Features of plastic lining for outdoor use

Facing the facade of the house is an important component of the repair and construction of the building as a whole, since the appearance of the building and the entire household plot will depend on the exterior design. The modern building materials market offers a large selection of different products for outdoor use, among which plastic lining with a number of specific properties and advantages can be distinguished.

Special features

Building a house is a process consisting of a series of mandatory works that are carried out in strict sequence. The decoration of the facade of the building is important not only in terms of aesthetics, it also warms the house and protects the surface from many factors. Wall cladding with plastic clapboard is in demand among many homeowners, since this material has many advantages.

PVC lining has a number of positive features:

- the big service life caused by the fact that material is not subject to rotting and corrosion;

- resistance to different temperatures;

- material does not burn;

- ease of installation;

- external attractiveness of the facade;

- surface does not require maintenance;

- good water repellency;

- affordable cost of production;

- products are resistant to the negative effects of the environment.

But like any other material, plastic products have some drawbacks.

These include the following nuances:

- minimum resistance to mechanical stress and pressure;

- the inability to securely fasten decorative elements to the panels.

Unlike wooden wall paneling, before installing PVC panels, there is no need to cover them with special antiseptics and other compounds that prevent material from rotting, which is a positive thing, providing a homeowner with money savings.

Kinds

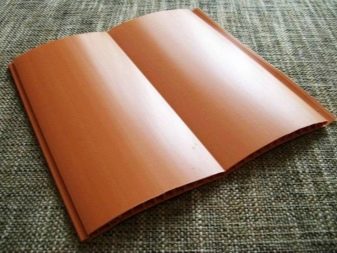

For the first time, lining began to be used for covering railway trains, and on this basis, the material acquired its name.In appearance, the product is a regular board with a smooth and smooth texture, on the sides it has grooves that provide a connection with subsequent elements.

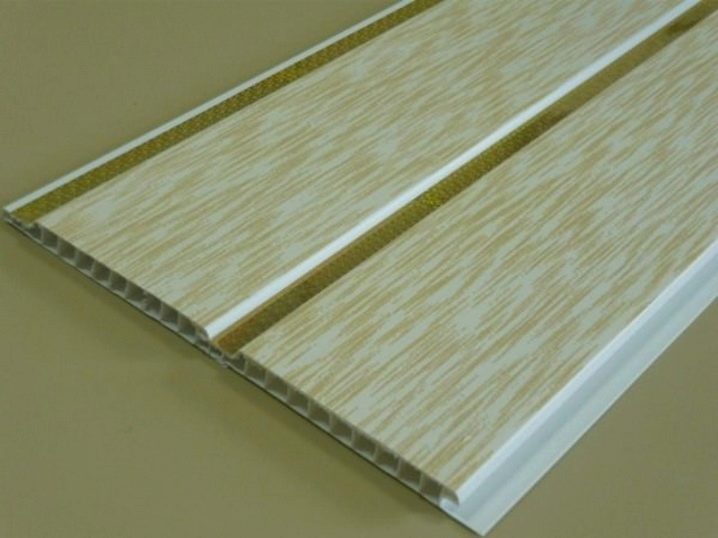

Plastic lining - is a panel inside which there are separate cells along the rail. The raw material for the production of material is polyvinyl chloride.

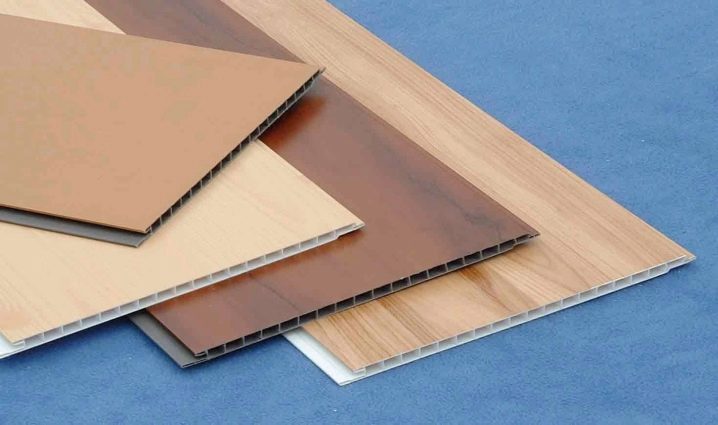

The material can be of the following types:

- a panel of the usual form, which visually looks like a wooden beam;

- calm, the advantage of which is a smooth surface, after its installation, the grooves on the panels are almost imperceptible;

- block house - a panel with a convex surface that imitates a log;

- "American" - a product with a recess inside the panel, which creates the appearance of laying boards overlap.

Lining-panel visually resembles a wooden beam, this design is the simplest, so most of the plastic panels for the walls are manufactured with this profile.

Calmness, or "collective farm", is popular due to the lack of grooves, which are usually visible in other types of panels.

Block house resembles a log cabin, the inside of the panel is flat, the mounting slots are located on the sides of the product.Products can be used for finishing the facade and for interior work indoors. In addition to the original appearance, this panel has a good level of plasticity due to the presence in the composition of special additives. They provide the product frost resistance and resistance to fading.

Lining "American" It is popular due to the peculiarities of its installation, since the located panels form a good protection of the joints against the effects of various temperatures and moisture.

Many experts classify plastic lining thus:

- multi-colored or white panels;

- products made under wood, stone or other materials;

- panels, the main difference of which is considered the method of their connection - seamless and seam.

When choosing a facade material, it is necessary to take into account that it is worth buying lining for outdoor work just for exterior work. Product differences are only in quality characteristics, visually panels for exterior decoration and products for interior work are not much different.

The front side of the slats has two main types - glossy or matte finish. In the assortment of some manufacturers you can find products with semi-gloss coating. Appearance of products does not affect the quality of the finished product.The most popular color for plastic lining is white, in second place - products under the tree. Much less often purchase color products.

DIY technology

In order not to be mistaken in the method of laying plastic lining, first of all it is necessary to study the technology of installation. Fix the panel in various ways. The most common option is the vertical and horizontal arrangement of the panels, so you can visually enlarge the walls, due to which the whole building becomes large. In addition, there is a rather old way - laying "herringbone", through which an interesting picture is created and there is an opportunity to save material.

Before you sheathe the house outside, you need to make a wooden crate to fix the panels. This design will provide a flat surface for installation. In addition, the frame system allows you to embed layers of insulation in the design.

Fastening elements begins strictly with the corner. The first part of the structure serves as a guide, so its installation should be treated with special responsibility.Having connected several parts together, it is necessary to use a level to control the correct and even position of the panels on both sides.

The option of trim in length involves laying where the spikes of the lining will be located at the top, so that excess moisture will not accumulate in the grooves.

Fastening products can also be a variety of means, each of them has its own advantages and disadvantages. The easiest way is to use a stapler or nails. However, these elements become unusable very quickly, so they may need to be replaced.

It is best to purchase special cleats or thin nails. The latter option is not quite aesthetic, and the use of staples allows installation on a brick wall or on a surface made of round logs or foam concrete.

When performing work, it is important to observe perfectly flat styling, in particular, this concerns independent works.

Tips and tricks

Plastic lining is an ideal material for covering buildings with high humidity, such as baths. When buying materials, it should be noted that the color of the lining of different manufacturers will be different.

Choosing a plastic panel, it is necessary to take into account the cost of production, since high-quality products will differ in high prices.

However, in order not to buy expensive products of poor quality, it is worth considering the main points that will determine the quality of the lining:

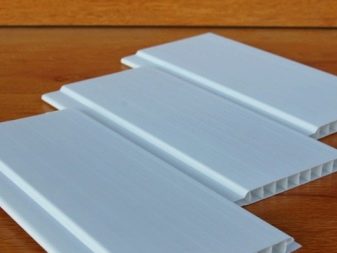

- the ability of the material to withstand the load depends on the thickness of the elements. Standard panel thickness is 10 mm;

- the thickness of the front surface of the product must be such that stiffening ribs are not visible through this side, otherwise a lamella of such quality is not recommended for use as a material for exterior decoration;

- product strength depends on the number of ribs and their stiffness;

- the distance between the ribs should not be more than 10 mm;

- color uniformity of the entire product. Many manufacturers do not add coloring pigment to the polymer composition during production, but prefer to treat them with only the front side. Such lining will very quickly lose its color, and possible scratches and defects will be clearly visible on the surface.

Buying lining, you must familiarize yourself with certificates for products,since the panels are made of toxic raw materials. A package that has just been opened may have an unobtrusive, but peculiar smell, which is considered normal. If the smell is felt from the product, which is in the store as a sample, then the safety of using such products is worth considering.

The weight of the finished product depends on the thickness of the lamella walls and the number of ribs. The standard is a value in the range of 1.1-1.5 kg / m2. Before you buy the entire batch, it is worth testing the panels for a good match with each other.

Experts agree that products of good quality should not contain more than 20% of chalk. Its excess is fraught with a decrease in the strength of raw materials. Chalk refers to materials that have a low cost, so it is often used in production in order to reduce the cost of the finished product.

The permissible content of this component is very easy to check - it is enough to bend a corner of the panel a little. If there is no crack at the bend site, you can use this material. A white stripe or defect indicates an excess of its norm in the total mass.

Products that are produced by well-known trademarks should be bought without fear, since companies have deserved their reputation for more than one year, primarily with the quality of goods, paying special attention to it.

Save on the purchase of materials for the facade cladding is not worth it, because it can result in cost overruns, due to the need for repair work with low-quality products. A good plastic lining will decorate the house and will not change its aesthetic and physical properties for quite a long time.

Beautiful examples

Cozy and attractive housing is the dream of every homeowner. The choice of style, taking into account which the house will be decorated, directly depends on the personal preferences of the owner and his desires. Modern high-tech housing or classic Provence can be beautiful and comfortable. For each option, plastic lining will be an excellent addition, thanks to which the facade of the building will harmoniously fit into the overall stylistic idea.

Clear and simple lines, contrasting colors of the facade cladding of the building are the main elements of high-tech style.The winning option can be exterior wall cladding panels of neutral colors, for example, white and black.

Conservative English style will help to set the plastic panels under the brick, which will advantageously complement the design of the house, emphasizing its respectability and restraint with its practicality and perfect symmetry of the lines.

The English style of the design of the facades of residential buildings is represented by democratic colors, a combination of natural textures or their good imitation with an emphasis on the high cost of decoration. Plastic panels, which are an inexpensive material, do quite well with the task of decorating walls, repeating a painted wooden floor in white or beige tones. Due to the fact that products can be easily painted with paint in almost any color, the walls of the house can be given the desired shade, corresponding to the overall design. The main thing - to paint using tools that are suitable for a similar surface.

Fashionable and current trend is the decoration of country houses in the style of a chalet. The facade of this structure, together with the interior trim is made of wooden beams.Expensive natural material can now be replaced with a high-quality analogue - block-wall clapboard. The material perfectly imitates a wooden frame, emphasizing the beauty and aesthetics. Frost-resistant plastic products do not fade in the sun and unpretentious to maintain.

On the peculiarities of plstkovaya lining for outdoor work, see the following video.