Technical characteristics of ball welded cranes

Ball valves are a type of pipeline valve with a locking or regulating element. By the type of connection, they are: for welding, flange, socket and combined. This article will look at the first look and its differences from other models.

What it is?

Welded ball valves are modern designs of stop valves, which are installed on pipelines for a long time using the welded method, which are small in size and are used to shut off the working environment. The locking element is a ball with a through hole, where the flow passes.Ball valves are used for transporting water, steam, oil and gas compositions, alkalis, compressed air and other thick media with a wide range of temperatures and consistencies.

These models are used in hard-to-reach systems, such as pipelines laid underground and surrounded by water, as well as in cases when leakage through a threaded joint is unacceptable.

Cranes of this type are installed mainly at heat or pumping stations, as well as boiler and block points, industrial and energy facilities. Proper use and installation help to completely avoid leaks.

Scope of application

- residential buildings;

- utilities;

- industries;

- pipelines transporting aggressive substances.

Benefits

- simplicity of design;

- reliability and durability;

- the ability to quickly shut off the flow;

- small weight;

- material: stainless steel;

- no maintenance required;

- ensuring tightness of the workflow;

- easy installation and maintenance of the device;

- corrosion resistance;

- service life up to 25 years.

Minuses

To the few drawbacks of this type of ball valves can only be attributed to the inability to use at temperatures above 200 degrees. Also, when using cranes with a cantilever handle, additional space is required for its regulation.

What should I look for when choosing?

When buying, you should check the documents confirming the quality. It is important that the products are certified and meet all sanitary and hygienic standards.

Consider the technical specifications. Pay attention to the temperature at which the product works without interruption, and from which raw materials it is made. Cannot be allowed to purchase fakes. Fake cranes are made of poor quality raw materials, different from the original. Sometimes it can even damage human health.

Popular brands

There are a number of manufacturers whose weld taps are the most sought after:

- Weld ball valves ALSO meet all the requirements of GOST Russian Federation. These models are devices that block the movement of a liquid or gas in a pipeline and are mounted using a welding joint.They are installed in hard to reach places. Welding ALSO should be made by electric welding machine with simultaneous cooling with the help of a cloth dipped in cold water. The temperature of the working environment - from -40C to + 200C. Production material - steel.

- Welding valves Breeze europe- modern and progressive type of valves. They are used when working with pipelines supplying natural gas, oil, as well as in gas and water supply systems. Products are manufactured in accordance with GOST and DIN standards. The presence of a laboratory for testing provides Breeze with the ability to identify the chemical properties of metals for the manufacture of cranes, as well as to accurately determine and eliminate defects. The temperature of the working environment is from -35С to + 180С. Production material - steel.

- Broen Ballomax. Broen products have a wide range of ball valves. Cases of Broen cranes are made of carbon steel. Cranes are designed to fully open and close the working environment, do not require maintenance. Reliable construction ensures long service life. The temperature of the working environment is from -35С to + 200С. Production material - steel.

- Genebre Full bore three-piece stainless steel ball valves for welding have a locking system, protection from leakage through the stem hole and the ability to directly mount an ISO 5211 electric drive. The temperature of the working medium is from -25 ° C to + 180 ° C. Production material - steel.

Special features

By design, welded mechanisms are divided into full bore and standard bore. Full bores have similar in diameter to the diameter of the hole in the ball with the diameter of the pipeline on which the valve is installed. Hydraulic losses in this embodiment are not possible. Standard bore or reduced cranes are distinguished by a smaller diameter of the hole in the ball by one size of the diameter of the pipeline. This model is applied only on pipelines, where a small loss of pressure is not critical.

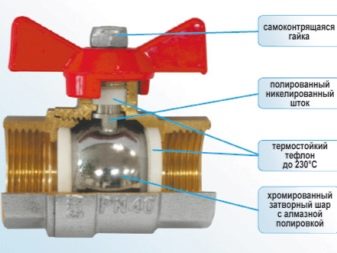

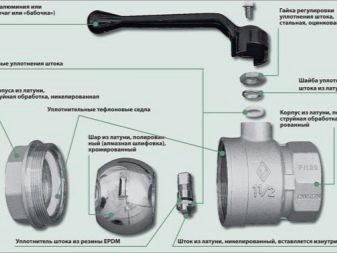

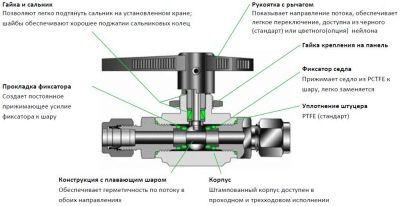

The device of welded cranes of the modern sample consists of the following parts:

- ball shutter - a movable ball-shaped part used to ensure the passage of the working medium;

- stainless steel case;

- fixing screw;

- adjusting nut;

- rubber seal;

- disc spring;

- a pen;

- Teflon sealing seats.

Weld ball valves are used without threads, which allows to exclude weak links when operating functioning pipelines installed in corrosive environments. This type is much easier to maintain, eliminates the need for constant technical inspections and preventive maintenance.

Assembly work

The spherical device for welding differs from other similar elements in that it is mounted in closed places where subsequent disassembly is not provided. Installation of the crane of this type is made by a method of welding and only qualified specialists. Only trained personnel with knowledge of installation and safety must be allowed to work. Installation is performed using electric arc or gas welding.

Strong welding joint is much more reliable than, for example, flange. And in contrast to the same flange or coupling valves, which are mounted on pipes with the possibility of easy removal and replacement, welded when dismantling the product must be completely cut. But the latter significantly benefit in price.

About how ball valves are made, see the next video.