Lining of aspen: the pros and cons

Decorating various rooms with clapboard is a fairly common practice. However, it should be noted that this material has a number of important subtleties, ignoring which can ruin the impression of the wall panel and damage the interests of the consumer. Among the various wood options, one of the leading places is occupied by aspen.

Special features

This hardwood breed is a serious competitor to coniferous wood. The cost is relatively affordable, while the visual structure of the tree is not too intrusive, like its smell.

Lining of aspen has a density of about 490 kg per 1 cu. m

Production of aspen lining differs little from the production of other similar wooden products.

It is divided into the following steps:

- evaluation of the properties of raw materials and its distribution by grade;

- drying;

- processing of facial surfaces to complete evenness;

- application of grooves, folding;

- culling foul products;

- packing of the released goods in accordance with its category.

Only by reviewing the reviews, you can figure out whose product quality, and which does not meet the necessary requirements. In appearance it is much more difficult. It is advisable to choose products that meet the requirements of GOST 8242-88, but most of the production, unfortunately, switched to individual technical conditions. Regardless of the lining class, there should not be a single wormhole or signs of a fungus.

Benefits

Aspen wood has a low thermal conductivity and almost does not crack, lends itself well to various methods of processing, even bending. It can be easily polished and painted. The material is relatively light, attractive white with thin fibers. Ease of processing is also associated with a minimum number of knots. Subject to proper processing, objects become strong and resist rotting perfectly.

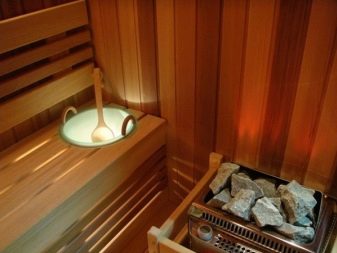

Aspen actively inhibits the development of bacterial organisms and microscopic parasites - it is an ideal choice for any bath andsaunas.

The condition of patients with rheumatism, bronchial and pulmonary inflammations improves.even dysentery. It is important to remember that it still can not in any case replace the full treatment, and any measures of this kind should be coordinated with the doctors.

disadvantages

There is only one obvious problem with aspen wood - its tendency to rotting the middle part. The problem is solved very simply, you only need to use for the construction of trunks at the age of 35-40 years (older ones rot more actively). All other difficulties are due to poor quality of work and non-compliance with the rules of treatment. It is important to take into account that flawlessly high-quality aspen is quite rare, so its cost is higher than that of many other types of wood.

Species

Differences between individual types of aspen wood are due to:

- the humidity level in the growing region;

- perfect processing;

- varieties;

- product quantities.

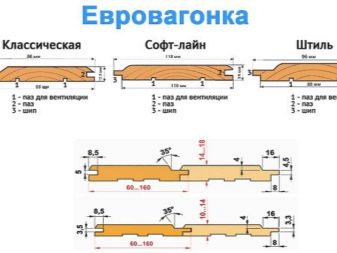

Russian lining differs from foreign products in that there are no elongated grooves in the back, with the help of which ventilation and release from condensate is provided.An increase in ridges and grooves up to 0.8 cm, characteristic of eurolining, helps to reduce the risk of a gap under the influence of high temperature and humidity, thereby increasing the strength of joints. European lining at the end of the work is sorting, it is packaged in a special film (mostly 10 pieces in one package).

Variety "Extra" considered to be the highest, to match him, the wall panel should not have a single defect or even a knot. Characteristics of the Extra grade allow to form any wooden structures, and they will be aesthetically perfect. In group A, the standards allow for the presence of knots and the difference in color from ordinary coloring, but mechanical and consumer properties are also quite good.

Grade B occupies an intermediate position between the main types A and C, it is relatively good and is sold for relatively little money. Category B includes wood of the second grade, a certain number of jagged and knotted areas is allowed on the surfaces of the boards. Cracks are sometimes permissible, knots should not fall out, but still they can cause accelerated damage to the wall panel.

Grade C It has extremely low raw material requirements - such wood may contain manifestations of decomposition and rot, a number of cracks and serrated areas, which are clearly abnormal in color to the area. In the decoration of such decisions do not apply, the only use - tools and accessories for work.

Thermoosin (that is, heat-treated aspen) is ideal for interior decoration of baths and saunas, because it can withstand considerable heat better than usual. Therefore, its increased cost is justified. In the process of preparation, the raw material is kept for a long time at temperatures above 200 degrees and even is exposed to it with steam.

As a result:

- wood moisture decreases;

- density increases;

- reduces the intensity of absorption of new portions of moisture from the air;

- swelling is prevented by constant contact with wet media.

It is difficult to find a more suitable material for the manufacture and finishing of a steam bath than the thermally treated aspen. It does not rot, unlike the usual variety of material, and therefore loses the only significant drawback.With high quality processing wood loses essential oils, therefore, increases its resistance to fire. However, connoisseurs of juicy and rich aromas, it is better not to use this type of wood for decoration, because it does not give a smell. In addition, you will have to handle the thermal nozzle more carefully than usual, since it is relatively fragile.

Dimensions

Typical dimensions of aspen lining:

- 1.25-1.5 cm in thickness;

- used width - 8.7-8.8 cm;

- width with spikes - 9.5-9.6 cm;

- typical length - from 100 to 300 cm.

Lining with a length of 4 meters is used extremely rarely, and only if it is justified for technical or design reasons.

Installation rules

In the process of finishing saunas and baths, lining is put either horizontally or vertically. In the second case, inexpensive, shortened boards are often used, the joints of which are hidden under the shelves or a decorative element. You can save money by using material of a lower grade in inconspicuous places than that used in areas that catch the eye.

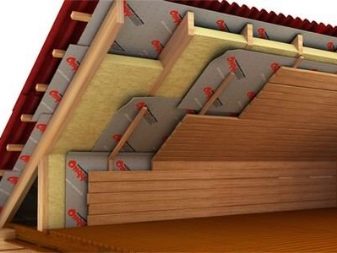

The first step in finishing is the creation of a thermal insulation layer on the ceiling and walls. - for this purpose, basalt cotton is used with a layer of 50-100 mm. Varying the thickness of the thermal protection, you can change the thermal properties of the room as a whole. Putting the cotton wool is necessary in the gaps of the timber, the cross section of which is 50x50 or 100x50 mm, a foil is placed above it to reflect heat, and the joints are treated with self-adhesive tape.

Then work begins with a frame of well-cut strips, placed on gaskets 10-20 mm thick. It is most convenient to put the wall paneling on the clamps, fastened with nails or screws. Having completed the preparatory work, in the corners and at the intersections of the walls and ceilings they put up internal corners and fillets. In case of need, splashes and outer corners are used.

The panel allows mounting the panel from any angle.But professionals believe that it is best to start from the left slopes. For the decoration of large premises, it is advisable to take the spliced lining, which does not differ from the usual technical, but much wider. Painting aspen blocks is not required. Natural lacquers, which additionally protect the material from moisture and steam, help to give an elegant look to these constructions.

In wooden buildings, the trim should be mounted directly on the ceiling or walls. It is possible to cover the internal volume of brick structures only with the rack lath, the same applies to cases when a hidden vapor barrier, waterproofing, and heat insulation is being prepared. Vertical and diagonal fastening is better than horizontal, because in this case water flows faster and does not stagnate in the slots.

The use of aspen lining does not cancel the obligatory impregnation of facing parts and structures of the batten with antiseptic compositions and hydrophobic preparations. This should be done not only before installation, but also after its completion, as well as during the subsequent time - at least once in 6 months. It is advisable to use special gels or liquids that do not give extraneous odors at a significant temperature and increased humidity.

The cost of an aspen is determined by its variety and length, and when calculating the need for the material it is necessary to take into account that the area shown on the packages will exceed the really useful coverage by 9%. That is, to finish the wall size of 5 square meters. m, you need to use a material designed for 5.5 m2.The rest of the volume will be wasted when cutting, as well as due to possible defects in lining.

Installation of aspen wall paneling with your own hands is relatively simple, but if you turn to professionals for help, the work will be done more quickly and efficiently. Compared to this benefit, the increased pay will not be that big.

Before installing eurolining, you need to store it strictly in the original packaging in a dry and clean room. At the same time it is necessary to prevent sudden changes in temperature and contact with sunlight. Preliminary "addiction" of the material to the environment is achieved by holding for 48 hours without packaging. Remove dust particles and dirt from the lining need, using a completely dry cloth, only occasionally you can apply a damp cloth. Before starting work, you need to make sure that the air in the room is not colder than +5 degrees, and its humidity is at most 60%.

It is recommended to paint aspen paneling before installation, because it is simpler and more reliable - the paint coating layer will be applied more evenly and will be stronger.

See the aspen clapboard in the next video.