Criteria for choosing a ball valve

Ball valves are widely used in various fields and are installed on all types of pipelines. In order to independently change such a device, it is necessary to understand its design.

Special features

The spherical crane is one of types of the locking system installed on pipelines. The crane got its name due to the presence of the main rotating part in the form of a ball.

Its design is simple and compact, it is distinguished by reliability in operation.

Domestic varieties are produced according to GOST and are characterized in it as a type of stop valves with a spherical plug, a hole in which ensures the passage of the working fluid and its regulation. Foreign counterparts use pipe diameter as a metric.

Kinds

The classification of ball valves depends on various criteria:

By type of housing

The all-welded crane has a cast steel body, does not disassemble, so there are fewer parts and lower cost. However, it cannot be repaired.

Collapsible type of products is easy to maintain, but more expensive and over time loses tightness, which requires constant maintenance.

In form

The direct option is the most common. In this case, both ends are located along the stream.

Angular modification is intended for connection in hard-to-reach places and pipe bends. In this case, the outputs are perpendicular.

By installation method

Threaded couplings are designed for pipes with a small diameter (up to 45 mm). Therefore, most often used for domestic needs: heating system and plumbing. They are simple, affordable, have a small size. However, over time, they become clogged with scale, which complicates their maintenance.

This design may be different depending on the thread of the coupling:

- the thread is located at both ends from the inside (vn-vn);

- at both ends from the outside (nar-nar), such a mechanism is called hoe;

- on the one hand internal, on the opposite external (vn-nar);

- on the one hand a cap nut ("American"), on the other - internal thread;

- choke type, in which choke fittings are screwed onto external threads on both sides.

Flanged ball valves are used for large diameter pipes. The name determines the regulating return flanges. They are characterized by the use of various seals that increase the tightness. Most often these compounds are used on high pressure oil and gas pipelines. They are mainly made of stainless steel or cast iron. Among the disadvantages, there is a decrease in airtightness during operation, “loosening” in places where bolts are tightened.

The welded products are fixed to the pipes by means of welding, therefore their repair is not possible. The all-welded crane is dismantled by cutting out a part of the pipeline, which is a minus of such a system. Material for production - steel and plastic.

As an advantage, you can highlight the maximum tightness of the connection.

By the coefficient of full pass

Full bore devices have a low drag coefficient.hydraulic loads. The diameter of the passage in products of this type coincides with the size of the hole in the ball part. Due to this, the load on the whole locking mechanism is reduced, the service life is increased, the reduction of water pressure during operation is eliminated. The throughput ratio is about 90%.

Standard bore (reduced) taps have an opening in the gate less than one size than the internal diameter of the pipe. At the same time throughput is reduced to 70 percent. Such products are installed in systems where a significant imbalance is not created when a head is lost.

Non-full bore systems have a passage that narrows in both directions, so they are characterized by increased hydraulic resistance. Throughput ranges from 40 to 70 percent. Such ball valves have different modifications, which differ in length and degree of permeability, are installed in communication systems, limiting the pressure.

By type of seal

The simplest type is butadiene rubber. It is used on household appliances.

Fluoroplastic or Teflon is used as a seal 99 percent of all manufactured products.It is a polymer that provides high-quality insulation of cold and hot water, steam, petroleum products, oils and natural gas. The maximum temperature range of use is from minus 40 to plus 200 degrees.

The metal-to-metal seal is produced for high temperature cranes. In this case, there are no soft layers between the body and the ball, however, to achieve high tightness in this case is quite difficult.

To destination

Regulators are designed to regulate fluid flow.

Underground cranes have an elongated stock, which allows you to adjust the flow from the outside when installing the device itself in underground communications.

Three-way, in contrast to other two-way products, have a more complex device, which leads to use in complex technological processes, in pressure and water indicators for temperature sensors, for example, heat meters.

Locking devices are necessary in order to completely block the flow of liquid or gas.

The area of destination - the main pipelines.

By type of management

The manual isolating mechanism is equipped with a butterfly handle.

Remote control type involves the use of different types of devices:

- the drive is powered by electricity, has the ability to emergency shut off the pipeline;

- pneumatic actuator is used in hazardous areas where sparks cannot be prevented, therefore, electrical analogues are not used.

Devices with a mechanical gearbox are mounted on pipes of large diameter and in those cases when it is necessary to achieve a smooth gradual flow.

Materials

The body material gives the name to the whole mechanism.

Brass faucet is most common and has been used for over a hundred years. Differs in high operational characteristics for water - and gas pipelines. Brass is resistant to various mechanical stress.

The disadvantages include the following factors:

- small diameter selection;

- small temperature range - for example, if the heating is about 200 degrees, then the tap can fail;

- the mechanism is not suitable for work on oil pipelines.

Some manufacturers use silumin instead of brass to reduce the price. First, they are required to warn about this in the annotations to the product.Secondly, you need to keep in mind that this material is fragile, so when repairing it is easy to damage. During the operation of the device microcracks may appear that cause leaks. It is best to install silumin valves on pipes with cold water.

Cast iron taps have almost disappeared from the shelves. They were actively used in the Soviet period until the 80s, and they had no analogues in quality. However, the development of industry led to the emergence of various types of steel, which had the same properties, but was cheaper. And the iron has faded into the background.

Steel faucets can be made of different types of steel:

- Carbon. Valves in a similar housing is widely used in housing and public utilities, as it is characterized by relatively low cost and wide range. Industrial use is limited to a temperature of -40 degrees, and cranes of this type cannot be used even on slightly aggressive media.

- Alloyed. The casing, made of alloyed steel grades, improves the properties of the above described analogues, extending the temperature range to -60 degrees. Otherwise they are identical.

- "Stainless steel." The locking systems enclosed in a stainless steel case are intended for use in production.

Of the advantages we can mention a large “run-up” on the temperature scale, high resistance to aggressive media.

Polypropylene valve is available for installation on plastic pipes. PVC products are characterized by lightness, durability and low price. However, they can be installed only on plastic pipelines, which limits the scope of application.

Shutter material also plays an important role.

The locking sphere must be absolutely smooth; for this, diamond polishing is used in production. The higher the quality of processing, the longer the service life, since the friction of the parts against each other is reduced.

Branded taps have a brass bolt, which is plated with nickel or chrome plated.

Cheaper options are made of metal, but it can be used for a short time in a humid environment and will rust over time. To determine the fake, use a magnet. He does not attract brass. It is extremely important that the spherical valve is insulated, preferably chrome-plated.

If the valve is made of plastic, then the ball stop mechanism will be made of high-strength PVC.

Also one of the known materials for the ball is ceramics.Ceramic valves are characterized by increased resistance to wear, absolutely not subject to corrosion.

For the protective coating, as a rule, chromium or nickel is used, which are applied by electroplating. However, there is a difficulty in applying the coating directly to brass, therefore, between the gate material and chromium have a substrate of copper or nickel. Thus, a high degree of protection is achieved. Some manufacturers cover the ball with teflon, but experience has shown that for these purposes the material is not suitable, because it has a low resistance for environments with mechanical inclusions.

Sealing saddles for the stopper mechanism are made from different materials. Most often it is rubber, nylon, teflon, polyester, polyethylene, bronze. The choice of seals is carried out depending on the conditions of use of the locking device.

Metal seats are suitable for pressure drops in pipelines and the presence of abrasive media. Graphite and polyamide will be effective for high temperature operation.

Fluoroplast can be used both in pure form and with glass or graphite fillers,and with the addition of metal powder. Such saddles provide a high degree of tightness and are resistant to wear. Another name for Teflon is PTFE.

Recently, it has almost supplanted other materials due to its universal characteristics, and the additives additionally expand their range.

Here are some of them:

- fiberglass increases strength and gives chemical resistance;

- carbon fiber gives the properties of electrical conductivity and resistance to deformation;

- bronze lowers chemical resistance;

- thermoplastics increase wear resistance, supereficiency, abrasivity disappears.

In addition, the thickness of the Teflon seals can be quite small while maintaining all the characteristics.

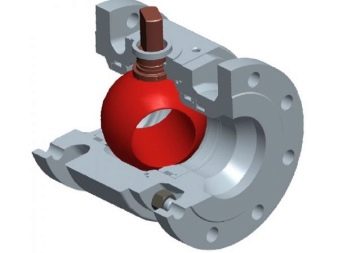

Device

The design of the ball valve does not have unnecessary parts, it is very simple, therefore reliable. The main element is a constipation in the form of a chrome-plated ball, which has a hole along one axis. The size of this part depends on the diameter of the pipe. If the hole is turned along the pipe, then the flow of liquid or gas occurs, if perpendicular, the flow is blocked.The shutter is always located in the center of the housing between the two seals in the form of rings. They are called "saddles." The ball lock is mounted on a pivot stem with a cantilever lever for adjusting with a butterfly-type handle.

The main details of a simple ball mechanism:

- Housing The outer shell of the locking system can be made of several types of alloys: brass, carbon or alloyed steel, stainless steel, cast iron, polypropylene. The highest quality brass models are considered.

- The handle is usually made of metal, covered for convenience with plastic or rubber. Moreover, experts decided to use colors to designate the purpose of the crane. So, the red handle says about the flow of hot water, blue - cold. Yellow and black tint are used for gas pipelines.

- The self-locking nut is also made from steel coated with chromium.

- Stock with oil seal. If the body is made of brass, then the rod will be of the same material, coated with nickel as protection against oxidation. The gland seals can be made of butadiene rubber or heat-resistant teflon.

- Ball shutter, the ideal form of which is achieved by diamond polishing. Chrome plating allows not only to provide protection against corrosion, but also a good move when turning.

- Seals for the ball (saddle) are made of plastic of different types.

The design of the shutter is of two types:

- With a floating ball. In this case, the ball element does not rigidly connect with the rod, but moves. Under the pressure of the incoming flow, the valve is pressed against the seal ring and closes the pipeline.

The design is simple, but can only be used on pipes of small diameter, since the increased pressure in large water pipelines makes the mechanism difficult to operate.

- With a ball in the supports. Spherical bolt rotates inside the special supports. In this case, the ball element is provided with a protrusion-pin, which provides additional pressure density. As a result, less effort is applied even when used on high-powered installations. In connection with the complex design of these cranes are much higher.

Depending on the number of working positions of the device is divided into two-way and three-way.

Two-way valve - the simplest type of locking mechanism. It is considered the most reliable and safe. The main parts are the body, the locking valve and the connecting pipes. Depending on the shape of the shutter, two-way valves are spherical, cylindrical and conical. The specified device is not designed to partially overlap the workflow, only “on” and “off”. Most often for control of such crane there is enough handle-lever with two possible positions.

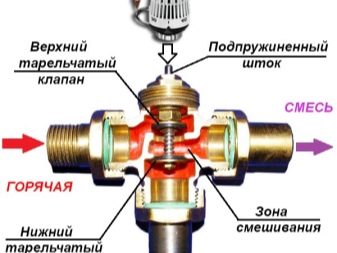

If it is necessary to divide or connect the working streams of different temperatures and be able to regulate different indicators, it is better to use three-way valves.

The mixer externally is a faucet with three connections: two inlets for receiving different streams, one outlet for the outgoing mixed heat carrier.

The adjusting sector is located inside the mechanism and allows not only mixing, but also regulating the temperature and force of the flow. Depending on the principle of control, three-way valves are manual, electric, pneumatic and specialized, for example, thermostatic.

For manual control, rotary knobs-valves are installed, they can be used to regulate the flow and force of the flow. The main disadvantage is uneven heating of areas remote from the carrier, for example, heating batteries.

Automatic cranes have a prefix in the form of a drive, whose main task is to adjust the temperature of the outgoing flow. The principle of operation is based on the use of sensors that measure the temperature and, in case of its decrease, give a signal to the control unit to turn on the electric motor. The latter regulates the incoming flows so that the temperature regime is aligned to the required level.

Thermostatic options are used in their control system thermostat, which plays the role of gas.

Sometimes a specialized fluid takes its place. For this purpose, a cavity is provided inside the check valve where the specified substance is placed. As the temperature rises, it expands, pushing the shut-off valve. The device requires careful tuning and constant prophylaxis. The three-way thermostatic faucet is highly sensitive because it reacts even to minor temperature changes.

In separators, unlike mixers, there is one inlet and two outlets. They are used in such circuits where it is necessary to redirect the flow from one system to another.

Welded valve is a type of ball valve with the simplest fastening system using welding.

They have a low cost, do not require maintenance, and are easy to install, so the demand for them remains high. In addition, in the absence of collapsible fittings tightness at the highest level.

The design of the shutter consists of the following elements.

- steel case;

- locking ball;

- handle in the form of a lever or valve;

- connections without threads, the ends of which are welded to the pipes.

The quality of welding is provided by the metals that are used to manufacture the hull.

The undoubted advantages of the design compared with other modifications of ball valves are the following factors:

- small weight;

- low cost;

- easy installation;

- no stagnant zones during operation;

- high degree of tightness;

- use in hard to reach places;

- no need for prevention.

Available disadvantages:

- repair is impossible, only complete replacement;

- the possibility of water hammer with a sharp opening;

- It is not always possible to use welding.

When installing, welding should be carried out carefully so as not to damage the spherical valve and seal rings.

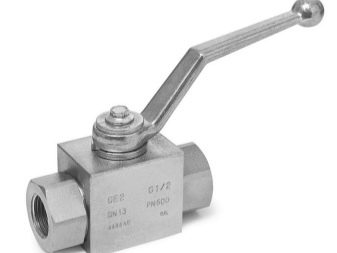

Coupling variation ball valve is connected to the pipeline through couplings with internal cylindrical or internal tapered threads.

Such types of fastenings are more often used:

- NN - thread at the inlet and outlet outer;

- HB - one nozzle has an external thread, the other - internal;

- BB - and the inlet and outlet connections are provided with an internal thread.

Since this modification has a small nominal characteristics, it is mainly used in utility systems and in everyday life.

It is impossible to install a coupling valve if the working medium temperature is about 100 degrees, the pressure is about 16 bar, and the pipe section is more than 100 millimeters.

For throughput such cranes are standard and full bore.

Similar designs of locking mechanisms are notable for low price, compact size, low hydraulic resistance.It is possible to install them in any position and flow in any direction. However, it must be borne in mind that if you open the valve too quickly, you can get a water hammer, which will lead to breakage.

The ball valve with a fitting is installed on various technological industrial lines: oil and gas processing, chemical, food, cellulose and others, which are characterized by environments with a high degree of aggressiveness.

This design differs in reliability, compactness and wear resistance. The convenience of cranes is that they can be repeatedly reinstalled and repaired. Therefore, they are an important element of various complex devices and machines.

The main difference between choke cranes from other modifications is that the nozzles have an external thread. Therefore, the fastener to the pipe is carried out using a cap nut.

One of the varieties is the choke-nipple design of the ball valve. Welded nipples are usually included with the purchase. These parts provide the ability to quickly reinstall and ensure smooth pipeline operation.

Fitting cranes not only regulate the working flows, but can also play the role of an adapter between pipes made of different materials, for example steel and plastic.

The design feature of the ball valve is the fastening of the bolt using a special system of clamps and gaskets. At installation the preliminary axial centering is necessary. Reliability and tightness is achieved by evenly tightening the bolts around the perimeter of the flanges. All flange designs are designed to work under heavy loads.

Like any other modification of ball valves, this type happens with a collapsible and cast body is classified into manual and automatic, depending on the method of control, divided into full bore and standard bore types in terms of throughput coefficient.

Ball valves with flanges are not designed to adjust the work flow, they are two-way, that is, they perform a complete closure or opening of the passage in the pipe.

It is necessary to carry out maintenance work regularly, at least 4 times a year, which will increase the life of the product and control the level of tightening of the bolts on the flanges.

When working continuously in one position, it is necessary to switch on the other mode from time to time, thus avoiding deposits on the ball valve surface.

Among the many advantages of flange connections are the following:

- Reliability due to which similar designs of locking devices are installed mainly for industrial purposes. In addition to prevention, they do not require other maintenance for many years.

- Maximum overlap of the workflow.

- Low hydraulic resistance.

- Installation in any position: vertical or horizontal.

- Wide range of diameters.

- Long operational life.

Among the disadvantages are the following factors:

- big weight in comparison with other analogs of spherical cranes;

- Flanged valves are not recommended for use in environments with solid impurities, as they cause abrasion of the suspension;

- should not be used for working with viscous working streams that form sediment causing shutter failure.

For sophisticated household appliances such as dishwashers, filter balls are used., which are designed to prevent the ingress of solid particles inside the expensive equipment to protect it from damage.

In fact, filter taps have an extensive scope. According to the type of filtering element, two types of locking devices can be distinguished: coarse and fine cleaning.

A coarse filter protects the system from solid particulate matter. Therefore, a ball valve with such a filter element is installed on water pipes and complex technical structures to protect against various oxidation products and mineral deposits. Outwardly, such a mechanism is a conventional crane, into which a fine-grained mesh is inserted. The cartridge may be replaceable, otherwise it is necessary to disassemble and clean the entire mechanism.

Fine locking products more expensivetherefore, they are recommended to be used only for systems that supply drinking water. The design implies a built-in filter cassette that requires regular replacement.

Recently, Finnish-type mixers have become popular. They are able to regulate not only the temperature of the water, but also its pressure. Their design refers to the type of "American."

This type of gate allows you to insert, without rotating the pipe itself. To do this, the design provides cap nuts and fitting. Thus, the axial clamp allows only two locknuts to mutually rotate, fixedly securing the valve in place. The cap fittings inside have gaskets to ensure the tightness of the structure.

Since leakage in such mechanisms is minimized, they are used in counters to obtain accurate readings.

Valves for heating systems differ from others in that they need a separate outlet for air. Mayevsky's crane is supplied for this purpose with a special valve. In GOST, the specified type of locking devices is designated as a radiator needle air valve.

Its most important structural difference from other mechanisms is the presence of a special air vent, the principle of which is based on the spontaneous release of air when the valve is opened. A feature of this type of shutter is a needle valve.

As a starting material for the manufacture of cranes, as a rule, brass is chosen.Separate elements, for example, a cap of an air valve, are made of high-temperature plastic.

The main parts are standard: body, threaded rod, O-ring. A distinctive element is the air cap.

The screw rod with the needle part is usually screwed into the hole to the limit. When airing the system, it must be unscrewed several turns to open the air valve. The density of air is lower than the density of water, so it comes out first. As soon as it starts to squeeze out the water, the tap closes. The procedure can be repeated several times.

Adjustment methods can be manual and automatic. The latter differ in the ability to install only in a vertical position. This is due to the presence of the float mechanism inside the cylindrical body.

The float is interconnected with the needle rod by means of levers. The entrance to the crane is provided at the bottom. The stem acts as a valve, closing the top outlet if necessary.

If there is liquid inside the mechanism, it presses the valve, blocking the outlet. As soon as air gets inside, the pressure weakens and the valve opens,letting the air out. After the air bubble exits, everything returns to its place, the tap closes.

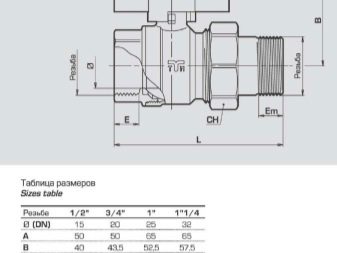

Dimensions

Dimensions of cranes are indicated on the basis of the internal diameter of the passage in the pipeline. The unit of measurement in domestic products is millimeter, for foreign analogs - inch. To go from one measurement system to another, it’s enough to remember that 1 inch = 25.4 mm.

When choosing a locking mechanism, it must be remembered that the indicated size of plastic and metal pipes is different even if they are the same.

The reason for the differences is that PVC pipes are measured by the external diameter, and steel analogs by the internal diameter.

The size and purpose of use depends on the size:

- Cranes with a diameter of 25, 32 and 40 mm (1, 25 and 1.5 inches respectively) are designed for infrequent use, and they are contraindicated for constant loads.

- Small size is appropriate for household appliances. Thus, a diameter of 15 mm (0.5 inches) is suitable for water supply systems, and 20 mm (0.75 inches) for heating circuits equipped with a circular pump.

- If the circulation of the working stream in the system is naturally caused, then pipes of a larger diameter are used, and hence taps corresponding to their parameters (from 50 to 75 mm).

- In production and in industrial systems there are different sizes up to 200 mm.

Dimensions of ball valves are set by the State Standard and are measured only in millimeters.

A parameter such as length is a value equal to the length of the pipe section, which will be replaced by a locking device. In other words, it is the distance from one end of the crane to the other.

Accordingly, the building height is the distance between the upper and lower points of the device.

The design of any pipeline must take into account the dimensions of the locking mechanisms. They must not only correspond to the diameter of the pipe and the working medium that passes through the system, but also provide free access to the valve for replacement and maintenance.

Dimensional characteristics also include the type of internal (in the form of a nut) and external (in the form of a bolt) thread. The latter type is also called choke.

The main thread parameters are diameter, depth and pitch.

The shape of the thread in the cranes is conical and cylindrical. The usual metric cylindrical shape is indicated in the metric by the letter M indicating the diameter, for example, M56.For fine thread add the size of the step (M5x2). Left-side cutting is designated by letters LH, also supplement marking with a class of accuracy.

Metric tapered threading is denoted by MK, all other parameters are similar to the above modification.

Most often in spherical cranes pipe cutting is used. Cylindrical is marked with G. Next to the letter indicate the value of the nominal diameter of the thread, expressed in inches, the accuracy class and the length of screwing. The conic is denoted by R. The literal combination Rc is used to characterize the internal thread.

If there is a trapezoidal thread, the marking will be Tr, followed by the nominal diameter in mm, pitch, direction (right / left) and accuracy class. Thrust (S) thread is less common in ball valves.

The size of the crane is influenced by its throughput and the permitted pressure of the working medium.

The maximum allowable working pressure is the most important criterion when creating any communication system using ball valves, which is measured in atmospheres or in pascals (Pa).The unit of measurement in 1 atmosphere is 1 bar.

Thus, for a domestic water supply system, a pressure of about 10 bar is typical for cold water supply, 20 bar for hot water.

Since overloads are possible in any design, this should be taken into account when choosing cranes and laying down a safety margin of half the nominal value. This will help avoid leakage due to water hammering that occurs in the centralized water supply circuit.

On the label pressure is indicated as follows:

- Nominal pressure - the maximum allowable value for the operation of the crane. It is denoted by the letters PN or "Ru". The latter was applied on products manufactured in the countries of the Soviet period and was regulated by GOST 26349-84.

- Test pressure is an overpressure at which the locking device is tested for strength, durability and density in the extreme temperature range. Denoted by "Rpr" and set GOST 356-80.

- The working pressure ensures the operation of the ball valve in a given mode. On the label indicated "RR".

The dependence of the working pressure on its nominal value, the temperature regime of the working stream and the material from which the valve is made is regulated in GOST 356-80.

Scope of application

The scope of ball valves is extensive:

- transportation of industrial liquids and gases through pipelines over long and near distances, for example, oil, natural gas or oils;

- the organization of branches from the main water supply system or any other;

- water supply and heating systems;

- drains;

- hydrants, including firefighters;

- appliances from washing machine to steam generator.

In the modern world, the installation of ball valves is not difficult even for ordinary citizens, with the exception of more complex modifications.

To last a long life, you must follow the rules specified in the instructions. It is important to correctly select the locking device for the functional parameters of the communication system.

Operating conditions dictate the choice of material from which the mechanisms are made, construction dimensions, allowable pressure, temperature mode of use, method of attachment.

So, for large cross-section pipelines, in which the working medium exerts a significant load on the valve, it is preferable to use valves with flanges.They will provide a high degree of tightness and reliability. For greater strength use special seals. A particular case of the use of such ball mechanisms are oil and gas pipelines. Moreover, in difficult areas where super-reliability is necessary, flange devices are installed in a molded case.

Fitting analogues are widely used in the chemical and food industries. Since they are under the constant influence of aggressive media, they have to be dismantled more often. A choke mount allows you to do this many times.

In the construction of using such types of ball valves, as welded. They are installed in tight, closed places, meaning that they will not be dismantled.

For domestic use, all modifications of the locking devices corresponding to small-diameter pipes are used. They are installed in communication systems, household technical devices: washing machines and dishwashers, water and gas meters, drinking water taps, heating batteries. Mixer-type taps are widespread, almost all use a coarse filter.

Manufacturers

Until recently, all high-quality ball locking devices were manufactured by foreign manufacturers. They were more durable and better than their domestic counterparts. To increase the competitiveness of Russian products, it was necessary to revise the structure of production and develop an effective communication system, apply new developments in various fields of science and technology.

First of all, it was necessary to upgrade the production metalworking equipment. In addition, use the development in the field of polymer coatings. To increase the quality characteristics of seals, production workers connect scientific and technical specialists in the field of chemistry.

The state went to meet the domestic manufacturers of ball structures. It subsidizes an increase in production capacity, thanks to which domestic analogues of ball closures have entered the market, having overcome a hard price barrier.

Foreign manufacturers have achieved significant success due to high quality control and automation of processes.

Russian plants are just starting automation.

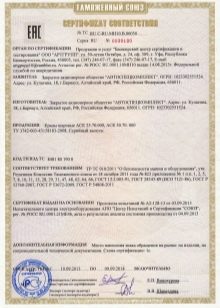

Now many Russian firms for the production of ball valves continue to develop quality control systems, for which enterprises create their own scientific bases with the assistance of qualified specialists. Technical centers equipped with precision numerical control devices are used. All these measures are designed to reduce the percentage of marriage and bring domestic producers to a new level of quality control. At the moment, the products are certified according to GOST, have international certificates.

Since the main raw material is mined and processed in Russia, it is possible to minimize costs and keep competitive prices.

Thanks to all of the above factors, manufacturers of ball valves appeared in Russia, the quality of which is not inferior to imported counterparts, and the cost allows competing in the global market.

Mass consumer of ball valves is industryIn particular, the largest companies in the following areas: oil and gas, chemical, pulp and paper, construction. Shut-off ball structures of domestic production of steel to replace imported counterparts on major pipelines.

To date, bona fide manufacturers of ball locking systems are accredited in industry reference books of Russia.

Russian company with a trademark Dinamika located in the city of Kazan.

Its main activity is the development and production of valves for the following areas:

- pipes for various purposes, including trunk pipes;

- environmental monitoring systems;

- instrumentation as part of high-pressure impulse lines.

The company has its own material, production, scientific, technical and logistic base. Due to this, domestic raw materials and components, as well as own developments are used in production. Therefore, the company has the ability to control purchase prices and offer favorable conditions for buyers.

Main products:

- Stopcocks

- flanged shut-off valves of different diameters and nominally acceptable parameters;

- needle valves.

- Ball Valves

- Flanged taps - designed for pipelines with a diameter of 15 to 200 mm.

- Coupling. The versions with manual control and internal thread are designed for a working pressure of 1.6 to 16 MPa,represented by diameters from 15 to 100 mm. In addition, there are models with an additional outlet for connecting to a pressure gauge.

- For welding. Devices are demanded on common industrial lines with a diameter of pipes from 15 to 200 mm, installed on a long-term basis.

- Fittings. Cranes with manual control and external thread have several variations according to the type of installation: welded, with clamps. They are designed for pipes of small section (up to 20 mm).

They are more often used in measuring systems and devices for selection.

It also produces wedge valves, check valves, selection devices, flanges and components.

Ball valves are represented by the widest range in the range of all the company's products. In particular, industrial analogues are designed for operating pressures up to 160 bar. Full bore modifications are developed for sections up to 200 mm.

At the moment, the general characteristics of Dinamika products are as follows:

- tightness of a class "A";

- nominal diameter from 15 to 200 mm, for reduced structures (non-full-pass) up to 250 mm;

- conditional pressure is from 1.6 to 160 MPa (in particular, 16, 25, 40, 63,100);

- working environment: oil, gas, salt solutions, hydrocarbons in the form of liquid or gas, water and steam;

- the temperature limit of the working environment is up to 200 degrees, with individual development it is possible up to 500 degrees;

- climatic temperature range for operation - from -60 to +40 degrees;

- steel used for hull st. 20, 35, 40, 09Г2С, 12Х18Н10Т;

- for individual orders are made acid-resistant cranes using molybdenum in the alloy.

All products are certified, undergo pressure testing, have a technical passport, corresponds to GOST.

In addition to development and production, the company provides all logistics communications from order to delivery.

LLC Research and Production Enterprise GKS - an enterprise whose production facilities are located in the city of Dolgoprudny. The company was established in 2004 as a production of reliable locking structures for the oil and gas industry and energy. Competitiveness is ensured not only by the release of products, the company is engaged in its own developments in the field of improving the quality characteristics of ball valves.

Ball valves and components are tested for testing on special stands according to approved programs.The quality of welds is checked by non-destructive methods of control, which have been certified by Gazprom and Transneft. Quality control complies with the requirements of GOST and international API standards. Own development have patents of the Russian Federation. All products are certified.

All welding specialists working at the enterprise are certified by the Gosgortekhnadzor.

Designers have extensive experience and have the opportunity to regularly upgrade their skills.

General characteristics of the products:

- Diameter - from 6 to 700 mm.

- Pressure up to 32 MPa. Today, the company produces unique types of ball locking devices that have no analogues in Russia, designed for pressures of 25 and 32 MPa.

Main products:

- ball clutch locking devices;

- choke-nipple modifications;

- flange taps;

- all-welded bolts.

The company has launched serial production of the following types of ball locking devices:

- ball valves with heating;

- taps with leakage control;

- three-way modifications;

- individual orders in the sizes and conditions of the customer.

For example, for the energy industry, the company launched the production of needle valves that have unique operating characteristics: pressure of 32 MPa, medium temperature - 450 degrees.

Production is designed for any climate and different types of working environment. All products are made of stainless steel, in individual cases from other grades of metal. For seals used high-quality elastomers: different types of fluoroplastics or rubber.

For automatic control, the taps are equipped with the following devices:

- worm gearboxes;

- electric drives;

- pneumatic actuators;

- hydraulic actuators.

In Russia, there are several more plants producing ball valves.

Some of them:

- Berd Electromechanical Plant. The company from the Novosibirsk region produces a wide range of various products, including ball valves.

- Ust-Katavsky Carriage Works (UKVZ) is located in the Chelyabinsk region. In addition to the main products associated with cars, produces various types of ball valves: coupling, flange, gas pressure regulators.

- Semenovskiy Foundry-Mechanical Plant has production facilities in the Nizhny Novgorod Region. Products are focused on the oil and gas industry and utilities. In addition to steel bolts, produces cast iron cranes.

- Kstovsky Pipe Plant operates in the Nizhny Novgorod region. Ball valves, which are manufactured by the company, are used in household communication circuits: water supply, heating, sewage, gas pipeline.

The material used is PVC, steel and cast iron.

- Ural Pipe Fittings Plant, located in Chelyabinsk, sells ball valves for liquids and gases, which are mainly used in the oil and gas industry.

- PKF "Ex-Form" (Saratov). Has patents on the developed gas spherical cranes. The congestion is designed for the following operating parameters: diameter from 15 to 100 mm, pressure from 1.5 to 2.5 MPa, working medium - liquid or gas, flow temperature - from -30 to +50 degrees, ambient temperature range - from - 60 to +45 degrees. Modifications are presented in five versions according to the type of fastening (clutch, flange, choke, welded, interflange) and two according to climatic conditions (moderate, cold). The products are characterized by a long service life (up to 30 years), an ideal geometry of a spherical gate, a corundum coating of the ball, resistant to corrosion. Ball valves have an A tightness class.Electric drives are used as automatic regulators.

Tips

Today, the sanitary market offers a wide range of ball valves for domestic use. Accordingly, substandard options have appeared that need to be learned to identify when buying.

To do this, use the advice of professionals:

- Before buying a ball locking device, carefully examine the place of its installation. It is necessary to find out the diameter of the pipeline, the type of thread.

- When buying, first of all pay attention to the accompanying documents: certificates of quality, warranty, technical passport.

- If you buy a metal bolt, it is better to make sure the quality of steel. If you get silumin, because it is cheaper than analogs, keep in mind that it is fragile, requires careful care and is only suitable for cold water.

- When buying plastic taps, it is better to purchase them with pipes so that the plastic is of the same brand and from one trusted manufacturer.

- The thread on the nozzles must have at least 5 turns for reliable connection.

- A perfectly flat chrome-plated or nickel-plated slide ball guarantees high quality.

- Reputable certified companies label products as clearly as possible.

Vague markings indicate that this is a fake or the manufacturer saves on casting molds, so they are already worn out.

- Communication systems have different characteristics, so ball valves for them are different. One of the important indicators is the allowable working pressure. Usually, 10 bar is enough for cold water supply, whereas for hot water it is from 20. Experts advise to install valves with a working pressure slightly higher than the allowable pressure in order to avoid breakage during a sudden hydraulic shock.

- Thermal insulation in houses is provided by heating circuits. They have a high temperature of the working medium, the pressure of which exerts substantial loads. To avoid leaks, it is recommended to use high-quality O-rings, for example, from heat-resistant Teflon.

About what to look for when buying a ball valve, see the following video.