Thermal insulation of facades: types of materials and methods of installation

When building and designing the facade of the house, it is not enough to take care of its durability and stability, of external beauty. These positive factors alone will instantly lose their value if the wall is cold and becomes covered with condensate. Therefore, it is extremely important to think over high-quality thermal protection and choose the most suitable material for it.

Ways of thermal insulation

Facade insulation solves four main tasks at once:

- winter cold prevention;

- heat prevention in the summer;

- reduced heating costs;

- reduction of current consumption by fans and air conditioners.

The device of a heat-insulation layer outside is considered the most correct step by all technologists.Professionals warm the home from the inside only if external insulation cannot be used for any reason at all. As practice shows, outdoor work:

- reduce the impact of weather and other adverse factors on basic structures;

- prevent condensation of moisture on the surface and in the thickness of the wall;

- strengthen sound insulation;

- allow the house to breathe (if everything is done correctly and the choice of material is accurate).

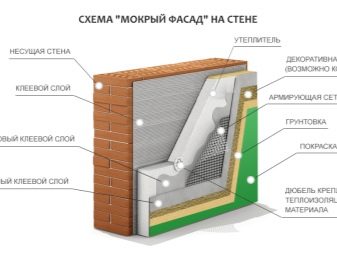

Plaster processing using wet technology is in demand more than other schemes, and the total cost and ease of implementation will allow it to remain the most popular option for a long time. The "cake" includes, in addition to the material of thermal protection, glue based on polymer cement, reinforcing structure and decorative finish. The formation of the hinged frame is necessarily under the ventilated facade and this inevitably makes the whole building heavier.

A prerequisite for reliable operation of such a two-layer type of walls is to leave a gap through which air will circulate. If you do not leave it, the moisture will become impregnated with other insulating materials, will begin to harm the walls themselves.

Another scheme - heavy plastering. First of all, there are panels that mainly block the heat leaving to the outside, and then a plaster layer is applied. It may seem that such a solution is better than a wet facade, because there are no restrictions on the density of materials. But at the same time, the quality of the insulator should be as high as possible.

This method is often used by amateur builders, since it allows not to align the walls to a perfectly smooth state.

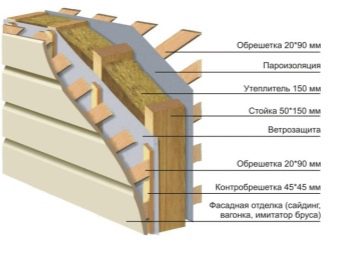

If you need to make insulation of the facade of the old house for year-round living, the simplest solution is insulation for siding. It is not only reliable and effectively prevents the loss of heat: the outer shell may look extraordinarily elegant; other options rarely allow you to achieve the same result.

Prerequisite is the formation of the frame. It is created using either wood or steel parts treated with protective agents. Then a layer of the vapor barrier is always put, and only after overlapping it with heat protection does it come to decorative panels.

All of these methods are intended primarily for brick, panel or built of expanded clay concrete blocks of houses. Wooden facades can not be insulated with polymeric materials. Mainly fibrous structures are suitable for them. It is important to observe the following conditions for thermal insulation:

- readiness of the house at least to the level of the roof;

- completion of construction shrinkage;

- preliminary waterproofing and warming of the bases;

- the end of the installation of windows, ventilation and all communications going to the walls (leading out of them);

- optimal weather (no severe frost, significant heat, wind and any precipitation).

It is also recommended to finish the rough finish of the interior, concreting and pouring the floors, preparing the wiring. The walls are studied in advance, and even with self-installation of thermal insulation consultation experienced builders will not be superfluous. When choosing a scheme, you should think about reducing the number of cold bridges to the limit. Ideally, they should not be at all. Warming with clay and straw is allowed only along wooden walls, but this is an archaic approach, suitable only in isolated situations.

All components must be closely interconnected, because the selection of heat-insulating, vapor barrier and waterproofing materials must be made simultaneously. It is not necessary to contact professional builders in order to obtain the necessary information. Most situations are successfully solved through the purchase of completely finished insulation schemes, which are already in production are equipped with fasteners and other equipment. Working with such kits comes down almost exclusively to following the manufacturer’s instructions. It will only be necessary to calculate the need for materials and not to be mistaken with the choice of a particular type.

To insulate panel facades, taking into account such considerations as:

- favorable or unfavorable climate conditions;

- precipitation intensity;

- average wind force and speed;

- affordable budget;

- individual features of the project.

All these circumstances directly affect the choice of a suitable option for insulation. For cost estimates it is better to contact the Criminal Code or a partnership of owners. Outside work is most often entrusted to industrial climbers (you can do without their help only onground floors). Under the mineral wool necessarily encloses the water vapor permeable membrane.

If foam insulation is chosen for the insulation of any house, it is imperative to require the sellers to have certificates for material compliance with G1 flammability (too often expert checks reveal a violation of this requirement).

If expanded clay is covered with expanded clay concrete, it is necessary to check that their thickness is at least 100 mm, and the sheets themselves are laid tightly, excluding the appearance of seams. Vapor barrier during the insulation of such blocks is strictly required. Above the claydite walls that do not have exterior finish, for greater energy efficiency, it is recommended to build on a brick cladding structure. The resulting gap is filled with various insulating materials.

If there is no desire to resort to complex and labor-intensive brickwork, you can use insulating blocks with industrial cladding.

Types of materials

Having dealt with the main schemes of thermal insulation of the facade, you now need to find out what materials can be used for this purpose, and what their specific parameters are.According to professionals, it is very useful to use polyurethane foam assembly foam. Since the composition is fully prepared for work in an industrial environment, it will only be applied with cylinders. Judging by the reviews, the assurances of manufacturers of balloon polyurethane foam about the combination of thermal protection with sound insulation fully correspond to the truth. The strength and increased elasticity of the resulting polymer composition at the exit to the outside has long attracted the attention of builders.

Polyurethane foam very quickly covers a large area and at the same time enters even the smallest gaps. It will not be able to rot or become a breeding ground for microscopic fungi. Even when exposed to open fire, the foam material only melts, but does not ignite. If it overlaps the metal base, reliable corrosion protection occurs.

At the same time, you should be careful not to use PU foam in places where the material may be exposed to direct sunlight or water.

Quite popular now at home from Cibit can be insulated in the same way as any other buildings. Both wet and ventilated facades are acceptable.Professionals recommend that the underground part be coated with extruded polystyrene foam or other insulants that are not susceptible to the action of water.

Fresh stonework, until 12 months have passed, it is better to leave alone. If it is warmed up to the end of this period, Cibit will not have time to dry and will become covered with mold.

If it is impossible to slow down the construction at this time (and most often it happens), it is worthwhile to insulate with the help of XPS. Its layer is displayed above the ground, over the pavement about 0.1 m. The fact is that if you just bury an uninsulated stone, it will not dry anyway, the soil waters found even in the driest soil will be in the way. The cap will be destroyed very soon.

The overhead segment can not overlap so that it dries out. It is also recommended to warm up and ventilate the base during the winter months, not to carry out wet work; Water vapor-proof plaster may be applied over the EPS.

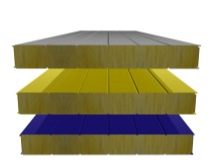

If a house made of Cibit or any other material has already served for some time, the problem of drying disappears by itself. Then you can consider the possibility of insulating the facade with sandwich panels.The prerequisite is the use of film vapor barriers and the organization of ventilation gaps. Quite good protective properties are shown by ruberoid and asphalt, which are applied to the walls themselves. Protect from the wind should be increased density materials located in the scheme above the insulation.

Returning to the sandwich panels, it is worth emphasizing such undoubted advantages as:

- mechanical fortress;

- reliable cover of the underlying layers from external influences;

- incombustibility;

- noise reduction;

- ease;

- protection of metal parts from corrosion.

Often sandwich panels are recommended for wooden structures that are operated for a long time. In them, the problem is not only the containment of cold, but also the external protection of the external circuit that has weakened over the years. Due to the wide variety of panel formats, it is easy to select the ideal option for a specific purpose.

Modern enterprises have established the production of panels with a variety of external shells. There is aluminum, and stainless steel, fiber and chipboard, plywood, and sometimes GCR.Advances technologists can protect products from ignition due to the use of fireproof layer.

The simultaneous combination of the highest practical and decorative characteristics is achieved when choosing steel sandwiches with an outer polymer layer. Those interested can even order an imitation of any natural stone.

During installation, the panels should be placed so that the insulating fibers form a right angle with the base to be sheathed.

The acquisition of a specialized tool will only bring savings in the long run. After all, there is no other way to quickly and efficiently, without unnecessary losses, slice a sandwich panel as required.

Insulation for exterior work often overlap with clinker tiles. It is possible to imitate its appearance on a wooden base using three methods.

- Actually the use of clinker bricks. Acceptable if the basement is wide.

- The use of facade thermopanels, covered with a tiled layer. Cement is not required.

- Plastic panels (the cheapest and easiest way to install).

It is worth mentioning the concept of Lobatherm, which provides for fixing insulation on the facade, the formation of a reinforcing layer based on a special mixture and glass mesh.You will also need to finish the surface with clinker tiles that look like bricks. Such a system is suitable for covering stone, brick, foam concrete and aerated concrete walls.

If all the work is done correctly, you can guarantee the viability of the coating for at least half a century without repair.

Heat-insulating plaster and finishing with special paint can be used only as an auxiliary means to enhance the protective properties of the main insulation. Talking about the warming of cardboard and even more practical Kraft paper is not serious.

Both materials are more likely to protect from the wind than help to retain heat. Cardboard weight is three times worse in its thermal characteristics than stone wool and even a third pine board. In addition, problems may be associated with the fire danger of the material and the fact that inside it creates favorable conditions for insects.

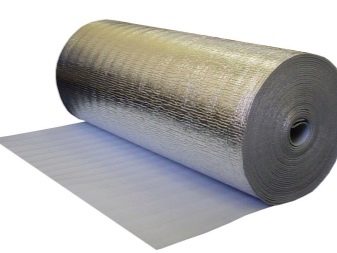

It is much more practical to insulate the facade with penofol, that is, with foamed polyethylene. The advantage of this solution is that it effectively suppresses the transfer of heat both by convection and through infrared radiation.It is not surprising, therefore, to achieve an impressive level of thermal protection. 100 mm of penofol are equal in their characteristics to 500 mm of high-quality brick wall. In addition to these advantages should be mentioned:

- ease of installation;

- vapor tightness;

- reliable protection from overheating by sunlight.

Such qualities can do without other waterproofing and vapor barrier coatings, significantly reducing the cost of repairs or construction. Penofol category A has a one-sided arrangement of the foil, it is not intended for the facade. But it gives excellent results in the insulation of the roof and various communications. Grade B has a foil on both sides, intended for the insulation of floors between floors in the first place. Finally, materials from group C can be used on the most inconvenient for work sites.

There are a number of other options - in some foils are complemented with mesh, in others there is laminated polyethylene, in the third polyethylene is given a relief structure. The foil is able to reflect up to 98% of the thermal radiation incident on its surface. Therefore, it effectively copes with protection from cold in February and from heat in June or July. Penofol can be simply glued to the wooden base.Also allowed by the technology of stapler attachment to the staples or nailing.

It is impossible not to take into account that the foamed polyethylene foam cannot “boast” of great rigidity, because after its application it is impossible to put additional finishing layers. Staples are worse than glue because they violate the integrity of the material and prevent them from performing their basic functions. In addition, truly complete insulation is possible only when using penofol in close conjunction with other protective materials.

Mechanically damaged areas of the insulator are manually restored using aluminum tape.

The use of felt has, of course, a much longer history than the use of penofol and other modern insulators. But if you look at the practical characteristics, then there are no particular advantages. The only advantage that is beyond doubt is flawless environmental safety. If, however, a choice is made in favor of this particular material, the service life of thermal protection will delight the owners.

Be sure to take care of the impregnation of flame retardants in an organization licensed by the Ministry of Emergency Situations.

Styrofoam

If experts say relatively little to felts, then foam plastic attracts much more attention. Disputes around him are boiling very sharp, and some are trying to prove the superiority of this material over others, and their opponents proceed from the assumption of its insignificance. Without going into discussions, one can say one thing: foam is an attractive solution only with careful surface preparation. It is strictly necessary to remove from the walls of everything that can interfere with the work.

This applies, by the way, to decorative elements, which for a long time operated houses appear a lot. Experienced builders will certainly test the plaster for strength by tapping the surface. To identify various deviations from the plane and the slightest flaws will usually help, plumb or long cord. There is not even a special need to use the building level. Defective areas of the plastering layer must be cleaned, then a chisel is used, removing the influx of concrete and excess mortar between the bricks.

You can not mount the foam on the wall, covered with oil paint, it will have to sacrifice a layer.Naturally, mold and grease stains, traces of rust and salt seeping out will be absolutely intolerable. Cracks deeper than 2 mm should be primed with compounds penetrating into the thickness of the material. The preparation is carried out using a brush. If irregularities over 15 mm are found, after applying the primer, plaster is applied on the beacons.

The starting bars of the frameworks must correspond in size to the width of the insulating material. Strips of glue are undesirable to make solid; dotted application will help to avoid the appearance of air "traffic jams". Laying and pressing the sheets of foam to the wall should immediately after applying the adhesive, otherwise it will have time to dry and lose its bearing capacity.

All sheets are checked in turn by level, otherwise very serious errors may occur. If necessary, adjust the position of the plate, it is completely removed, scrape off the old glue and apply a new layer.

Glass wool and ecowool

Glass and ecological wool are very similar to each other, but there are also significant differences. So, glass wool is dangerous to health and is not very convenient in daily work.It is categorically not suitable if you need to insulate the walls outside by the wet facade method. The advantage of glass wool is its absolute inertness chemically. In the domestic environment simply do not meet such substances that would react with this heater.

Low density avoids a significant overload of the foundation, which means that glass wool is compatible even with lightweight buildings. A serious drawback is its high hygroscopicity, but the effects of open fire and strong heating can not be feared. Even foiled glass wool should be blocked from the outside with layers of vapor barrier and waterproofing, otherwise it will not be able to complete the task. Glass wool can also be used as part of a ventilated facade, then it is laid on a batten or fastened between its parts.

From the cotton layer to the surface of the wall should not put any films or membranes, they are still there superfluous. Moreover, the presence of glass wool in the gap between the vapor barrier layers will only make it inevitable damage by liquid.If you suddenly make such a mistake, you will have to disassemble the entire cake, dry the insulation and strictly observe the technology during the next attempt. Ecological cotton wool is similar in its properties, except that it is not so prickly and completely safe to handle.

The choice between these two materials is more dependent on the specific brand than on the species.

Basalt slabs

Thanks to the latest technological developments, basalt wool can be used not only to fill the walls. On its basis, excellent insulating plates are created. The initial raw materials in their production are andesites, diabases and other breeds, which appeared as a result of volcanic activity. After melting at temperatures of 1400 degrees and above, which is replaced by blowing in a fast moving gas stream, the liquid mass turns into filaments.

Basalt slabs are widely used in the process of warming frame houses, and at the same time the impact of street noise decreases.

The outer walls are covered with a preliminary crate. You should always maintain a slight gap to the finish plating.To keep the plates on the draft wall, they are attached with screws. The next layer will be a film holding the wind, and last of all they mount siding, wall paneling, porcelain stoneware or any other coating to taste and financial possibilities.

The advantage of basalt wool-based slabs is the excellent resistance to mechanical loads, including those arising during the installation of the facial finish.

Polyurethane foam

PU foam can be represented not only in the form of foam pumped into high-pressure cylinders. Professionals use a more complex mixture, applied to the facade with the help of specialized equipment. One rent it can significantly increase the cost of repairs. Not to mention the fact that to perform all manipulations qualitatively fail, It is always necessary to entrust such processing to real masters.

It is important to take into account that the thermal conductivity of polyurethane foam found in advertising brochures (0.2 or even 0.017 W / mx ° C) refers only to ideal conditions and is never achieved in practice.

Even with the strictest observance of technology and the use of the latest equipment, it is possible to reach such figures only when filling the cells with inert gases prohibited for environmental reasons.In most cases, at Russian construction sites you can find PUF, the foaming of which is provided by water. Such material can not reach half of the advertised figures.

If the coating with open cells is sprayed, the money for finishing and insulation is spent less, but the protective qualities are reduced even more. And finally, gradually, even inside closed cells, processes occur that contribute to the volatilization of gases and their replacement by atmospheric air.

High level adhesion is not provided for any type of polyurethane foam and not on any surface. It is basically unattainable with a polyethylene substrate. Big problems are waiting for those who, under the influence of manufacturers' promises, will decide that the wall surface can not be prepared at all. So, a thin exfoliating plaster layer or dusty areas, or greasy stains can devalue all efforts. Professionals always apply polyurethane foam only on perfectly dry walls, but dosed hydration will even be useful for forming a structure with open cells.

Surface preparation

You should not assume that the condition of the facade being insulated from the outside is very important only when applying polyurethane foam.Rather, the opposite: whatever is written in the information materials by marketers, careful preparation for work only increases the chances of success. The probability of the fact that the formed coating will become unusable is significantly reduced. Often it is necessary to prepare the walls under the tile, because it:

- looks great in almost any situation;

- durable;

- resistant to negative external influences.

Alas, the easiest method of leveling is not acceptable for street walls - installation of plasterboard sheets. Even their moisture-resistant varieties are not reliable enough, because they are not adapted to the effects of negative temperatures. Have to use a variety of leveling mixture.

Before using them, you still need to remove dust and dirt, to eliminate the largest protrusions mechanically. Any mixture, including plaster, is kneaded and applied strictly according to the manufacturer’s instructions, the “expert advice” is totally unacceptable here.

When using beacons, the very first of them are put on the corners, and when the mixture hardens on the wall, it will be possible to stretch the threads, which will become the main guidelines for exposing the remaining profiles. Important: the plaster is prepared in such an amount that can be fully consumed in 20-30 minutes. In some species, the life cycle of a solution may be longer, but it is not worth the risk, it is more correct to keep a supply of time for yourself.

So that the tile does not fall off, the plastered wall must be primed. The choice of colors and textures depends entirely on personal preferences.

It doesn’t matter whether the tile will be applied outside or not, there are some subtleties and nuances when weatheting a concrete house. So, before applying polystyrene foam a layer of concrete should be covered with an antiseptic and a primer. Instead of plaster, leveling is often done with a mixture of cement and sand. The calculation of the need for insulation material is simple, you only need to know the total area of the facade and prepare a stock of sheets of about 15%. The sheets of medium size are optimal for work: very large ones are difficult to fasten, and if you take small ones, you will have to create a mass of joints that make the structure unreliable.

It will be necessary to take five dowels to all the plates and provide for a reserve of 5-10%, as experience of experienced builders shows, it is almost always depleted.For your information: it is desirable to apply an antiseptic several times, this will only improve the result. Glue is always smeared not only the corners, but also the very middle of the sheet; dowels are screwed in the same places. Sticker styrofoam lead from any of the two lower corners. The mixture will dry completely in 48-96 hours.

After the glue has dried, a reinforcing mesh is attached to the surface of the plates using the same composition. Then this grid will need to be coated with glue on top, level it with a spatula and putty. Next comes the primer layer, and finishing materials are put above it (most often siding panels). Concrete can be insulated with special plaster. But in itself, this option is recommended only for the warmest areas of the Russian Federation.

A special approach is required when warming a foam block dwelling. Sometimes it is performed by facing the walls outside with blocks of the same low-density foam concrete. Rebar is used to connect two planes. Such work is long and laborious, it should be done by qualified masons. For the greatest efficiency, mineral wool is put into the gap, cellulose insulation or liquid foam concrete is poured in.

A good result is achieved with the use of polymer plates of different composition, especially finished with plaster. Low vapor permeability can be compensated by increased ventilation. If you plan to block foam blocks with a ventilated facade, it is difficult to find a better solution than traditional mineral wool. The front layer is often siding or the like of a bar formed by metal parts.

Before installing the expanded polystyrene, it is worthwhile to mount a plate of steel at the bottom; it will not only support the plates, but also prevent rodents from getting to them.

Experienced builders necessarily care about roughening polystyrene plates. They are rolled from the back with needle rollers or manually cut with a knife. Glue on the surface of the plates can be applied with spatulas or toothed floats. Important: before installing insulation thickness of 5 cm or more, it is necessary to spread the glue on the wall itself. This will increase costs, but is justified by increasing the reliability of fixing the material.

Before plastering, it is possible to install only those metal grids that are resistant to alkali.When insulating a monolithic house of arbolit, one should be guided by the climatic conditions of a particular region. In a number of places, the thermal characteristics of the units are good enough so that you can avoid fear of frost damage or overcooling at home. But even in ideal conditions it is required to carry out the exterior finish, for which plaster mixes are used or siding with a vapor barrier. Such a solution allows, at least, to bring the dew point to the external surface of the blocks.

In addition to arbolita, there is another material that is safe for thermal properties - aerated concrete. But, even having built a house from gas silicate blocks, it is not always possible to avoid additional warming. The vast majority of construction crews already use standard mineral wool and foam sheets.

The first option is better than the second, because low cost does not justify low vapor permeability. The remaining types of heaters are not at all competitive when working on the facade of aerated concrete housing.

Subtleties of installation

Warm-up private houses with defects in walls greater than 2 cm can be warmed only after leveling the surface with cement solutions.After drying, these solutions are coated with a primer, which stops the destruction. Under the installation of the ventilated facade you can level the base with the use of brackets. If mineral wool is used, the installation of insulation can be made using a wooden batten frame. Strengthen attachment to the walls will help anchor.

On uneven surfaces, it is worth to use a special mineral wool, which contains layers of different density. The least dense layer must be fixed to the wall so that it bypasses, covers unevenness and makes the structure more even. Then there will be no problems with the penetration of cold to the surface.

The technology of finishing the overlying layers can be any, as long as it turns out to be convenient. If polymer plates are superimposed on the wall, all layers are shifted horizontally by 1/3 or ½.

It is possible to increase the fit of the plates by cutting off the corners of the side faces. To reduce the need for fasteners will help screw in dowels into the edges of the docked parts. It is recommended to pay attention not only to the type of insulation, but also to the fact that its thickness is correctly determined, sometimes calculation with the help of professionals only saves money.

It is necessary to be guided by information about the coefficients of thermal resistance assigned to a particular locality. The maximum layer of insulation must be mounted on top of reinforced concrete, because it is this material that has the highest thermal conductivity.

Useful tips

The types of systems for exterior facade insulation of a stone cottage are about the same as for concrete surfaces. Ventilation gaps and air vents should be displayed strictly on the cold side, that is, out. Air vents for air flow must be at least one in each room. Then in the summer and in the winter months the microclimate inside will be perfect. When insulating buildings from cinder block, many experts recommend polystyrene foam brand PSB-S-25.

In the process of finishing the cinder can not do without decorative plaster. The holes for dowels in this material are drilled exclusively with a perforator. Exterior lines are measured with a laser or water level. The same requirement applies to other buildings, even dacha or garden extensions.

Full warming of the premises attached to the houses is achieved only in a comprehensive manner,In the same verandahs, special layers must also be installed under the floor and inside the roofing.

How to warm the facade of a private residential building, see the following video.