The intricacies of the process of external warming corners of the house

Residents of houses are very often faced with the problem of the formation of moisture and mold on the walls, especially in the corners of houses. Often this is due to miscalculations in construction, which did not take into account the thermal conductivity of the materials used for the construction and finishing of the house, and the internal temperature of the rooms.

Special features

If in winter time condensate in the form of water droplets forms on the inner wall of the room, and later - mold, this indicates insufficient insulation of the walls or the material from which they are made.

In addition, in the winter season, if there are small crevices in the corners, the walls and corners may even freeze due to the inflow of very cold air. The reason for this can be as a gap between the slabs or bricks, and voids in the slabs themselves.

Due to this unpleasant phenomenon:

- wetted and lagged behind wallpaper;

- walls painted with water-based paint are covered with unpleasant stains of red color;

- the layer of plaster is gradually destroyed, no matter how durable and of high quality;

- fungus and mold appear on the walls.

You can eliminate these disadvantages by insulating the walls from the inside. For example, laying the heating pipes vertically along the corners or making an additional bevel of plaster in the corners of the room. However, the most effective and efficient way is external insulation of walls and corners, which eliminates the reason itself - poor insulation.

Main ways

Modern industry offers several options for insulation, differing in the use of various materials and the method of their application.

- The use of "warm" plaster. In this case, granules of foam are added to the composition of the plaster instead of sand. This significantly reduces the thermal conductivity and the total weight of the layer of plaster. Its use reduces the overall thermal conductivity of the walls and corners, while allowing the walls to breathe, which stops the formation of condensation on the walls.

- The use of liquid insulation. Produced by many manufacturers.They are a liquid solution containing microspheres of ceramics, glass or silicone. They have excellent thermal insulation, allow to work in hard-to-reach places, including in the corners of houses.

- Installation of foam blocks outside, mineral wool or polystyrene foam. This method has the strongest thermal insulation characteristics in contrast to the previous two. At the same time, the outside walls of the house are completely covered with light heat-insulating blocks, which are not subject to corrosion and have excellent resistance to temperature extremes and high humidity.

- Thickening masonry. This very simple and effective method is very often used at the stage of building houses and is visually distinguished by the fact that additional brick laying was carried out at the corners of the houses. Additional styling can be done later, if the architecture of the building allows it.

How is the insulation?

Among the many ways of warming everyone chooses his own - the most convenient and affordable option.Most often it is necessary to insulate the walls and corners in the corner rooms, as in them, as a rule, two walls go outside the house. At the same time there are some subtleties when using these or other materials.

The process of warming corners and walls can be performed even at the stage of building a house and design solutions for decorating rooms. For example, only rounding of the interior and exterior corners of the facade can reduce the temperature difference between the wall and the air inside the room by up to 20%.

Installing fixtures in drywall panels directly in the corners of the room provides heating of the walls and offset dew point. This eliminates the reason for the appearance of wet walls in the room.

Everything else in the construction of wooden houses should take into account some features of the log cabins in the "paw" and in the "bowl". So, one of the disadvantages of felling in the "paw" is that it is a source of increased heat transfer, and hence the heat consumption. As a result, increased cooling of the inner surface of the walls and corners, the formation of moisture on their surface.

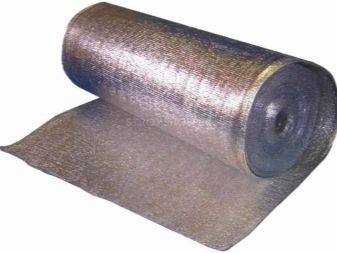

Using penofol for insulation, it should be noted that the main thing in its application is the creation of an air cushion between the wall and the material itself.If you do not fulfill this condition, then insulation using penofol will not work and will not be able to perform its functions. In addition, with insulation outside it penofol sits on three frame support grids.

To strengthen the foam with the panel method, it is necessary to calculate the area of material 5–10 cm thick so that it covers the entire surface of the outer wall with a margin. Themselves cut to size panels are fixed on the walls and log cabins with a special glue. After all the foam is fixed, and the glue is dry, it is necessary to overlap the fiberglass mesh on the foam sheets to give mutual strength to the glued sheets.

Then the sheets of foam are covered with a special putty to protect against moisture penetration inside between the sheets. For the final coating using structural plaster or facade paint.

With an unspecified source of insolvency, modern technologies can help. In this case it is necessary to use thermal imaging of the room. Experts in this area will be able to accurately determine the location of the insulation violation and give recommendations on how to eliminate the identifiedlack of.

On how to properly insulate the house outside, see below.