Ball valves: instructions for choosing and installing

The ball valve is mounted on pipelines through which water, gas and heat are supplied. The main purpose of this device is to regulate or completely cut off the movement of a liquid or gaseous medium with the formation of absolute sealing.

Reliability and ruggedness of the design determine the extensive use of both industrial pipelines and pipelines in the residential sector.

Construction features

The ball valve is a valve with a valve having a spherical configuration.

Consider the main components of this design.

- The case of the device. It is made in one piece (by welding) or collapsible.The first version of the device is not repairable. Collapsible modifications are repaired, but have a more complex device, more weight and price, in comparison with products that have an integral housing design.

- Ball valve. It is produced in floating or fixed execution. The diameter of its bore hole may coincide with the nominal diameter of the valve or be smaller.

- Movable spindle mechanism, through which the movement of the locking mechanism in the shell is reported.

- Removable handle. It can be implemented as a lever or flywheel.

- Rings. Sealing between the shell and the polished ball valve is provided by means of end rings made of fluorine-containing synthetic polymer (fluoroplastic).

The structure of the ball valve is reliable and simple. A metal ball valve placed in the valve shell has a through hole along the flow path. Rigid fixation of the stem and the ball forms an axis of rotation, placed at 90 degrees relative to the flow line.

The flow of liquid medium occurs when combining the axial line of the hole in the spherical gate and the axial flow line.When you rotate the rod 90 degrees, the axles will orthogonal to each other, and the ball will block the feed.

Varieties of gates

Depending on the design characteristics Ball valves are of several types.

- Direct-flow. The main characteristic feature is low hydraulic losses. Most of them are mounted to regulate the flow of liquid to the heating system.

- Passable. The gas feedthroughs of the valve and the valve for the liquid medium are mounted on the straight section of the pipe and are intended for the complete cessation of the supply of the incoming medium.

- Corner. The installation of angular devices is made to bend the piping system. The function of the valves is to block (cut off) the incoming flow.

- Three-way or mixing. Mounted on the system when the need for mixing two streams of incoming liquid medium having different temperatures.

Fastening methods

According to the technique of fixation, ball valves are classified into the following varieties.

- Coupling (threaded). The threaded-type mechanism is commonly practiced in private water systems of small diameter (no more than 65 millimeters), for gas and for heating systems or a liquid medium. The clutch valve is distinguished by the ease of installation.For installation of the device, taking into account the fact that the pipes are threaded in advance, there is no need for a specialized tool and high qualification of a specialist.

- Flanged. Devices mounted by means of specialized elements (flanges) are mainly used for mounting on industrial pipelines with a diameter of 50 millimeters. Such a device is more durable and sealed.

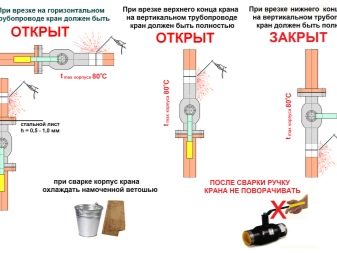

- Welded. Mounted on metal plumbing by welding. Fixing such a valve is the most reliable, however, to install the device requires a certain qualification. For the most part, welded valves are mounted on industrial gas pipelines where high sealing is required.

- Combined. Connect to pipes by various methods. Products of this type are endowed with multifunctionality and are practiced in a variety of communication systems with such connections: flange connection plus welding, mating by means of thread plus welding, and others.

Selection

It is necessary to choose the structure of ball valves in accordance with the parameters of the pipeline and the work being done.

Ball devices for structures transporting liquid, gaseous substances are sold by all companies that supply pipes. From the whole mass of manufacturers can distinguish such companies as Rehau, Valtec, Lavita and AS Gruppe. Products of these firms are on the market for a long time, they have been tested in practice by a huge number of users and do not raise questions about quality.

One of the main differences of high-quality devices from their unreliable prototypes is the metal from which the body is made. Choosing a ball valve, first of all, focus on the shell of the device - it should be made of CW617N brand lead brass. Inexpensive Chinese products are often made from recycled brass, the structure of which may contain additives that are dangerous to humans. Do not disregard this circumstance and, in case of need, ask the seller for a hygienic certificate and a sanitary-epidemiological conclusion on the products.

It is also necessary to focus on the stop and control valves, because in order to reduce the cost of goods, brass is often replaced with ordinary iron, which eventually rust.During the operation of such a product, due to corrosion of the locking mechanism, the sealing of the valve can be broken, which would lead to a breakthrough in the water supply system.

When choosing a ball valve, it is better to inspect the surface of the ball. The sphere should shine like a mirror, be perfectly glossy (surface treatment of the ball is carried out with the help of diamond grinding). All this indicates a high quality device. If the surface of the ball-shutter has a dim gloss, matte coating or even has roughness, then this suggests that you have a fake. This will affect the capacity of the device in the open state, and specific liquid noise will occur when the liquid medium moves.

By the way, even if the externally locking knot looks excellent, it can be additionally checked using a magnet. If it “sticks” to the sphere, it means that the ball is made of steel, designed for use in electrical engineering. Such material quickly becomes rusty and does not withstand long-term use in a humid environment. By the brass magnet is not attracted.

In the valves for water supply systems, the lever for regulation always has red or black color, in devices for gas pipelines it is yellow. If the pipeline system is pulled out in conditions of insufficient space, it is advisable to purchase a modification with a small butterfly-shaped handle.

Installation

Proper installation of the ball valve can be easily done by hand.

- First of all, of course, you need to choose a valve. You can purchase a ball valve with a double-sided external or internal threaded connection, a modification in which there is a union nut (American) on one side, and a threaded connection on the other. In addition, remember that the diameter of the vent hole must necessarily coincide with the communication parameter.

- Remove liquid from the entire system. To do this, turn off the water supply and open the valves.

- It is necessary to correctly determine the place, so as not to have problems in the installation, and the movement of the swivel lever does not interfere with other devices. At the installation site of the future tee, the pipe must be cut and made its preparation. Depending on the type, it is necessary to cut the thread on it, or simply to clean the outlet from dust and dirt (when replacing the valve that has worked its time).

- Screwing must be carried out by means of an adjustable (gas) key. At the same time, it is necessary to control the pressing force and the direction of the thread. It is impossible to overwhelm the product immensely, otherwise it may twist and the tightness of the system will be damaged.

- The thread of the product must be rewound tape fum (sealing tape), tow or specialized paste is used. This is required to protect the thread and ensure maximum tight junction of the bends.

- The sealing tape is wound no less than 5 turns.

- Turning the device on the heating system outlet, the pressure pipe or any other hydro-communication is performed only on 5 full turns of the threaded connection. With a smaller number there will not be the required conjugation, and with a larger number of turns, a butt joint can be obtained, which will collect all kinds of garbage from the water supply system.

- When the work is completed, it is necessary to additionally examine the place of connection and turn on the water. If water ran out from the bottom of the valve, then it must be dismantled and inspected the gland (some negligent manufacturers sell products without it).

In some cases, it has to be put on its own or to make additional sealing with flax rope or specialized fillers.

How to choose the best ball valve, see the next video.