Lining of pine: the pros and cons

Lining made of pine today is quite popular. It has more advantages than disadvantages. Such spliced lining has a certain grade, in which it is necessary to sort out in more detail in order to better determine the choice.

Special features

The construction market is in a state of continuous development, proposals for the choice of finishing materials are presented in the widest range. Continuous modernization of production technologies contributes to improving product performance.There are two main areas: natural and artificial coatings.

As a rule, natural materials are the preferred choice. Over the years, one of the leading positions takes lining. The product has come to a wide market from the world of rail transport. It has been used since the time of the development of Siberia and the construction of the Trans-Siberian Railway.

Thin boards of the same size with fastening "thorn-groove" are ideal for covering cars. Over time, amazing practicality made them extremely popular. Made of various types of wood (both hardwood and softwood), the wall paneling is an environmentally friendly product, ideal for interior and exterior use. Differs in natural beauty and at the same time is realized at an affordable price!

Pine wall paneling is especially popular: it is extremely practical and shows excellent aesthetic properties. The natural shade of yellow or yellow-red looks very interesting. Due to the natural basis of such lining is absolutely safe.Let's get to know this amazing product in more detail.

Pine Wood Panels

Lining made of pine is made of natural, environmentally friendly material - wood, the natural features of which are known to be unique. The wall paneling is created by nature itself as a universal finishing material of a wide range of applications, which is unusually strong and reliable, demonstrating unexpected ease in the dried state. Drying, due to the low saturation of raw materials with moisture, is cheaper (which affects the final price) and takes less time.

A large number of resins in wood act as preservatives and imply long-term use of the product. Pine panels do not need additional treatment with antiseptics, their low weight makes the work process easier, and the natural softness of the material facilitates easy installation. The use of such an element is possible even for a novice in construction. With proper operation, the product can last for a long time. Reasonable price makes the material extremely popular. The product is marketed in a wide range of prices and has a different configuration.

The natural texture of the tree makes an unforgettable impression, the aroma characteristic of coniferous trees creates the absolute illusion of pine trees. Over time, the wood acquires a noble reddish tint, which gives extra warmth and comfort. The atmosphere of the rooms covered with a pine panel positively affects the emotional state and contributes to the active rehabilitation of people.

Particularly useful such sessions aromatherapy for diseases of the respiratory tract. For this reason, the panels are so popular when decorating rooms for rest and recovery. The material demonstrates antibacterial features peculiar to coniferous wood and contributes to environmental disinfection.

Benefits

It is possible to highlight the following main advantages of pine panels:

- create an atmosphere of comfort and freshness;

- have excellent quality;

- easy to process and easy to install;

- offered on the market in a wide range;

- possess amazing characteristics;

- strong and very light;

- initially contain a small amount of moisture;

- capable of long-term operation;

- have a pleasant and memorable natural pattern;

- do not need additional treatment with antiseptic;

- the design is easy to repair;

- differ in the democratic price.

Technical parameters and classification

Products vary in size, humidity, type and class, which ultimately affects the cost of materials. For carrying out various types of work, they use clapboard, which is most appropriate in its characteristics for the task.

The size

The panels are on the market in a large assortment, the differences vary in all indicators. Thickness - in the range of 12-22 mm, the width is even more expanded: 96, 120, 130, 145 or 195 mm. It makes sense to choose the size of the coating so as to minimize the level of waste. Price, as a rule, is indicated for 1 m2. In rare cases, there may be a price per cubic meter or running meter. Length - from 1.8 m to a maximum of 6 m. This is the most important parameter, it determines the scope of the product. Initially, short lining because of the characteristics of production - the material is not of the highest quality, and therefore costs somewhat less.

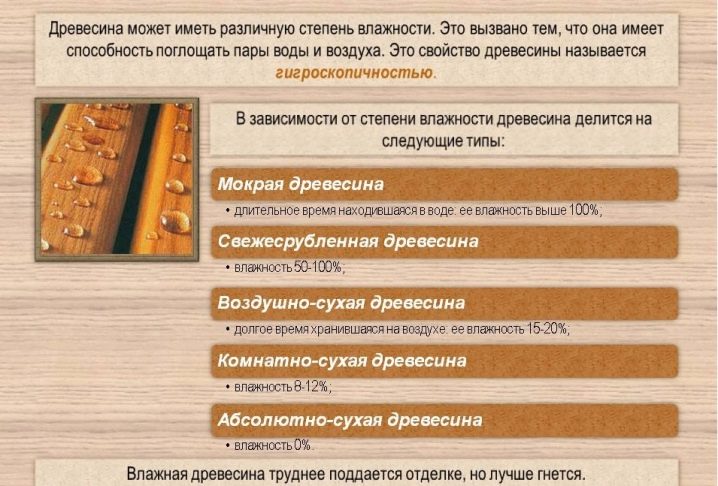

Moisture level

The essential technical parameter is humidity.The panel can have natural moisture (raw lining) or be treated in special drying chambers (dry lining, water in it - 10-15%). Wood processing enterprises pay great attention to the observance of heat treatment rules: this directly affects the quality of the panels. Wood can be treated in a gaseous environment: it can be a mixture of air with flue gas or steam supplied at atmospheric pressure.

Pine initially has a low natural percentage of moisture contentthat allows you to speed up the drying process and make it less expensive. A dry panel is lighter and about a quarter more expensive due to the process of removing moisture. It is worse amenable to deformation and rotting.

Type of

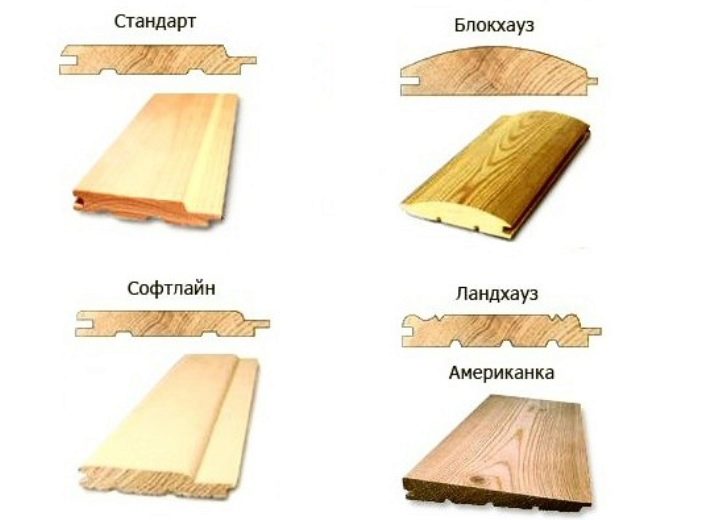

There are many types of panels on the market, some of which are quite rare: “in tongue”, double-sided, “American”, “taiga” and many others. But three main types of pine clapboard are in great demand.

- Standard lining (quarter) - pine planed board. It is usually made of wood of natural moisture (not dried), Chamfer is selected on the longitudinal side.This is a affordable model and, accordingly, the most common. Simple and inexpensive - this is the reason for the high demand for this type of product. Only suitable for technical work - no finishing work on this material! It has a thickness of 15-25 mm.

- Lining. It is produced according to the western standard DIN 68126 with a special lock system. A characteristic feature of the design - the shelf, is designed to drain moisture in a vertical installation (most often used). Permissible humidity - 12-16%, thickness - 16 mm.

- Lining calm - a padded board. It is made from fully dried board (12-15% moisture), chamfers are selected along the longitudinal side. Shelf is not provided by the design. Specially done on 45-55 mm wider than the ordinary euro model (up to 145 mm, when the standard - 90 mm). Most often used for finishing the ceiling. By increasing the width of the panel, coating assembly time and installation complexity are reduced. The optimal application is horizontal.

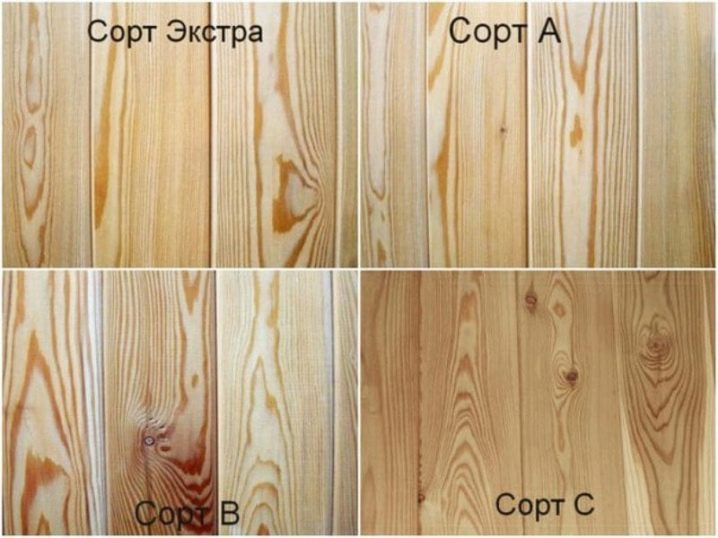

Class

When choosing a material, it is necessary to determine exactly what types of work you plan to carry out: for different purposes apply coating of different classes, which ultimately will allow you not to overpay where you can save and achieve the desired level of quality cladding.

Lining is divided into 4 main classes.

- Extra. A product of the highest quality and the corresponding price. Ideal, not having flaws in color and wood: the knot or the core is completely absent, the presence of cracks is not allowed. To achieve the most consistent natural wood pattern, you should take panels from the same batch.

- Class A. A bit worse Extra. It is allowed to have several knots and (or) a resin pocket on 2 m.

- Class B. Small cracks, 2 or 3 knots and a few resin pockets are allowed.

- Fourth grade. Technical wood. The most unclaimed class. Has knot holes and other types of mechanical damage.

For high-quality interior decoration, you must use Extra or Class A - this will give you the opportunity to fully use the potential of natural pine panels.

Scopes of use of pine clapboard

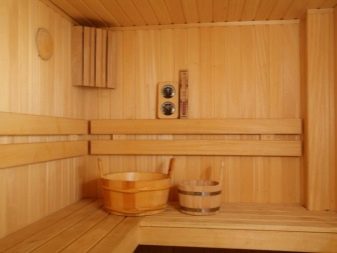

Natural wood trim has always been in steady demand. It doesn’t matter whether you ennoble the interior or work outside, the panel of wood will always be useful. The scope of application of the unique material is unusually wide: the owners of country householdsthey use clapboard for finishing facades and rest rooms in saunas and bathhouses, craftsmen sheathe garages, balconies and loggias, and how the wooden hallways of apartments glow with comfort.

Reasonable price and excellent technical characteristics make the material very popular!

Pine in the bath

The use of pine-wood panels for cladding bath rooms is occasionally found, but it can hardly be called successful for a number of factors.

- Bathrooms have a specific environment: the extremely high temperature in the steam room itself and the very high humidity make us carefully choose the material.

- Pine boards under the influence of temperature actively emit resin, which creates an inconvenience for users.

- In addition, low moisture resistance of wood reduces the durability of the finish.

Nevertheless, pine panels are used in baths: a waiting room, a rest room and other adjoining rooms can be sheathed with this material. The wonderful smell of needles will create an indescribable atmosphere of freshness and increase the level of well-being of those present. Wood has natural bactericidal properties and has a calming effect on the nervous system.

Despite contraindications, there is no clear ban on the use of lining in the steam rooms. Experts say that if the steam room from the pine is thoroughly heated (in the absence of the rest), and the tar is removed, then it will be possible to steam for a long time without any fear.

Conclusion

Environmentally friendly lining of pine boards is able to satisfy the most demanding owner. The unique capabilities of the material allow you to perform tasks in different conditions: the material is suitable for work inside and outside the premises, for horizontal and vertical platings.

Presented in a wide range of classes and types of "castle", has sufficient strength and durability. It is necessary to approach the choice of lining from a pine with accurate calculation, using technical capabilities of classes and the sizes. This is a very practical material that is sold at an affordable price. Qualitatively collected pine siding will delight you and your guests for many years.

How to sheathe the walls with clapboard made of pine, see the video below.