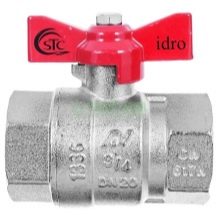

Ball Coupling Cranes: Varieties and Their Characteristics

When carrying out and operating any hydraulic system, cranes are used to control it. Ball clutch valves - one of the types of such equipment. They are well established and are very popular for convenient and easy operation, combined with high reliability and affordability. Ball valves are divided into various types according to their purpose, specificity of couplings, material of manufacture, type of closure and other parameters.After a detailed acquaintance with their features, the selection of the necessary crane will not cause any particular complications.

Special features

Specificity of ball valves in the application of a spherical chamber and a locking plug, which has a throughput hole and when rotated 90 degrees, takes one of two positions: open or closed. Material manufacturing ball varies, can be used brass, bronze, steel and polypropylene. The choice of crane material depends on the specifics of a particular hydraulic system.

The main components of the ball coupling are:

- product case;

- sealing gaskets;

- control mechanism:

- lever arm;

- valve;

- electronics;

- spherical stop cap;

- axial screw;

- stock;

- sealing spheres.

Positive and negative features of clutch valves

Ball clutch valves have excellent performance, which affected their popularity and widespread use. The following can be attributed to their positive characteristics:

- a huge operational resource, ball valves are designed for 5 years of continuous use, which ranges from 20 to 25 thousand openings / closures;

- compact size and a wide choice of products with different specificities allow you to choose a crane for any needs and use in the most unpretentious conditions with high convenience;

- high reliability - cranes provide full tightness;

- low weight - due to the compact size of the product does not require a significant amount of material for its production;

- resistance to corrosion processes;

- high flow rate overlap, especially in console type with a handle;

- do not need constant maintenance, can work for a long period without lubrication;

- operating temperature range ranges from - 50 to + 200 degrees;

- small coefficient of hydraulic resistance;

- for the production of a ball valve does not need a lot of material, which makes the price / benefit ratio of use even higher;

- can be used with various types of liquids, including highly polluted, viscous, suspensions and pulps;

- a simple structure makes it possible to independently purchase a part and make a replacement;

- does not create a zone of stagnation.

But also ball valves have their weaknesses, the following can be added to them:

- a relative disadvantage is the presence of a very long and massive stock, which can cause inconvenience in tight conditions;

- the valve requires a smooth opening, otherwise a hydraulic shock may occur at high pressure;

- cannot be used in a heating system with a working temperature of more than 150 ° C and a pressure of 1.6 MPa;

- salt deposits may form that complicate the operation of the crane in the future;

- in case of poor quality it is very likely that the ball cap is clogged;

- small particles of sand and rust that are present in worn waterways, can damage the ball, resulting in a sealed tightness in the closed state;

- low-cost versions of the ball valve often give a leak for a short time after the start of operation;

- when used on a cold water main, the positive temperature must be maintained, otherwise the water will freeze and the valve will break.

Kinds

Depending on different parameters, clutch ball products are classified.

By type of threaded connectors

Depending on the specifics of the threaded couplings (“input” or “initial”), there are several types of taps, namely:

- "Inner-inner", on such a crane, both couplings have an internal inlet thread, used for installation of pumping stations;

- "Inner-outer", on one side of such a tap is an internal inlet thread, on the second - an external initial thread, supplemented with a cap nut;

- "Outdoor-outdoor", on both sides of the valve, an external original thread is applied to the couplings.

Bandwidth

Depending on the diameter of the hole in the ball valve, the ability of the crane to fluid through the hydraulic system varies without weakening the flow or with a certain decrease. There are three types:

- Full bore. The bore hole is as close as possible to the parameter of the pipe on which the stop valves are mounted. Reduced fluid flow in the range from 1 to 10%. The main field of application is domestic water supply systems.

- Reduced. In such a product, the diameter of the bore hole is smaller than the main line. Flow reduction ranges from 10 to 30%. Installed in places where the reduction in flow is not significant, or a slight decrease is necessary for certain reasons.

- Impassable The bore hole has a much smaller diameter than the main line. Flow reduction ranges from 30 to 60%.

Used when necessary to significantly reduce the flow, mainly for industrial purposes.

On the device of the locking mechanism

Depending on the fastening system used for valves and fittings, ball clutch valves are divided into two main types.

- Floating ball The spherical plug and the spindle do not have a solid connection - they move freely relative to each other. When pressure is applied, the valve is pressed against the sealing ring, as a result of which flow is blocked. Such valves are used in hydraulic systems with pipes up to 200 mm in diameter and low pressure due to the significant impact of the ball on the seals on both sides.

- The ball in the support. The locking sphere is supported by supports. The pin is designed as an axial protrusion and has a recess in the lower part. High pressure firmly presses the seat to a polished spherical surface.

The ease of operation and reliability of the design is compensated by the relatively high cost of such clutch valves.

By type of management

Coupling ball products are divided into several types depending on the specificity of the control device, these include:

- cantilever with a handle, allow you to quickly block the flow, very easy to use, mainly used in the civilian sector;

- valve, allow you to adjust the reduction of flow more accurately than taps with a handle, can be used in the heating system to adjust the flow of hot water;

- automaticThis type is used for industrial purposes in enterprises with an automated production process.

You can also choose the full bore option, with rolling, three-way, with American, empty and so on. They all have good technical characteristics.

Materials

For the manufacture of ball clutch valves used various materials. The most commonly used brass, steel and propylene products. Each species has its own characteristic advantages and disadvantages.

- Steel. Steel ball valves are characterized by high durability and reliability, withstand high pressure and temperature.However, a significant problem is their poor resistance to corrosion processes, after a year or two, the damage to the product begins, which will further bring it into complete disrepair. The advantages of steel cranes include their low cost.

- Brass. Brass taps are in many respects similar to steel, but one of the main comparative advantages is great durability. The life of such cranes is calculated for decades. Brass products are more resistant to corrosion, in addition, can be combined with any other metal products. The main disadvantage of brass is a significantly higher cost, although, if we take into account the duration of operation, in the end it pays off.

- Polypropylene. It has good performance properties, resistant to corrosion. Mainly used in the domestic sector when distributing water with the help of "soldered plastic". It has minimal screw connections. Another advantage is the price, which is more than reasonable.

You can also choose stainless, nickel or cast iron.

Tips

When choosing a ball valve should consider a number of recommendationsThey will help you to get a better quality product that meets your needs.

- Since the crane is designed to work in conditions of high pressure, products from any manufacturer must have a certificate of quality. The choice of crane material is primarily related to the specifics of the substance flowing through the line: the more aggressive the substance, the more stable the material is needed. The next step is to select a crane with an inlet to the corresponding pipe in diameter.

- Examining the selectable ball valve with the ending, need to pay attention to build quality. Every detail should sit tight, the handle should not walk freely, but turn with a slight effort. There should be no rust on the surface of the material, any stains or overflows, if any, the product is made of low-grade alloy. The hull walls must have the same thickness.

- Need to check the ability of the product to withstand hydraulic shocks. Quality products have standardized markings reflecting the specific use of the crane. The marking system for Russian and Ukrainian cranes complies with GOST, for European manufacturers, for example,Valtec, STC-UNO, Giacomini uses another taxonomy, the figures almost always indicate the throughput diameter of the crane.

You can find out how to replace the ball valve under pressure by looking at the video below.