How to fix the wall paneling?

In our time, the range of finishing materials is very diverse. High-quality and beautiful products can be selected for both exterior and interior. Separately, it is worth to highlight such a popular material as lining. Today we will look at how to fasten it correctly.

Special features

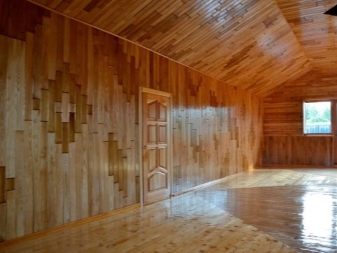

The rooms, decorated with wooden materials, look incredibly comfortable and hospitable. That is why many buyers opt for such design options.

For such an attractive performance, you can use a variety of coatings., from special wood panels to laminate wood. However, one of the most popular and sought-after recognized different types of lining.This material is not uncommon - it is easy to find in specialized stores.

Qualitative lining from a tree is distinguished by impressive service life. According to manufacturers, such products can seamlessly serve from 15-20 years without losing the original appearance.

The durability of the wall paneling largely depends on the proper care of the home owners. Such coatings should be treated from time to time with special antiseptic formulations. They are necessary to protect the natural material from the appearance of fungus or mold. It's no secret that wood is a favorite "dish" of various insects, but with the use of special impregnations such problems can be forgotten.

As a rule, lining is processed by similar means at the stage of its manufacture. However, over time, the material will still need self-care. Fortunately, the shops sell many suitable products and varnishes that will provide excellent protection against negative external factors.

Advantages and disadvantages

Lining is rightfully recognized as one of the most sought after materials.Consumers choose such a finish, as it has not only a harmonious and natural appearance, but also a number of other positive qualities.

- The main advantage of lining is its environmental friendliness. Currently, not every finishing material can boast of such quality. Lining does not emit dangerous and harmful substances, even if it is in conditions of high temperatures.

- The paneling can be given a perfectly smooth and pleasant to the touch surface.

- To install such wood panels it is not necessary to involve professional teams of dressers. Fastening of such materials can be done on their own, adhering to simple instructions.

- Many consumers note the pleasant woody aroma inherent in such finishing materials. Thanks to this property an indescribable atmosphere is created in the room.

- High-quality lining boasts resistance to mechanical damage and strong shocks. It is not so easy to break or damage.

- Lining is not a brand material, but if contamination appears on its surface, then it will not be necessary to exert much effort to remove it.

- It is worth noting the excellent insulating properties of the lining. The room in which there is such a finish, will always maintain a comfortable microclimate.

- Also, lining has soundproof properties. Thanks to similar materials, the audibility of extraneous annoying noises in the room is significantly reduced.

- Under the clapboard you can hide unpresentable elements such as wires and various communications.

- This finish can be applied not only in a country or country house, but also in a normal city apartment.

- It is possible to finish clapboard not only walls, but also a ceiling. The overlaps, designed in this way, look very aesthetically pleasing and neat.

Of course, the wall panel has its drawbacks. You should also read them if you want to refer to this material in the design of your home.

- To install the wall paneling often requires a frame. Most often, such installation structures have to apply when it comes to finishing the ceiling. Also, the framework is indispensable if the walls in the room are too uneven and have noticeable drops.

- The disadvantage of the wall panel can be attributed to the fact that it is not fireproof. Of course, this quality can be corrected if the material is treated with special means, but even they will not make such raw materials 100% non-flammable.

- Over the years, the wall paneling can change its geometric parameters. Most often, such deformations occur if the owners improperly care for the trim or improperly assemble it.

- Clapboard can not be called cheap material. Moreover, many consumers find it quite expensive.

- It was mentioned above that clapboard should be periodically maintained by treating with special protective compounds. Most consumers attribute this feature to the number of disadvantages.

Kinds

There are several varieties of clapboard. They are made of different materials and have different performance characteristics. Consider them in more detail.

Wooden

The most popular lining made of wood.

The process of its manufacture is rather complicated and occurs in several stages. Due quality of such finishing material can be achieved Only if you strictly adhere to a certain technology:

- the edging board is first prepared;

- after that it is dried in a special industrial way;

- further work is carried out on sawing grooves;

- then wooden lining is carefully polished;

- at the end of all production processes, the resulting panels are always sorted.

Properties of wooden lining largely depend on the type of wood from which it is made.

Aspen

Aspen boards have a light shade. There are practically no pitches in their composition. Such materials can boast of good thermal insulation characteristics, so they are often used for interior decoration.

Aspen paneling can also be installed in baths or saunas. Of course, in such cases, we should not forget about the quality processing of the material so that it does not rot.

From spruce

As a rule, for the manufacture of lining used northern spruce. It has a rather dense and solid wood. With such finishing materials you can decorate not only the walls in the dwelling, but also the ceiling.

Spruce lining is not afraid of moisture and moisture.However, it should be borne in mind that over time it changes its color and becomes darker.

From pine

Pine clapboard is one of the most common. It is inexpensive, but it has excellent quality, so many consumers choose it.

Pine clapboard is distinguished by a beautiful natural structure, which also becomes darker over time.

From oak

Oak lining is expensive, but it does not affect its popularity. Such a finishing material is not subject to rotting and is easy to process.

The main advantages of oak lining are its amazing color and structure. With this decoration you can transform the interior, making it richer and more solid. Experts say that oak paneling must be poured and pickled.

Hardwood

Hardwood carpeting practically does not emit tar and is characterized by low density. Due to such characteristics, it can be safely used in facing of a bath or sauna.

Wooden wall paneling may have a different cross section.

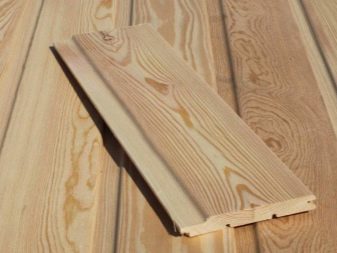

- Standard. Such panels are equipped with a standard thorn-groove locking system.As a rule, the studs in the wall paneling are always slightly shorter than the grooves. This is necessary so that with a strong cracking of the wood there is no deformation of the material. Panels with a standard cross section have good sound and heat insulation.

- "Calm". Otherwise, panels with this section are called “collective farmer”. They have rounded outer corners. Such materials look very neat and tidy.

- Lining. Such varieties of wooden wall paneling have a longer groove, so as a result, the surface takes on a completely different appearance.

- Softline. Such finishing materials also have rounded bevels and a long groove.

Also lining from a tree is divided into classes.

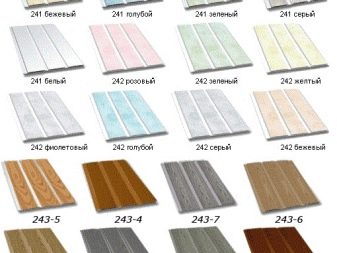

- "BUT". This class includes high quality panels. Small knots are sometimes seen on their surface, but they do not fall out. Also on these materials you can find a few small cracks and cracks. Class A lining can be safely used for interior decoration.

- "AT". The slats of this class have a length of 1.5 m. There can be no more than 3-4 knots on their surface. Also, these types of lining have small resin pockets and non-through gaps.Experts do not recommend the use of such materials for interior cladding.

- "WITH". Materials of this class are not of high quality. As a rule, they trim household buildings for which the design is not so important. In such slats, noticeable knots can fall out, and also through-slits are often present. Their color is far from standard.

- "Extra". Extra-class lining is an ideal finishing material. There are no defects on the surface of such panels.

Metallic

Instead of wooden, you can use metal clapboard. Most often, such facing materials are turned on when you need to arrange the base, which is in conditions of high humidity. Such panels are not afraid of negative external influences and protect from them the foundation on which they are installed.

Many consumers stop the choice on the metal lining, as it has a virtually unlimited service life. It does not require complex and regular care, which speaks of its simplicity.

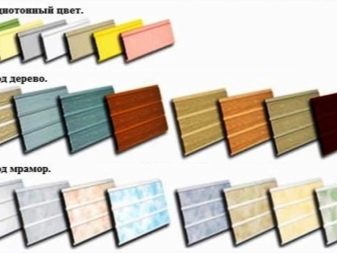

Metalboard is good because it is presented in a very rich color spectrum.In addition, this finishing material may have a different texture.

The advantage of metal panels is the fact that they are non-flammable and do not sustain combustion. These qualities can not boast of popular wooden flooring.

Such materials are also environmentally friendly. In their composition there are no hazardous compounds harmful to human health. You can install metalboarding yourself. Moreover, this material can be mounted both on the wall and on the ceiling.

Plastic

If metal and wooden types of lining seem to you too expensive, then you should look for more affordable plastic options. Such coatings are made of polyvinyl chloride. This material is safe for human health, so do not have to worry about the health of the household.

As a rule, PVC lining width is 10 cm. Wooden elements have similar parameters. In addition, plastic panels can be used not only for indoor but also for exterior home decoration.

Plastic lining happens not only monophonic, but also multi-color. In some stores you can find more original materials with interesting prints or patterns. Especially popular today are panels that imitate natural wood.

For exterior finish it is recommended to use a special frost-resistant lining. For its manufacture special plastic is used, supplemented with necessary additives. This finishing material easily tolerates both low and high temperatures.

Plastic lining for outdoor work can not boast such a wide selection of different colors. Here, as a rule, monochrome variants of calm tones are used, as well as wood coatings.

The advantages of PVC lining include:

- heat and noise insulation properties;

- fire safety;

- resistance to high temperatures;

- non-susceptible to mechanical damage;

- moisture permeability;

- small weight;

- democratic cost (especially when compared with natural wood materials);

- unpretentiousness.

It is not necessary to care for plastic clapboard regularly with the use of expensive means. In addition, it is very easy to remove dirt and dust.

Wall preparation

Before installing the wall paneling (especially if it is wooden), it is necessary to prepare the walls with high quality. The lining itself after purchase should be placed in a dry room for at least a day. There she must stand and adjust to room temperature. Only then can you start cutting the finishing material to give it the desired length. If you neglect this stage of work, the panels will not be tightly attached to each other.

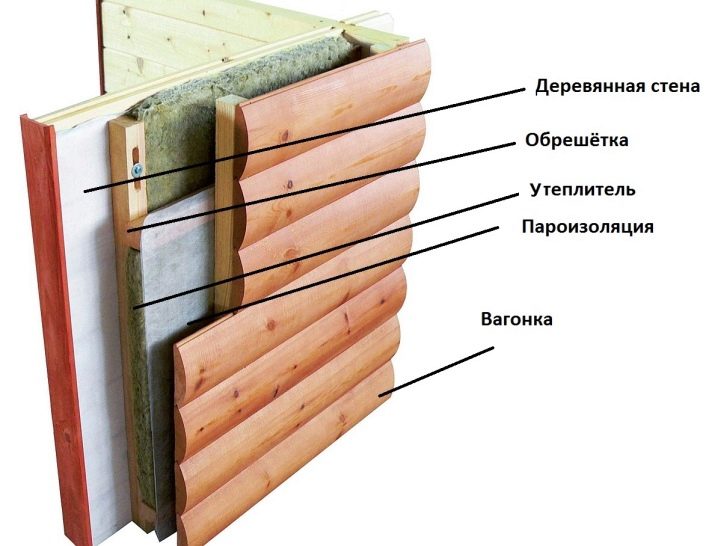

As for the walls themselves, they will need to provide a good vapor barrier. To do this, they first need to nail the slats. Their width should not be less than 3 cm. These elements should be nailed in 1 m increments. Then you need to take a film of polyethylene, foil or roofing material and install it on the fixed slats. Small openings need to be made at the top and bottom of the vapor barrier to provide better ventilation.

This stage can not be called strictly mandatory, but experts recommend using it if we are talking about a room with a high level of humidity from the outside.

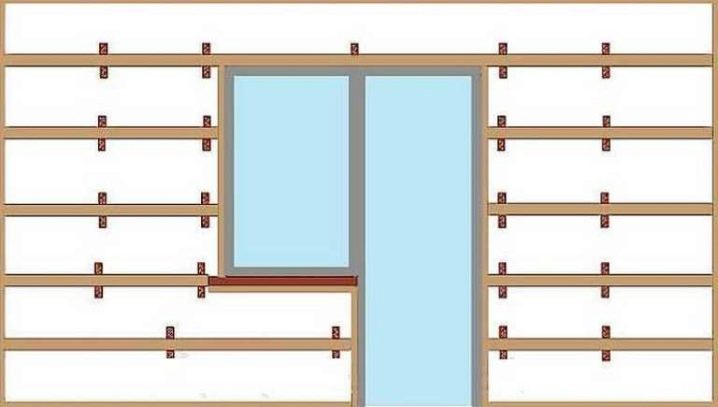

Next you need to build a quality crate under the wooden lamella. Slats with a cross section of 20x40 cm must be fastened with a screwdriver. Follow the step of 40-50 cm (horizontal). Constantly check the installation of all parts using the mounting level.

With the help of slats, you can properly align the wall before installing the wall paneling. Thus, the boards will be much easier to attach to the base. In addition, to build a similar frame should also to ensure that the gap between the overlap and wood trim was ventilated.

If the walls do not have a flat surface, then you need to put something extra under the crate. You can also build a crate of greater thickness. For the lining, a sheet of plywood, a wooden block or a mounting wedge is best suited. The crate should be fixed with long screws and dowel-nails. The bottom slats should retreat from the floor 5 cm, as in this area there will be a plinth. The same indent should be followed in the upper part of the structure, since there will also be a plinth, but already a ceiling one.

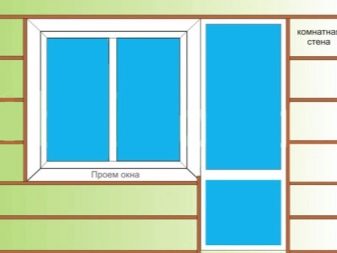

The crate must be mounted around door or window openings. Such designs are made not only from a tree, but also from metal or plastic.

If you have not installed a vapor barrier on the base, then the crate should be mounted directly to the wall. If it is present:

- if the laths to which the vapor barrier was attached were fixed vertically, then the parts of the batten should be installed horizontally and vice versa;

- fastening of the batten to the rails on which the vapor barrier is placed should be made with long screws.

In the appeared "windows" it is necessary to put a heater. Experts recommend to buy for this mineral wool. The insulation should be fixed with polypropylene spar so that over time it will not shrink.

It is possible to put another layer of vapor barrier on the insulation. It should be attached with a rough side to the insulating layer.

Instruments

For installation of the frame and cladding walls clapboard, you must have the following devices:

- screwdriver;

- perforator with the necessary nozzles;

- building level;

- hammer;

- mallet;

- jigsaw;

- electric stapler;

- wooden corners;

- self-tapping screws;

- mounting gun;

- nails;

- profile (for the frame);

- staples.

Mounting methods

In total, there are two main options for fixing lining.They differ from each other in directions. Consider them in more detail.

Vertical

Vertical fixture lining occurs in this way:

- The starting detail is set in the corner. To do this, use nails, which are then hidden under a decorative corner. If you don’t have this item, you can simply bite off the caps with side cutters. Hammer nails as carefully and carefully as possible.

- Always check whether you are correctly laying the vertical laying of the wall panel - any errors can lead to the fact that the next lamellae will curve more and more.

- The fixed part must be attached using klyimery. After that you can proceed to the installation of the remaining slats. However, they must first be inserted into the grooves, and only then fastened.

- After every 5 elements it is necessary to check the flatness of the surface with a level and plumb.

- The final lamella must be filed to the required dimensions.

Horizontal

To make laying of lining in the horizontal way, it is necessary to observe the following rules:

- Lamella in this case, you need to fix, starting from the ceiling. The groove should be pointing down.If the finish is similar to a rounded log, then it should be installed groove upwards to hide the joining points.

- Bind the parts together should be the same principle as in the vertical method of installation. It should be borne in mind that for more reliable fixation of the board should be diced.

- Gradually, going down from the top down, all the lamellae will be much more convenient to fasten with the help of studs. It is very important to hammer them in such a way as not to harm the front side of the wall paneling.

Calculation of the amount of material

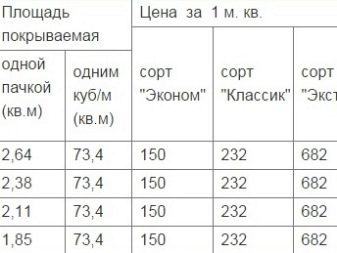

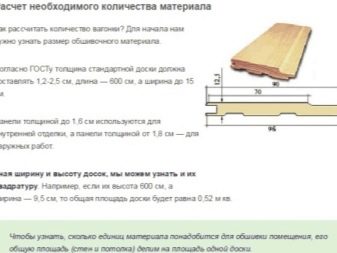

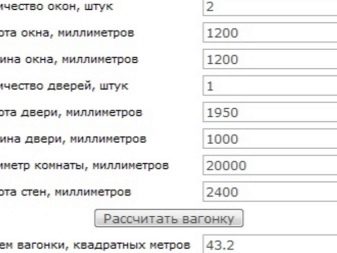

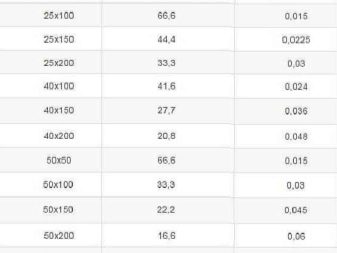

Selecting lining, you need to understand the amount of finishing material that you need. As a rule, the cost of wooden lamellas is indicated in square meters (less often in cubic meters). However, the elementary mathematical calculation in this case will not work, since such parameters as the length of the lamellae, the height of the ceiling in the house, the dimensions of the door and window openings will affect the quadrature.

There are two ways to help calculate the amount of lining.

- Intuitive. Following this method, you should calculate the perimeter of the surface area that you plan to trim with lamellae.From here you need to calculate the dimensions of the openings. Add to the result 10-30% for waste. This method of calculation is simple, but not the most accurate.

- Mathematical. This method of calculation is more scrupulous. To do this, the lamellae should be counted individually, considering their length and width, as well as the dimensions of the openings. To calculate, divide the surface length parameter by the lamella width. So you can determine the required number of lining. As a result of all calculations, it will be possible to obtain a fairly accurate value. In this case, the waste can be left no more than 10%.

Tips and tricks

If you decide to do it yourself with clapboard walls, then you Some simple guidelines should be followed:

- In the process of installation, make sure that there are no ugly gaps between the lamellas. You can avoid these defects if you constantly monitor the level of laying material.

- In calculating the required amount of material, do not forget about such elements as doors and windows. Around them you need to build a frame. Slopes from the wall panel can also be built with your own hands. The main thing is to adhere to the correct dimensional parameters.

- If you want to refresh the atmosphere, then you need to create different geometric patterns on the floors with your own hands. To do this, you need to adhere to several options for the layout of the slats.

- In winter, laying the wall paneling is not recommended. Such work is better to postpone until the summer or spring, so that the material is not subjected to deformation.

- If you chose a clapboard for finishing, which has the shape of a rounded log, then you should install it with a groove upwards. This is necessary to hide the docking of individual parts.

- Many users are confident that the lining can only be mounted on a metal profile. Of course, such constructions can be used, but they are more suitable for those cases where the ceiling in the room has too strong irregularities and drops.

- Originally looks diagonal upholstery clapboard. It should be made on the frame in which the racks are located at a closer distance to each other.

- After installation, the wall panel will require regular maintenance. To do this, you need a primer for wood, antiseptic compounds, bio-oil, alkyd varnish, antipyrine, forming a refractory layer and other similar substances.According to experts, the processing of the wall paneling must be made prior to its direct installation.

- When choosing a suitable material, pay attention to its class, since it is recommended to sheathe living quarters with some lamellae, and other outbuildings with other lamellae. Of course, for the inner lining is best to use the highest quality materials of class "extra".

- Reserve in advance all the necessary tools. Screws should be screwed with a screwdriver, as this will take a minimum of time. However, do not forget about accuracy. Take care not to damage the finishing material.

- In areas with high humidity, the skin should be laid so that the lamellae do not fit into the grooves until it stops. Thanks to this technique, the material will not be deformed.

- Do not hit the grooves with a hammer. This can lead to serious material damage.

The way of fixing wooden clapboard on different types of claimers is described in the video.