Bathroom tile trim panels: types and features of the application

The modern market offers the consumer a variety of different materials for repair, where a special place is occupied by products whose quality has been tested by time. However, most of the materials of the last generation are not inferior in characteristics, and in some moments even exceed the raw materials used for a long time. This also applies to panels for the bathroom under the tile.

Special features

Very often, without having complete information about new products that appear on building counters, deciding to perform repairs in the bathroom, consumers use traditional materials, in particular, tiles, unaware that there are worthy alternative finishes for this room. Moisture resistant MDF panels,as well as PVC products - high-quality and attractive products, which in practice proved to be practical and durable finishing material for bathrooms.

The features of these products include ease of installation in comparison with the usual tile, which requires special skills for laying, and the work itself often takes several days, which is very inconvenient for residents of an apartment or house.

The panels are resistant to high humidity and are able to imitate the texture of tiles. The main function of wall panels, in addition to the aesthetic component, is to protect the base from moisture, since high temperature and water contribute to the formation of mold and mildew on surfaces.

In order to get rid of such unpleasant situations in the bathroom, where tiles are finished, aggressive chemical compounds are used to help get rid of microorganisms, but at the same time gradually destroying the material itself. When using wall panels, the risk of such situations is minimal, and the appearance of the products is not inferior in its attractiveness to expensive finishes.

Advantages and disadvantages

Like any other material, panels have strengths and weaknesses. The advantages of products include the following qualities of products:

- A good level of moisture resistance, thanks to which the panels are recommended for use in bathrooms.

- Quick and easy installation of products - anyone can cope with the task of installing MDF panels or plastic elements, it is enough to have minimal construction experience. To perform the work there is no need to purchase a specialized tool, the product has a small mass.

- For the installation of the panels do not need to provide a perfectly flat base, as required by the tile.

- Thanks to the use of such products, the level of thermal insulation increases, since plastic and chipboard elements are warm raw materials.

- The soundproofing level of the bathroom is increasing, which is important for residents of apartment buildings.

- Products have such qualities as strength and long operational life, however, the correct installation of products in this case plays an important role.

- Elements do not need specific care; to keep the panels clean, it is enough to wipe the surface with a damp cloth and avoid prolonged exposure to water.

- Wear resistance and resistance to mechanical stress.

- Acceptable cost, which can be attributed to the lack of costs to pay for the work of specialized hired power and the purchase of expensive consumables.

The disadvantages of waterproof panels for the bathroom are:

- Unlike ordinary tile, products for finishing of MDF swell from immersion in water. From this it follows that in situations where the bathroom is flooded from the upper floor, the material will be irretrievably damaged.

- Low level of durability of panels at impact.

- The absence in some models of the grooves at the joints between the products, due to which the gaps will need to be filled with a sealant.

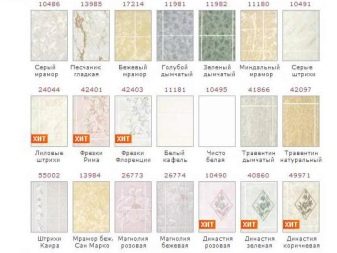

Types and characteristics

To make the right choice, it is necessary to study the varieties of these products. The main criteria by which the classification of panels takes place is the material that acts as a fundamental component, as well as the shape of the products.

Panels are completed:

- from MDF;

- from polyvinyl chloride.

The first group is produced using wooden chips and special impregnation consisting of paraffin and adhesive components.Paraffin is responsible for the stability of products to moisture. Products manufactured by taking into account all requirements do not emit formaldehyde during operation beyond the allowable value, therefore evaporation from products will not pose a threat to humans.

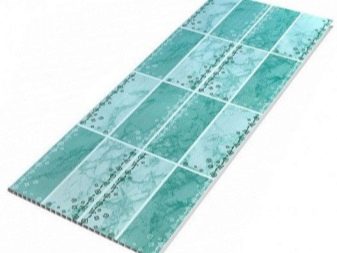

Panels for MDF tiles due to the specificity of the composition can be used even in rooms where the humidity level is about 80%. The thickness of the products varies from 3-8 mm. In order to create an imitation of tile, tile panels are additionally treated with polyvinyl chloride or covered with a special film, on which a pattern or any other decor is set.

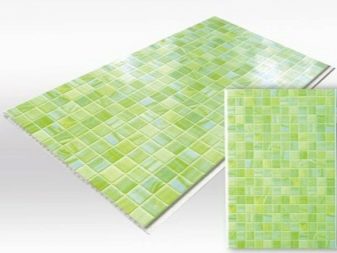

PVC plates have different dimensions. The thickness is usually 4-8 mm. Such material is easy to cut.

The decor is set using thermal transfer or by using a special film that is attached to the base. Such technologies allow to increase the operational life of the product, since they increase the resistance of panels to abrasion.

Taking into account the shape, there are these types of products:

- tiled;

- leafy;

- rack

The first type often has the shape of a square, but there are products that are made in more complex versions, for example, there are also hexagonal elements. The installation of the panels to the base is carried out with the help of an adhesive composition, and between them the composition is combined with fastenings, due to which a complete mosaic is formed on the surface.

Plastic products are very popular, since tiles can be combined despite their size, color and shape. This makes it possible to realize their most original fantasies regarding the design of the room.

Large sheets are in demand due to the ease of installation and the minimum number of joints. This feature is very relevant for rooms with a high level of humidity, because it is through these places that moisture can get inside. Variants of sheet panels are not limited to monotonous variants, since many products are being produced that have a bright appearance.

Rack type panels allow you to visually expand the space of the room. In appearance, they are similar to ordinary clapboard. An excellent option would be to use these products in bathrooms, where there are various niches and protrusions on the foundations.

Design Ideas and Decor

The acquisition of moisture resistant wall panels is an option that allows you to create a more attractive finish in the bathroom, compared to ordinary tiles. The combination of different in size, color or texture of the elements will allow you to arrange the room in an exclusive style, the main thing is to use panels of the same thickness and made by one manufacturer.

An unusual pattern is quite simply formed when installing products at a certain angle from the floor - products can converge at one point and diverge in different directions. You can decorate the ceiling of any complexity, it all depends on the imagination.

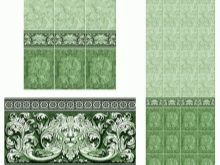

Products with a frieze do not require the creation of complex shapes, since they are remarkable already due to their decor. In addition, they can mimic the texture of wood or stone. Panels are made in glossy and matte performance. To visually increase the area of the room or to visually raise the ceiling, you can use products with a reflective surface or to assemble elements with mirror inserts.

Panels are monophonic or color. The use of offset printing allows you to create original compositions.The use of the frieze greatly expands the product range, since the panels can have a variety of texture, color and shade.

Dimensions

The main characteristic of the panels is the size. To choose their desired dimensions, one should proceed from the area of the room.

Sheet products have the following dimensions: width - 1, 25 m, length - 2.5 m, with a thickness of from 3 to 7 mm. Tiled panels are with a side of the square from 30 to 95 cm. Rack elements are available with a width of 13 to 28 mm with a length varying from 2.5 to 3.8 m. The thickness of the slats is 8-14 mm.

For the rational use of material in the process of installation, it is worthwhile to acquire the type of bathroom panels where there will be a minimum amount of waste generated during fitting to the dimensions of the base.

Installation

There are several ways to lay the panels:

- using glue or liquid nails;

- on a special frame.

The last option is recommended for lath panels, and PVC and MDF products are perfectly fixed to adhesives. If necessary, the free space between the products and the wall can be filled with insulation or use this space to arrange electrical wiring.

Arrangement of the frame is performed using an aluminum profile using the following technology:

- the profiles are arranged, the stiffeners of which are placed horizontally;

- the fastening pitch is calculated based on the width of the product, but this value should not exceed 50 cm;

- Further preparation of the rails is performed - the ends of the elements from MDF are recommended to be additionally treated with a sealant;

- in the case when the floor has an insufficiently flat surface, the resulting gaps are hidden with the help of a plinth;

- all areas where switches, sockets or communications should be located should be marked;

- fasteners reek performed on screws or staples, in some cases, you can use special clips.

Installation of panels on glue can be carried out in bathrooms, where the bases have a straight geometry, and also do not need specific preparation. Otherwise, you should pre-finish the walls with plaster and prime the surface.

After performing such work, you can proceed to gluing panels. The technology for this task is as follows:

- The joints between the elements of the composition, including the corners and the joining of the panels to the floor and ceiling, can be arranged with the help of moldings.This option will provide a more accurate appearance of the surface. These works are not necessary if the fixation of the components is carried out using grooves or other fasteners.

- The application of the composition on the products can be done pointwise or in the form of zigzags.

- The panel with the composition applied to the back side is applied to the wall and pressed over the entire area.

- If excess glue has protruded around, they should be carefully removed from the base.

- Installation of panels must always begin with a corner.

- All unattractive places where cuts are peeped at the edges of products, it is best to hide under the baseboard. It can be made of any material and have a similar color or vice versa - to serve as a contrast component of the composition being created.

Beautiful examples

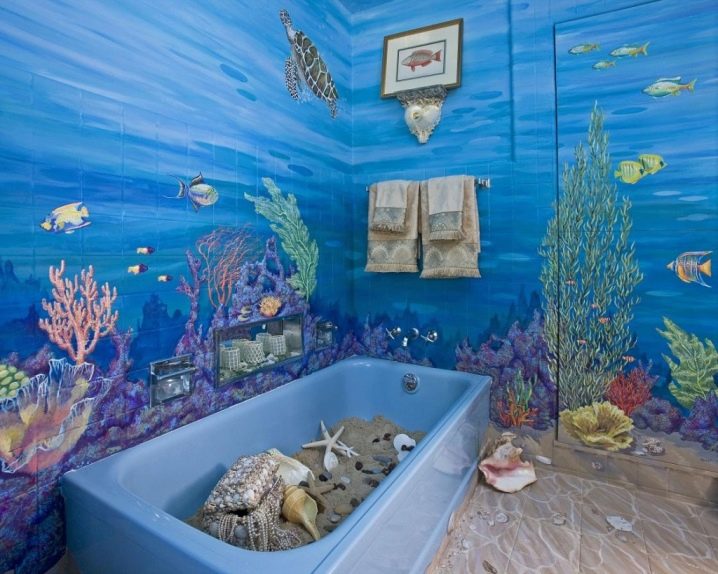

Blue has always been associated with sea and water. To add bright colors to the interior of the bathroom, you can use panels under the tile with a printed pattern on the marine theme, made in blue. This option will refresh the design and is guaranteed to be enjoyed by kids. And the image of marine flora and fauna will help you relax while conducting water procedures and remind you about the mass of positive impressions from the rest on the seashore.

Bathroom in modern style, decorated in black and red colors, will be an original and bold solution for lovers of extraordinary ideas in creating interiors. This finish will be a real highlight of the whole dwelling, as well as a luxurious, but, nevertheless, an inexpensive option.

About the advantages of PVC panels under the tile, see below.