Features of ball full bore cranes

Various supply systems, whether liquid or gas, always need maintenance and adjustment. Most of these systems require special reliability, such as gas pipelines or oil pipelines. This quality has a full-bore ball valve. Also, a significant advantage of such products is “independence”, in other words, they do not require maintenance during operation.

What it is?

The crane is called a ball because of the locking part, which has a spherical shape and is connected to the control handle. Products are used both in everyday life and in industry as locking, but not regulating devices.

The diameter of the bore hole is usually equal to the cross section of the valve.For example, the valve DN50 should have a hole with a diameter of 50 millimeters or a value as close as possible to this number.

Full-pass models are different from others. This is an increased bandwidth. It is also worth noting that the coefficient of hydraulic resistance is much lower for them, which is also undoubtedly a plus. The downside of such devices is their price.

Experts advise to choose such a valve, if you expect a long operation. Otherwise, it is better to purchase a non-full passage device, whose price category is much more affordable.

Special features

Most ball full bore valves have a nickel-plated coating, which is applied by electroplating. This makes it possible to use products in pipelines that supply drinking water. Hot water also does not harm them.

The turning radius of such models is 90 degrees. It follows that for opening and subsequent closing of the system, no long manipulations are needed. Enough of one hand movement.

The advantages of ball valves are obvious.

- Versatility. In production, only those materials are used.which can be used in conditions of exposure to high temperatures. This may be the transportation of petroleum products, water supply, ventilation, etc.

- Reliability. Simplicity of a design and operation, and also the materials checked by time do this type of cranes to one of the most reliable.

- Efficiency. As mentioned above, opening / closing does not require additional actions.

- Interchangeability. Different types of ball valves can be replaced by each other (subject to compliance with safety regulations relating to the use of such structures).

- Tightness. The service life of a properly installed product is thirty or more years.

- Durability. The crane maintains about 25,000 operating cycles.

- The temperature of operation can vary from -40 to +200 degrees Celsius.

- The pressure maintained by such a construction is in the range of 1.6-4.0 MPa.

- Products are resistant to aggressive media.

- The probability of stagnation is absent.

- The throughput is 90-100 percent.

- There are models with a built-in filter.

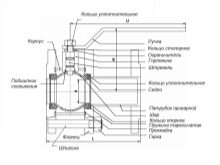

As for the design features, it is worth highlighting one important point.Ball locking mechanism can be "tied" to the supports. In other words, it is clamped by the trunnion and saddles. The more complex the device, the higher its price. Also the position can be floating. In this case, the pressure of water (or other substance) does not allow it to leak, pressing the element against the body ring.

Species

Ball locking mechanisms can be divided into several categories according to different parameters. Each of them, in turn, is also divided into several subspecies.

For the manufacture of valves using various metal alloys and polymers. The material of manufacture can be divided into 4 main types:

- brass;

- bronze;

- from a stainless steel;

- from carbon steel (lead in strength characteristics).

Depending on the type of pipeline, as well as on its design, choose one of four installation configurations.

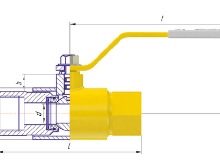

- Coupling installation. As the name implies, such products are threaded. It can be internal or external, as well as conical or cylindrical. This option is most popular in plumbing systems.

- Flange mounting. This type is used in cases when it is impossible to use a welding machine (for example, if there are communications nearby, for which the risk factor is sparks and elevated temperature).It is also used in the case when you need to quickly assemble, and then disassemble the structure. For the most part, flanged valves are used in production.

- Welded installation. This option is considered the most durable. It is also suitable when work is performed in hard to reach places.

- Combined installation. One of the most popular options. Such a valve can have both a thread and a flange or a surface suitable for welding. Combinations of fastenings in such options can be very different.

The following category is the principle of work:

- manual (opening / closing of the valve occurs manually);

- hydraulic (works by hydraulic pressure);

- pneumatic (works like a hydraulic drive);

- electric (driven by an electric motor).

View of the swivel mechanism:

- "Butterfly" - suitable for limited spaces;

- lever - if you want to use force.

Range

Now the market is represented by a lot of ball full bore valves of various sizes (from small household to huge production).

- The most popular models are steel. The minimum cost of such a crane in the online store is 174 rubles. The product is made of stainless steel, made in Italy. Model carving - 3/8. Weight is 70 grams. Connection type - coupling.

- Another option is the standard pass. Such products are also made in Italy. They are made of nickel-plated brass, have 1/2 thread. This option will cost you already 331 rubles. And its weight will be 210 grams.

- Flange A crane with a diameter of 76 millimeters and a weight of 17 kilograms will cost 3,250 rubles including VAT. The retail price of a flange valve with a diameter of 250 mm, made from steel and weighing 175 kg, is 106,000 rubles.

Video review ball valve STOUT see below.