Types of pumps Belamos and their technical characteristics

Today a large range of pumps is on the market. Such equipment is in demand, as many people are the owners of country houses or villas, where you can relax from the bustle of the city. In such areas there is not always a central water supply, heating and sewage. To create comfortable conditions using a variety of pumping equipment. Among the great variety are the devices manufactured by Belamos.

Special features

Belamos has been manufacturing pumping equipment for about 20 years. The pumps of this company are presented in different versions. In the range there are submersible, drainage and circulation options. Moreover, these species are divided into several subspecies.Judging by the reviews, the company's products have high quality, reliability and affordable price.

Brand products are intended for domestic use. Among them, the most popular are submersible models. Such devices differ in the form and design, but all variations also have certain elements characteristic of any model of a submersible pump.

The case of such a device looks like a capsule, the diameter of which can be from 12 to 15 cm.

Submersible pumps with a diameter of 15 cm are not so popular, but they have a very high performance, which is their main feature.

The submersible pump got its name due to the fact that it is capable of pumping out water from there into the well. Most people use pumps specifically for pumping water from wells, so the manufacturer tried to minimize the size of the devices of this type. Such products are not afraid of serious stress. The engine does not heat up during operation, as it is in the water. As for the maintenance of such a device, it is necessary only in rare cases.

According to experts, for optimal pumping operations, pumps should have a slightly smaller diameter than the size of the well itself. For example, if a well has a diameter of 18 cm, then a device with a diameter of 15 cm is quite suitable. If the diameter of the device is larger, it will closely adhere to the walls of the well. Because of this, the engine will not be able to cool.

As mentioned above, the manufacturer also produces drainage types of pumps that are similar in principle to submersible pumps. The main difference of the drainage unit is in the field of use. This option is used for pumping fecal, sewage, cesspools, etc. This type of pump is not used as often as the previous one, but only when necessary.

Circulation options are used to circulate the coolant through the heating system. The design of such a pump is very simple, as it performs an easy task.

However, often in the organization of the heating system to do without such a pump does not work. The manufacturer understands this and pays due attention to the quality of models of this type.

Species

As for the types of brand pumps, there are many.Most popular series: SP, TM, TF and TS. Also, the units have different modifications and types of structures.

The main types of pumps, as already noted, are three.

- Submersible. This type of pump is used to transfer water to the water supply system. It is considered stationary. Such models have in their design impellers that pressurize the water in the hose and thus deliver fluid to the surface. It should be noted that such pumps are able to supply water from a decent depth. The maximum depth of a submersible pump with an average power reaches about 60 meters. At the same time he is able to create water pressure on 120 meters. These pumps are made of stainless steel and plastic.

- Pumps of drainage type. This type of pump is used for pumping dirty water, sewage, septic tank and even mud from a silted well. Such pumps also inject fluid into the hoses, but with the help of reinforced impellers and a large output channel. Garbage in the pumped-out place can have a large size. Therefore, a filter is installed at the inlet to such a case, which separates the debris from the liquid, allowing the latter to be freely pumped out.Basically, pumps of this type are capable of delivering fluid to 14 meters. They are made of high-strength plastic. The main difference of this type from the previous one is its size. Drainage pumps are made in the form of flasks, the diameter of which is several times smaller than the height of the body.

- Circulation pump. Such models are simple and reliable. Basically, this type of product is used to organize forced pressure and coolant circulation in heating systems. The main work in this case is performed by the impeller, which is mounted on a weak motor. The impeller forces pressure in the system and thus forcibly forces the fluid that is in the system to move in the right direction.

All three types of pumps are very relevant and in demand among owners of suburban areas. They are used for different purposes, but in principle the actions of all types are similar, since all of them perform the function of pumping fluid and feeding it under pressure.

If you are interested in borehole, deep faecal, and well well pumps, you should pay attention to the following popular models:

- tf3 60;

- TF3-80;

- TF3-110;

- DWP 2200;

- DWP 450;

- DWP 750;

- SP 5;

- SP 40;

- DWP 1500/22;

- DWP 1300 cs.

But before you make a purchase, pay attention to what country is the manufacturer. Experts do not advise buying Chinese-made goods, as if a control unit breaks down or if you need to replace any spare parts, you may have difficulties.

Installation and repair

When purchasing a Belamos unit, it is better to immediately buy a couple of inch shooters, tees, a valve and a water purification filter. Installing the pump is pretty easy. It is performed according to a specific scheme.

First, a filter and check valve are installed. They are not considered reliable elements, so that each owner decides whether he should spend money on them. In addition, these parts can adversely affect the pressure in the system and resist water. As a replacement, you can use a piece of soft rubber, which is quite capable of replacing the check valve.

According to the recommendations of experts, the threaded connection should not be sealed fum tape. It is better to use the "old grandfather's" methods, that is, flax with paint. The use of fum tapes implies a reliable and fixed system.If you use it on a moving system, then soon it will be depressurized.

Then a small amount of water is poured. For these purposes, on some models of the brand there is a special opening (for example, on XP 05). If the pump is connected to the system tightly and keeps water well, then it is not necessary to fill it every time.

So, you kind of pumped water into the system. After this, connect the unit to the power supply and open the valve. The pump begins to perform its function. In order to stop the operation of the device, it is necessary to turn off the tap and disconnect it from the power supply.

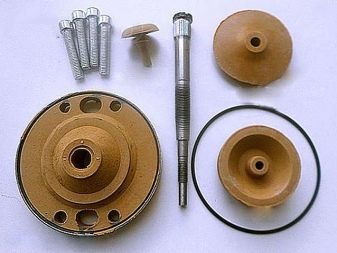

Usually such products do not need to be repaired, but sometimes they are still needed. The main cause of damage is the clogging of the impellers and the failure of consumables. In order to accurately determine the cause, it is necessary to get the unit out of the well and clean it. Understanding submersible pumps is pretty easy.

If the cause of the breakdown is not clogged, then it is necessary to check whether the seals, bearings, impellers are in good condition. If you find an item that has failed, you need to replace it.

If, after an inspection and a performance check, you were unable to accurately determine the cause of the breakdown, then you should seek professional help. If you continue to use the device, the screws or the motor may be damaged.

As for drainage patterns, the underlying causes of breakdowns may be the same. Carry out activities to find the cause of need for a similar pattern. However, in this case, you will spend much more time, because it is much more difficult to disassemble and assemble such pumps.

Tips and tricks

Before buying a unit, you need to decide on the scope of its use. In accordance with this, it is necessary to choose a suitable type of pump, its parameters and characteristics.

For example, if you purchase a pump for pumping water from a well, then you first need to know its size. It is worth remembering that for the pump to work effectively, its diameter should be several centimeters smaller than the diameter of the well. The wrong choice will affect not only the quality of pumping water, but also the life of the device. Also in the well will need to install a siege pipe, which will greatly facilitate the removal of the pump in case of need for repairs.

Judging by the recommendations of experienced specialists, when selecting a pump for a well, its performance must also be taken into account. (how much liquid it is able to give for a certain time). If the performance of the pump will be more than the well, then the device will pump out the water too quickly and will run idle for a while, disrupting the stability of the water supply. Also, experts advise when selecting pumping equipment to ensure that the parameters of the unit are in depth of the well.

Before choosing a particular model, you can read the reviews of the company's customers who have already tried the device in action. Most of the opinions about the brand's products agree that with correct selection of parameters, the equipment works flawlessly. There is a high quality of products, as well as the reliability of the units and the duration of their use.

Belamos pump disassembly - in the next video.