How to choose a Euro race?

Lining - an environmentally friendly material for decoration, which is made from different varieties of natural wood. With proper care, namely: timely lacquering or painting, this material is able to serve an average of 15-20 years.

What it is?

Glued lining received its name because of the initial scope of application: finishing train cars. Initially, they were thin wooden slats, but nowadays each rail is equipped with a special lock for easy installation. The tree is still considered a popular material in the construction industry - it can be found in the decoration of premises, both external and internal, as well as in the construction of houses and any structures.One of the main advantages of wood is the ability to accumulate and evaporate moisture, making graphs of temperature and humidity at the same time softer.

Lining, as a material for decoration, has many advantages:

- convenient installation thanks to a well-thought-out system of fasteners and connection of parts to each other;

- a large selection of colors, sizes and materials from which the panel itself is made;

- a light weight;

- wide scope of application;

- democratic value.

Manufacturing

Production of lining is divided into stages and begins with the release of edged boards. With the help of a sawmill, the necessary blanks are cut, which correspond to exactly the specified parameters and dimensions, using the material of the best purity: between the bark and core of the tree trunk. The next step is drying - the accuracy of the geometrical dimensions of the material and their stability depend on it. During drying, all microorganisms are destroyed, both inside and on the surface of wood, excess moisture is removed, which reduces the weight of the material and simplifies its further processing.

The final stage is the final processing of the front side and chamfering, after which a perfectly smooth and even board is obtained. Some unscrupulous manufacturers often neglect this stage, not bothering with high-quality polishing and removing knots that may fall out. Also dishonest manufacturers often do not dry the board, because of which the buyer has enormous problems: lining begins to change the geometry, bend, respectively, further use is impossible.

Types and characteristics

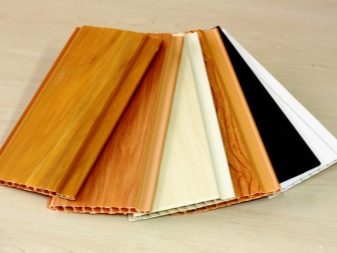

Lining can be as classical, made of wood, and created from materials of a completely different class, such as plastic or MDF. Plastic lining. The type of finish used with this material is also called panel trim. This type of finishing material is extremely resistant to moisture, very light compared to analogues and does not lose its appearance under the action of sunlight, however, due to the effects of low temperatures it often becomes brittle and it becomes extremely easy to damage the panel.

Plastic paneling is about 2-3 times wider than the ordinary wooden version. It simplifies its installation the possibility of bending around it both internal and external angles — you just need to cut a small amount of stiffeners from inside the panel and heat it.In addition, such a material can have any pattern, as a stylized wood, or any pattern or even a whole image, which will be folded from the panels.

But nevertheless, it should be remembered that plastic is not an environmentally friendly material, so you need to carefully select high-quality panels so that they are not emitted into the air harmful substances.

Lining of MDF. MDF panels are an absolutely environmentally friendly and clean finishing material, which is a good competition for plastic panels or classic wooden paneling.

MDF panels produced by pressing small and dry wood chips under high temperature, using high pressure to form. The material is bonded through the release of a natural substance that is present in wood - lignin. Due to this, MDF is an absolutely safe material that does not emit harmful substances, since in its production no epoxy resins are used.

From the characteristics of this type of product it should be noted a variety of patterns and stylizations for various materials.

Lining made of wood - the most common type of finishing material.She was the very first to enter the market for building products.

Wooden lining has many styles of design, but in appearance it can be divided into two types:

- with a flat front panel;

- with a rounded front panel that mimics the structure of the timber.

Types of wood:

- Aspen - light, hard wood, not prone to cracks, has a small weight.

- Pine - medium strength wood, rather heavy, yellowish, and sometimes red. Over time, a little darker. When processing by specialized means lining from a pine perfectly resists fungi and mold, as well as insects.

- Larch - solid wood, practically does not change its size under the influence of external factors, colors can vary: from light yellow to red-brown.

- Cedar is very durable and expensive wood. It has a pleasant aroma and useful resins, which are endowed with healing properties.

- Spruce - light yellow wood, similar in properties to pine, but less common.

Advantages and disadvantages of the material

The best properties belong clapboard of larch, pine, as well as cedar, spruce and aspen. Lining, made of coniferous wood, is used for all types of finishes: both external and internal. However, the material is made of hardwood, suitable only for installation inside, as it does not tolerate moisture.

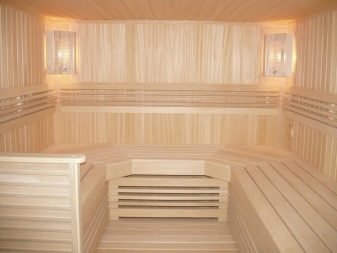

Coniferous woods always contain large amounts of natural resins and oils., due to which they can be used at high humidity and resist the formation of mold. This material is suitable for interior decoration, but it cannot be used for lining saunas and baths - because of high temperatures, resin is released, so the material is covered with its sticky layer and it can even catch fire on its own. Therefore, before facing with coniferous clapboard in a sauna or a bath, the boards should be freed from tar - this is the case in some European countries.

Hardwood, such as linden, alder, oak or ash, has a shorter service life, but does not contain a large number of resins, and therefore does not emit them, which is why it can be used in baths and saunas.Hardwood lining requires regular and timely processing, otherwise the surface loses its proper appearance and turns black. It should be added that for baths and saunas you can use wood only with a small density, since it transfers less heat and, therefore, heats up.

Lining is sold in packs of 1 m2. A metal net is usually wrapped around it.

Dimensions

It should be noted that eurolining and ordinary lining have different sizes, which are often indicated in tables on manufacturers' websites. Dimensions of ordinary lining are set directly by the manufacturer of the material, but there are the most popular, which have become the standard parameters.

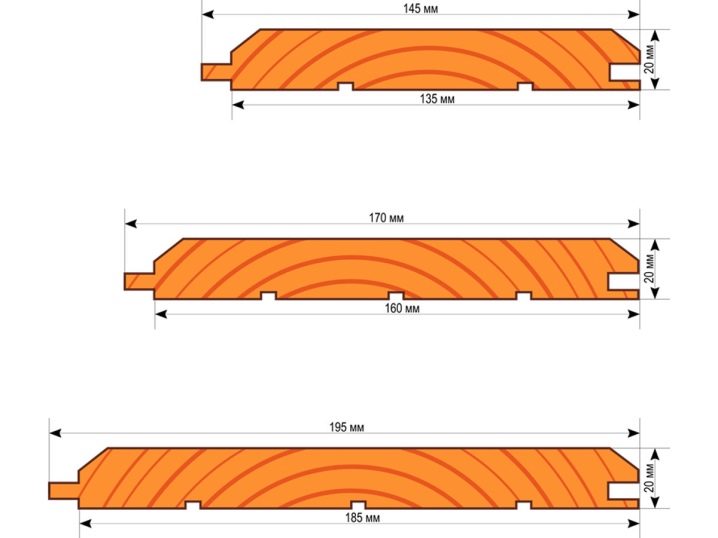

The dimensions of wooden lining can vary widely:

- thickness - from 12 to 40 mm;

- width - from 76 to 200 mm;

- board length - from 20 cm to 600 cm;

- spike height - 4-5 mm.

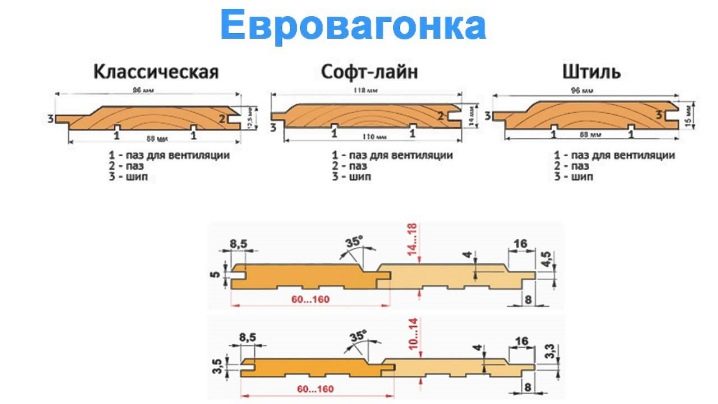

Dimensions eurolining

More standardized parameters are inherent in eurolining:

- thickness - 13, 16, 19 mm;

- width - 80, 100, 110, 120 mm;

- board length - 50-600 cm;

- spike height - 8-9 mm.

Possible errors:

- thickness - up to 1 mm;

- width - up to 1 mm;

- length - up to 5 mm;

- spike height - up to 0.5 mm.

It should be mentioned that the short boards lining have a much lower price.This is due to the fact that the details of small length are often scraps of the final processing of long boards. The reason is that on the long parts in the process of final processing, you can notice dead knots that need to be removed, as they may fall out during use - this will save the grade of the lining.

What are the differences between varieties?

In the decoration used in various varieties of lining. Below is a description of each class.

There are 4 classes:

- class "Extra";

- class A;

- class B;

- class C.

In category "Extra" enters the board light color with the complete absence of knots. The board in this class is completely devoid of cracks, chips and other defects. The moisture content of this type of product should not exceed or be lower than the standard values by 12-14%. The class "Extra" implies the highest quality of the material - it can easily be used to finish living spaces. The boards are extremely carefully processed and have a pleasant appearance without flaws.

AT class "A" includes light-colored boards, on the surface of which knots may be present in small quantities, resin plots, cracks and chips.However, their presence does not significantly affect the strength of the board. The moisture content of the material should not exceed or be below standard values by 12-14% percent. Also suitable for interior decoration.

AT class "B" boards of dark color enter which often presence of knots, chips, cracks and other defects is characteristic. But at the same time their number should be no more than 20%. The dimensions of the resin plots should not exceed 15 cm. The moisture content of the material in this class should also be within the standard values with a deviation of up to 12-14%.

AT class "C" the most low-quality boards of various color enter. Defects can occupy up to 30% of the entire board area. The material of this class is devoid of finishing, so the installation indoors is undesirable. This type of lining is used for exterior decoration.

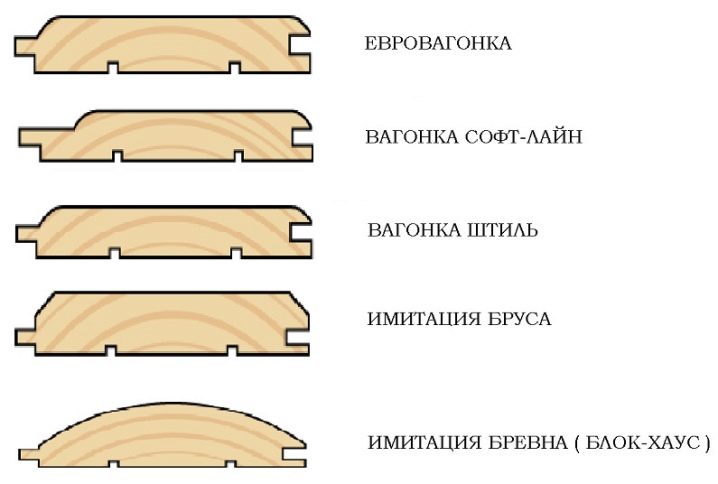

Types of lining profiles

It should be mentioned that only wooden lining possesses a diverse number of profiles - the other types are made in a standard profile.

Profile type "Standard". The front side of the board is flat, and its edges are beveled at an angle of about 30 degrees. The edges of the board have special grooves and protrusions of the “thorn-groove” type for reliable connection with each other.At the same time, the height of the spike is made somewhat less than the depth of the groove, in order to compensate for thermal expansion and take into account production errors, as well as to give the opportunity to fasten boards of different lots together.

Profile type "Calm". This kind of wooden wall paneling differs from the classic only by the rounded corners of the boards. The rest of the product is completely similar to the standard version, but it looks better than the classic lining with its sharp edges.

Profile type "American." The profile of this type has a front part with beveled edges, because of which the installation effect of laying boards overlap.

Lining. In contrast to the usual, familiar lining "euro" has a thicker spike, which guarantees greater reliability and durability of the finish during operation. In addition, after the installation, Euro-lining forms a solid pattern, and not chaotic, as is the case with the classic version. This material is quite easy to put and, if necessary, can be painted with your own hands with acrylic paint.

This material is manufactured according to the European DIN standard. European standard obliges the manufacturer to adhere to extremely stringent requirementsto the moisture and quality of wood, the geometry of the board and the thoroughness of the polishing and processing. Also, eurolining boards have two grooves or grooves on the back side, which serve to drain condensate and ventilate the space between the skin and the wall. This protects both the board and the crate with insulation from decay and the appearance of fungus or mold as a result.

Also, these grooves somewhat help the boards to withstand thermal expansion and changes in the geometry of the material due to humidity drops.

Tips for choosing

Before you choose a product, first of all, you should decide on the material for lining. Wood lining has long established itself in the market as an affordable and reliable material for interior decoration. Of the positive qualities of wood, it is worth noting the good sound and heat insulation, as well as the convenience of working with the product itself. Wooden wall paneling has a wide range of applications: it sheathes baths and living rooms both inside and outside.

Lining of wood can be made of different wood speciesaccordingly, they all have a separation by properties.When choosing wooden wall paneling, attention should be paid only to Euro-lining. The main difference is quality. A thicker lock, high demands on wood and its moisture content, as well as surface treatment, make eurolining incomparable in quality with the usual option. However, if you need to save the budget, then classic lining is also a good option. But one should keep a close eye on the quality when choosing a material, as well as be prepared for difficulties in the form of a poorly connected castle, a rough surface, falling out knots and possible cracks if installed in a damp room.

The wooden paneling should be fixed with the help of clamps. Kleimer is a bracket that is attached to the crate with nails or screws and presses the lining lock to the base, but it is not fixed rigidly to the board. This allows the wall paneling to change its dimensions without any problems due to thermal expansion and humidity and to move vertically, which guarantees reliable fastening and the absence of future cracks or extraneous sounds.

Separately, it is worth noting the scope of the lining, as the decoration of baths and saunas.Softwood clapboard is rarely used in baths, as it can release resins, but it helps it to resist aggressive conditions, such as temperature and humidity drops, as well as fungi and microorganisms. In saunas and baths, alder or lime linings are most often used - such wood does not produce any resin at all. Hardwood lining has a shorter service life due to the porous structure of the material, but due to the same porosity this wood can withstand high temperatures.

Plastic panels appeared on the market not so long agobut gained a good reputation. They are not suitable for exterior decoration, but are great for facing loggias and bathrooms or showers. Since the plastic is not sensitive to water, the panels can withstand any moisture, and are also insensitive to sunlight. Unlike wood, plastic wall paneling can have any pattern or pattern that repeats wood or stone. It should only beware of poor-quality panels, which, at the slightest decrease in temperature, become extremely fragile due to the fact that the manufacturer saves on the quality of plastic.

MDF lining is laminated, veneered and painted. Laminated options are covered with PVC film, have a lower price and are more wear-resistant than veneered, which are covered with veneers of premium wood. Painted panels, as the name implies, have a uniform color. In general, this is a good alternative for the previous options. MDF-wall paneling has all the advantages of a wooden version and is produced in a wide range of colors. Such an alternative is suitable for the whole apartment - it can be used both in the kitchen and in the corridor, applying it in facing of walls or ceiling.

Be sure to monitor the quality of the material when it is selected: the surface of the product should be smooth and smooth, uniform color, without browning and cracks. You should not trust the exhibition samples, as the sample may be from another party, or the wall paneling could be stored in unheated and wet rooms. Unfortunately, it is impossible to know exactly the quality of storage of the material, therefore, as an option, you can buy one or two packages of material and see what happens to it at the installation site.

Care

Lining practically doesn’t require care - it’s enough just to pay attention to it during installation: if the material used for lining production is wood, then it should be coated with varnish or paint. Lining of other types does not require such manipulations.

It is important to know that it is not necessary to wet the wooden paneling unnecessarily when cleaning or cleaning - the tree readily absorbs moisture. Under no circumstances should abrasive materials be used to clean the panels - this may damage the design.

Beautiful examples of finishes

Exterior decoration of the building with wooden clapboard with a profile “American” looks stylish and beautiful.

Finishing the sauna with linden linings is an expensive veneer option that will immediately indicate to guests the status of the owner of the room.

The decoration of the room with plastic PVC panels in the interior looks very stylish and emphasizes the basic design of the room. In combination with white color this situation can become even more attractive.

About what mistakes should be avoided when choosing eurolining, you will learn from the following video.