Types of thermal insulation "hut"

The heat insulator "izba" is distinguished by its durability and practicality. Due to this, he deserved a large number of positive feedback from consumers. Insulation can be used for thermal insulation works in different types of buildings.

Advantages and disadvantages

Basalt insulation base is basalt. From here and the name designating merge of the words "isolation basalt". Since the base is a stone, the insulator is also called stone wool. Basalt is mined in quarries, and then shipped to the plant, where it is processed.

Mineral wool "Hut" is used for the insulation of walls and floors, floor, roof and attic, as well as plaster facades. It has a porous structure and at the same time has a high density.This means that, despite the small thickness of the product, it does an excellent job both with warming and sound insulation.

- Insulation is refractory and non-flammable, it can withstand temperatures up to 1000 degrees due to the fact that it was created from the melt of rocks. About the incombustibility of the material also says a special certificate. The products are non-toxic, they do not emit harmful substances under the influence of high temperatures, therefore they are recommended for use on objects of different types. In addition, they are moisture-resistant, treated with special compounds and absolutely do not miss the liquid. This makes it possible to apply the material in rooms with high humidity.

- Mineral wool "izba" tolerates enough mechanical stresses. At the same time, its small elasticity is noted, which is expressed in the fact that the product can be deformed under strong pressure. At the same time the product does not shrink and retains its shape over the life of the product. And due to the porous structure, which has in its composition fibers of different lengths, the insulation has excellent noise insulation properties, in addition, has a low thermal conductivity.

- Insulation resistant to negative environment and temperature extremes. It is not subject to rotting, the effects of microorganisms, fungi and mold. With all this, products have an affordable price, especially in comparison with products manufactured abroad.

- The heat insulator does not create problems during installation. Work can be carried out both with their own hands, and turning to experts. The manufacturer denotes the warranty period of products in 50 years, provided proper installation and proper operation.

Among the shortcomings, in addition to the low elasticity of the product, it can be noted quite impressive weight and fragility. When the product is installed, crumble and form basalt dust. At the same time, a huge number of consumers consider “Izba” insulation as a high-quality and convenient material, in comparison with analogues.

In those places where the insulation is connected, there are seams. If we examine the reviews, we can conclude that the users of the material do not see any problems in this, since the thermal conductivity characteristics do not suffer from this fact. It should also be borne in mind that this nuance is faced by everyone who decides to use any roll insulators.

Kinds

Thermal insulation "hut" can be divided into several types. Their main difference is the thickness of the plates and their density.

Super Light

This insulation is recommended for installation in structures that do not bear a serious load. It can be used both on an industrial scale and for the construction of private houses and cottages.

Mineral wool "Super Light" is used for thermal insulation of the floor, walls and attics, as well as ventilation and heating. The density of materials is up to 30 kg / m3.

"Standard"

Standard insulator is used when working with pipelines, attic, tanks, walls, attic and pitched roofs. It is a piercing mats with a thickness of 5 to 10 centimeters.

Insulation density ranges from 50 to 70 kg / m3. Insulation does not absorb water and falls into the middle category.

"Venti"

The mineral wool "Venti" is released specifically for the insulation of ventilated facades. Its density is 100 kg / m3, the thickness of the layers is from 8 to 9 centimeters.

"Facade"

This type of insulation is designed for outdoor use. Performs noise absorbing and heat insulating functions.

An important nuance is that after the installation of the insulation will need to close it with a reinforcing mesh and plaster. The density of the material reaches 135 kg / m3. This insulation is not deformed and is able to perfectly keep its shape during vertical laying.

"Roof"

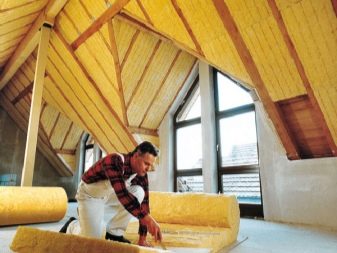

This insulation is designed for thermal insulation of roofs and attics. It can also be used for insulating floors in cold basements.

The material has the highest density - 150 kg / m3. For flat roofs, two-layer insulation is used, the density of the material increases to 190 kg / m3.

Installation Recommendations

The installation of thermal insulation “Hut” can be carried out both with the involvement of specialists and independently. When choosing the second option, you need to carefully study the installation instructions and calculate the consumption of materials, and you also need to know some of the nuances.

Installation of any insulation has its own distinctive features. They depend on the type and purpose of the structure.

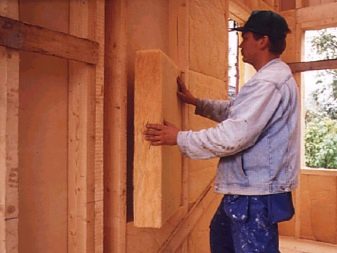

- First of all, it should be noted that Work is carried out on frame technology. To do this, the surface must be sheathed with a bar, the thickness of which will correspond to the thickness of the insulating material itself. When insulating the ceiling and floor, vapor barrier must be provided.For fasteners, it is best to use stainless steel screws.

- Thermal insulation material is placed in the cells. and covered with wood paneling. In order to prevent moisture from entering the joints, they should be sealed with the help of mounting tape. If necessary, plastering work required pre-laying reinforcing mesh. Only after it is firmly fixed on the surface, can plastering be started.

- When working with pitched roofs It is necessary to lay the insulation inside the supporting frame. It can be located in 2 or 3 layers, while you need to try to minimize the presence of joints.

- When working with a flat roof insulation "Hut" fits as smoothly as possible between the cells (try to prevent the material from bending). A vapor barrier is superimposed on it, which closes the roof. If metal or corrugated sheets are used as a roof, the distance to them should be at least 25 millimeters. When working with flat sheets - 50 millimeters.

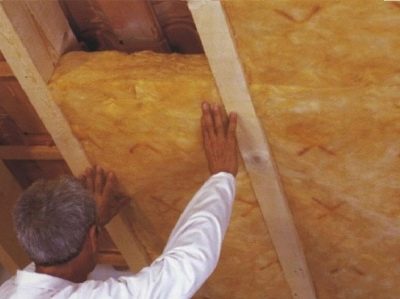

- If you want to warm the ceiling of concrete, first of all, it is necessary to lay the material for vapor barrier.After that between the beams is mounted heat insulator "Hut".

- In conclusion, set the finish. This method is also relevant when working with hardwood floors that have a windproof layer.

In the next video you will see an overview of the basalt insulation "Hut".