Three-way ball valves: types of construction

The three-way ball valve has long gained popularity among millions of consumers. Its history is more than a century. It is known for its simple design and the ball-shaped control tool, to which it owes its name. Based on it, it can be concluded that the device has three exits to which the pipes are connected.

Products of this type have many varieties of construction that are used for various purposes in various fields (from small household to large-scale industrial purposes). The differences of the types are in the dimensions and materials, as well as in the degree of ease of opening and closing the valve. With such a variety it is easy to get confused, and to choose the desired type is very difficult.Therefore, this issue requires a detailed study of the features of the work and technical characteristics of products.

Device and features of functioning

The internal composition of the ball valve is simple, but it performs a number of useful functions. Among the main elements can distinguish the ball. It is very important because it allows water, gas, air and petroleum products to pass through the pipeline.

Also in the design there is a rotating shutter. It is a small spherical element with a special hole (it is intended to create a passage of transported substances), the diameter of which corresponds to the diameter of the pipe. These cranes belong to the group of full bore (there are also standard bore or reduced). The movement of the liquid can be completely blocked, it is enough just to move the ball ninety degrees.

There are also parts that are designed to seal the structure. It may be gaskets and seals. Important elements are pens. They are of different types: butterfly handles, butterfly handles, levers. The basis of the design is the body.It is made of stainless materials, which provides special strength and durability of the product.

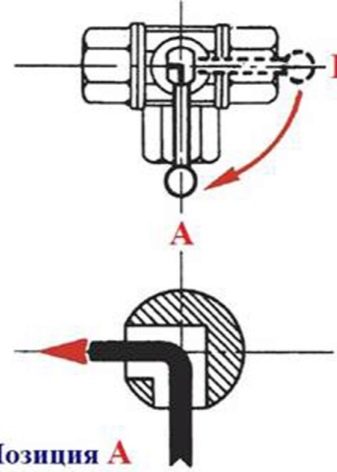

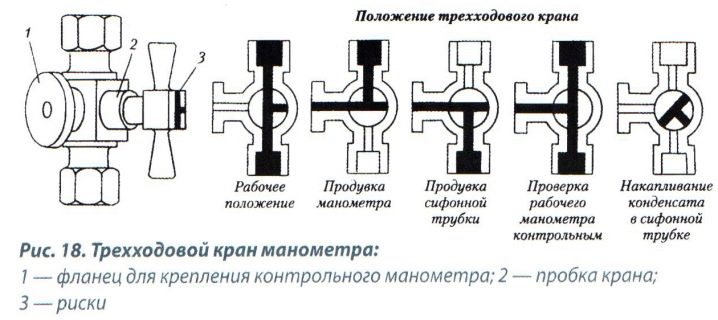

To connect a polypropylene tap, a pressure gauge is needed to check the pressure level. Its principle of operation and operation is not very complicated, the main thing is that the manufacturer is reliable.

Kinds

There are different criteria for the classification of cranes. Consider some of them.

For the implementation of sealing:

- floating ball - for miniature diameters;

- fixed ball - for large diameters.

By way of integration.

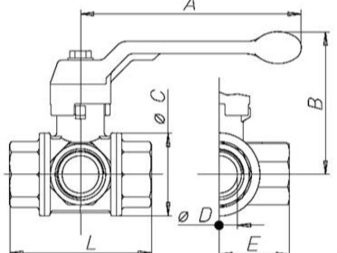

- With the help of choke. So the pipeline is connected to the device crane. Additional elements are also needed: a cap nut, a gasket for the seal, a nipple, as well as transitional elements (a coupling or a square will fit). This option is characterized by the creation of the highest tightness and strength.

- Using a 1 inch threaded coupling. Most often, this method is resorted to when installing cranes made of non-ferrous metals or cast iron.

- With the help of welding. A great option for cases when work is conducted on hard-to-reach, but key parts of the pipeline. It as well as choke, provides reliability and rigidity.

- With the help of flanges. They are special parts for equipment with a large pass size. Details are round. They are a “lifesaver” for repairs in areas where welding is prohibited. They help with the partial installation of the pipeline.

- Combined method. Proceeding from the name, it can be concluded that the method is universal, and for each individual case special tools and methods of action are selected (for example, welding and flange, etc.).

By type of movement:

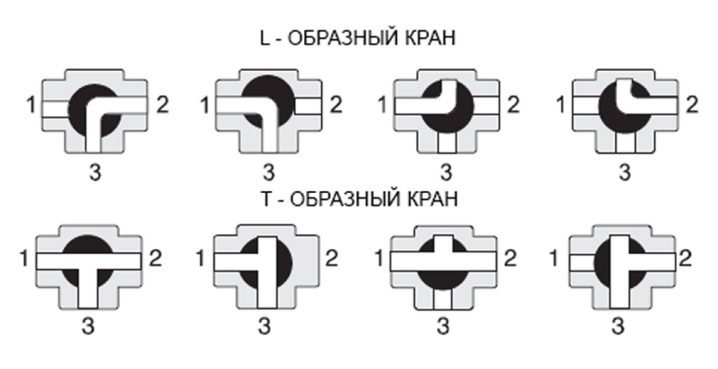

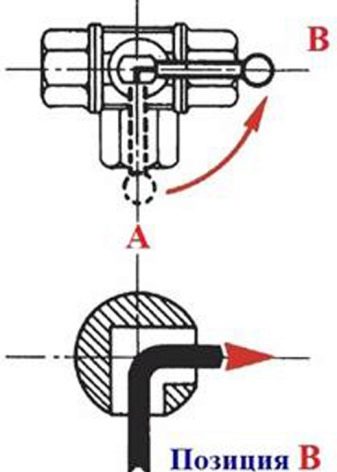

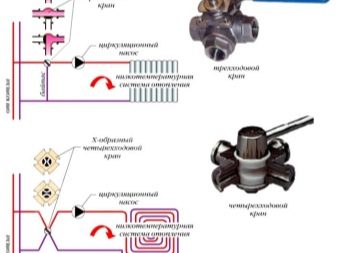

- L-shaped (corner);

- T-shaped (allow you to open the passage in all directions).

As already noted, the valve may have different diameters of the passage. It may be small. A major advantage of this type of crane is that it is designed for manual adjustment. To do this, use special handles: "lambs" or console.

For diameters of more impressive sizes, various drives are usually used: electric, hydraulic, and pneumatic drives. They provide mechanization and greatly simplify the use of devices. So, for example, for cranes designed to conduct gas, the drive is the working medium, distilled inside the pipeline.

Nuances of work

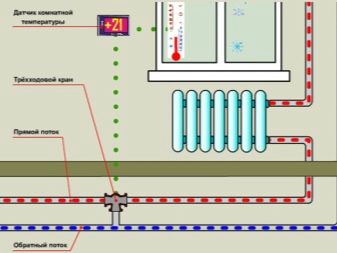

The design of the crane has a simple to understand functionality. In the period of prolonged cold weather it is advisable to use the maximum temperature supply mode. To do this, fully open the hot coolant.

To adjust the temperature regimes, you can experiment with the flap. For example, to supply less hot water, you can slightly open it up. Customization is possible for individual needs.

To supply only cold water, on the contrary, it is necessary to bring the structure into a fully closed position. This method is often used during repairs when water is not needed in the system.

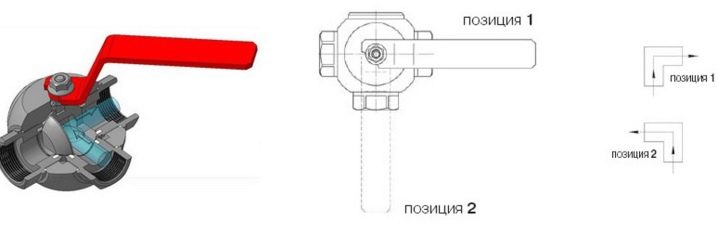

There are the following modes of operation:

- streams are mixed;

- streams are divided between output lines;

- changing the direction of fluid flow;

- stop the flow of the working environment.

Benefits

The modern world is developing rapidly. Modernization affects many aspects of social life. Changes affected the device and pipeline valves. Now we have half-turn three-way ball valves, which easily distribute the flow of substances. Previously, valves were used instead. This brought a lot of inconvenience.

- Were needed regular technical checks.

- These devices were very large and heavy. This, of course, greatly complicated the process of operation.

Their successors have a number of undeniable advantages. Among them:

- tightness at connection;

- simplicity and ease of management;

- possibility of use in polluted and inconvenient environments;

- no need for ongoing inspections and maintenance;

- smooth twist;

- synchronization with various liquids (nitrogen, carbon dioxide, oils);

- compactness in size and weight;

- durability, strength, resistance to various influences;

- possibility of operation in cold climates;

- simplicity of design;

- significant savings in money on heating fees (have the ability to regulate the temperature).

The three-way ball valve is a very useful and convenient device. Although during the operation of such products, some minor flaws were identified. For example, they cannot be used in conditions where the temperature is above 200 degrees Celsius. But if to compare this moment with the above-listed advantages, it loses significant importance, and there is no doubt about the effectiveness of the described device.

Manufacturing

Due to the popularity of the crane in question, ensuring its durability and reliability is simply necessary. This is possible only when using high-strength materials in the manufacture of the product. Today, most often they are rubber, photoplast and other substances with a synthetic composition.

So there was a modernization of the design of cranes. The new composition provided the durability of the elements, reduced friction, increased the effectiveness of sealing. That is why it became possible to use products in very serious industries. Now they are used not only in domestic premises, but also in the largest industrial enterprises.

It is important to note that there is a wide range of materials from which such devices are made: from plastic to cast iron. It also includes steel (including stainless), brass, titanium, ceramics and nickel. These substances just provide high strength and hardness, allowing long and efficient operation of the crane.

Other materials are used to create individual elements. For example, special gaskets for hardening are made of Teflon, chrome is used for balls, and rings are made of metal or fluoroplastic.Do not forget about the high temperature conditions. In this case, it is advisable to use brass taps, which are famous for their resistance to any temperature effects.

An important group consists of stainless steel food valves. This is a very reliable material, which is used in important industries. For example, such products are used in the food or chemical industry.

Application Methods

As already noted, three-way ball valves are trusted by users, which determines the breadth of their application. They are resorted to in various areas of industry, among them:

- agrarian and technological area;

- pharmaceutical companies;

- food factories;

- oil and gas industry;

- chemical industry;

- shipbuilding;

- steam supply

They can also be built into washing machines, provided they are made of corrosion-resistant steel. The important point is that when combined with other elements, you can create a structure for many needs. As you know, a three-way ball valve is used in the heating system, plumbing.

Conclusion

Ball three-way valves are not in vain received recognition of consumers.This device with compact dimensions and light weight has a wide functionality and greatly simplifies the life of people and entire enterprises. Products meet all modern requirements, have high reliability, and most importantly - durability. With them, you can forget about the systematic repair, so they are used in key industries.

It is noteworthy that such a crane can be installed independently. The construction works in both horizontal and vertical position. You can easily customize your device for your own needs.

For information on how the three-way ball valve works, see the video below.