Concrete sinks: the pros and cons, the finest workmanship

Without a sink it is impossible to imagine a single bathroom or kitchen. It should be reliable, practical and aesthetically attractive. Today, one of the most popular options for making sinks and countertops is concrete, which has several advantages over other materials.

Advantages and disadvantages of the material

First, consider the strengths of concrete structures.

- Cheap stuff. Stone worktop and sink are ideal for the bathroom and kitchen, as they are of impeccable quality and high durability. Concrete structures are no worse than stone products in terms of performance, they look very presentable, and they are incomparably cheaper.

- Suitable for interior design of any premises.

- Concrete products can be easily made without the help of experienced professionals.

- The material is strong enough and hard, so the tabletop and the sink are not afraid of any temperature.

Concrete is a versatile material that has, perhaps, only one drawback. Acid has a negative effect on the concrete surface. For example, even a drop of lemon juice will leave a speck. This is because the composition of concrete is calcium, which acts as a binding element. It is easily damaged by acids.

Using a protective polymer layer, you can solve this problem. In addition, the protective layer simplifies maintenance of the concrete surface. The only drawback of the protective polymer coating: it is impossible to put hot dishes on it without a substrate. This is because too high temperatures lead to the destruction of polymers.

Chipboard, OSB, which have a low price, can also be used as materials for the manufacture of tabletops, but they are short-lived compared to concrete or stone.

Designs

Real masters in the field of construction and design embody any ideas into reality. They are not limited to simple square or round shapes.

- Concrete shell in the form of shells. Elegant configuration, fine lines, original design. This option demonstrates an endless imagination in the manufacture of concrete products.

- Integrated (built-in) concrete sink. When you design your own space, each person tries to fill it with the most convenient elements. It often happens that it is impossible to find a suitable solution for a bathroom, therefore interior items can be made to order. The integrated sink meets all the requirements of customers for aesthetic and operational characteristics, while the customer has the right to choose the color, shape and size of the product they like.

- Rectangular sink - a classic version. It is quite easy to use, as during washing the water will not splash. Models of such sinks are the most popular and are offered in a wide size range.

- Oval design considered today the most ergonomic option.

Style and design

Concrete is considered a rough material, but with the right approach, it can turn any structure into a real work of art. Trusting your imagination in the interior design, you can effectively apply this material.

Consider several options for the use of concrete sinks in different interiors.

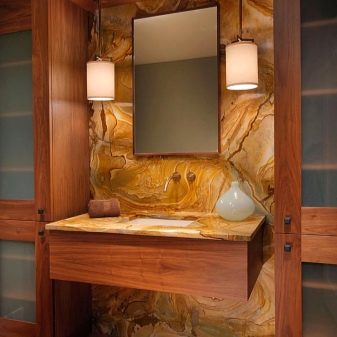

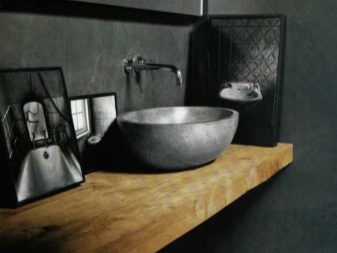

- A polished concrete sink in combination with a wooden table top looks very stylish. This option is ideal for the interior, decorated in a loft style.

- Against the background of concrete shells candles look especially romantic. A large round mirror in this interior compensates for the simplicity and coarseness of the concrete structure.

- Variants of concrete products in a bright interior create a sense of sterility.

- Concrete sink perfectly harmonizes with wooden furniture.

Constructions of concrete harmoniously fit into a variety of stylistic directions.

- Concrete sinks and washbasins are very common in modern bathrooms and kitchens. Most often we are talking about integrated versions of the classic or original form. Concrete sink will be the ideal option for the interior in a minimalist style.

- Concrete is one of the basic materials used in the loft style.

- Unusual forms of concrete sinks - the main criteria for bathrooms in the style of high-tech. This interior has a minimum of shades used, plenty of lighting, simple geometry of shapes and lines.

How to do it yourself?

It is rather simple to make a sink with a table-top from concrete; you only need to follow certain instructions. At the same time, it must be borne in mind that this is a laborious process and requires working with different materials and tools.

Training

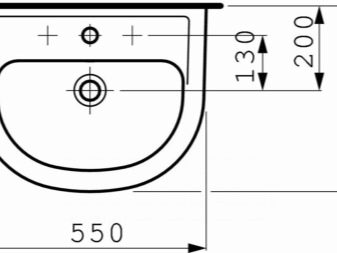

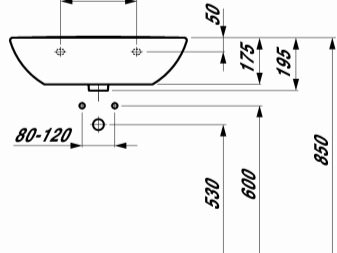

Prior to the commencement of all work, it is necessary to create a sketch of the future structure. This will help determine with precision how much material is needed for work. Sink can be consignment note or built-in. The surface sink has a significant difference - the presence of a horizontal rim.

It is overhead products that are commonly used for self-manufacturing. The presence of the side will allow you to hide small errors made in the manufacture of the product. Then the location of the future sink and table top is outlined.

The working surface is cleaned from wallpaper or paint.

Manufacturing

The next stage is the formation of a framework (formwork), where the concrete solution is poured. It is necessary to make a solid formwork so that it can withstand the pressure of the mixture for several days. Materials for the manufacture of the frame: large-sized plywood sheets, wooden bars, boards, sheets of plastic.

Required tools:

- device for cutting materials, for example, electric jigsaw;

- perforator;

- screwdriver;

- scissors for metal;

- hammer;

- capacity for concrete solution;

- ruler, level, roulette;

- spatulas.

To form the formwork it is necessary to lay the plywood sheets on a flat base. Then they copy all the details of the sketch. The material is cut and bent according to the shape of the future product. Along the perimeter of the base set the bars of wood. For the formation of holes in the sink is recommended to use a plastic pipe, for example.

Then you can proceed to the installation of reinforcing mesh, which serves to harden the concrete. Using a perforator in the side walls of the formwork, holes are drilled for the metal bars of the reinforcement. They should be positioned in such a way that the reinforcing mesh does not touch the bottom of the frame and is in the thickness of the concrete solution.

The finished formwork can be attached to the wall.To give the frame the necessary strength, special attention should be paid to the fixing of the walls. For these purposes, you will need screws longer than 6 cm or metal corners, with the help of which a reliable connection is ensured. Under the base of the formwork down the support of bricks.

After the preparatory work proceeds to the mixing of the concrete solution.

For this you will need:

- cement (part 1);

- sand (3 parts);

- crushed stone (3 parts);

- water (0.5 parts).

Water in the concrete solution should be added slowly, so as not to get too liquid composition. Ideally, the mixture should resemble a thick sour cream.

The prepared solution is poured into the formwork. During the pouring it is necessary to tamp the mortar to seal the rubble and remove air bubbles. Concrete must be poured in several layers so that, as a result, the height of the compacted mortar was several millimeters higher than the formwork itself. This results from the fact that in process of drying the volume of concrete solution decreases, respectively, level falls.

A week later, the composition is gaining sufficient strength, which allows you to remove the formwork and proceed to the finish.They begin dismantling from above, at the end they remove temporary supports from bricks. But they can be left until the entire structure is completely dry.

After dismantling the formwork, you can remove the tube from the holes for draining and overflowing.

You will learn more about how to make a sink out of concrete in the following video.

Finish

At the last stage of the creation of the concrete shell should be sanded and polished surface with sandpaper or a grinder. The shell is first polished with a disk or coarse-grained material to remove irregularities and open the pores, which must be treated with a solution of cement and acrylic filler.

The result is a beautiful, smooth and shiny sink. It can already be used, but, above all, it is recommended to treat the surface with antiseptics and protective compounds to protect against external irritants.

If desired, you can decorate the countertop. For this most often used ceramic tiles. A leveling compound is applied to the surface to be treated, then tile glue and only after that begin laying ceramic tiles.For washstands more complex designs, you need to cut each tile to the desired size. An adhesive composition of a thicker consistency is applied to the side surface, and it is rubbed into the seams with a rubber trowel.

Independent manufacture of the sink will cost much less than the purchase options. In addition, you can always deviate from the standard options and show all your imagination in the manufacturing process.

Different materials can be used to decorate the tabletop: concrete, wood, and even epoxy resin.

What else can you make a sink for the garden?

Concrete sink is a solid, sustainable option that is more suitable for private homes and cottages. However, very often there is a need for lighter and simpler structures, for example, for a country house.

Cottage washbasin can be easily and easily made from scrap materials. The best option is the design of a plastic bottle. The production of such street washstand will take a few minutes. It will serve perfectly until such time as there is a more reliable option.

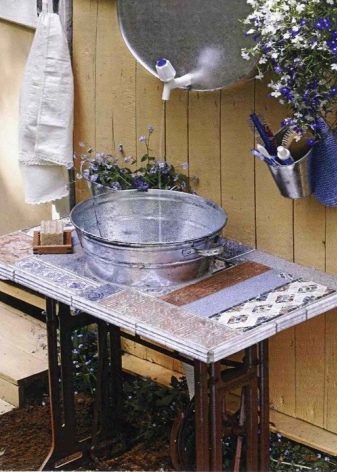

However, the plastic garden sink does not meet the needs of the whole family, even with very economical use. You can install a similar larger version of the washstand made of plastic or metal cans. For these purposes, even fit a bucket.

It is enough to make a hole for the tap in the selected container.

A more reliable and convenient option for giving may be a washbasin with a pedestal. This design can be installed both in the yard and inside the house. One of the most common models of summer washbasins is “Moidodyr”. It is a frame structure that is sheathed with sheet or panel material.

To create it are used:

- plywood;

- drywall;

- DSP;

- steel;

- plastic.

As a sink, you can use an old sink that was used or a basin or even a bucket. The water tank is better to buy in the store, although here you can use an old canister or other container. Such a washstand is usually supplied with a table top and a dryer, for the decoration of which ceramic tiles are used. You can also paint the surface with acrylic paint.