Characteristics and advantages of TechnoNIKOL heaters

The TekhnoNIKOL company produces a wide range of products for construction. Thermal insulation materials of the Russian brand stand out against their counterparts and have a number of advantages. The development of materials is carried out with the introduction of innovative technologies. This is reflected in their quality and explains the demand in the market.

Special features

The products of the Russian corporation are known far beyond the borders of the country. Thermal insulation materials are developed in accordance with the needs of different climates. They are different in terms of operating conditions and construction conditions. However, almost all types of heat-insulating raw materials comply with building codes and fire resistance requirements, as well as environmental friendliness.

The range of materials for warming is quite wide. Each buyer has the opportunity to choose the option based on their financial capabilities. Despite the general indicators, the level of insulation in different lines varies. Some of them are more effective in comparison with others. Thermal conductivity depends on the composition of the material, its density.

The main range of insulation is characterized by stability characteristics during the entire service life. With a tight fit, not only the heat loss coefficient is reduced. The material reduces noise by absorbing sound. He does not allow it to spread further. The company is the only Russian manufacturer of wedge-shaped insulation. It produces kits for roof sheathing, excluding the formation of stagnant zones.

Installation of insulation of the company is carried out by means of special glue or dowels. The manufacturer has provided a convenient cut if necessary. To do this, you can use the usual hand tools.

Insulation companies do not retain water.If it gets to the surface, it does not have time to condense. Water vapor is brought out, the structure of heaters prevents its retention.

The thickness of the insulation is different. This contributes to widespread use in the construction industry. However, the basis is the main factor in choosing the option for insulation in each case. You need to buy a certain type of raw materials. Some people better cope with floor heating of different types (heated, floating). Others do not provide a huge load, calculated for the roof. Others are more suitable for the reconstruction of buildings.

Some materials reduce the design load on the bearing structure. They are characterized by rigidity. The presence of foil in other modifications excludes moisture ingress into the structure of the material. The company's products are antiseptic. It will not start a fungus or mold. It is the protection of the bases and layers of structures from fire.

Advantages and disadvantages

Domestic goods have many advantages:

- Low thermal conductivity. Losses of heat in the rooms will be minimized, which will be especially noticeable during the cold season.

- Resistance to deformation. During operation, the insulation does not shrink and does not change in size.

- No formaldehyde. Trademark heaters do not emit toxins into the air, so they will not cause harm to health.

- Easy installation. Warming with corporation goods is carried out quickly and does not require the involvement of specialists from the outside.

- Resistance to corrosion. Trademark heaters are passive for biological and chemical activity.

- Fire resistance. Thermal insulation "TechnoNIKOL" is a kind of barrier to the spreading fire.

- Resistance to decomposition. Regardless of weather factors, brand insulators are not subject to rotting.

- Resilience to rodent destruction and durability.

Depending on the variety, its service life is up to 50 years.

Insulation brand reduces the cost of heating the home. Regardless of the change in temperature conditions of external factors, the temperature of their surface will remain unchanged. At installation the specialized equipment is not required. Some varieties of material can be installed on weak ground. Other options (for example, "Extra") are an intermediate layer for subsequent protective and decorative plastering using a special reinforcing mesh.

Each type of material from the manufactured range is tested for compliance with established GOST standards for the main types of characteristics, which include:

- compressive and flexural strength;

- thermal conductivity in different conditions;

- water absorption;

- vapor permeability;

- combustibility;

- flammability;

- toxicity level;

- temperature mode of operation;

- geometric indicators (dimensions).

For each of the indicators there is a label indicating the data and a mark with values for passing the test. This allows the buyer to become more familiar with the characteristics and select the desired option for a specific base, the climate of the region, the type of foundation and construction material. Any insulation brand is certified.

The disadvantages of some types of insulation include several factors:

- Some of them must be protected from UV rays and precipitation during transport.

- You can store them under cover in the open air. However, this is only allowed with reliable packaging. In this case, a prerequisite is the presence of bars, pallets.

- After 10 years of operation, some types of thermal insulation material lose their original properties.

- Versions with lower density in separate series are marked by heterogeneity of structure. This is especially true of mineral wool.

- The difference in quality between budget and expensive types of material is obvious. In an attempt to save money, the quality of warming and durability are lost.

- Alkaline solutions must not be applied to them.

In some packs, the first and last layers are thin, non-uniform, therefore they are not suitable for insulation.

Specifications

Physical and mechanical characteristics determine the suitability of a particular material for the specific needs of the buyer. The plates are distinguished by their strength, the presence of a slope, thickness and cost.

Fire resistance

Most insulation materials are non-flammable. The group of combustibility of raw materials has its own marks. For example, heat insulation plates “Pir” for a bath and a balcony are marked with a G4 mark. Materials lined with fiberglass and foil have indicators G1 and G2.

Extrusion varieties "Eco" and professional insulation with carbon have indicators G 3 and G4.In this case, smoke generation and flammability are marked with markings D3 and B2. Techno piercing materials are non-combustible type of heat insulating material for any material thickness (from 30 to 80 mm). Options based on basalt and basalite sandwich are labeled NG (non-combustible).

Thermal conductivity

The performance of each material is different. For example, the level of thermal conductivity is:

- technical heat insulators - 0.037-0.041 W / ms;

- extrusion analogues in the form of plates - 0.032 W / mS;

- heat-insulating plates “Pir” - 0.021 W / ms;

- analogs based on basalt - 0.038-0.042 W / mS;

- options for shipbuilding - 0.033-0.088 W / ms.

Density

The density of insulating materials is different. In some types of products, it varies from 80 to 100 kg / m3. In general, the density range is from 28 to 200 kg / m3. It directly affects the type of surface. For example, for sloping, it is better to purchase a material with a thickness of 15 cm at a density of 35 to 40 kg / m3. If the indicator is less, insulation can subside.

When you need to insulate partitions, the density should be increased. It is better if it will be 50 kg / m3. The density of the material for the facade should be greater. Here you need an option in the range of 80-100, 150 kg / m3 and more.The thickness can be from 10 to 50 mm.

Composition

The collections of thermal insulators of the Russian company TehnoNIKOL have a different composition. For example, some varieties are made from mineral wool. The finest stone fibers are made from processed gabb-basalt. Phenol is added to some varieties. The basis of a separate series is carbon. Due to it, the characteristics of insulation change. Other types of foam polystyrene are made. Due to this, such options are less weight.

Release form

The company offers two types of insulation: in rolls and in the form of sheet material. The second type is heat insulation from sheets in the form of rectangles. For convenience of transportation they are sold in packs of several pieces. The number of sheets in a pack may be different. It depends on the thickness of the insulation and its composition.

For the convenience of the buyer, the manufacturer indicates on the marking the number of square meters. This allows the lining of coiled or sheet material to take into account specific parameters of the base.

Dimensions

Apart from the fact that the dimensions of the roll and tile materials are different, the brand provides a flexible approach to each client.By the individual order it is possible to execute a heater in other format convenient for the customer. The dimensions of standard plates are 1200x600x100, 1200x600x50 mm. The thickness of the material varies on average from 1 to 15 cm. The sizes of varieties with an edge are 1185x585, 1190x590 mm with a width of 20, 30, 40, 40 mm. The length range is from 600 to 12000 mm, widths are from 100 to 1200 mm.

Application

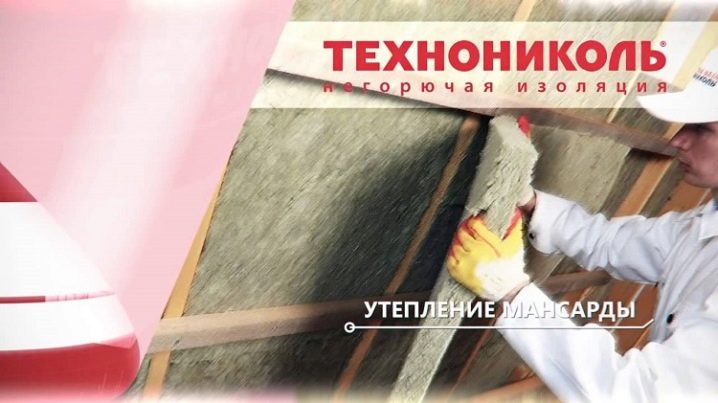

Depending on the type of thermal insulation, the material of the Russian manufacturer can be used for insulation of buildings inside and outside. It can be used for:

- pitched and flat roof;

- walls, floor and ceiling of the house;

- wet and ventilated facade;

- upper floor and attic floor;

- insulation attic, cottage, cottages.

In fact, these materials are applicable for interfloor overlappings. In addition, they can be used for interior partitions and frame systems of wall ceilings, as well as ventilated facades.

Payment

The rules for the calculation of insulation should know every master, and even the customer. Sometimes repair teams purposely overstate the figure. To avoid becoming a victim of fraud, you can use the online calculator. However, you can do some simple calculations yourself. The underlying factors are density and approximate area to be covered.

To make it clearer, you can take a clear example as a basis. It is planned to use insulation 5 cm thick. The size of the material is not taken into account. Need to find its total. The planned height of the facade is 3 m, its perimeter is 24 m.

Calculate the area: 3 * 24 = 72 m2.

The thickness of the insulation is converted to meters: 50 mm = 0.05 m.

Multiply the resulting quadrature by thickness: 72 * 0.05 = 3.6 m3.

After that, it will remain to look at the packaging labeling. Usually the volume in cubic meters is written on it. It remains to divide the resulting figure on this mark. For example, it is equal to the standard value of 0.36 m3. Then the number of packs is equal to: 3.6: 0.36 = 10.

Thus, for 72 m2 with a material thickness of 5 cm, 3.6 cubic meters will go. m or 10 packs of insulation. The same method calculates the flow rate for multilayer insulation.

In order not to get confused in the calculations, they proceed from the total thickness of the material. Knowledge of cubic m will allow to approach the issue of buying the right amount with a great concept.

Kinds

The corporation manufactures products for interior and exterior works. These are roll and tile materials. They are designed for insulation of the facade, roof, foundation and floor. The range of thermal insulation materials "TechnoNIKOL" includes:

- stone wool products;

- fire and technical insulation;

- extruded polystyrene foam;

- PIR insulation boards;

- shipbuilding insulation.

Each line includes a wide range of thermal insulation materials.

Basalt

The range of materials based on stone wool consists of 41 names of heat insulating products. It includes fireproof hydrophobized slabs of mineral wool based on basalt wool rock. In addition to soundproofing properties, they are soundproofed. The purpose of the plates is the facade insulation with an air gap. They can be used for the top layer or in combination with other plates of the series.

The application is designed for low-rise construction, it is appropriate in shipbuilding. It is possible to use plates for warming of the vertical, horizontal and inclined planes. This is an intermediate element in the attic, walls with frame systems, siding, partitions. The most popular materials of the series are:

- "Technoacoustics";

- "Technofas";

- "Techno-block Standard";

- Technolight;

- "Basalite";

- Rocklight;

- "Technoruf Extra".

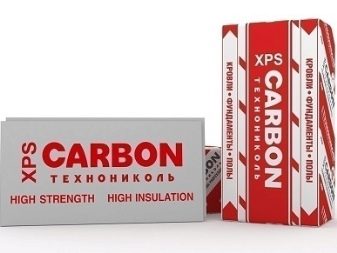

Extruded polystyrene foam

The XPS series includes 11 types of thermal insulation materials “TechnoNIKOL Carbon” and “Technoplex. The latter is a thermal insulation that is compatible with the “warm floor” system. It can be used for private housing and insulation of apartment buildings. Due to graphite in the composition, the level of thermal conductivity decreases and its strength increases. These are plates of silver tone with a layer thickness of 1-10 cm.

The TechnoNICOL Carbon series consists of the best products for home insulation, including the foundation. These are slabs with a rough surface and extreme rigidity. The front option "Carbon Eco" is a plate with closed cells, evenly spaced over the entire surface of the insulation. They are characterized by better thermal conductivity, lightness, and are intended for insulating buildings made of aerated concrete, timber and other light frame structures. The line includes a deviation-forming heater in the form of plates-wedges.

Popular materials of the series are:

- "Carbon Solid" (A, B);

- Carbon Eco;

- "Carbon Prof";

- Carbon Eso Fas.

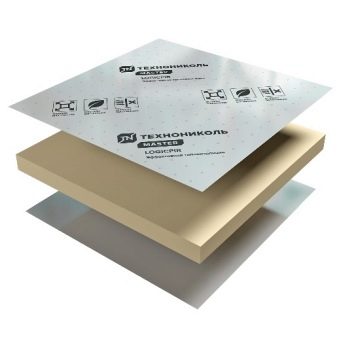

Insulation boards

The series includes energy thickeners of small thickness with improved performance characteristics. They are intended for internal warming of premises, suitable for warming buildings outside. The line consists of 7 items of materials for insulating floors and walls. They are relevant in the insulation of baths, saunas, balconies, loggias, practically have no water absorption.

Materials for a floor provide laying under a different finishing covering. Varieties of fiberglass can be used for flat roofs, using the adhesive method of fixation. This is a roofing material in the form of slabs with edges, although it can also be used for plaster facades.

In contrast to the material with fiberglass lining, foil analogue, in addition to wall insulation, can be used for insulation of cattle roofs.

The most popular materials of the series are:

- "Logicpir";

- "Logicpir bath";

- "Logicpir Wall";

- "Logicpir floor."

Fire-resistant and technical

The series includes about 10 different types of insulation. These are rolled products and options in the form of plates.A distinctive feature of the line is the focus on objects of industrial type. The specificity of these materials is to impart fire resistance to reinforced concrete foundations, insulation of metal structures. By structure, the materials are non-combustible insulation of a technical nature based on mineral wool from basalt and a low-spheric component.

The line includes varieties with laminated foil type and analogue of fiberglass. Roll options are thermal insulation of pipelines. They are distinguished by the presence of self-adhesive overlap for the convenience of self-assembly. The mats of the series are used for air ducts, boilers and various power equipment. The varieties differ from other lines by a large range of temperature conditions of operation.

The sought-after raw materials of the line are:

- "Mat Techno"

- "Plate Techno OSB";

- "Plate Techno OZM";

- "Plate Techno OZD";

- "Techno T".

Installation technology

The installation of a brand insulant depends on the type of foundation, its preparation and the type of work as a whole.Before the start of construction work you need to finish all the basic work inside the building. Window and door openings should be ready, as well as roofing. The standard installation option is as follows:

- Prepare the necessary inventory, purchase thermal insulation and the necessary components.

- The surface must be prepared carefully. It is leveled, then get rid of dust and dirt. It is especially important to remove fat stains if glue fixing is planned.

- The surface is ground with the subsequent drying, then the profile is fixed, the width of which corresponds to the thickness of the insulation.

- After that, you need to put glue on the back side of the insulation point or strip across the surface.

- Then it is necessary to correctly lay the plates mechanically on the profile frame, not forgetting to fasten them together.

- After make installation of a layer of waterproofing. To do this, use a special film, put it on the frame at a distance of 2-4 cm from the warming material.

- Perform a finishing or trim.

Reviews

Brand products have conflicting reviews of buyers and owners of private buildings.Presented conclusions about the manufacturer based on the opinions of buyers and professional craftsmen in the field of construction. Insulators "TekhnoNIKOL" are an excellent product worthy of purchase, - the masters say. However, the choice must be correct.

The desire to save leads to the selection of inappropriate material, which affects the durability and performance characteristics of brand insulators. Professional masters note the importance of considering the base and thickness.

Thermal insulation differs in density and characteristics. Therefore, according to their opinion, the same types of material cannot be used in different places.

How to insulate the house with stone wool "TechnoNIKOL" you can find out by watching the video below.