Insulation for roofing Rockwool "Ruff Butts"

In the construction of modern buildings, preference is increasingly given to flat roofing structures. It is no coincidence, because such a roof can be used in various ways. In addition, the construction of a flat roof is financially more profitable than a traditional pitched roof.

As at any stage of construction, the arrangement of the roof has a number of its features. To avoid overheating or overcooling of the room, builders recommend the use of heaters of mineral wool or rolls. This material is easily mounted, and is also ideal for insulating flat roofs, as exploited often and rarely. Fortunately, in the modern market there is a wide choice of heaters that are easy to use.

The world leader in the production of heat and sound insulation solutions made of stone wool for all types of buildings and structures is the Danish company Rockwool. Insulation solutions of this company save consumers from cold, heat, reduce the risk of fire, protect from external noise.

Merits

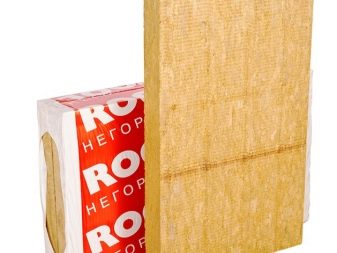

Insulation for the roof of Rockwool "Ruf Butts" is a rigid insulation boards made of stone wool based on basalt rock group rocks. "Ruff Butts" is not by chance one of the best insulants, because It has many advantages:

- dense, durable composition increases the endurance of the material, which does not lose its shape and structure, even undergoing frequent and dense loads;

- low thermal conductivity will provide cool in summer and warm in the cold season;

- resistance to high temperatures (up to 1000 degrees Celsius) does not give the heater a chance to ignite, exposure to ultraviolet rays also does not leave a trace on it;

- Rockwool mineral wool boards practically do not absorb moisture (moisture absorption coefficient is only one and a half percent, this amount easily disappears in a few hours);

- a structure that combines two layers in itself (internal soft and external hard) allows preserving the unique thermal insulation and does not overload the structure;

- high elasticity provides ease of use, installation becomes simpler, the probability of breaks is reduced to zero;

- using "Ruff Butts", you are guaranteed not to encounter the effect of the sauna in the room due to the high vapor permeability of the material;

- producing their products, the company Rockwool uses only natural mineral rocks with the addition of a minimum amount of binders, the number of which is safe for human health;

- All of the above advantages ensure a long service life of insulation.

The disadvantages include only the cost of products. The price of insulation is higher than the average market. But it is better not to save at the initial stage of construction in order to avoid further problems. It is safe to say that in its niche Rockwool "Ruf Butts" is one of the few universal insulation, and the presence of several types of "Ruf Butts" only contributes to its further spread.

Types and main characteristics

Today, the company Rockwool produces a large number of varieties of insulation for the roof "Ruff Butts." Consider their specifications.

Rockwool "Ruff Batts N"

This type is designed for the lower layer of insulation, it is of medium density, does not withstand heavy loads, but has a low price. Used in combination with the top layer of Rockwool of the “Ruf Butts B” sample.

Main characteristics:

- density - 115 kg / m3;

- the content of organic substances is not more than 2.5%;

- thermal conductivity - 0.038 W / (m · K);

- vapor permeability - not less than 0.3 mg / (m. h. Pa);

- water absorption by volume - not more than 1.5%;

- insulation slab size - 1000x600 mm, thickness varies from 50 to 200 mm.

Rockwool sample "Ruff Butts In"

This type is designed to protect the bottom layer of insulation. Differs in the increased rigidity, high durability and small thickness - only 50 mm. The characteristics of this type coincide with the lower layer, with the exception of the density - 190 kg / m3, and the size of the slab -1000x600 mm, thickness - from 40 to 50 mm. The tensile strength of the layers - not less than 7.5 kPa.

Rockwool model "Ruf Butts C"

If you plan to use insulation together with a sand screed, consider this special option. It will provide reliable adhesion coatings.The density of Ruff Batts C is 135 kg / m3, and the tensile strength of the layers is the same as in the previous version (not less than 7.5 kPa). Insulation plate size - 1000x600 mm, thickness - 50-170 mm.

Rockwool "Ruff Batts N and D Extra"

An unusual variant of insulation, consisting of two types of plates: thin (density - 130 kg / m³) below and more durable (density - 235 kg / m³) from above. Such plates, while maintaining their thermal insulation properties, have less weight, provide easy installation. Insulation plate size - 1000x600 mm, thickness - 60-200 mm.

Rockwool "Ruf Butts Optima"

This option differs from its “brother” described above only by its lower density - only 100 kg / m³, which makes it more suitable for rooms that are rarely used. Insulation plate size - 1000х600х100 mm.

Rockwool "Ruff Batts N Lamella"

Lamellae - strips cut from stone wool slabs are used for thermal insulation of roofs with different bases, the shape of which can be either flat or curvilinear. The size of such bands is 1200x200x50-200 mm, and the density is 115 kg / m³.

How to choose?

To choose the right insulation, it is enough to carefully examine the features of the materials on the market.But whatever type of material you choose, it will provide maximum strength, low thermal conductivity and will last for a long time.

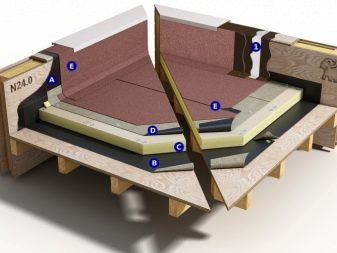

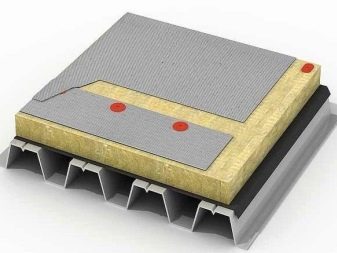

Apply Rockwool can be different: as the base or the front surface of the roof. A variant that suits the majority is the simultaneous use of Rockwool Roof Butts H and Roof Butts B. Such a solution will ensure the longest operation of the facility. Rockwool categories marked “C” are ideal in those cases where it is planned to provide access to the surface to be covered. Special additives make this insulation an excellent base for screed, prepared on the basis of a solution of cement.

Installation

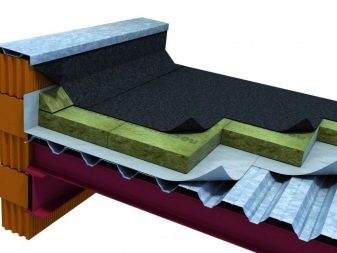

From the name “Ruf Batts” (“roof” from English - roof) it becomes clear that this insulation was created for a specific purpose - to isolate the roof. The specific task in the manufacture of the material allowed the creators to maximize all the demands of customers. According to consumer reviews, working with Rockwool insulation is simple and pleasant. Consider the main stages of working with insulation:

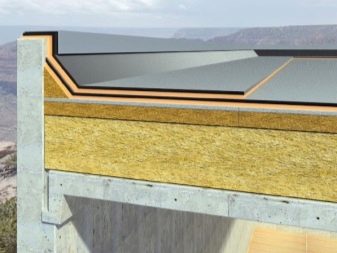

- foundation preparation;

- using the solution, install the first level of the plates;

- then install the second level of the plates (to avoid the penetration of air between the layers of the plates, they are overlapped);

- we additionally fix the insulation with dish-shaped dowels;

- if necessary, we also install a waterproofing layer;

- we lay down roofing material or any other covering, roofing material can be replaced with a coupler.

Buildings with a flat roof, covered with roofing felt and facade dowels, are becoming more and more common. Of course, this layer will protect the house from some environmental influences. But, unfortunately, even a powerful concrete barrier does not completely preserve the house. Having timely protected the building with insulation materials from a trusted manufacturer, you will not only ensure the safety of your building, but also save a lot of money and time.

For a review of Rockwool Roof Butts, see below.