Features of wall insulation outside a private house

The Russian climatic situation, perhaps, is not so different from that of other northern countries. But people living in private housing, not to distracted encyclopedic studies. They need high-quality insulation of their homes, so as not to suffer from the cold and not lose too much money when buying fuel for stoves or paying for electric heating.

Pros and cons of outdoor insulation

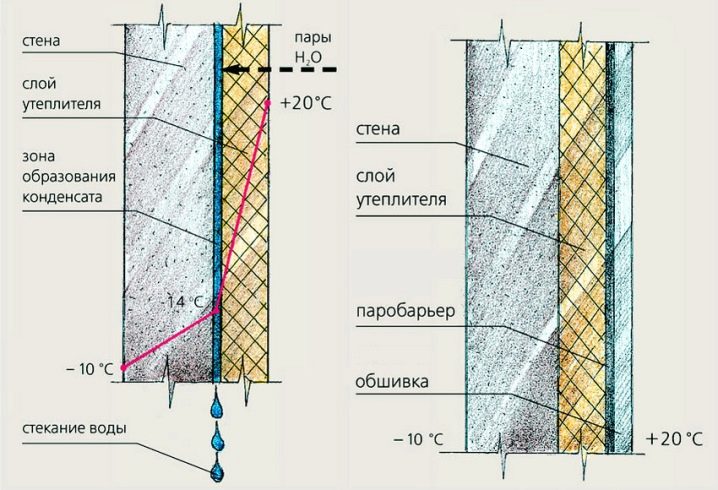

First of all, you should figure out - is it really necessary, this is the most facade insulation. He has at least one positive side always, this is that the entire thickness of the wall is insulated. The elimination of the heating of its individual parts initially solves the problem with the formation of condensate inside, with "weeping" surfaces in the house.Engineers claim (and reviews confirm their assessment) that the insulation of buildings from the outside allows you to leave the inner space inviolable. It will not be spent on very thick and not always beautiful looking designs.

Before you rejoice and look for SNiP, suitable for a particular home, you should pay attention to potential disadvantages. Obviously, to do such work in any weather will not work: rain and wind, and sometimes cold do not allow to do it qualitatively. The total cost of such finishing is very high, for many people such expenses are unbearable. The severity of the external conditions limits the choice of insulating materials or forces them to create protective structures. And besides, if the house is divided into two halves, there is no point in insulating only one of them from the outside, the heat loss will decrease only slightly.

Ways

So, the insulation of the walls of a private house on the outside is much more pluses than minuses. But it is important to understand the features of individual materials and structures.

Houses made of expanded clay blocks are insulated from the outside, most often with the help of:

- mineral wool;

- foam plastic;

- its more modern analogue is penoplex.

The first option is preferable in view of zero danger of burning and low cost. But the problem is that the affordable price is largely negated by the need to organize a protective screen. Polyfoam is light, also belongs to the budget group of materials, and you can mount it quickly.

However, we must not forget about the danger of damage to the insulation layer by rodents, fire risks. Penoplex is ecologically safe, mice and rats will not be delighted with it. Disadvantages - a hefty cost and lack of microventilation.

Quite often, people are faced with the problem of warming the exterior facades of old panel houses. The main condition for high-quality thermal protection is its device in which the permeability to steam rises from the living space to the street. There is no need to remove the outer lining of the dwelling, a number of technologies have been developed that allow you to mount insulation on top of it.

When choosing a suitable option, it is worthwhile to give preference to solutions that do not overload the foundation excessively and absorb the least amount of water.It is the considerable gravity and the finding of the dew point inside the hygroscopic thermal protection that gives the most problems to the owners of panel buildings.

Warming homes in the country for winter living is very important.

Be sure to provide thermal protection:

- internal floors on the ground;

- floors of the first tier (if the foundation is not insulated);

- external walls;

- cold attic floor or attic roof.

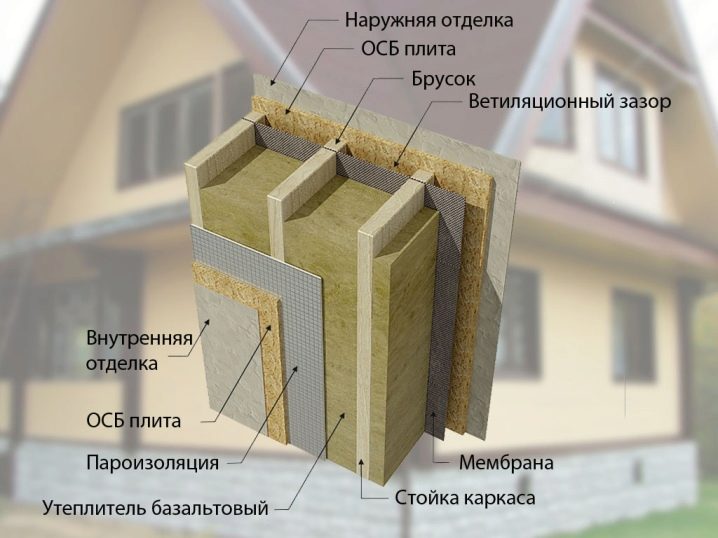

To single out one of these elements, even as important as walls, does not make sense. If at least one site is not insulated, all other works can be considered spent in vain, as well as the money spent on them. The walls must be equipped with waterproofing and vapor barrier; when choosing mineral or ecological wool for insulation, a 50–100 mm gap should be left. The insulation of the panel house from the outside has its own specifics. The slightest irregularities are supposed to be removed, and ideally - to be leveled using a primer.

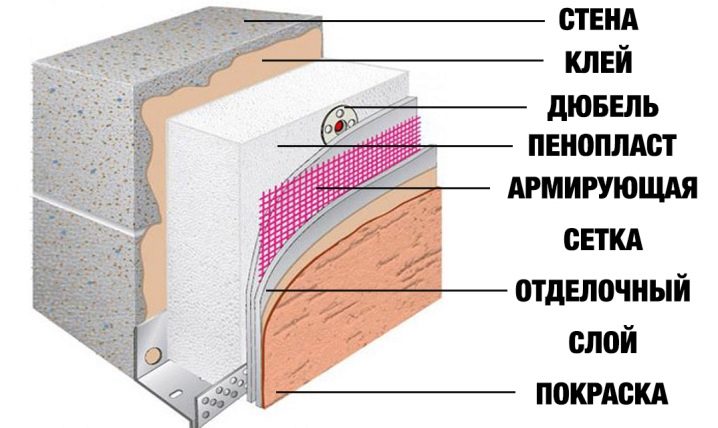

If splitting of paint, flaking of a different finish is found - all these layers remove, even if by technology there is no need for such manipulation.In most cases, foam is applied to the external heat-shielding of concrete walls, and the most reliable way to fasten it is to connect glue and dowels. Works are conducted from bottom to top; a special bar is mounted at the lowest point, designed to prevent material from slipping. For your information: it is allowed to replace dowels with plastic nails. Regardless of the mounting methods, it is necessary to carefully control the gaps that appear.

Separate conversation deserves the insulation of the junction of the wall to the roof. This work is done traditionally with the help of stone wool, but for lovers of modern technology, it’s better to focus on Macroflex foam. In many cases, a steel bonding apron is formed. Whether it is needed in a particular house, on a specific wall - only trained specialists will be able to find out. The insulation of the junction is too difficult for the house owners themselves to do, or the random craftsmen found by chance.

Types of materials

External warming of walls of private houses can be made by the most various materials. Use of sawdust for this purpose does not work,because such protection is always bulk. Strictly speaking, the layer of sawdust fits inside the wall and should be quite thick. Predominantly this decision is resorted to by the owners of frame and bulk structures. But it should be considered the last thing: even wood-added waste wood production is too susceptible to caking and soaking.

For the construction of private homes, many prefer to use foam concrete or aerated concrete; These two materials are stronger than wood. However, they should be insulated according to a special scheme. Preferred solutions are polyurethane foam and mineral wool. The second material is the cheapest and is not subject to ignition, it is easy to work with it. In the cotton layer, extraneous sounds are extinguished, and they will be less annoying to residents.

Some developers use opilkobeton, it is great for saving heat in frame houses. For the manufacture of this material with their own hands, you can use large sawdust and calibration chips obtained on woodworking machines. The required component of the mixture is liquid glass.To prevent the mixture from splitting into separate components will help to hold reinforcement structures through the walls. It is recommended to drill holes for them immediately.

Perlite is used not so much outside as in the composition of multilayer walls. A prerequisite for reliable service of this material is a vapor barrier inside and high-quality waterproofing outside. To reduce the risk of saturation with water and loss of heat, perlite is usually mixed in equal proportions with cement and expanded clay. If you need a heater that has really outstanding characteristics, it is difficult to find something more practical than basalt wool. Since the work on the facade of it in its pure form is impossible, it is necessary to buy special plates.

Like other cotton pads, this solution improves not only thermal insulation, but also sound insulation. This circumstance is very important for private houses located near highways, railways, airports and industrial buildings. It should be borne in mind that not every glue is suitable for attaching such plates to a base of wood. Installation can be done wet and dry.In the second case, it is required to purchase dowels with expanded caps.

To finish the facade of a private house, it is permissible to use only basalt slabs with a specific mass of at least 90 kg per 1 cu. m. As an additional thermal protection, sometimes people use reeds; everyone who wants can prepare the necessary raw materials and prepare it for work. The stems will have to be laid as tightly as possible so that between them there are as little as possible loopholes for cold air. The problem of fire danger is solved by impregnating with a fire retardant or bischofite, these substances increase the fire resistance of the reed mass to the level of G1 (spontaneous quenching at the termination of heating).

Polyurethane foam

If there is no particular desire to use natural materials, you can safely use the foam panels. The advantage of this solution is a combination of thermal and acoustic protection of the living space. Polyurethane foam does not pass water, and therefore there is no need for a layer of additional waterproofing, saving is achieved. PPU easily sticks to the base material and therefore it is quite easy to work with it.It is necessary to take into account weaknesses - high cost of coating, its instability under the action of ultraviolet radiation.

Siding

In some cases, the cake, finished outside with siding, also becomes a heat insulation construction. By itself, the metal, no matter how beautiful it looks, transmits a lot of heat. And even vinyl designs are not much better for this indicator. Extruded polystyrene foam is often used as a lining for steel or vinyl, but when choosing it you should take into account the high flammability. Also EPS and foam sometimes can not effectively suppress extraneous sounds.

Lightweight insulation under the siding provides roll materials, including foam with an external coating of foil. Foam-concrete and gas-concrete heaters allow to avoid interest from the gnawing animals and to guarantee full heat protection. When using expanded polystyrene, you first need to cut the sheets in accordance with the exact dimensions. Under the condition of planning the lathing for specific sheets, the number of parts to be cut will be minimal. If mineral wool is being installed,It is recommended to leave it in the promoted state for 60-90 minutes before cutting or filling the frame, then the result will be better and more stable.

Mineral wool

Minvata is good because it does not interfere with ventilation in the room through the walls.

It can also close uneven reliefs on:

- a tree;

- brick;

- stone

In this regard, subsequent finishing is simplified, and the rough surface becomes as smooth as possible. When working on the outer side of the walls, in contrast to the internal insulation, the problem of formaldehyde emission completely disappears. Important: if the relative humidity of the air exceeds 85%, putting mineral wool in any form is unacceptable.

Fastening is usually done with anchors, and a brick wall is placed on top of them. When weatherization of an already operated house, metal structures should not be left inside the walls, they can rust very quickly.

Plaster

The insulating properties of plaster with gypsum, even advertised by manufacturers, are not very impressive in practice. It can only be used as an auxiliary solution that enhances thermal protection by other methods.The advantage lies in the fact that plaster insulated plates at the same time look beautiful and reduce the need for other specialized materials.

As a result, the total thickness of the wall and its load on the foundation are noticeably reduced. To improve the thermal properties of the house, the most common dry mix is suitable, to which is added perlite sand, pumice crumb and other small fraction fillers.

Styrofoam

The use of foam constructions is excellent for providing thermal protection of buildings. This heater is quietly functioning at temperatures from -50 to +75 degrees. Among the different options of the material is worth paying attention to those that are impregnated with flame retardant additives and filled with non-combustible carbon dioxide. Bacteria and fungal organisms do not like foam plastic and practically do not settle in it. Cracked sections of the walls and holes will have to cover up in advance to get a decent result.

On the listed materials the range of heaters, of course, does not end there. Quite a few people use polyurethane foam, which is no worse than ready-made PU foam panels.Excellent adhesion helps the liquid to immediately penetrate the surface and reliably last for many years. Low-pressure cylinders are commonly used for domestic purposes: the quality of the reagent is no worse than in professional equipment, the only difference is that its output is slower. It should be noted that this technology can not eliminate until the end of the appearance of air bubbles in the foam layer, and a wall of poor-quality material is sometimes damaged by pressure.

Arbolite is used not only for the construction of houses, but also for improving the thermal qualities of the structures already erected. This building material is almost entirely made of natural wood, which allows to improve the thermal protection of stone and brick buildings. But it is important to understand that by itself it is easily blown and soaked, almost instantly penetrated by cold bridges.

If the thickness of the arbolit wall is 0.3 m or more, the masonry is correctly made, there will be no special need for additional cover from the cold in the regions of central Russia. Woodblock insulation is required in the regions of the Far North (over the entire surface). The points where the outgoing heat is most intense should be insulated in any terrain.

From natural materials for external thermal protection of walls, clay is often used (it is used both by itself and in mixtures with straw or sawdust). The undoubted advantages of such a solution are low price and no risk of fire. Many people are attracted by the simplicity of the workflow.

Important: Inattention to the proportions of the components of the mixtures can lead to a rapid loss of their valuable properties and to the separation of the prepared insulation. To keep the clay mass on the surface of the wall, it will be necessary to install structures made of boards and durable cardboard.

Good results can be achieved with felt insulation. It is especially recommended for thermal protection of wooden houses. Laying can be carried out in several layers at once, which improves the quality of the insulation, the reasonable price allows you not to be afraid of excessive costs in this case.

For your information: before ordering a material, you should check with a professional if the felt insulation is suitable for a specific climate zone.

Like wadded insulation, it suppresses sounds penetrating from the outside, but you should also bear in mind possible problems:

- lack of efficiency in large dwellings and in multi-storey buildings;

- unsuitability in warming stone and brick structures;

- relatively large thickness of insulation;

- the need for careful alignment of styling (each small fold is very harmful).

An alternative to natural materials is insulation of walls with izolon. This heater effectively reflects the radiant infrared energy and, following the results of a number of special checks, was recognized as a comfortable, safe product. It is very widely used both in private and in apartment buildings. Izolon is sold in large-format rolls, so it is especially important to calculate how it should be needed. In general, approaches to the calculation of the need for insulation deserve special attention.

Calculation of material thickness

The calculation of the required thickness of the penofol mats should be carried out in accordance with the standards laid down in SNiP 2.04.14. This document, approved in 1988, is very difficult to understand and it is better to entrust the work with it to professionals. Non-specialists can estimate the necessary parameters approximately using both online calculators and installed software.The first option is the easiest, but not always correct; It is difficult to take into account all the necessary nuances. Penofol canvases are always standard width - 200 mm.

You should not strive to buy the most thick material, sometimes it will be more profitable to vary the desired number of foil layers. The double aluminum block differs in the highest thermal and acoustic qualities. Optimal results (judging by operating experience) are given by penofol 5 mm thick. And if the task is to achieve the highest thermal protection and sound insulation, not stint on the costs, you should choose a centimeter design. A layer of penofol of 4-5 mm is enough to provide the same protection as when using 80-85 mm of mineral wool, while the foil material does not get water.

Wall preparation

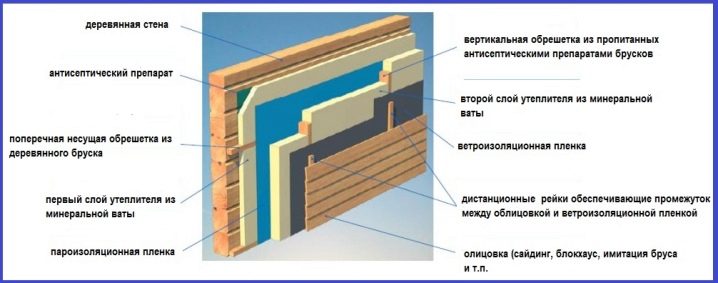

The formation of crates on the tree is the most simple and easy compared with the treatment of walls from other materials. At the same time, the design of the layout of the material must take into account the basic properties of wood: its high permeability to steam and the likelihood of fungal infection. The framework can be formed from a wooden bar or an aluminum profile. It is necessary to provide special attachment points for the heat-shielding material and a crate for the front finish. Roll insulation is attached to the walls of the timber on the slats.

Double-layer thermal insulation coating should be mounted on a double crate (simple or supplemented with brackets). You can get a wooden frame with an electric jigsaw (if you choose the right blade), but aluminum structures are recommended to be cut with metal scissors. You should not try to speed up the process using angle grinders, it damages the anti-corrosion layer, lowers the shelf life of the insulation. Screwing bolts, bolts and screws into wooden walls is best done by a screwdriver with a set of nozzles. The battery version of the device is best suited, because then there will be no interfering wire.

It is advisable to hammer in parts made of wood and hammer disc-shaped dowels with a hammer or rubber mallet. If you need to install membrane films, the best solution is to use a stapler with a set of staples. When preparing the batten, each part of it is calibrated according to the construction level: even minor deviations, imperceptible to the eye, often lead to improper operation of the insulation. Of course, even before the installation of the wall of wood must be saturated with several layers of antiseptic composition. To accelerate this impregnation will use the spray gun.

Installation steps

It is useful to consider step-by-step instructions on how to insulate with your hands the external walls of gas silicate houses. A prerequisite for the normal operation of most of these buildings is the installation of insulating material and protection from moisture from the outside. If the blocks are decorated with bricks, all protective materials are laid out in the gap between it and the gas silicate. Laying 40-50 cm thick in central Russia does not usually require additional insulation. But if constructions of 30 cm and thinner are used, this work becomes mandatory.

It is recommended not to use cement mortars, they form insufficiently dense joints, abundantly transmitting heat to the outside world and frost inside the building. It is much more correct to mount the blocks themselves with the help of a special glue that guarantees maximum tight fit. At the same time, it reduces the likelihood of cold bridges.

When choosing what technology to insulate a gas silicate house, you should pay attention to:

- the number of floors in it;

- use of windows and glazing method;

- carrying out engineering communications;

- other structural and architectural details.

The majority of professionals during the insulation of gas silicate prefers slab structures based on stone wool or XPS. On the third place in popularity are facade insulation complexes based on plaster. Polyfoam and traditional rolls of mineral wool are outsiders: there are no special advantages over the leaders, but there are additional difficulties. Of the newest developments, you should pay attention to the thermopanels, which are distinguished not only by excellent thermal protection, but also by a decent aesthetic appearance.

If any type of mineral wool is chosen for work, you will need:

- mount vertical sheathing;

- pave waterproofing and vapor barrier (separate or combined in one material);

- mount the cotton itself and let it stand;

- put the second level of insulation from moisture and steam;

- put a reinforcing mesh;

- apply primer and finishing material;

- paint the surface (as needed).

Installation of cotton plates is made only by those adhesives, which are indicated on the package. It is permissible to finish the walls above the insulation not with paint, but with siding.It is recommended to choose the most dense varieties of cotton to avoid premature caking and sliding. When installing guides, they are mounted 10-15 mm closer to each other than the width of a single plate. This will allow the most densely fill the frame and eliminate the slightest gap.

Styrofoam for insulation of houses from the outside is even better suited than mineral wool. But its increased thermal insulation is depreciated by low mechanical strength. If significant loads will obviously act on the wall, it is better to refuse such a decision. Filling the joints between the plates is allowed only assembly foam. Exterior plating siding or applying facade plaster will prevent the harmful effects of weather elements and ultraviolet radiation.

External insulation of the basement in a private house should be made only with materials that are as resistant to moisture as possible. After all, even the most reliable protective layers may be violated, and to solve this problem, for obvious reasons, quickly and easily will not work.

The basic requirements are:

- carry out all work only in the dry season and in warm weather;

- be sure to remove the soil around the basement of the house;

- apply moisture resistant mastic in a continuous layer;

- remove insulation by 50 cm above the upper basement line;

- process the heat-insulating layer remaining under the ground with an additional waterproofing coating;

- arrange drainage;

- decorate the basement with decorative structures and materials

Useful tips

Professionals warm the house of reinforced concrete slabs as carefully as possible. This material, not only allows a lot of heat to pass by itself, but is also designed in such a way that the thermal efficiency is significantly reduced. Developers tend to make concrete products light and compact by construction standards, so it is recommended to consider the information from the accompanying documentation.

A common mistake is to use the cheapest grades of foam; they are too short-lived and do not allow even for the service life to provide high-quality insulation. For your information: before warming the basements, it is recommended that you first ensure their high-quality ventilation in full.

Insulation with foil is a fairly new and practical solution that combines three valuable properties at once:

- containment of heat flow;

- blocking the blotting of the warming layer and its substrate;

- external sound suppression.

Modern versions of foil materials allow at the same time to insulate both the wall, and partitions in the house, and pipelines, and even ancillary buildings. Mineral wool, covered with foil on the one hand, is recommended for use mainly in non-residential premises. Regardless of the type of material, it is attached in such a way that the reflector “looks” inside the building.

From the exterior to the insulation layer, it is necessary to leave a gap of 20 mm in order to enhance the insulation of the air gap. On the first floors it is necessary to insulate not only the walls, but also the floor.

Industrial wastes are quite widespread in the thermal protection of private houses, many people use metallurgical slag for this purpose. Nickel and copper smelting wastes are in greater demand than others, since they are chemically resistant, and the tensile strength starts from 120 MPa. Using slags with a specific gravity of less than 1000 kg per 1 cu.m, you need to create a heat-shielding layer of 0.3 m. Most often, blast-furnace waste is used for warming floors, not walls.

Sometimes you can hear statements about cardboard insulation. Theoretically, this is possible, but in practice there are a lot of problems and difficulties with this. The only option that meets the necessary requirements is corrugated cardboard having air gaps that retain heat.

The paper itself, even if very dense, only protects from the wind. Corrugated material is supposed to be put in several layers with obligatory sizing of the joints. The fewer connections between individual layers, the better.

The best grades of cardboard:

- hygroscopic;

- when wet, it smells very bad;

- conduct too much heat compared to other options.

It is much better to use kraft paper: it is also thin, but much stronger than a cardboard sheet. Such a coating effectively protects the main insulation from the wind (in most cases mineral wool is located below). According to the parameters of thermal protection, kraft paper is identical to natural wood, and it also passes steam well.

At least the fact that products for it are manufactured on an industrial scale and even according to different technologies speaks about the merits of environmental wool insulation. The dry method of applying pulp involves the filling of granules in the allotted niche. It is important to bear in mind that ecowool is produced in the form of a fine fraction and can “dust”. A number of reagents contained in this heater can provoke local allergic reactions. Therefore, all work is carried out using rubber or cloth gloves and respirators (gas masks), and the layer of ecological wool is surrounded by a barrier of kraft paper (it cannot be replaced with cardboard!).

How to insulate the walls of the house outside with your own hands, see the following video.

If there is a material opportunity, it is better to call professionals with a special machine and order water-glue processing. It is not only safer for health, but also more effective and reliable over time.