews of users, is the high cost of materials and the work of masters of finishing.

How to make installation and warming by thermopanels, look in video below.