How to choose a cable for submersible pumps?

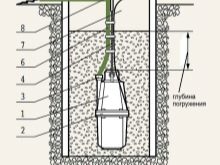

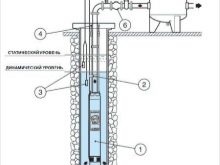

Submersible pump is designed for pumping fluid from boreholes, sewers, wells and process tanks. The device is divided into sucker-rod submersible pumps and rodless. The pump motor is powered through a special power cable, so the wire must be waterproof and withstand pressure deep under water.

Requirements

The cable is an important element that ensures all the work of the submersible pump, so it must meet all the requirements stated by the manufacturer. First of all, they include the resistance of the cable to water. This means that the wire must be waterproof and well protected from water ingress.Quality brands are Hydrotech, WFP and Aristoncavi.

If this property is not indicated in the relevant certificates for the product, then you should not buy it and check whether it can withstand water. Acquisition of poor-quality or, even worse, not designed for water cable conditions will cause a motor to burn out. PVA and their analogues are used only for installation in rooms. You should not save on the product, then to overpay even more.

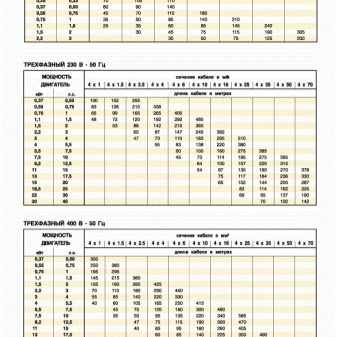

The second requirement is that the cable must withstand the current load, and the cross section must provide no more than 3% of the voltage drop. To do this, use a special formula that calculates the length of the cable. It takes into account the strength of the electric motor current, voltage drop, cable material and Cos factor, temperature. Accordingly, the time of voltage drop at the end of the cable with the increase in its length, which is determined by the distance from the point of connection to the fixed network to the level of the location of the submersible pump, will depend on the engine power.

When choosing a cable for a submersible pump, you should read the information provided by the manufacturer. Preference should be given to a product having the same manufacturer with a pump.It is also necessary to explore other companies that can recommend the experts involved in the installation of the entire system.

Standard cable sections of 3x2.5 mm and 3x1.5 mm for pumps are too small and are not suitable for work at depth. They should be determined by the diameter of each cable core.

Recruitment

To purchase the correct cable, you need to familiarize yourself with the entire range of construction store, as well as with the relevant parameters, including:

- power consumption, which, if the wiring thickness is insufficient, will not be fully utilized, which will cause the device to heat up;

- the amount of electrical power, which should be 220 or 380 V for single-phase or three-phase connection, respectively.

The single-phase submersible pump operates with a mains voltage of 220-230 V (50 Hz). To determine the length of the section is to add stock. For this type of pump, the maximum length is calculated by the formula: L = UnomΔU / Ix2x100x (PFxp / q), where

- L is the cable length (measured in meters);

- U is the rated voltage (in Volts);

- U is the voltage drop (in%);

- I is the rated current of the electric motor (in amperes);

- ρ is the resistivity of 0.02 (Ohm x mm2 / m);

- PF = 1;

- q is the cross section of the cable cores in a waterproof sheath.

Three-phase connection operates at 380-400 V (50 Hz). When choosing a cable, it is necessary to pay attention to permissible maximum loads for a particular pump model and in this case to be oriented with current. For the convenience of searching the Internet, you can find a large number of tables with a choice of engine power, conductive cable cross sections and parameters of electric pumps.

If necessary, you can extend the wire. It is advisable to choose a water immersion KVV or high quality ECV. Extension of the line can be performed independently, given all the recommendations.

Cable connection

Unfortunately, sometimes manufacturers do not pay enough attention in the manufacture of special immersion cable and wires for connecting the pump. Only this item is the most important, because it is responsible for the long service life of the device. As mentioned earlier, the cable must be completely waterproof and have an insulation resistance of at least 100 MΩ, measured 24 hours after the dive. For testing, cables must be clean.

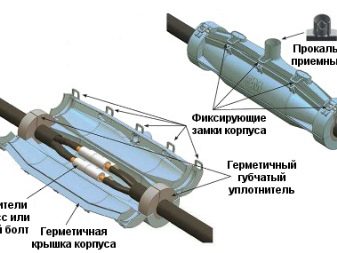

The power cable is attached to the pump with a moisture resistant shrink or filler sleeve. There are several options for connecting the cable to the submersible pump. They are described below.

- Detachable contact connection, which is more suitable for pumps operating on the surface. All submersible pump mounts must be properly attached.

- Filling or sealing as the most well-known cable connection method. For it use couplings, which must protect the wire from moisture. The shrink look can be found with such names as Grundfos for KM 3x1.5-6 mm2, for SQ / SQE, Heisskraft KMH - 3x4 mm2, 3x6 mm2 and the Dzhileks set with article number 9017.

- Wellhead with a terminal block inside, which is not very popular among specialists. This is due to the fact that, despite the lower cost of this method of connection, the reliability of this design is much less.

- Cable entry is used more often for drilling oil wells. It is designed to seal the cable cores that pass through the rebar with ESP. Rubber material V-14 TU 38-005-1166-98 is used at temperatures from -60 to +100 C.Cable entry is quite simple to install, as it has a housing with connecting threads NKT-48 according to GOST 633-80.

Of course, each of the compounds presented has its pros and cons. Therefore, you can choose any of them, only it must be installed qualitatively, because when disconnected, the water gets inside the pump and cable and will damage the entire apparatus.

Recommendations

In the market of building materials you can find a huge range of submersible pumps and cables to them. When buying a product, it is necessary to examine all manufacturers and reviews of their products, check all certificates for quality. According to the documents, the product must meet all the requirements for safe use.

The correct cable cross-section must withstand the assigned current load, the maximum ambient temperature and the permissible voltage drop values. If it does not cope with all the parameters, the resistance will increase, which will lead to overheating. Because of this, the pump may suffer - breakage will occur.

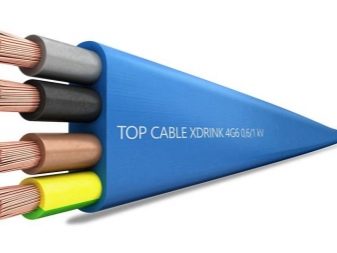

In addition, it is worth noting that the cable is divided into three- and four-core.For a single-phase connection, both types are suitable, and for a three-phase one, a product with a large number of cores should already be used. For example, this cable is available from Grundfos and Wilo.

Also, cable elements are divided according to the application of the pump. These can be wires for a submersible water, oil submersible and submersible submersible pump. They should not be confused, as the use of other than the intended purpose can lead to instantaneous breakdown of the device. If the task of choosing the right cable is too difficult, then you should contact the specialists and ask you to choose the appropriate wire depending on the type of pump and all the necessary characteristics.

You will learn more about connecting the well pump cable from the following video.