Types of plaster for the bathroom

For finishing rooms with a high level of humidity, only materials with good moisture resistance are suitable. Certain types of plaster will perfectly fit into the bathroom, as they tolerate high humidity, temperature changes and exposure to household chemicals. Such compositions can be used as a base layer for further finishing, as well as a decorative topcoat.

Special features

For the decoration of the bathroom materials have special requirements. Indoors created not the most favorable operating conditions. High humidity, frequent temperature changes adversely affect the finish and contribute to the appearance of dampness, fungus and mold. Plain plaster is not a suitable material for bathrooms.

Plaster mixture must be resistant to moisture and antiseptic properties.Such compositions can be used as a decorative layer, as well as to level the surface of the walls and protect against moisture penetration.

Advantages and disadvantages

Plaster for the bathroom is of several types. The performance characteristics of a mixture primarily depend on its composition.

However, all bath plasters have a number of common advantages.

- Good vapor permeability.

- The coating does not pass moisture and does not absorb it.

- Resistance to the spread of microorganisms. On such a coating does not appear fungus or mold, even in conditions of constant humidity and poor ventilation.

- Like any plaster mixes, bathroom compositions well mask defects on the surface of walls and ceilings, as well as level the base.

- In the construction market you can find a lot of decorative moisture-resistant compositions, which will not only perform a protective function, but also play the role of a beautiful finish.

- Plaster is suitable for applying on almost any material.

- The starting layer of moisture-resistant plaster can be painted, tiled, covered with decorative mixtures or any other materials for finishing.

- Low consumption per square meter. An exception may make decorative compositions.Certain application techniques require more finishing coating consumption.

- Good adhesion.

- Ease of application.

- High drying speed.

- Resistance to cracking.

The disadvantages of plaster for bathrooms mainly depend on the specific type of material used.

Consider the main disadvantages of most mixtures.

- Decorative plasters are quite expensive material. In addition, certain application techniques require a high consumption of the mixture.

- Plaster mixes do not tolerate direct contact with water and too high a level of humidity in the room.

- Most decorative compositions require certain skills and craftsmanship for their application. Doing finishing work with their own hands is not so easy. If you work with the material incorrectly, you will not be able to create a reliable and beautiful coating.

- It is difficult not only to apply decorative mixtures to walls, but also to dismantle them.

- Cement-based plasters can crack if they are improperly laid or the layer is too thick.

Kinds

In the construction market you can find a large number of various plaster mixes for wet rooms.Bathrooms are available in both basic and finishing compositions. The type of plaster will depend on its technical characteristics and decorative properties. Most formulations are made on a cement or plaster basis. Decorative plaster for the bathroom on the composition can be divided into several types.

- Mineral Such mixtures are made on the basis of various minerals (most often marble or granite chips) with the addition of high-quality Portland cement and lime. This type of plaster is often used to finish the facades of buildings, which indicates a good resistance of the material to external negative factors.

- Based on acrylic. The composition of this plaster includes acrylic resins, which play the role of the main binder component. This coating is characterized by high strength and resistance to cracking. When applied correctly, the material can last more than 25 years without loss of appearance and technical characteristics.

- Based on natural silicone. This composition perfectly aligns the walls, and also plays the role of a decorative coating.In addition to silicone, this plaster contains special components that prevent the formation and spread of microorganisms and protect the treated base from dampness, fungi and mold.

- Silicate. The basis of such mixtures is an aqueous alkaline solution of sodium and potassium silicates with the addition of antiseptic components. Plaster does not deteriorate from contact with water and is characterized by good moisture resistance.

In the form of release of plaster are divided into ready-mixed and dry powders. Ready-made compositions are convenient because you do not have to spend extra time preparing a solution.

Venetian

Aesthetics and practicality combines Venetian plaster. The material is made on the basis of hydrated lime. As additional components, dyes, microcalcite, acrylic and other polymeric additives are used. Due to the presence of ground marble in its composition, the coating perfectly imitates the structure of natural stone. Instead of microcalcite, granite and onyx dust, quartz flour or other fillers may be part of the Venetian plaster.

Venetian blends are great for decorative decoration of small areas. The shimmering coating fills the small room with light, which allows you to visually increase the free space. This type of finish has not only a great view, but also excellent performance.

Venetian plaster is not afraid of moisture and temperature changes, and also has high strength. This option of decorative trim is ideal for bathrooms.

To improve the performance and decorative properties of the finishing coating, it is recommended to cover it with special wax.

Textured

This plaster is a heterogeneous mixture, which may include various natural fibers, small pebbles, crushed rocks. Thanks to such fillers, the textured coating can imitate various textures. A distinctive feature of this finish is the relief created on the surface.

Textured plaster has excellent technical characteristics.that allows you to use it in areas with adverse operating conditions.The coating can be cleaned with household chemicals or regularly wiped with dust with a damp cloth. The material is also resistant to mechanical stress and is not afraid of contact with water.

Gypsum

Gypsum plaster is an environmentally friendly material. The mixture is used for interior decorating in order to prepare and level the surface before finishing. The composition can be applied to the walls with a thick layer that allows you to disguise almost any base defects. In this case, the wall is not previously puttied.

Gypsum plaster is suitable for applying on virtually any material. The mixture has good adhesion due to special additives that are used in the production of the solution.

It should be noted that the gypsum composition is suitable only for rooms with moderate humidity. Due to the high porosity, the coating absorbs moisture well.

Under the influence of high temperatures, absorbed excess moisture comes to the surface and dries quickly. However, when wet, the gypsum coating can delaminate. Use this mixture for basic wall decoration in the bathroom is only in the case,if there is good ventilation in the room and the starting cover is finished with a waterproof material.

Cement

Cement-based plasters surpass plaster mixes in their technical characteristics. This coating is durable and durable. The material is resistant to moisture and temperature extremes.

The composition of cement plaster are divided into the following types:

- cement and sand;

- cement lime.

For bathrooms, the most suitable option would be a cement-sand mixture. The composition of most cement plasters include special additives to improve the performance of the material.

Sanitizing solutions

Substances, called sanitizing solutions, are a system of two or three components.

- Primer solution. Instead of a primer, some manufacturers produce basic plaster for sanitizing mixture.

- Sanitizing plaster composition.

- Finishing sanitizing putty coating. This component is optional and is not included in the composition of sanitizing systems by all manufacturers.

These systems are necessary to protect walls and finishing materials from moisture.Plaster retains the salts contained in the water, which contributes to the rapid evaporation of moisture. The plaster coating has a porous structure, which prevents the accumulation of salt deposits and deformation of the finishing and walls.

Sanitizing solutions are easily applied to the surface and are fast drying. This coating is resistant to external negative factors and is not subject to cracking. Sanitizing plaster material does not belong to the finishing decoration, but is used only as a protective layer. This surface can be painted, tiled or other materials.

Sanitizing systems are not recommended for plaster walls. The basis under such plaster has to possess high durability. It is possible to apply solution only on the pure, degreased, cleaned from the old finishing layer surface. The mixture can be applied in several layers, the thickness of which together should not be less than 2 centimeters.

What type to choose?

When choosing the type of plaster for the bathroom you need to familiarize yourself with the technical characteristics, as well as take into account the advantages and disadvantages of each type.A large role is played by the type of foundation that is to be finished.

For concrete walls, cement-based or polymer-based compounds are perfect. Both cement, and plaster solutions well lay down on the brick bases. For the finishing of cellular concrete, it is recommended to purchase special formulations intended for this material.

And it is also important to decide whether the plaster will play the role of a finishing coating or the base layer for further finishing. Special decorative blends are available for finishing, which have excellent aesthetic properties and high technical characteristics.

Plaster mixes in bathrooms should be used with great care. Such plaster does not tolerate exposure to a wet environment. At hit of water on a surface the splitting of plaster can occur.

Some manufacturers produce moisture-resistant plaster mixes. However, the structure of such a coating will still be porous, which contributes to the absorption of moisture and can lead to complete destruction of the coating. For bathrooms more suitable mixtures based on cement.

Whatever type of plaster you choose, it is important to consider several factors when purchasing a material.

- You must carefully study the description and characteristics of the composition on the package. On the product must be a mark that he belongs to the category of waterproof materials.

- To make the coating reliable, durable and durable, you should not save money on the purchase of plaster for the bathroom. You can first get acquainted with the rating of popular manufacturers and reviews of their products.

- When buying it is also important to pay attention to the shelf life of the product. Materials with an expired shelf life may not correspond to the declared qualities, as they partially lose their technical characteristics.

Technology

The technology of applying plaster depends on the chosen material and the surface to be treated. Starting finish plaster mixtures is almost the same, regardless of the type of composition. The application of decorative solutions provides great design opportunities due to the possibility of using various finishing techniques.

Preparation and application

Before applying the plaster composition it is necessary to prepare the base. The surface is cleaned from the old finishing layer. If you apply the solution to a painted, bleached or previously plastered surface, the new finishing layer will create a load on the old coating. After a while, the old finish may begin to fall off with the new layer.

If there are deep cracks in the wall, they must be cleaned and sealed with a solution of cement and sand. Then the walls must be cleaned from dust, dirt and grease stains. If you are going to plaster a brick wall, then before finishing work it is necessary to deepen the joints of the brickwork up to 0.5 cm for better adhesion.

It is recommended to make notches with a depth of no more than 0.4 centimeters on too smooth brick or concrete bases. To improve adhesion, it is recommended to treat the surface with a primer. It is best to choose a primer with antiseptic properties.

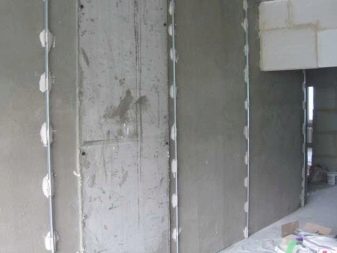

In certain cases it may be necessary to install lighthouses. Lighthouses are necessary if the bathroom has a fairly large area, and the irregularities are more than one centimeter.This process consists in fixing the perforated T-shaped profiles. Fixation is carried out using a gypsum mortar, which is distributed in small strokes along a vertical line. Profiles are pressed into the plaster mix in increments of 1 to 1.5 meters.

Splattered

The spraying procedure is performed for more reliable adhesion of the plaster to the base. Thanks to the spray, cracks, chips and other defects on the wall surface are filled. This process involves the use of a liquid cement-sand mortar. To prepare the mixture, it is necessary to mix one part of cement with three parts of sand and dilute with water to the consistency of sour cream.

Before applying the solution, it is recommended to moisten the wall well with water. The mixture is spread over the entire surface of the base with a plastering trowel by spraying. The thickness of the continuous layer may be in the range from 0.5 to 0.9 centimeters.

Draft layer

After the spray has grasped a bit (this may take no more than three hours), it is necessary to prepare the mixture for the draft layer. In this case, the solution should be slightly thicker than for splashing.Make a mixture of cement and sand in the ratio of 1 to 3.

The resulting composition is distributed on top of the previous unlined layer. If beacons were installed, the mixture is applied between two adjacent profiles. Then the aluminum rule needs to level the applied composition. Movement should be carried up profiles.

Upon completion of the finish, the draft layer should dry out slightly, after which the beacons are removed. The remaining recesses from the profiles are filled with cement-sand mortar and smoothed with a spatula.

Finish stage

The finishing stage involves the application of a layer of plaster before further lining or the distribution of the last decorative coating. The difference will be in the thickness of the mixture. The base coat should not exceed 2 millimeters when the finishing layer is applied with a thickness of 4 to 7 millimeters.

All work is carried out after partial drying of the rough finish. If the draft layer has managed to harden well, it is recommended to moisten the surface with water. Using a narrow spatula, a plaster mixture is applied to a wide tool. At an angle of not more than 20 degrees a large spatula spread the solution on the wall surface.Movement at the same time should be smooth and smooth.

To finish the surface in the corners of the room will be easier to distribute the mixture, moving the spatula horizontally. The areas adjacent to the corners, the easiest way to trim using vertical movement. Lightly hardened coating is treated with float for plaster, making circular movements counterclockwise. In areas where protrusions have formed, grating is necessary to press more.

When using a textured mixture, the application process will be slightly different. As the main tool, you must use a narrow metal spatula. The direction in which it is necessary to carry out movements with the tool will depend on the chosen technique of applying decorative plaster.

To learn how to plaster the walls in the bathroom, see the following video.

Useful recommendations

If the plaster is used in the bathroom as a base layer, then such a coating needs additional waterproofing. Especially when it comes to plaster mix, which is important to reliably protect from direct contact with water.In the market of building materials, you can buy special tools based on cement with the addition of polymers.

To work with decorative plasters in most cases a perfectly even coating is required. The hardest thing to work with the Venetian mixtures. If you apply such a composition on the base with defects - they will be seen through the finishing layer of plaster. The solution is distributed over the surface in thin layers, the number of which can reach ten.

Despite the fact that textured plaster is resistant to the spread of microorganisms, it is not worth creating a coating of high relief. Chance of exposure to a wet microclimate of mold formation in shallow recesses of the coating is high.

Sections of the wall that are subject to frequent and direct contact with water (bath, shower, sink), it is better to finish with tiles.