Features of Grundfos circulation pumps

All less predictable weather conditions have led to the development of technologies to effectively insulate buildings. Everyone knows that insulation can be internal or external. It is important to design the heating system correctly. By the way, it can be easily made more economical by examining in detail the features of Grundfos circulation pumps.

What it is?

Forced circulation of water in heating systems is a good alternative to systems with natural circulation. This option of heating systems is inefficient for medium and large buildings. Since the circulation is slow, the radiators warm up badly. To eliminate the risk of pipes freezing, pumps are installed in heating systems.The device provides a constant and uniform heat release from radiators located in all areas of the house.

The circulation pump is a device that is necessary when organizing heating systems, floor heating, hot water supply. The country of manufacture of the pumps Grundfos - Denmark. Representative offices are located in different countries, and in some there are production departments. In particular, the existing production is in Russia. Circulation pump is a device operating in a closed engineering system that facilitates the movement of media in the pipes. The device does not affect the amount of media in the pipes, does not contribute to the filling of the system.

The circulation pump operates according to the principle of creating a continuous circulation of fluid. The installed device usually works continuously, so the main requirement for the device is noiselessness.

Another device is chosen on such principles as:

- energy efficiency;

- durability;

- usability.

Since the scope of application of these devices is quite extensive, it is worth studying the technical characteristics of the most popular types in more detail.The choice of equipment is usually based on numerous parameters.

The main parameters in the selection of circulation pumps are as follows:

- the required amount of thermal energy;

- hydraulic resistance data.

Professionals are able to select optimal models of equipment. By the way, experts believe that dry rotor pumps are more efficient, but usually noisy. Units with a wet rotor are smaller in size, usually silent, suitable for small-sized heating systems. These options for circulating pumps should be considered in more detail.

Kinds

Dry rotor circulation pumps can be repaired. For them, the quality of the coolant does not matter. The Danish company offers consumers a dry rotor pump for domestic use. They have good efficiency, and the size of the equipment practically does not differ from the apparatus with a wet rotor. Spare parts for such pumps are cheap, but it is worth considering that the replacement of the mechanical seal is needed regularly.

Unlike the first option, wet-rotor pumps do not have an end seal. When operating the pump should be given maximum attention to the quality of the seal. If the system is of poor quality coolant, the pump will quickly fail. Dry type pumps are units in which the coolant does not come into contact with the motor. The type of equipment is widespread where you need to create a good pressure. Another circular pump is actively used in systems where aggressive types of media are pumped.

By design features, dry pumps are a conventional electric motor, which is mounted on the housing with the participation of the sealing ring. A pump with a motor can be connected with a single shaft or clutch. The engine is controlled through an electronic unit.

Pumps with a dry rotor are divided into such types as:

- In-Line are units with suction and discharge nozzles that are on the same axis;

- block versions are units with a centrifugal motor of constant rotation and an air cooling system;

- cantilever versions are pumps with a standard electric motor of constant rotation and an air cooling system.Most dry rotor pumps are of the latest design.

Specifications for wet rotor pumps are as follows:

- motor parts not separated from the pump, working directly in the liquid;

- automatic lubrication of bearings by pumping over the carrier;

- automatic cooling of engine parts.

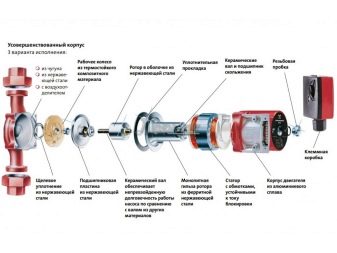

The role of the motor rotor in these variants is played by a special element with an integrated sleeve. This element is also the protection of the motor stator. The sleeve is made of high-alloy steel with non-magnetic qualities. The motor and pump shaft is usually made of stainless steel. The shaft rotates due to graphite bearings.

Moving the coolant using these options is faster. With pumps of this type can be used in heating pipes of smaller diameter. The use of units provides a reduction in energy costs for the system. The main parameter for selecting a wet type pump is the change in the temperature of the working fluid. Due to temperatures above the working format of the unit, deformations may occur. They will lead to a quick breakdown of the equipment.

Pumps with a wet rotor, considered by the manufacturer, are represented by a series of UPS: units - 25-40, 60, 32-80, 50-180. The working units of the engine and pump in the devices are located in the same housing. The impeller fixed on the shaft of rotation is isolated from the pumped liquid. The design does not provide a mechanical seal. Two glands used in the construction ensure reliability of the unit operation. Bearings in the models are ceramic. Management of the UPS mechanical models.

Among the positive qualities of these units should be noted such as:

- high level of efficiency;

- reliability and repair suitability;

- several modes of speed.

The UPSD variation is distinguished by dual electric motors. The decision affects the improvement of operational life. Warranty periods for a series of these models are extended - 12-15 years. There are several modifications of UPSD pumps. For example, there are options with a backup pump, which is included in emergency situations. And also, you can additionally purchase automation, providing adjustment of circulation. There are options that allow the simultaneous connection of two independent heating circuits.

The units of the UPA 15-90, Alpha2, 100 A series are distinguished by automatic settings, which themselves set up the unit for the system parameters. Devices are characterized by absolute noiselessness. Models can be used in various fields. The recirculation pumps of the series: 130, UP 15-14 BUT, 120 are devices that allow to avoid the loss of water and heat. Devices successfully maintain temperature stability at all points of the media intake. To recirculate hot water, a drain line is installed in the system. As well as a recirculation pump, the temperature of the carrier increases. Thus, one device will accelerate the movement of water through the pipes, as well as provide a forced return of the coolant, while the liquid does not lose its original temperature.

Scope of application

Currently, the use of circulating pumps in heating systems is widespread. Thanks to the work of the unit in a private house creates a more favorable microclimate. The premises of the house warm up faster and more evenly. A high-quality pump reduces the conditions for the performance of the heater, and reduces the cost of electricity.In addition to water heating systems, pumps are successfully used in floor heating systems. Properly selected pump increases the efficiency of the heating system. The disadvantages of the equipment used in this area often include noise during operation. According to experts, this appears due to installation errors, as well as if air has entered the pipeline system.

Circulation pumps successfully used in systems with cold water. With the installation of the pump will appear a stable good pressure in the system. A good option is the arrangement for hot water systems. With the installation of recycling does not have to wait for hot water from the tap. Pumps for high-quality circulation of the carrier in hot water supply are installed in both central and autonomous versions.

Grundfos for DHW is divided into series. For example, the comfort model is a recirculating unit made of bronze with a permanent magnet. Autoadapt software is provided to control the model. Automation analyzes the flow of coolant and selects the appropriate mode. In innovative heating systems, circulation pumps are also often used.Just the technology of solar and geothermal heating is not yet widespread.

The units providing high-quality circulation are installed in air conditioning systems. Here devices help to cool pumped liquids with higher quality. Air conditioning systems, as a rule, are configured not only to cool the air, but also to heat it. Such systems are called recuperative. The blocks heat the air entering the room by removing the existing one. Ethylene glycol circulates in the devices. To improve the performance of the unit need a circulation pump.

The versatility of circulation pumps is rated by gardeners. The unit successfully solves the problems associated with watering plants. Pumps are usually used to improve water pressure. The pump regulates the speed and pressure in popular drip irrigation systems. Water for irrigation usually accumulates in storage tanks, and circulation pumps pump it further through pipes or hoses. Self-flowing systems often do not meet the expectations of gardeners, they try to achieve greater efficiency.

Installing models can be a little difficult.

Be sure to pay attention to such parameters of pumps as:

- power;

- maximum possible pressure;

- volume and lift height for circulating fluid;

- tips on installing units.

Installation

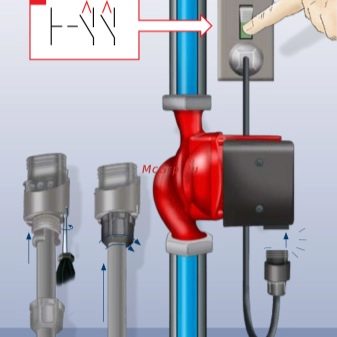

Detailed advice and installation rules are in the accompanying documentation. It is standard on the original equipment. In practice, the instructions are addressed at the last moment. Usually, when something is already broken or stopped working. Installation of a circulating pump with dry rotors in the heating system is carried out on the return line, usually immediately after the expansion tank. Wet rotor circulation pumps can be installed in feed pipes.

Although installers argue that in this matter it is better to take into account the features of a particular heating system. The general rules imply that the return temperature is lower than the temperature of the carrier, therefore the pump will operate sparingly. As well as the efficiency of the device installed on the return line, the best. From the standpoint of hydraulics, the location of the pump in a closed loop does not matter.Do not run the installed pump with a system of empty fluid. When installing, take into account the correct position of the unit.

Only with a vertical arrangement the coolant will fully lubricate the friction parts. At the wrong connection the unit will fail faster, it will need repair. This happens when the device is installed horizontally, since the internal volume of the case is not completely filled with coolant. With frequent power cuts, it is recommended that pumps be supplemented with uninterruptible power supplies. They will contribute to a better safety of the unit from damage.

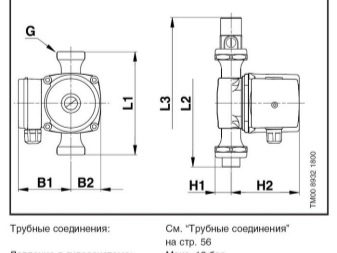

During installation, it is necessary to take into account such work procedures as:

- First you need to mount the water circuit. The unit must be installed with a threaded joint with an equal diameter in the pipes and in the pump. The correctness of the direction of installation of the device can be determined by the arrows, which are equipped with the device;

- using the couplings offered in the kit, you need to connect the pump;

- need to fill the heating system;

- remove any air that could remain inside the pump. To do this, unscrew the bolt on the top cover, which closes the engine.

You need to select a working speed mode. Experts advise to set the minimum speed. In this mode, bearings and other rubbing mechanisms wear out less. As a rule, at minimum speed the load is not particularly strong. During further operation, it is worth choosing the mode in which the entire heating system will warm up more evenly. If a model with an electronic unit is purchased, these units will independently select the desired circulation rate for the connected system.

Increase the service life of the pump will contribute to the water filter. It is necessary to install the filter before mounting the unit. Neglecting the filter will shorten the life of the unit, as the dust will get into the device case along with the coolant. In order for the installed device to be repairable, you need to install shut-off valves, which can block the access of fluid. Connections between taps must be tight.

When connecting the device, it is worth considering the order of filling the pipes with coolant. Experts recommend running the fluid first into the lower tubes, then gradually fill the entire system.Such a process will contribute to the accumulation of air in the expansion tank. If the air remains inside the pipes, it will lead to system inefficiency. Mayevsky's taps or special automation will help to better remove air from the system.

Tips

It is possible to eliminate the appearance of malfunctions in Grundfos pumps, but subject to the purchase of an original product. As practice shows, a large proportion of failures accounted for mainly fakes.

To avoid buying fakes, you should follow the following rules:

- It is worth buying a suitable option only in the official outlets of the company. The products of the Danish manufacturer is certified by Rostekhnadzor. Accompanying documentation must be included. Original products include instructions in Russian;

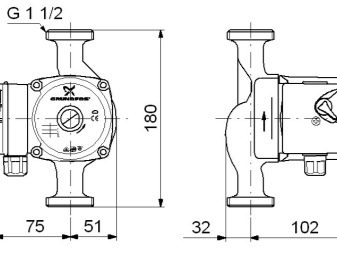

- When buying, you need to pay attention to the dimensions of the product. The original pumps are 18 cm long, known fakes, as a rule, have smaller dimensions. Corpus surrogates - 13 cm;

- Painting the original case should be of high quality and uniform;

- toggle switch speeds usually non-removable;

- specialists also distinguish constructive differences. For example, the mandatory components of the unit are the rotor, stator, stainless sleeve, bearings;

When buying you need to pay attention to the cost. Prefabricated products cannot be cheap. The cost of falsification is half the original. The choice is complicated by the fact that the cost of units varies greatly. The difference can be from 5 to 80 thousand rubles. When buying you need to pay attention to the specifications.

The cost of the model increases the presence of a twin engine, an automation unit. Buying expensive models sometimes justifies all the funds invested in it. Such models, as a rule, do not require further maintenance. However, it is not necessary to choose an expensive model. When choosing to take into account the size of the heated area and the capacity of the unit.

Approximate parameters of a specific unit are usually available in the accompanying documentation. To facilitate the selection, it is worthwhile to carefully study the information given in the papers. You need to know that all Grundfos pumps are warranted for 7 to 9 years.Most models sold have a three-year factory warranty. By the way, Grundfos is a bit more expensive than other analogues known on the market. Danish company pumps are better in performance, more reliable.

The duration of the operation of the unit is influenced by such factors as:

- correct installation;

- the quality of the fluid circulating in the system.

For information on the features of the Grundfos circulators, see the following video.