Choosing wooden wall paneling

Sheathing wooden clapboard today is becoming increasingly popular. Before you begin, you need to know how to nail it properly and which fasteners to choose. Read the answers to these questions below.

Special features

Wooden wall paneling is a universal facing material, its mounting on the surface of any type is not associated with special difficulties. Features of operational properties allow the use of wooden wall paneling in almost any conditions.

Advantages and disadvantages

Wooden wall paneling is a practical and reliable material with extensive advantages, and its disadvantages can be compensated for by the additional processing of the coating.

Several characteristics can be attributed to the positive qualities of the wall paneling.

- Completely natural product. Non-toxic, does not cause allergic reactions, does not emit toxic substances during combustion.

- Nice smell. Wood, depending on the breed, exudes a specific odor, thereby creating an excellent atmosphere that positively affects the health and mood of the residents.

- Great appearance. From an aesthetic point of view, the texture of the wood canvases has an attractive appearance. A wide selection of different patterns, colors and shades is provided by the variety of wood species, allows you to create a unique interior design and fully satisfy the most exquisite taste.

- Acceptable price.

- Camouflage communication lines. Under the clapboard, gas and heating pipes, wiring, distribution units and other objects will be perfectly hidden.

- High vapor permeability. Provides ventilation of walls, as a result, “breathing” of rooms and the absence of dampness.

- Easy installation. The surface, trimmed with clapboard, does not require scrupulous processing, the panels can be easily cut to fit the size.Products are fastened by the lamellar method - for each other and can be mounted by a person without perfect skills, provided they become familiar with the technology.

- Durability. With the correct selection of impregnations and timely care wooden lining can be operated for up to 50 years.

- Additional finish. The surface of the wall paneling can be coated with various types of finishing materials: paint, varnish, artistic decoration, etc.

- Low moisture resistance. The dual quality, in the positive aspect, is considered as a natural moisture regulator, when, as it rises, wood absorbs surplus, and when it falls, moisture evaporates back into the air.

- Excellent heat and noise insulation.

The weak qualities of wooden wall paneling include:

- weak moisture resistance;

- vulnerability to extreme temperature changes;

- high flammability;

- the possibility of deformation of the structure.

The disadvantages of wood can be compensated for by treating the material with an impregnation from the negative effects present in a particular situation, for example, with a hydrophobic mixture when used in the bathroom. In addition, the level of moisture resistance varies, depending on the type of wood that also needs to be considered when selecting a material.

The main characteristics of the material

To better understand the characteristics of lining, it is worthwhile to get acquainted with the main characteristics of the material from which it is made - wood.

The main parameters of quality are several indicators.

- Strength. A property that characterizes the ability of a tree to withstand mechanical loads. Strength depends on the thickness of the panel and wood species. When choosing lamels, the specifics of their operation should be taken into account and the appropriate option should be chosen.

- Hardness. With an increase in hardness, the processing process, for example, trimming of panels is complicated; however, this property directly affects the ability of a surface to withstand objects attached to it, for example, a TV set.

- Moisture resistance. It determines the conditions in which a particular type of wood can be used and can be enhanced by impregnation.

- Grade. Determines the quality of raw materials from which the paneling is made. The main standards - European DIN and GOST, in addition, the manufacturer may have its own criteria for grading, so you should know the general differences.

- "Premium", "Extra", "Premium". The perfect texture of the product without defects such as knots or cracks, the heterogeneity of color or roughness is possible only on the back side of the plank.

- "Class A". The presence of knots with a diameter of up to 1 cm of no more than 1 piece per meter of meter, small, possibly, filled cracks is acceptable. Minor flaws on the back side.

- "Class B". Knots with a diameter of not more than a third of the width of the panel, quantitatively - 4 pieces per meter. There may be hollow resin pockets, minor through cracks.

- "Class C". All lining that does not meet the above criteria. A significant number and strength of defects, violation of the monotony of color spots and other defects.

- Wear resistance. An important quality when decorating rooms with constant contact with the surface, such as a bath or gym.

- Fire resistance Determines the rate of ignition of wood, can be modified by impregnation. The characteristic is important when used in places with an open source of fire, for example, in baths or near fireplaces.

- Aesthetic features.

- Therapeutic effect.

Kinds

Wooden lining has two main classifications: according to the material from which it is made, and the form that it is attached to during processing.

By production material

Lining is made of various wood species, it determines both the main operational and aesthetic features of the product.Also, the material determines the price category of lining: the rarer the wood, the more expensive the slats. The main types include:

Hardwood

- Linden. High strength, pleasant texture and color, which darkens over time. It needs treatment with impregnation to improve durability and preserve the appearance. It can be applied in rooms with high humidity.

- Alder. It is distinguished by excellent moisture resistance and high content of tannins, evaporated into the air during heating. For its qualities it is widely used in the finishing of saunas and baths. Beautiful shade, high heat and noise insulation. Must be treated with impregnation to extend the service life.

- Oak. Elite variety among hardwoods. High strength, excellent aesthetic and performance properties. Mainly used for interior cladding.

Exotic

A group of valuable red species, mostly native to the tropics. Wood with excellent aesthetic properties is used for interior design finishes.

Conifer

A distinctive feature is the high moisture resistance of the entire group.

- Spruce. It is allocated with softness and plasticity, it is easily processed, it can be bent in rounded forms on a constant basis. Very low surface roughness. Beautiful, but low-key texture. Weaknesses are: a large number of knots, a predisposition to fungal infection and the presence of bugs, one of the most unstable of conifers. Often subjected to additional processing during production. Spruce boards can be used for both interior and facade works.

- Pine. One of the most common materials for lining. Combines strength and lightness with wide availability. Good texture and color, as well as a pleasant smell will create an excellent atmosphere of coziness and comfort for a reasonable price.

The disadvantages include the possible separation of the resin, even after special treatment for up to 10 years. Low density contributes to damage to the surface of the slats, even under a minor impact.

- Larch. High strength, comparable to oak, increases over time from the process of smolizatsii, excellent performance indicators in all parameters, exceeding the corresponding quality of the other softwood.Excellent thermal insulation, the breed contains phytoncides, natural antioxidants and substances that soothe the nervous system. Resin wood is a natural remedy for parasites, which reduces the cost of additional processing. Excellent texture is combined with a pleasant red tint, not subject to fading with time. The minus of this breed is its high cost.

- Cedar. It has a distinct characteristic odor due to the high resin content in the wood. The material is not subject to warping and has a high density. Good thermal insulation is combined with durability, both when used in interior spaces and for facade finishing, provided it is impregnated with a hydrophobic mixture.

Also contains tuyaplicin, a natural antiseptic that helps calm the nervous system and relieve fatigue. In addition, the specific smell of the breed repels mosquitoes. The disadvantages, like the larch, are the high cost of cedar lining.

According to the form of manufacture

In the process of processing, the lamellae are given a certain shape that determines the specifics of the locking mechanism, and, accordingly, the installation of the product and its appearance.

Recently, brick products have become popular.

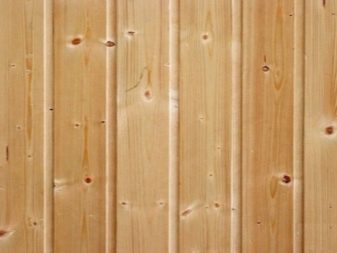

- "Standard" ("Calm"). Differs smooth and very smooth surface, resembling timber.

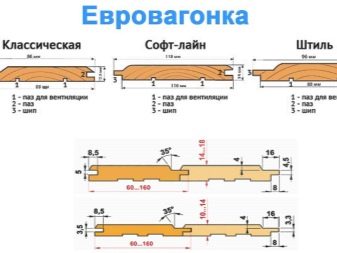

- "Euro Lining". It is similar to the standard form, but at the junction it leaves a small groove 15 mm wide. In the manufacture of higher quality standards are observed.

- Softline. It is similar to the standard view, however, it has more rounded corners, creating a specific relief of the finished surface.

- Landhouse (Country House). It is characterized by longitudinal grooves and slightly convex edges.

- "American". It is distinguished by a specific horizontal mounting method. It forms a characteristic coating with an overlapping lamella arrangement, which helps protect the panels from the penetration of precipitation under the surface.

- "Blockhouse". The wall, decorated with such clapboard, is similar to the wall of the house from round timber.

- "Wooden wallpaper." A new type of lining for interior work, imitates the walls of a wooden house. Subdivided into subspecies:

- "wave";

- "House";

- "Embossed";

- “With brushing”;

- "threaded".

Dimensions

In addition to a certain form, the slats can be executed in a different dimensional format.Tolerances of European products are governed by DIN quality standards, domestic producers - GOST.

The standards include the following values.

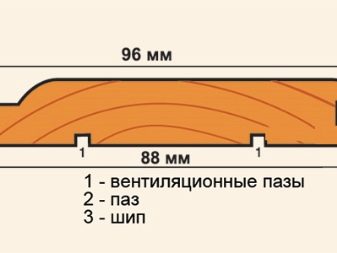

- "Standard lining". The thickness of such products ranges from 12 to 40 mm, width - from 76 to 200 mm, and length from 20 cm to 6 meters. Spike - from 4 to 5 mm. Characteristic enough significant weight.

- "Euro Lining". It is characterized by more accurate dimensions, 13, 16 and 19 mm in thickness, 80, 100, 110, 120 mm in width, length from 50 cm to 6 meters, spike from 8 to 9 mm.

It may have errors: thickness 0.7 mm, width 1 mm, length +/- 5 mm., Spike +/- 5 mm.

Finishing ideas

Lining can be used for continuous plain lining and at the same time create a rather beautiful environment, it can also be used for various design techniques.

- To enhance the feeling of open space, you need to combine the lining with a matte texture and lacquered products when facing walls and ceilings.

- Painting the wall paneling with oil paints with your own hands, you can achieve artistic texture with the original pattern. This method is widely distributed among creative natures.

- With the help of clapboard, you can create different shapes, applying strips locally, and not a continuous coating.

- "Japanese processing" involves the creation of patterns using a blowtorch with a further opening with oil paint, showing the texture created by burning.

- An excellent combination is wooden lining, painted in pastel colors, and a bright, contrasting ceiling surface, for example, violet or acid green.

- An interesting idea is the combination of wooden lining and phytoplits of dark shades with a pronounced wood texture in various combinations.

- It is possible to place the lighting devices under the clapboard, while leaving small gaps for the penetration of light. Such a finish will create a cozy, calm, peaceful atmosphere.

- Finishing of individual zones with clapboard enhances the coziness of the room. Use better products painted pink, bluish, pastel and other soft shades, combined with bright, but not catchy furniture.

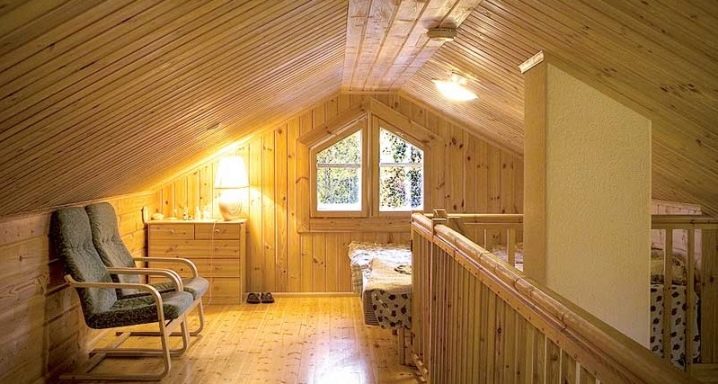

- For the attic floor, a good option is to combine wall paneling for ceiling planes and wallpaper for walls. Such a design is not as overloaded as a solid facing of the “wooden room”.

If you need to sheathe a plastic door, then white lining is best suited.

Beautiful examples in the interior

The contrasting combination of milk and coffee shades is combined with the use of clapboards of various shapes. The room is zoned, the two-color interior looks very impressive and original.

The harmony of the wall paneling and the transparent panels hiding the lighting devices with a wavy ceiling give the room a unique originality and profound ideology of expensive designer repairs.

The combination of contrasting colors changes the visual perception of the space, the original decoration of the balcony creates a great mood while drinking a cup of coffee or tea.

About what mistakes should be avoided when installing wooden lining, see the following video.