Technical characteristics of ball flange valves

To date, ball valves are used in different piping systems. They are indispensable helpers when it is urgent to close the pipeline chain. The product is useful for plumbing and allows you not only to redirect the flow of water, gas, but also to block the desired area. To buy really the right kind of such a device, you need to know its technical characteristics.

Special features

Externally, the device ball valve is no different complexity. These valves are similar to two circular discs with a cylindrical mount and a tap. The part has a fixed body, as well as a rotating part (ball). Classification is carried out in two ways, such as:

- type of working medium - for liquid, gas, steam;

- installation method.

Typically, such a crane is attached to the flanges, due to which the connection is reliable. The ball flange valve is easy to use and versatile. For this reason, he successfully replaced the valves. In addition, the flange taps by type of attachment are muftovymi, welded and choke. They are used in the installation of pipelines and gas pipelines, highways of oil environments, oil pipelines, cooling systems and highways of compressed air. In addition, such devices are indispensable in agriculture, food, chemical industry and shipbuilding.

Due to the strong interflange connection, they ensure the tightness of fasteners with the main pipe. Their distinguishing feature is the ease of dismantling if necessary. The size of the products is different, which allows the use of these devices in different pipelines.

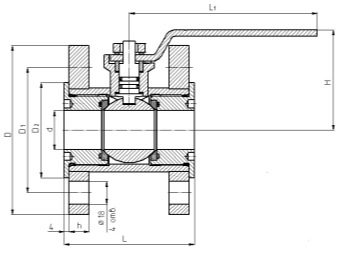

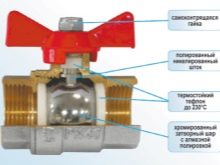

The central component of such a product is the ball-bolt. Inside it usually has a hole in the form of a circle or square. The shutter itself is fixed inside the case through a certain combination of fasteners and gaskets. It has a connection with a lever, thereby ensuring control of the flow of the working medium of the pipeline system.The crane has two positions: open and closed.

Specifications

The design of these devices are subject to GOST. The standards clearly spell out all the technical characteristics of such devices. Tightness usually corresponds to type A. The range of diameter of cranes varies from 15 to 1400 mm. The conditional pass of the devices is different. In the rulers of well-known trademarks, you can see products with a nominal diameter or a conditional passage, for example, the DN of 40, 50, 65, 80, 100, 150 mm.

The highest demand among customers enjoys a variety of 50 mm and more. With a small value of the diameter of the ball is called floating (DN 25, 32). When this figure exceeds 50 mm, the ball is sealed on supports. The weight of the product on average is about 13 kg. PN is the nominal (maximum) pressure of the working medium at which the operation of the crane is possible. It usually ranges from 1.6 to 4 MPa. The building length of such products may be 102, 254, 356, 533, 850, 914 mm, with a slight deviation in length of up to 2–8 mm.

The degree of passage of the working medium determines the type of crane. It can be incomplete if it misses up to 50% of the total.

Classical or standard versions miss about 70-80% of the working environment. Full bore analogues provide transmission of substances up to 90%. Products are suitable for the vertical and horizontal direction of the pipeline.

Typically, manufacturers indicate on the crane marking with the designations of its type, type, conditional passage, pressure and standard. Example: the crane is marked with a KS label. F. 500-2500 GOST 28908-91. In this case, the marking indicates the following:

- KSH - ball valve;

- F - flange;

- conditional passage 500 mm;

- pressure 2500 MPa;

- parameters GOST 28908-91.

Knowledge of the marking will make it possible to accurately buy a device for specific needs. The disadvantages of ball flange valves are a lot of weight and not always the appropriate length of the handles in the manual type of models.

In addition, customers note that not all products meet the requirements stated in GOST, which is reflected in the low quality of individual products. This is due to the presence on the shelves of counterfeit goods from low-quality metal. This causes poor performance and a short service life. In addition, in comparison with other analogues, flanged ball valves cost more.

There are limitations: they can not be used in pipelines, the fluid flow of which has impurities of solid particles. This leads to abrasion of the chassis, and then the formation of leaks.

It is undesirable to use such devices in pipelines with oozy liquid. Accumulation of sediment will quickly lead to breakage of the crane and failure of its operation.

Kinds

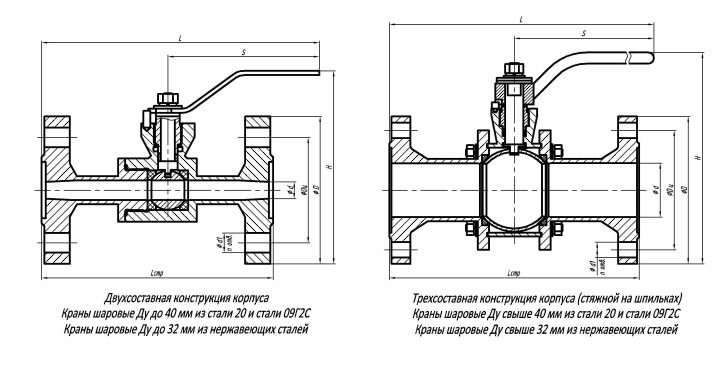

Depending on the different values of the diameter of the products the ball flange valves are different. They have a different body, which can be two- and three-part. However, the design of the case may not only be collapsible. Most of the market is occupied by all-welded cranes. Collapsible analogues are different in that the worn parts in them can be updated. This allows you to extend the service life of products up to several years.

Disassembly of such products is simple and does not take much time. The material of manufacture of all varieties is stainless steel. It is resistant to corrosion, while the ball valve in the products of foreign companies may be hollow inside. The class of drive used in the device is also different. The gearbox can be manual or electric, requiring the presence of auxiliary supports. In addition, the drive may be pneumatic.

According to the material of manufacture today such products can be not only steel. On the shelves of shops you can bathe products made from materials such as:

- cast iron;

- bronze;

- brass.

The best types of products are steel versions of stainless steel devices with a locking mechanism that regulates the flow of the working medium up to 80%.

Manufacturers

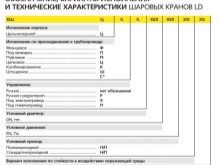

In the modern market for similar products, many flanged ball valves are offered to the attention of customers. According to the consumer’s assessment, shut-off valves of the following companies can be called noteworthy:

- Broen;

- LD;

- DZT;

- Naval;

- Danfoss Jip FF.

These versions of cranes are able to completely block the substance that enters through the pipeline. For example, Naval products have an all-welded body. The product is easy and easy to use. Due to the high density it is not afraid of pressure drops. Thanks to the removable handle, it is possible to change its position by 180 degrees.

Other options may be flanged, welded or threaded. Choose these products due to the fact that they significantly reduce hydraulic losses. Devices withstand temperatures up to 250 degrees.Their installation is carried out taking into account counter flanges with certain parameters of diameters, fasteners and gaskets. The connecting sizes submit to GOST 12815.

Tips

Sometimes you can hear the term "ball valve under the valve." This means that the values of the construction lengths of the crane itself and the valve are consistent. The explanation you need to know in order to choose the right product when buying. Thus, the length of the crane KS F DN 50, 80 and 100 corresponds to the lengths of valves steel 30s41nzh ZKL-2 31s31nzh ZKL-W 31s38nzh, 30s41p ZKS, SIC and the lengths of valves iron 30ch6br, 31ch6br, 31ch7bk, 31ch17br, 31ch16br, 31ch12nzh , 31ч11нж and ЗКВШ, characterized by the same diameters. Usually the length corresponds to the European standard DIN.

Installation of the crane is simple. Prior to this, conduct a full revision of the device. It is important to exclude any damage to the system. In addition, the crane must be checked for alignment. The same applies to the pipeline itself.

During the work use interflange seals. In addition, before installation can not do without checking the axial alignment. It is important that the bolts are screwed evenly around the perimeter. With regards to the use of the product, it is necessary to systematically perform inspection It does not matter what kind of crane purchased.If you ignore this aspect, you can prevent leakage.

Several factors affect the frequency of inspection. One of the most significant is the working medium itself (liquid or gas inside the pipeline). However, regardless of this check is carried out at least 1 time in six months of operation of the ball valve. In addition, it is necessary to take into account an important nuance: the crane should not be permanently in one position. Periodic change of position will prevent the formation of deposits on the surface and will increase the service life of the product. The frequency of such work is about 2-4 times a year.

The last factor that determines the quality of the crane, is to buy in a proven store, it is important to ask the seller for a certificate confirming the conformity of the goods to the stated standards of GOST.

See a video review of the ball flange valve below.