Wilo circulation pumps: product range

The performance of the heating system in many high-rise buildings is not satisfactory. This is due to the small diameter of the pipes used, which is water, and too low pressure. If the second problem is solved, then it will be possible not to even think about problem number one, since with a good circulation pump it will be possible to ensure the normal movement of the carrier along the wiring, thus increasing the operability of the entire system.

Special features

Not all manufacturers can offer a good productive station for pumping fluid.As a rare exception, we can call the German company Wilo, whose pumps can be presented in different variations. All proposed models are distinguished by high-quality ergonomics and modern controls.

Wilo pumps can be used to provide hot water to any heating system and various air conditioning systems, are considered the most versatile type of equipment that is designed for small areas of the residential sector, providing high-rise buildings and industrial applications.

Benefits of Wilo pumps:

- universality and wide scope of application;

- substantial savings;

- compact dimensions of components;

- corrosion protection;

- reliability and durability of the device;

- overheat protection;

- reliable cleaning system;

- reasonable rates.

Technical characteristics of circulating appliances for heating Wilo can be called several parameters.

- Convenient control in the form of a mechanical or electronic switch. You can adjust the power and speed of the coolant.

- Models with electronic controls have a built-in thermostat.

- The electric motor and the rotor will be protected from electrical power surges.

- Device performance: head of water column from 1 to 7.5 m, heated area - from 100 to 2200 m2, throughput capacity - from 1 to 12 m3 per hour. Working parameters of temperature are from-10C to + 110C.

Kinds

The manufacturer offers the consumer a range, the technical characteristics of which are almost similar, the main difference is only in the flange parameters.

Wilo Star Series

The Star-RS unit is a low power device that is perfect for home use. The body is made of high-quality cast iron, the impeller is made of plastic, and the shaft is made of stainless steel. Used for pumping clean water, in which there are no abrasives and various impurities.

The RS series includes 12 samples, which have the name from 15-4 to 30-8. These circulation products for heating have a capacity of 6,000 liters per hour at a normal pressure of 10 atmospheres.

- Star-RS 25/4 - this is a surface type pump for clean water, throughput - 3 m3 per hour, water pressure - 4 m, power 68 W.

- Wilo 25/6 pump get to supply water in small heating systems and closed systems.

They can be chosen for multi-family and private homes.

- Circulating device Wilo Star-RS 25/7 for heating systems - three-speed equipment with a threaded connection type.

- Product Wilo Star RS 25/2 with threaded connection and wet rotor. Designed for installation in air conditioning systems, heating and cold water supply, and in industrial systems.

- Wilo Star Z Series Nova - it is a device with a wet rotor and a synchronous electric motor, resistant to blocking currents, used in industry for equipment of various types of structures.

- Aggregates Wilo-Star-RS 30/8 used for work in different temperature parameters: with ventilation systems, with different radiators, floor heating system. And they are also used in air conditioning systems.

- Star-RSD - This is a dual mechanism, which allows to increase the reliability in operation: during the breakdown of the first mechanism, the second starts to work automatically. Otherwise, the devices operate simultaneously, while water will be supplied through different lines: separately for heating and hot water supply.

You can choose one of two models: 30-4 and 30-6.

Wilo Stratos-Eco

This is the most advanced electronic version, which is released for operation of boilers with low power.The device controller will monitor the operation of any heating system, which guarantees savings when using the resource and its operation at the lowest temperatures. Wilo product is represented by seven markings: from 25 / 1-8 to 65 / 1-2, which are equipped with a wet rotor and are suitable for hot water supply with a large amount of oxygen.

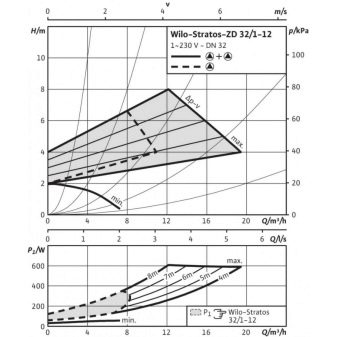

Wilo Stratos-Zd has a preliminary speed for operation in a constant day-night automatic mode. Available in 2 types: 32 / 1-12 and 40 / 1-8.

Wilo Top and DHW

This series is used for space heating systems that have an area of more than 1,500 m2. Wilo Top circulation equipment is a water pressure up to 10 m of water column with a working pressure of 10 bar. Among Wilo Top flange pumps can be found.

- Top-Rl and Top-S - equipment of two-phase type, performing high-quality work in a continuous mode. The pumps operate at temperatures from -20 to +130 C, can be used for a separate circuit in the closed-type water supply and hot water supply systems.

- Top-S 40/10 - does not require maintenance, has a threaded or flanged connection; If desired, you can select the speed stages for precise power control.

- Pump Top-S 50/15 can be used for different water heating systems, air conditioning systems, refrigeration and industrial systems with circulation.

- Top-Z Series need to pump water to drink.Silent operation is provided by the wet rotor design. Full protection of this motor is guaranteed by an electronic shutdown system.

Pumping equipment is placed even in the most unsuitable places.

Equipment for heating Wilo

These devices, including those for hot water supply, the company released not so long ago. This equipment is adapted to water with a relative degree of hardness with a low content of magnesium and calcium. In models of this series the driving wheel is made of stainless steel.

The modification was designed specifically for large heating systems. Such equipment can be connected to boilers with a capacity of 25 kW.

Characteristic features of the Wilo Stratos device with an electronic control unit can be considered:

- power output of the Wilo 2 is 48 W;

- there is a night mode when the use of electricity decreases;

- automatic adjustment of the parameters of work - the controller is connected to the thermostat, which will allow you to choose the optimal speed, performance depending on your needs.

Wilo yonos

It has an electronic control unit, protection against airing of the system and the function of removing solid particles from the environment of a specific heat carrier.

Switching operating modes in Wilo Yonos is made using a separate switch. It is possible to use fixed settings. For the most economical power consumption, the module can be switched to automatic mode.

The Wilo Yonos pump control unit has an indicator panel, where all information about power, system pressure and other parameters is displayed. In addition to the usual installation length of 18 cm, production of small-sized devices of 130 mm was launched.

Device

The company produces pumps of two subspecies:

- with a dry rotor;

- with a wet rotor.

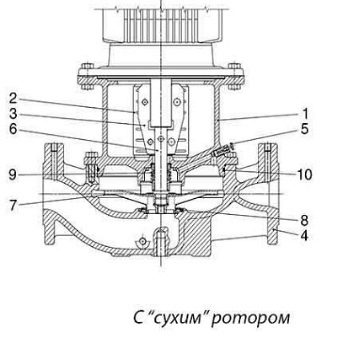

Pumps with dry type rotor

This type of pump indicates that the rotor of an electric motor has no contact with water. The connection of the engine with the working part is made with the help of special sealing rings, which will not allow the used fluid to be in the electric drive.

This unit consists of two parts: the 1st part is the electric motor itself, the 2nd part is the body with two branch pipes - one branch pipe of the injection type, the other - the suction side. In addition, it has an impeller that performs pumping.

This type of pumps are used in systems with a fairly large length of pipelines and large diameter. Most often they can be found in industrial and heating boilers.

The main indicators of the device:

- high level of efficiency - more than 80%;

- It is necessary to install filters to prevent foreign objects and particles from entering the product.

In the room where this equipment will be installed, there should be no dust, otherwise the sealing rings will quickly become unusable. It will be quite difficult to replace the rings, only a specialist can do it. Type of connection, as a rule, flange.

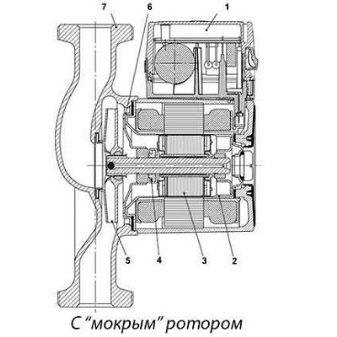

Wet Rotor Units

This product is often used for domestic needs. The device of such pumps will differ significantly from other models. The motor and the impeller are located in the housing itself, which has both an inlet and an outlet. The transfer of the coolant is carried out as if by the rotor itself, which is equipped with an impeller.

The bearings are cooled and lubricated by the pumped liquid itself. This product is used in heating systems with a small length and small pipe diameters.They are connected by a threaded connection.

Main equipment indicators:

- almost silent operation;

- has the most compact execution;

- if necessary, you can change the parameters of work, which will help to significantly save on electricity consumption;

- long term work;

- almost does not require constant maintenance.

Wet rotor models for various heating systems are equipped with three-mode impeller speed adjustment units. Management of these blocks is carried out in manual mode. The temperature parameters in which such units can operate range from - 20 to +130 degrees.

To properly connect the selected pump, be sure to familiarize yourself with the wiring diagram, and best of all - contact an experienced technician.

Installation

The installation of the Wilo unit in the heating system must be carried out in full compliance with the existing instruction manual, which is provided by the manufacturer. During installation, several important rules must be followed.

- Only vertical installation of the units of this company is allowed. Horizontal placement of Wilo pumps in the system is strictly prohibited. The exception will be only those models that are specifically designed to connect in a horizontal form. The installation position of a particular pump can be found in the detailed instructions.

- Connection of system of heat-insulated floors - The device is installed in a special node. The correct placement of the Wilo heating product will be indicated by arrows, which are located on the housing of the unit itself and on the hydraulic wiring.

- Connection to radiator type heating system - Installation is made in reverse heating, directly in front of the boiler. In order to prevent a complete stop of the circulation of the coolant, a bypass is also installed here.

The installation rules for Wilo devices allow you to choose equipment for heating systems with both natural circulation and forced circulation.

- Installation and maintenance - the pump is mounted vertically in compliance with the direction of the coolant, which will be indicated by arrows on the body and node. Installation must be carried out only by qualified craftsmen.

- Ways to install the device will depend on the chosen model, as a rule, they are described in some detail in the instructions. With proper connection to the special service, the Wilo pump does not require.

- On the bypass frame, you need to put a coarse filter immediately in front of the pump. Take into account all the specifics of the installation of the Wilo heating pump, disassemble and reassemble it, carry out repairs can only experienced specialist. Installation of the device is carried out in just 2-3 hours.

If you also install a bypass, you will need 4-6 hours.

Connection steps:

- the pump is assembled, the connection point on the circuit is selected;

- turns off the water, there is a tie-in to the heating system;

- the device is mounted, the main thing is to install it in the right position;

- connections are tightened and sealed;

- the product is connected to electricity;

- fluid is supplied to the circuit, and the device starts up;

- tested in operation.

An extraneous hum during operation of the device will indicate a number of possible malfunctions. The air vent may be clogged, as a result of which air will not be removed from the system. Another frequent malfunction will be in the wrong mode of operation.

Reducing the speed of the device with his hands usually leads to the disappearance of the hum. If this does not happen, the pump must be serviced.

Operation Tips

You can offer a few key recommendations. which will ensure long-term operation of this type of equipment.

- It is possible to leave the device in a permanent mode without fear.

- Experts advise sometimes to turn on the equipment for 10-20 minutes after the heating season is over.

- The equipment can be switched on only if the heating system is filled with carrier.

- Models that have a wet rotor in their structure, are used for lubrication coolant. When turned on, if the lubricant is missing, the bearings can burn very quickly.

How to connect the circulating pump to the heating system, you can learn from the following video.