Fan speed controller: models, features and wiring diagram

Fans are widely used in various fields of human activity. The devices can be found in residential and public buildings, they are used to cool computers and laptops, they are installed in exhaust and supply and exhaust ventilation systems and air conditioning systems. However, the operation of the device at full capacity is not always necessary and appropriate. Therefore, to limit the frequency of rotation of the blades using special devices - fan speed controllers.

Specifications

A fan speed regulator is a small device that can reduce or increase the rotational speed of the working shaft. The controllers are connected to the fans in a specific pattern and are controlled using the manual method or automation.Automatic models are closely interrelated with other devices of the air handling unit, for example, with sensors that determine temperature, pressure, movement, as well as photo sensors and devices that determine humidity. Data from these devices are transmitted to the controller, which, on their basis, selects the appropriate speed mode.

Mechanical models are controlled manually. Speed control is carried out using the wheel mounted on the instrument housing. Often, controllers are mounted on the wall according to the switch principle, which makes their use convenient, and allows you to smoothly change the number of revolutions at any time. The devices are available in a wide range of power and are capable of operating at voltages of both 220 and 380 V.

The principle of operation and purpose

During constant operation of the fan at maximum speed, the resource of the device is exhausted quickly enough. As a result, the power of the device is noticeably reduced, and the device fails. This is due to the fact that many parts are not able to withstand such a rhythm, because of which they quickly wear out and break.To limit the speed of rotation of the blades and increase the service life of the fan, a speed controller is built into the ventilation unit.

In addition to saving work life, controllers perform an important function to reduce the noise from operating ventilation systems. So, in office premises where there is a large accumulation of office equipment, the noise level can reach 50 dB, which is due to the simultaneous operation of several devices whose fans operate at maximum speed. In such conditions, it is difficult for a person to tune in to the working mood and concentrate.

A way out of this situation is to equip the ventilation units with speed controllers. Another strong argument in favor of the use of regulators is the economical consumption of electricity. As a result of reducing the number of revolutions and reducing the total power, the fan begins to consume less energy, which has a positive effect on the budget.

The principle of the controller is to change the voltage that is applied to the winding of the fan motor. There are more expensive models that can adjust the speed of rotation by changing the frequency of the current.However, the cost of such products often exceeds the cost of the fan itself, because of which their installation is impractical.

Scope of application

Speed controllers are used almost everywhere where there is ventilation. Regulators are indispensable in the arrangement of ventilation systems of gyms, offices and cafes. Often such devices can be found in individual climate control systems. Air conditioners for space heating are also equipped with controllers - powerful transformer devices capable of controlling the rotational speed of the impeller.

However, the most common option for installing a controller are computers and laptops. Regulators can significantly reduce fan noise and are often equipped with additional features such as lights, a temperature sensor, and an emergency shutdown sound. Some models are equipped with a display.

Controllers for computer fans are called reobas and are capable of servicing several fans at once.

Species

Fan speed limiter controllers come in several forms.

Step models using autotransformer

The essence of the operation of this device is that the device winding is branched, therefore, in the process of connecting to the branches, the fan receives a slightly lower voltage. Using a special switch, this or that fan is connected to the required winding section, and its rotational speed drops. Synchronously with this reduced consumption of electricity, which leads to an overall saving of the resource.

Adjustment of the device is carried out using a special handle, equipped with a stepped scale, which has 5 positions. The advantages of the models is their reliability and long service life. The disadvantages include a fairly overall control unit, which is not always convenient when placing the device in confined spaces, as well as the impossibility of smooth switching. However, when connecting temperature sensors and a timer, the rotation speeds can be automated.

Autotransformers with electronic control

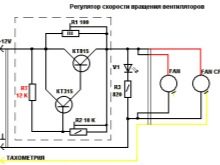

The essence of the operation of such devices is somewhat different from the principle of operation of previous models.The device is equipped with a transistor circuit and is able to modulate the pulses, smoothly changing the voltage. The strength of the voltage depends on the frequency of the pulses and pauses between them. So, with short pulses and long pauses, the voltage will be much lower than with long pulses and short pauses.

The advantages of this controller are small size and comfortable cost. The disadvantages include the short length of the connecting cable. This necessitates a separate location of the unit from the control knob and its placement closer to the fan. Electronic models are used in large industries in conjunction with powerful ventilation systems. They are resistant to overloads and are capable of continuous operation for a long time.

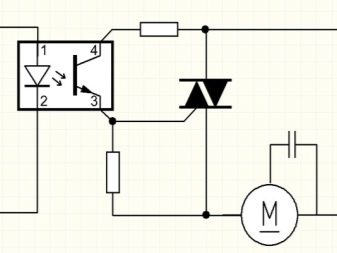

Triac (thyristor) controller

This type of regulator is the most common. The device is used to connect to a single-phase AC fan, however, it can work with a constant. When the device operates, each of the thyristors lowers the output voltage, thereby reducing the number of revolutions per minute.The advantages of the devices are low cost, low weight and the possibility of reducing the speed to almost zero.

The disadvantages include the likelihood of sparks on the winding, a short service life and restrictions on the power load.

How to connect?

You can connect the speed controller to the fan with your own hands. To do this, you must carefully read the instructions and observe a number of safety measures when working with electrical appliances. Depending on the type of construction and the type of serviced fans, the controllers can be installed on the wall, inside the wall, inside the unit or in a stand-alone closet of the “smart home” system. Wall-mounted and wall-mounted regulators are fixed with screws or dowels, depending on the size and weight of the device. Fasteners are usually included along with the instrument wiring diagram.

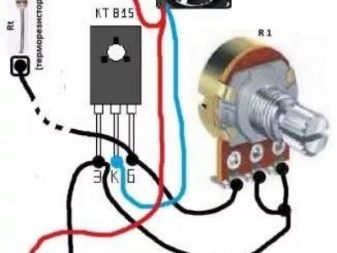

Connection schemes for models may differ, however, there are still general patterns and sequence of actions. First, the controller must be connected to the cable that supplies current to the fan. The main purpose of this phase is the separation of wires "phase", "zero" and "earth".Then connect the wires to the input and output terminals. The main thing is not to confuse the wires in some places and to make the connection according to the instructions. In addition, you should check that the size of the cross section of the power cable and the connection corresponds to the maximum allowed voltage of the connected device.

When connecting a speed controller to a laptop fan with a voltage of 12 volts, it is necessary to find out the maximum permissible temperatures of the device parts. Otherwise, you can lose a computer that has a processor, motherboard and graphics card failing to overheat. When connecting the controller to the office equipment, you must also strictly follow the instructions. If you need to connect several fans at once, it is better to purchase a multi-channel controller, since some models are capable of servicing up to four fans at the same time.

Fan speed controls are an important all-rounder. They protect the equipment from overheating, prolong the life of the electric motors of the fans, save energy and significantly reduce the noise level in the rooms.Due to its efficiency and practicality, devices are becoming increasingly popular and growing consumer demand.

How to make a fan speed controller with your own hands, see below.