Screw pump: what is it?

The screw pump is a popular type of pumping equipment and is widely used in industry and everyday life. The simple and trouble-free design of the device allows it to be used for pumping fluid of different viscosity between the tanks and delivering it from the well to the pipeline system.

Device

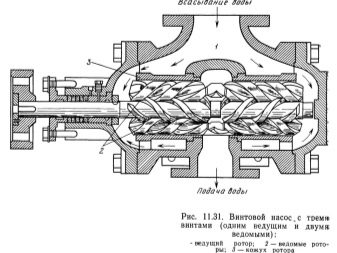

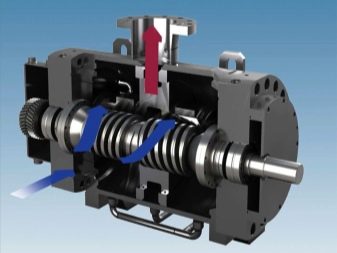

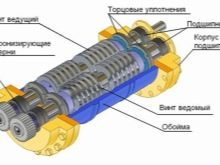

A screw pump is a structure in a closed case consisting of a working chamber, a rotor and a stator. Also, the device is equipped with outlet nozzles, gearbox and sealing parts. The driving part of the design is a rotor having the shape of a screw and located in the cavity of the stator.

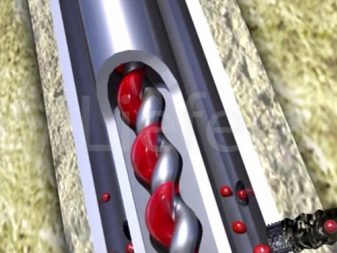

The principle of operation of screw pumps is quite simple. On the lower part of the body there is a supply opening through which the liquid enters the internal working chambers of the device. Then it is captured by the rotor blades and pushed into the upper part of the chamber to the pressure port.

The pump belongs to the type of submersible devices and can carry out its work while being at the bottom of a reservoir or reservoir. One of the main technical indicators of the device is its performance, indicating the amount of water that the pump is able to pump over a certain time. This figure depends on the length of the screws (augers), and their number. Most models are equipped with a single screw device and are designed for domestic use. More serious industrial pumps may have a structure consisting of two or more screws.

An important design feature of auger pumps is their shape, which is an elongated narrow cylinder. This allows you to create complex hydraulic machines with high power and small dimensions on the basis of screw pumps.

Thanks to its robust casing and reliability, pumps are successfully used at great depths, the values of which often reach 100 meters.

Technical characteristics of screw pumps are as follows:

- model performance ranges from 1500 to 2000 liters per hour

- liquid head is 60 m. v. $

- engine capacity can reach 5 kW.

The devices are capable of pumping contaminated liquid with solid fractional inclusions up to 2.5 mm in size.

The casing parts of screw pumps are made of stainless steel, and the internal elements are made of high-strength plastic. Rubber and silicone are used as material for the sealing elements. The device operates from an electrical network of 220 V.

Special features

Screw pumps are a rotary-gear rotary apparatus. The devices are highly resistant to mechanical loads and aggressive chemicals, which allows them to be used when working with all types of liquids, including polluted and industrial drains. Pumps are able to pump water with sand without the risk of clogging or failure. Unlike surface models, screw devices need to be fully submerged under water.

In the case of a decrease in the level of liquid, the device automatically shuts off, which prevents it from overheating when operating at idle.

The scope of use of screw pumps is very wide. The devices have found their application in the food industry. They can be used to pump viscous substances, such as condensed milk and batter. Devices are actively used in gas, oil and artesian wells, with the arrangement of fountains and domestic water supply, to fill storage tanks and pools.

The units operate at a depth of 8 meters, the rotor rotates at a speed of 6 thousand revolutions per minute, and the fluid pressure at the outlet is from 4 to 25 atmospheres, depending on the purpose of the pump and the number of screws.

Another feature of screw devices is their ability to work virtually silently, which adds convenience to their use, for example, when supplying water from a well located in a house.

Screw pumps have a very large resource development, high strength and durability. This allows them to be used not only for domestic needs, but also as a pumping equipment at large mining and processing industries.Model performance ranges from 1500 to 6000 liters per hour.

pros

High consumer demand and the popularity of screw pumps are due to a number of undeniable advantages of auger design.

- Long service life of pumps is achieved due to the absence of friction between the rotor and the inner side of the housing.

- The pumped liquid moves in a uniform flow without slowing down and pulsation.

- No noise and low vibration.

- The presence of a protective system that ensures the shutdown of the device in case of a liquid level falling below the permissible limit.

- Excellent suction capacity and high performance of the pump allow fast pumping of large volumes of fluid of various degrees of pollution.

- Compact size and versatile shape make pumps ideal for diving in wells and narrow wells. The diameter of the devices is 12–15 cm, which favorably distinguishes the screw units from other types of deep-seated technology.

- The ability to create a state of deep vacuum in the tank and the ability to work at any depth.

- Full preservation of the structure of the pumped liquid.Due to this property, screw models are widely used in the food industry.

- Simplicity in service, the small sizes and weight do pumps popular for arrangement of a water supply system in country houses and on personal plots. The units do not require regular maintenance and do not need expensive spare parts and repairs.

- The location of the intake openings above the electric motor ensures its permanent presence in the water, thereby preventing overheating of the device.

Minuses

The disadvantages of screw pumps include the high cost of particularly powerful models. This applies mainly to industrial specimens, which are equipped with two or more screw mechanisms and are designed for serious loads. Household products cost much less and are purchased with pleasure by the owners of country houses and cottages. The disadvantages also include the inability to regulate the pumped volume.

What is the difference?

Pumping equipment is divided into surface and submersible. Screw pumps are submersible models and can operate at great depths. Unlike other types of pumping systems, screw models are able to work effectively with rather thick media without overheating and without clogging.

Another difference is the smooth flow of water, without drops and pulsation. As the power of the device increases, only the speed of the pumped liquid increases, its outlet pressure remains unchanged.

This quality is very important when it is necessary to preserve the specified parameters, which is usually required when working with oils and petroleum products.

Kinds

Screw pumps are classified according to two criteria: immersion depth and number of working screws. According to the optimal depth for exploitation, standard models and depth units are distinguished.

- The first are applied more for domestic needs, such as pumping water from household wells up to 25 meters deep. Also, shallow-water pumps are indispensable when working in wells drilled in sandy soils. This is possible due to the design of the screw equipment, ensuring its immunity to the content of sand in dirty water. Such models are usually small-sized and are great for individual use.

- Deep devices have a longer body and are designed to work in artesian wells to a depth of several hundred meters. Such pumps are characterized by high cost and increased productivity. The power of deep industrial products is also several times higher than that of domestic counterparts. The average electricity consumption of pumps of both types is from 1.5 to 5 kW, which allows them to be connected to standard power supplies with a voltage of 220 V.

By the number of screws, pumps are divided into one-, two- and three-screw models. The first most often have a standard design and are intended for use at shallow depths. Twin-screw specimens are already used for pumping out highly viscous and highly contaminated fluids, or are used as well equipment and can be used for pumping mineral, fresh and sea waters. The resistance of the case to the effects of salts and chemicals is due to the presence of a plastic casing that securely covers the metal elements of the case.

The cost of such pumps is quite high, especially for industrial-grade rod models, the price of which can be compared with the cost of injection hydraulic models.They are designed to work in particularly unfavorable conditions with a large amount of polluting waste, for example, when pumping oil from oil wells and pumping finished oil products such as fuel oil.

Among the twin-screw products stand out vacuum models. In them, the two rotors rotate in different directions, due to which there is a more powerful pumping effect. Three-screw models are used for pumping non-aggressive lubricants that do not contain abrasive and coarse fractional suspensions, or contain them in minute quantities. The choice of the necessary option is carried out taking into account technical needs and on the basis of the calculation of the necessary power of the unit, its purpose.

Manufacturers

The modern market of pumping equipment offers a large number of screw models from different manufacturers.

- The best-selling Russian-made device is a submersible pump. "Aquarius". The product is characterized by an ideal ratio of price and quality, and serves as an excellent alternative to expensive foreign counterparts. The only drawback of the device is a lot of weight and not very reliable cables.mounts.

- Another no less worthy representative of the pumping equipment is the model “Octopus"Also produced in Russia. The pump is characterized by resistance to corrosion and wear, impact resistance of parts of the unit. In addition, the plant provides maintenance services and guarantees the long life of its pumps.

- Among the foreign manufacturers are the most famous companies. Gadrena, Aquatica and Werk, whose products are of the highest quality, ease of use and long service life.

Tips

In order for the screw pump to perform its work for a long time and efficiently, the device must be correctly installed. And although the installation scheme of augers is not much different from the installation of centrifugal devices, some of the nuances and features of their installation must be considered.

The process of immersion and connection is very simple, it consists of several stages.

- Pre-new well pump should be connected to the mains and run for a short time. This procedure is necessary to test the device for operability and detect faults before the pump is submerged down.

- During normal operation of the unit, connect the cable and the hose. Then you need to tighten them among themselves along the entire length with clamps.

- Tie safety cable.

- Connect the float level sensor to the equipment.

- Carefully lower the pump into the pipe, trying to avoid the body striking the inner surface.

- After the unit has reached the desired depth, fix the device by tying the top end of the safety cable to the pre-mounted fastener.

- On the plumbing to install the valve, pressure gauge and branch elbow.

- The top of the hose should be connected to the pipeline. It must be remembered that in the absence of a check valve in the design of the pump, it should be installed independently.

- After the device is lowered, securely fastened and connected to the pipeline, a test run should be performed, during which attention should be paid to knocking and vibration in the operation of the equipment. If there are extraneous sounds, raise the pump to the surface and reinstall it. It must be remembered that the screw apparatus does not create vibration during operation, therefore its presence indicates either an incorrect installation or a malfunction of the unit.

Screw pumps are robust and reliable devices for pumping water. Due to the simple design, the devices are a reliable mechanism and do not require increased attention and regular maintenance.

The acquisition of auger pump for a long time will solve the problem of pumping out polluted water, filling and draining the pool, as well as the functioning of an autonomous water supply system.

The principle of operation of the screw pump is shown in the following video.