The principle of operation of submersible pumps and recommendations for selection

Pumps have been used by man for three millennia. During this impressive period of time, people have adapted them to their needs to the fullest. The history of the pump originates in ancient Greece. There, for the first time, these systems were used for irrigation purposes, then in systems of primitive water supply and sewage. Soon, the principles of pumping facilities began to be used throughout the world.

With the help of pumps, they learned how to extinguish fires, eliminate the effects of floods, drain large areas for agricultural needs, and supply homes and tanks with drinking water.The area of their application is constantly expanding due to new innovations and modern developments.

Special features

In the classification of pumping systems, submersible pumps are characterized by high performance and a wide range of applications.

The individuality of each device is based on one component: all submersible pumps in operation are in the water. This feature is decisive for all varieties of this type of devices. Therefore, the fundamental qualities, including the presence of adhesive properties, automatically include wear resistance, tightness and stability of the materials of the body during the operation of devices. The body of submersible pumps, as a rule, consists of high-strength materials with anti-corrosion coating.

A characteristic feature is also the fact that in the process of operation, the heating elements of the unit are automatically cooled with water. This significantly increases their lifespan.

This type of equipment is versatile and easy to operate and maintain. He does not need special skills during installation.

Submersible pumps are the basis of autonomous systems of water supply, drainage and circulation of water.The range of their use is diverse: from industrial scale to meet domestic needs, from irrigation to drainage and drainage of flooded areas.

Pumps are divided into pumping and pumping out water, respectively, borehole and drainage. Well, which also include well and deep, are used for water supply of private households and municipal facilities. Drainage used in industry for draining flooded areas in the home - in sewer systems.

Small in size, these devices are quite compact and have good performance, since under conditions of limited installation area they are supplied with additional technical systems capable of pumping more water. This is a determining factor in the pricing policy of this type of product.

The principle of operation of submersible pumps is based on the supply of water by raising its pressure. This is an innovative approach compared to the previous air exhaust from above.

Well pumps also work effectively in all water bodies and water tanks. They have a cylindrical shape, the diameter of their larger engine, which allows to increase performance at the initial rate of energy consumption. They are well below the downhole, and this is partly their advantage.

But they also have their own characteristics and create strong cravings when working. Therefore, they can not be brought close to the bottom of the well, otherwise you can significantly reduce the quality of drinking water.

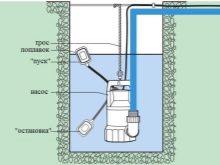

Well pumps are equipped with special floats - controls the operation of the device.

Drainage pumps pump out water from flooding sites and other water-filled facilities that need to be cleaned. Initially, the principle of their work was used when pumping clean drinking water. But over time, they were replaced by models designed specifically for this purpose. Drainage structures, despite their high performance, have limitations in working at depth, which is on average up to 10 meters.

Fecal pumps have a narrow specialization, but do a good job with their job of cleaning up drains and wastes. They are indispensable in this application.

All devices in this series have their own characteristics.It is important to find and select an individual model and accurately calculate its power. When choosing a pump, it is important to consider the technical parameters, features, functionality and purpose of the pump.

Kinds

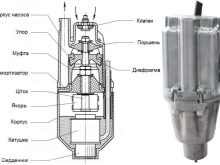

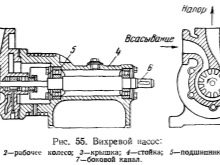

According to the principle of operation, submersible pumps are divided into vibratory (or electromagnetic), centrifugal, vortex, screw and manual.

All of them have their pros and cons due to the characteristic differences and principles of use.

- Vortex submersible pumps have a lower capacity than centrifugal pumps.

- Screw - the most inexpensive. They are good only at a depth of no more than 10-15 meters.

- Vibrating pumps are also affordable, easy to operate, but their vibrations drive sand and small particles from the bottom of the wells, which invariably affects the quality of the water produced in this way. Therefore, cleaning elements and special filters are included in the package for this pump.

- Manual submersible pumps are a good solution for summer houses and areas where there is no electricity. They are unpretentious and very durable.

- The most common on the principle of action in use - centrifugal pumps.Their work is based on the concentration of vacuum in the body element of the device, on the use of centrifugal force. Due to its pressure and the movement of water occurs. A centrifugal pump is a slurry pump. It is used for pumping out hydraulic fluids with the content of abrasive substances, in which the quantitative content of solid particles of sand and clay can reach 80%.

These pumps are very powerful and are widely used in industry. There are also some models used in everyday life.

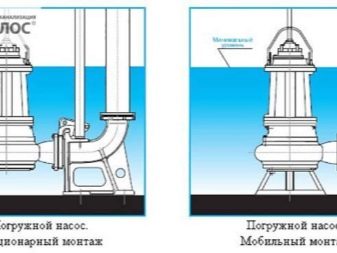

There are two types of pumps: sucker-rod and rodless. In the aquatic environment, rodless devices are used, which are submerged in water with a power cable. These are electric water pumps. In function, they have minor differences and are subdivided into borehole, deep well, drainage, well and faecal pumps. Such pumps are easy to use and are widely used for water circulation, in sewage systems of residential buildings and in summer cottages.

Fecal pumps are equipped with a special grinder, drainage pumps with a float-water level indicator; Well are easily mounted, they are also called surface because of their universal properties.All types of pumps are mobile, they can be dismantled if necessary and moved to another place. There are also stationary types of pumps that are installed at a permanent place of use.

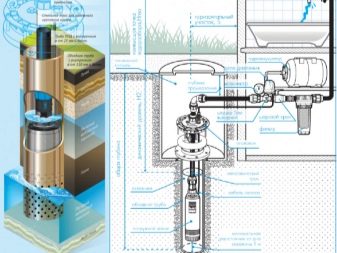

Borehole deep well pumps are widely used as a hydraulic station in private households. Due to their high productive force, they can work at a depth of several tens of meters.

Scope of application

Downhole pumps pump water from wells, ponds and wells of various depths. They are actively used in agricultural work; in industry they are used in mines and technical tanks, in artesian wells - in the extraction of mineral water.

Their field of application is the extraction of oil, uranium, precious and rare-earth metals. Submersible pumps for oil are also used for pumping liquefied gas, sludge, combustible substances, industrial and technical effluents. In metallurgy and energy, these pumps play an important role. They are called reversible, as they work in both directions - to pump out and fill pits and tanks.

The most popular is the water supply of residential and country houses, industrial buildings. In agriculture, they are used for irrigation, drainage of wetlands, as well as in the fishing industry. In everyday life, submersible pumps are also used to fill pools.

In addition to the function of automatic pumping of clean water, some types of this equipment are used to drain rooms from polluted domestic wastewater, from tanks with stagnant water, and flooded basements. They have a weak power, therefore, to implement the function of pumping clean water unsuitable. However, they are often used for these purposes.

Pumps are also indispensable in sewer systems. Fecal devices are used for this. They are specialized in pumping out viscous substances and are equipped with special waste disposal mechanisms.

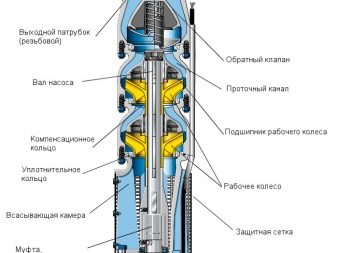

Device

Design features of submersible pumps are characterized by the principle of operation and the type of functional motor.

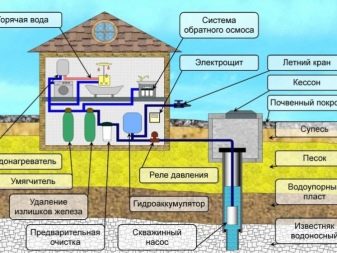

The centrifugal borehole pump consists of two parts - the built-in or external drive motor and the target part of the device. Fluid intake is made through a pipe, which is lowered into the source with water. The driving motor is at a certain depth. It is fed through an electrical cable, protected by a special sheath.

The principle of operation of this device is the effect of centrifugal force on a flexible diaphragm, which, deforming, creates a low pressure that supplies water to a special chamber. The spring mechanism is in progress, the diaphragm returns to its original position, the valves close the inlet and water flows out.

During operation, submersible pumps are located below the submerged liquid, which ensures pumping of liquid media from a considerable depth. When this occurs, the cooling units of the apparatus, which ensures uninterrupted operation of the pumps, and also allows you to produce gas-containing liquids.

Centrifugal submersible pumps come with indicators of water and air. Some of them work as a result of filling with water, others - with air. All of them are divided into single-stage and multistage. The latter create a higher water pressure than others, which significantly increases the performance of instruments of this type.

In models with vibration devices, liquid is taken through the lower part of the body, which is a necessary condition for protecting part of the well from sand and sludge accumulations. Constructions of centrifugal deep-well pumps are the most complex of all, but during operation they give high indicators of quality and reliability.

Vortex pumps are equipped with a special vibrating element, which ensures the pumping of water. They work on the principle of induction of vortex flows, hence their name.

All submersible pumps are necessarily equipped with a coarse filter that protects the inside of the body from the ingress of solid particles. As a rule, in all types of submersible pumps, automatic sensors are used that can stop the process of pumping water at any time if, for some reason, it suddenly fails, the device overheats, or there is a problem with its operation.

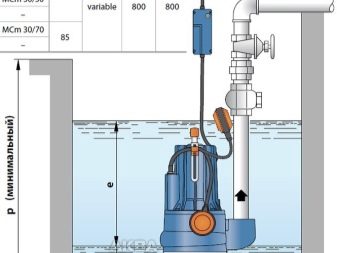

When watering cottages and private homes submersible deep-well pump is mounted in the well, well or any other body of water.

To install it is not necessary to be an expert. The device is quite simple to install and durable to use.With the right approach, the pump requires almost no special maintenance and repair.

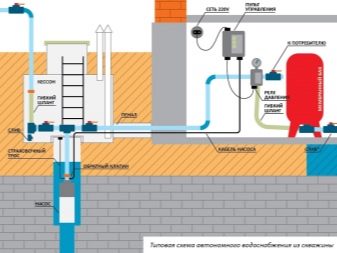

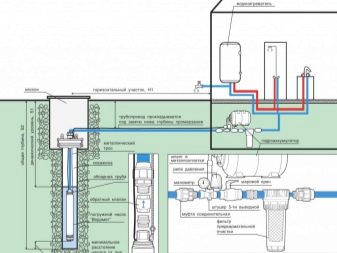

The water supply scheme of a private house is activated by simply connecting the electric cable to the power source, after which the water immediately begins to flow to the drain, to the house or to the irrigation site.

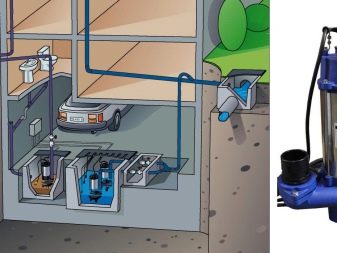

Fecal pumps belong to drainage type, they are intended for pumping out of sewer drains. In the overall premises, restaurants, shops, located in the basement of buildings and other similar structures, they are mounted together with sewage substations. They are a small unit with an integrated pump.

Fecal pumps are equipped with a special grinder, which greatly facilitates the process of pumping waste. The pumps themselves have all the advantages of autonomous work, including self-diagnosis, as well as work in difficult situations.

The operation of such pumps is regulated by a special control cabinet, which is included in the kit along with the device. There are several such pumps in the installation, which ensures the coordinated alternate operation of the unit as a whole.This ensures uninterrupted operation and durability of the pumping station. In case of malfunctions and breakdowns, one pump replaces the other.

When the automatic system is flooded, it triggers, the cabinet receives information about changes in the station's tanks and the pump is connected. In the event that there is not enough power, other pumps come to help, which are also connected by automation. Sewage stations are universal, mobile, simple and unpretentious to maintain. With high power, they are quite economical and silent, which is their advantage. The principle of their work is to divert sewage through inclined pipes.

In the domestic sphere, installations are used consisting of a fecal pump and a special tank. Installation is quite fast and without problems. The main thing is to correctly connect the pump to the tank, and then it will work as the storage tank is filled with waste medium. The larger the waste pit, the longer the fecal pump will work. For safety, it is desirable to have a manual system for pumping liquid media from the tank.

It is important to know and take into account the device of various types of pumps, their capabilities,individual qualities and characteristics are still at the acquisition stage in order to competently approach their exploitation in the future. This will significantly reduce the cost of servicing the water supply systems, which will significantly extend the warranty service of the pump.

Manufacturers

Many modern Russian enterprises produce household and industrial pumps. The market is constantly updated with new brands. Pump designs of various types are in great demand not only in Russia, but also in other countries of the world. The main advantage of this type of product is that at cost they are significantly lower than their foreign counterparts, and in terms of quality they are not inferior to them. Therefore, in the market for this type of product their rating is always high.

Pump products of Russian manufacturers are quite simple to complete, rational in terms of price and quality. A big plus for them is a warranty service, which includes installation and maintenance of devices. The quality of the pumps is carried out by using in the production of reliable domestic raw materials.

Among our manufacturers, such companies as “Dzhileks”, “Pinsk Experimental Mechanical Plant”, “Livgidromash”, who have been successfully specializing in the production of this equipment for many years, have recommended themselves well. The products of these companies have all the necessary quality certificates.

Pinsk Experimental Mechanical Plant OJSC is one of the leaders in domestic pump engineering. Its products are fully unified with market analogues of these products.

The firm "Dzhileks" keeps among the leaders in the market for this product for more than twenty years. HMS Livgidromash JSC is one of the largest Russian enterprises for the production of pumping equipment. Due to the innovative approach, this manufacturer occupies one of the leading positions in the field of domestic pump engineering.

In the market of this product you can also meet manufacturers: CJSC “Metab”, LLC “Plant“ Fan ”, LLC NPO“ Tehnohim ”, CJSC“ Group of Companies “Himagregat”, LLC “Sumy Pumping Technique”, CJSC NPO “Uralhydroprom”, LLC “Belebeevsky Machine Building Plant”, PJSC “Sumy NPO Frunze ", LLC" Areopag dosing equipment plant ", JSC" Livnynasos "and others.

How to choose?

When buying a pump, you must take into account the individual characteristics and purpose of the device. For wells there are downhole submersible models, for reservoirs, barrels and other containers - pumps, specially created for irrigation. Changing the purpose of submersible structures, you can simply disable them. Therefore, it is necessary to carefully study the parameters and characteristics of each of them, before making a choice in favor of any.

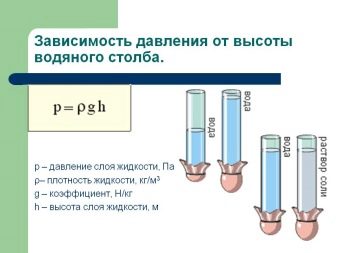

When choosing, it is also necessary to take into account the size of the well and the depth of the bottom of the object where the mobile hydroelectric station will fall. Detailed information is contained in the annex - technical documentation. Also taken into account indicators of water level. Thus, the dynamic index is the sum of the distance from the bottom of the reservoir and to the surface line of the reservoir, and the static one - from the ground to the water edge. Given the static performance, you need to make calculations to determine the value of the water column, for this, subtract its digital value from the size of the depth of the well.

Measuring the diameter of the pipe, it is necessary to calculate the required pressure and at the same time take into account its flow when turning on the device in the network.You need to connect the system through a separate machine, taking into account the indicators of a stable mains voltage.

When choosing, it is necessary to consider the quality of drilling work. Drilling should ideally be carried out by teams using special equipment. Such wells are more reliable in comparison with wells made by the so-called cheap labor.

Competent expert calculations are the key to long life of the well and a guarantee of the quality of the water produced by the pump.

Submersible pumps for wells are more expensive, since the configuration takes into account the factor of protection against blockages and warranty service specialists.

These small, at first glance, the nuances must be considered, if you correctly approach the process of selecting the desired model. The correct wells are universal. You can install any type of submersible pump in them - from simple to specialized models.

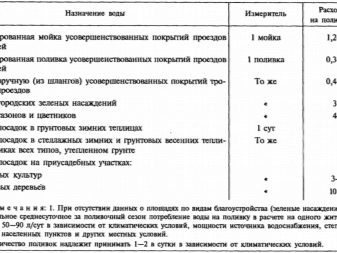

One of the main indicators when choosing a device is the quantitative consumption of water per day. It should be borne in mind that in the winter and summer periods, these figures differ in the direction of increasing water consumption in the warm season.Is taken into account and the cost of watering, based on the size of the irrigation area. If there is a small farm, for example, pets, livestock, and so on, the daily rate of water consumed can increase.

As a precaution, you need to choose four-inch pipes for the well, which is slightly larger than pumps with a three-inch diameter. In fact, most of this equipment is designed for more space. When calculating, it is necessary to convert the measurement indicators to inches: divide the digital indicator by a factor of 2.54. Pumps visually differ in power: stronger in size and weight are significantly different from weaker ones with low productivity.

Choose better pumps with performance margin. For work at a depth of 40 meters, it is better to choose models for work at a 50-60 meter depth. If the device for a shallow depth is used at full depth, it simply will not withstand such a load for a long time and breaks.

The pump device must be equipped with protection against idling, as in case of emergency situations it is necessary to immediately disconnect from the network. The protection is triggered when the voltage drops, the indicators turn off the device in the event of a water supply failure.

Availability automatically - an important aspect when choosing a pump model.

Installation

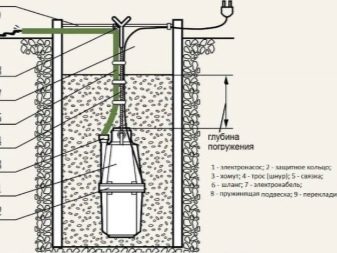

Thanks to compactness and small weight the pump is mounted without special skills. Before installing it, you must make sure that all elements are insulated, as well as the integrity of the case. A feature of the submersible models is their inclusion at the time of lowering into the water.

The pumps are equipped with special automatic floats that regulate their work in conditions of changing water levels. Vibration pump models are attached using stainless steel cable. To protect against seizure, you should install a special barrier in the pipe. The pump is fixed with a cable on the surface.

It should also be borne in mind that some models work with incomplete immersion. Installation of a well pump for intake of clean drinking water should be made at least one meter from the bottom of the water basin or well. This will protect the water from particles in it with admixture of sand and earth and significantly improve its quality.

Drainage models of pumps, on the contrary, are installed on the very bottom, which guarantees absolute cleansing and drainage of space.

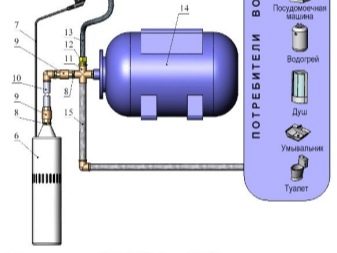

When installing an automatic pump for a well with full automation, it is important to bear in mind that this system is completely autonomous, which means it will not require control of the operation.The correct setting saves the desired operating parameters of the device. The principle of an autonomous system delivers water to a storage accumulator that maintains a pressure rate. After that, the device turns off. Re-start occurs when the tap is opened in the water system. Then the pressure drops, causing the pump to turn on. Pressure dimensions are set in the instrument settings in advance. A well pump is installed, as well as a hydraulic station, on the principle of a nodal system.

A downhole pump is installed similarly to a well pump.

After work on distributing water supply pipes and winding, a drainage system and an electrical cable are connected to the pump. Connection diagram of the submersible pump comes with the device.

Wires and water pipes around the perimeter are fixed with tape, after which the equipment is ready for immersion. After the equipment is lowered to the desired depth, the device is fixed using a special device through the tip. This protects the well from blockages. The water supply system is connected to the top. He connects the pump with the plumbing.

An important step is to check the correct connection of the equipment before putting it into operation.

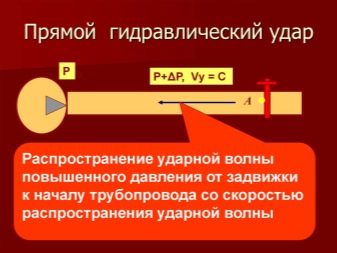

Experts recommend connecting a pump to the pump. This will ensure the supply of water and significantly extend its work. The water supply will be consumed automatically, the device itself will regulate the filling and the flow of water. Control is achieved by reducing the number of inclusions of the device, which leads to significant savings in electricity and water consumption, and also prolongs the period of operation of the pump. Such a connection has many advantages, including, in addition to protection against pressure drops, protection of valves from hydraulic shocks. This allows you to use the water supply system fully without energy losses.

Models with a hydroaccumulator are installed similarly to other pump models. But there is one feature - they have a special pressure switch that turns on automatically when the water level drops.

You can install the pump without much difficulty. You just need to use the appropriate components and adhere to some rulesamong which an important place is occupied by the correct choice and compliance with the technical characteristics of the device.

It happens that submersible pumps malfunction. In this case, it is best to contact the experts. They will accurately determine the degree of breakage, repair and replace defective pump structures. But knowing the device of this unit, it is often possible to solve some problems on their own.

If the power magnet fails, a circuit may occur. Sometimes vibratory pumps break down due to some minor malfunction. You can resolve these problems without the help of specialists on your own.

If the low water pressure and the water supply worsens, perhaps the root of the problem lies in loosening the nuts. This problem can be solved by strengthening the nuts and fastening additional washers. The offset of the shock absorber due to the weakening of the nuts leads to idle operation of the device. Simply tighten the nuts to make it work.

Malfunction of vibration models often occurs due to the integrity of the valve caused by its wear.In this case, the rubber parts should be replaced. And if this does not help, replace the valve itself. In centrifugal models, the cause of the deterioration in performance is the impeller failure.

Broken stem is the most serious damage. Replacing this part of the pump is almost impossible.

If the cable suddenly burns or plugs are knocked out, then the electrical cable is faulty. Some pump models do not provide for cable replacement, so they often have to be replaced. We should not forget that in the absence of water it is strictly forbidden to turn on the pump in the network! Even the inclusion of a short time can instantly disable the device.

The device may break if idle, i.e. without water. In the absence of a cooling medium, this will inevitably lead to overheating of the engine. The so-called “dry run” is dangerous for the sealing structures of the device, designed for operation in a liquid medium.

Common causes of pump breakdowns are water hammer, which occurs as a result of idling. This disables the blade design of the device. It may also result from the ingress of air into the water intake.

It is important to keep in mind that before starting work, some types of pumps require pumping with water or air.

Tips

Some advices regarding the selection, installation and operation of the device will be appropriate.

First of all, you should know that the service life of the pump, its performance is directly dependent on the appropriate operation and maintenance costs.

So, for year-round use of garden pumps, the well is specially buried, arranging a three-meter well from above. This is necessary to protect against freezing of drain pipes in trenches. This installation is best to entrust a specialist.

If the water in the well leaves quickly, it means that the flow rate calculation is incorrect. In this case, the water consumption should be reduced or the existing pump should be replaced by an analogue with a lower burden.

When sand particles are found in drinking water, you should rinse the filter and raise the pump by half a meter.

If you frequently turn on the anti-protection protection, you need to check the water level in the well. This happens when the device is installed with a violation of the static and dynamic indicators of the water level.

It is necessary to buy a submersible pump, firmly knowing the indicators of the quality of water in which this device will be operated. For example, such as impurities, pieces of soil and sand. These parameters are contained in the technical characteristics of the device. So you keep the pump intact and extend its service life for many years.

An approximate calculation of pump performance is made by calculating the volume of water pumped by the pump per hour. 100 liters per hour multiplied by the number of cranes. Then add ten percent for stock.

Performance and well production should be correlated in the correct proportion, which will protect the device from overheating and ensure its uninterrupted operation. It is enough to make calculations accurately and you can save money on a model without a circuit breaker.

When buying a pump, take into account seasonal indicators, under what conditions it will work. For year-round use choose modern innovative models of submersible pumps.

The purpose of the water determines the choice of the pump. Some of them are suitable for the extraction of clean drinking water, others are suitable only for irrigation, others are universal, they can be used for any purpose.

The frequency of water injection is also important. Intermittent water supply involves connecting to a hydraulic accumulator.

In borehole models, a rubber hose is often used to pump water to the surface. During operation, such a hose wears out quickly, which affects the quality of the water supply. To avoid work on the replacement of the hose, it is better to immediately install plastic components of the appropriate purpose and size.

When buying a device, correctly calculate the water pressure using the formula: depth + 30 + 10%. It also takes into account the diameter of the pump, which should not exceed the diameter of the well pipe, and ideally be slightly smaller.

Do not allow water to freeze in the pump and water pipes of the water supply system. This may damage the unit. Weatherable room mines pumps should be given considerable value not only in the winter.

Sudden temperature drops and temperature jumps have a very negative effect on the operation of the pump and can lead to its breakdown.

Increasing the maximum allowable water temperature has no critical effect and does not affect the pump,as it is equipped with thermal sensors. However, it should be borne in mind that the heat transfer can significantly deteriorate.

To make the pump serve for a long time, follow the simple recommendations on safety and operation of the device specified in its technical documentation.

You can learn more about choosing and installing a submersible pump from the video below.