Rules for the selection and installation of surface pumps

The construction of country houses is becoming increasingly popular every year. It enables many people to solve the housing problem. In addition, this solution will provide fresh air and an amazing view from the window. But there are some shortcomings. For example, in the cottage villages there is often simply no infrastructure. And one of the main problems is water supply. Of course, the well may reduce its severity, but for urban residents who decide to leave the city, such a decision will be unsatisfactory.

For this reason, almost every site gets its own autonomous water supply system. In some systems, the main element will be wells, and in some - wells.If at the heart of such a system is just a well, then the surface pump will be most welcome. It is quite affordable in terms of price and easy to maintain. And the use of such a device will allow you to create a more or less stable supply of water at home.

Special features

Surface pump is a device that is designed to work without immersion in the working environment. It is usually necessary to immerse in it the appropriate hose, which is called water intake. This is convenient, because the maintenance and care of the device is greatly simplified. That is, you can inspect it and fix it if necessary.

But such an advantage can be the cause of a serious problem. The point is that the surface pump is too small to lift water from a great depth. The maximum depth with which such devices can operate is 10 meters. And in most cases at this level is water that is unsuitable for drinking. So if you are looking for a unit that is supposed to be a source of drinking water, then this is definitely not what you need.

But if you just need technical water to water the garden, for pumping water from the basement or an artificial pond, then you can safely buy a surface pump. In addition, such models are versatile.

For example, they can successfully equip both wastewater systems and water supply. It is also about drainage systems, as well as those that carry out watering of plants on the land plot.

Kinds

The pump unit, which is designed to be a universal helper in the household, is most often performed according to a self-priming scheme, has a low weight and average head and performance characteristics. Most pumps of this type will belong to one of four groups:

- Whirling surface self-priming pumps that have a load control mechanism. As a rule, they are made in the form of a monoblock, which is located horizontally with the removed power cord, control board, as well as connections for water inlet and outlet. Usually they are needed for pumping water that is not dirty.

- Surface centrifugal self-priming pumping units, in which there are devices for preliminary raising of water from the minimum depth of the well or tanks.According to this scheme, which uses the centrifugal principle of discharge, surface pumps are usually made for pumping dirty water.

- Screw surface models that are designed to work with viscous and very heavy liquids. Most often they are used as a fecal or sewage treatment. They are not universal at all, since they will not be suitable for most tasks at all or only with great difficulty.

- Water mud surface membrane and volumetric ring pump systems. Most often, such options are used to work on communal communications systems. Usually they have special protection, which makes it possible to work with water that is very heavily contaminated with silt.

By the way, the latter option does not apply to mud or special. If we take its characteristics, it is close to faecal drainage pumps, but, as a rule, it is not completed with a shredder.

All the pumps that were mentioned, unlike submersible ones, are not designed for contact with water at all, although they have a closed casing and also sealed insulation pads.

Vortex models are the most affordable and compact in size. They create pressure 4-8 times higher than the same models that are centrifugal. But at the same time, their efficiency is significantly lower - 45%. They in no case can not be used for pumping water, which contains various impurities or a lot of sand. This may cause rapid impeller damage.

Such a pump raises water with the help of a rotating shaft and a wheel on which special blades are located. They transfer water to the energy of the working axis.

If we talk about centrifugal models, they are also not suitable for too polluted water. But they are not afraid of traffic jams or air bubbles. Such models will be more expensive vortex, because they are multi-stage. This design works thanks to the wheels that pressurize. The principle of their work is simple: the wheel drives the working shaft, which is based on the mechanisms of bearings.

It should also be said about such a category as a pump with an ejector. The presence of the ejector allows you to significantly increase the suction depth of the surface pump, but significantly reduces its efficiency. Such a pump can take water from 15 to 20 and from a depth of 30 meters.But now pumps with an external ejector almost never occur. Submersible pumps are used instead because of their greater productivity and better efficiency.

It should be noted that the vortex and self-priming devices have a number of fundamental differences:

- Given that the speed of movement in the same diameter of the impeller is equal for both models, the vortex, or, as it is also called, screw pump, can create twice the water pressure than the centrifugal one. It is for this reason that models with a vortex device are used to supply water in large volumes or to equalize the maximum pressure in the system. Also, this model is used for deeper wells.

- A self-priming pump makes almost no noise, while the vortex model, due to the air being pumped into the channel, “snail” produces a rather loud sound during operation. You should also say that the centrifugal pump has a fairly large size. The vortex model is used only to supply clean water.

Scope of application

If we talk about vortex models of pumps, then, as noted above,with equal characteristics, such systems give a much greater water pressure, which significantly exceeds the characteristic characteristic of the usual 1-stage centrifugal counterpart. It is almost double the excess.

If we are talking specifically about the places where such a solution can be applied, then it can be used both for dacha and home. For example, you can use this type of pump in order to provide a family with water from a well, or you can pump water into a cistern with drinking water. You can also use the vortex pump to pump out rain water from a well or sump. You can use it for watering the beds, shrubs and trees, as well as for washing sidewalks and paths. In addition, if necessary, such a pump can be used to clean any surfaces or containers. For example, car trailer or pool.

If we use an intermediate additional dirt collector, then this type of pump can pump out water from cesspools or the basement.

The surface vortex pump has self-priming properties due to the features of its design without the use of any additional devices,like the same screw or centrifugal models. To do this, simply leave a small supply of water inside the working chamber.

If we talk about centrifugal surface pumps, then such systems are more convenient and compact at least due to the fact that they have a higher efficiency of the impeller. That is, here you need a motor two times smaller to ensure the same performance as that of the vortex pump. Therefore, to distinguish such a device from the vortex is not difficult.

It should be noted that in addition to conventional solutions, there are also two-stage pumps, which make it possible to obtain an increased water pressure at the outlet. And this makes them a rather serious alternative solution.

Screw surface solutions are not as common as the above options, but in general the use of a shaft with a profiled surface makes this option not only the most durable, but also the most unpretentious to the fluid that will be pumped.

At the same time, the effectiveness of this category of models, as well as its performance will be two times less than the models that were described above.But the ability to work with rather viscous liquids makes such a model a great solution in a private house or, say, in the country. If we talk about direct application, then it can be used, for example, to perform drainage of a marshland after rainstorms or floods have occurred. In addition, with such a pump you can irrigate, as well as pumping water, as with any other pump.

Also, an interesting category of models can be called a volumetric ring pumps. Their peculiarity is that they use a star-shaped impeller. This makes it possible to work with extremely polluted liquids. In order to hold up the largest particles, in such a design, a front closure is used, which does not allow the elements of the pump rotor and housing to become jammed, or a special trap.

There are practically no analogs of this category of devices, since here it is necessary to take into account the consistency of the pumped liquids. Another important characteristic of the operation of such a device is that it can work when the temperature of the liquid being distilled is up to 95 degrees Celsius.

Installation

It is believed that installing surface pumps is much easier than submersible counterparts. Somewhere it is, and to some extent not. In any case, a number of important points should be taken into account, which, with proper installation, can significantly improve the efficiency of the pump and prevent possible malfunctions.

For example, it is best to locate such equipment in insulated or heated residential premises.

In order to connect the surface pump, you should have on hand such materials:

- hose for water intake;

- connecting nipple, which is usually installed between the hose and the pump;

- watering hose;

- hose or tube for connection to the storage tank;

- connecting fittings;

- fasteners;

- special adapter for the second exit;

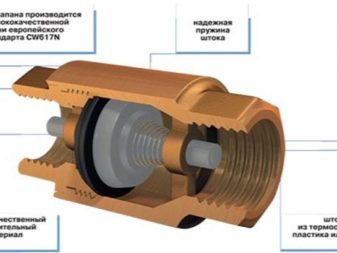

- check valve with strainer.

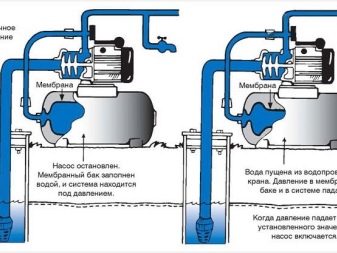

If mounting is carried out with a hydroaccumulator, then you will also need a pressure gauge, as well as a pressure switch. If only a storage tank will be used, then it is necessary to have a float sensor. You will also need various keys and accessories to work with fasteners.In addition, you will need a construction level, tape measure, insulating materials for threaded connections, as well as a soldering iron for polypropylene pipes.

Before connecting any elements to the pump, it is necessary to install it on an even and strong base. This is an extremely important point, since even a small problem with stability can cause a serious decrease in the performance of this device. It would be best if the base is made of solid wood, brick or concrete.

In order to stabilize the pump, it is best to use anchor bolts. For mounting in the device there are special holes. Sometimes a large rubber gasket is installed under the pump casing.

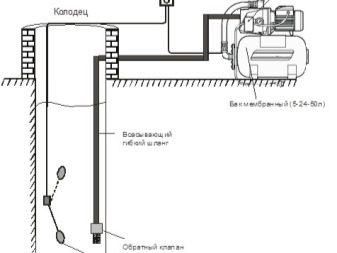

It plays the role of a shock absorber that completely dampens vibration when the engine is running. Now you need to install the supply hose. A non-return valve is attached to its lower part, on which a strainer is put on. As fastening the coupling with external threaded connection is applied.

It is very easy to buy such a hose, but it will be cheaper to make it yourself, which will make it possible to save a lot.Yes, and with proper installation, such a device will be no less reliable than the industrial model. Sometimes they install two check valves: one near the accumulator, and the second at the end of the hose.

The top of the hose is connected to the pump with a union. By the way, if you wish, instead of a hose, you can use a polypropylene pipe with a diameter of 32 millimeters. After that, the hose is lowered into the water so that the check valve is immersed in it for at least 30 centimeters. A special fitting should be used to connect the check valve to the surface pump.

The check valve itself is to protect the pump from idling as well as from contamination. After that, the pump is connected to a storage tank or a hydroaccumulator. It must be remembered that the horizontal part of the hose should have a slight slope. If the installation of elements is carried out on threaded connections, then care should be taken to properly seal with the help of fum-tape or some similar seals.

Now you need to connect the structure to the plumbing system at home.When laying pipes should also be aware of the correct slope. Very important is the insulation of pipes that were laid in the ground. Today, there are a large number of heaters on the market, so choosing the right option will not be difficult.

In order to mount the part of the water supply system joining the pumping station, a set of fittings, PVC pipes, and a device that will allow them to be soldered will be necessary. Only after the common highway, which was connected to the inside of the house water supply, is made, can the entire system be tested.

Improper start-up of the pump can cause its failure. In this case it is better to have spare parts on hand.

Details of the launch are usually set out in the manufacturer’s instructions, which should be studied before launching. Before this, surface pumps are filled with water using a special hole. Water must fill not only the pump, but also some space of the line before and after it. After this, the filler hole should be closed.

It is also necessary to immediately record the pressure readings in the system and in the accumulator. This information may be helpful in further customizing the entire system. It may be necessary to blow the air out of the hydraulic tank or pump it there. Then connect the pump to the electrical network and turn it on to fill the hydroaccumulator and storage tank with water. Now you should check all connections for leaks and fix problems, if any. If the system has been assembled correctly and there are no leaks, you can configure the control equipment.

After that, you should check the operation of all automatic mechanisms. To do this, simply open the water and watch the process. When nothing remains in the accumulator, the pump should automatically turn on and off when the tank is filled with water to a certain level.

As a rule, the pump is turned off automatically at the moment when the pressure in the system will be three atmospheres.

After that, the water is drained until the pump turns on again. Now we need to fix the real pressure in the system and compare it with the indicator given by the manufacturer.If the differences are significant, then you should adjust the operation of all devices.

Tips

The rating of the best pumps, though made up on the basis of reviews, but should not be completely trusted. The fact is that everyone has unique conditions at home, and to be sure that this or that model will behave in different situations more effectively than the other would be rather silly.

In order to choose the most efficient model of a surface pump, one should be guided by the following technical indicators:

- head;

- performance;

- suction depth

At a minimum, this data will be important if you use a circulating pump for irrigation. If we are talking about a device that will provide water to the house, then you should focus on the following parameters:

- the amount of water consumed by the family;

- necessary pressure in the water supply system;

- number of points of consumption.

Another tip - use the equipment exclusively for its intended purpose. The use of a centrifugal model with a built-in ejector, which is designed to work with clean water, to pump some viscous substances, such as diesel fuel or diesel, will definitely cause the pump to fail.

As mentioned above, the pump is best kept in a dry place with a suitable temperature. There are no serious restrictions here, as long as the equipment does not suffer from sudden changes in temperature and their permanent effect.

If you need to store the pump without using it, then this should be done in compliance with two rules:

- the unit should be stored in a special box;

- in the hoses and the tank should not be moisture.

As you can see, it is not difficult to choose and mount the surface pump with your own hands, even for a person who has not previously encountered such equipment. The main thing is to know clearly what you need a pump for and how exactly this unit will be used, as well as to have on hand all the necessary materials and components.

In the video below you can see an overview of the surface pumps Aquario (Aquario) series AJC.