Drainage pump with integrated float switch: device, connection and adjustment

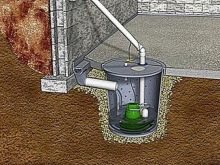

The field of operation of drainage pumps is huge, which is why this tool should be in every owner of a private house. The pump is intended for the forced pumping of rainwater and waste liquids from various containers and recesses. There are household appliances with low power, and there is also industrial equipment designed for large-scale work.

Purpose and features

Most of the country houses are equipped with autonomous water supply systems. The main working elements of these systems are household drainage pumps. It is on the effectiveness of their work depends on the durability of the entire building.

With the help of a pump designed to perform drainage, you can implement a number of tasks:

- pumping from flooded parts of water that appears as a result of heavy precipitation, melting snow or raising the level of groundwater;

- pumping water from trenches and pits created during construction;

- drainage of sites located in the valley;

- for dirty water that is pumped out of cellars and cellars;

- cleaning of wells from deposits on the walls of mines and in the bottom part;

- transfer of dirty liquid medium between the modules of local treatment structures;

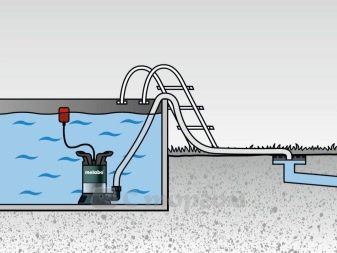

- pumping fluid from a natural reservoir for its further operation as watering plants.

Drainage pumps with an integrated float switch can also be used to pump clean water, for example, to fill storage tanks.

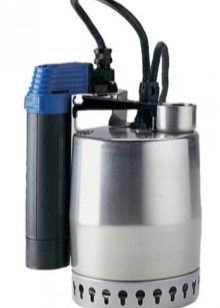

The scope of operation of the pumps is huge, and this makes them popular among owners of country houses and cottages. All equipment, regardless of type, has a similar device. The main components include the rotor, pressure chamber, impeller, motor stator and float switch.The efficiency and durability of the tool, as a rule, depends on the quality of the glands, designed for airtightness of the electric motor from wastewater. In expensive models they are made from ceramics. The body is made of stainless steel or cast iron, which are resistant to the formation of corrosion and mechanical stress.

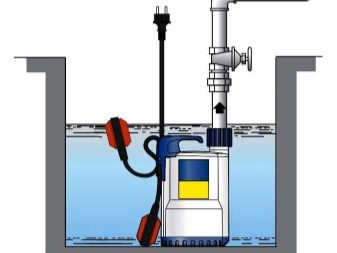

The pump is controlled by a float switch, which automatically switches the drive on and off. This element is a plastic box with a steel ball and an electrical switch inside.

The essence of the drainage pump is that the liquid that is pumped out is poured into the functioning chamber, where under the influence of the pump and the turns of the running wheel moves upwards - towards the outlet pipeline, cooling the drive.

Species

All drainage pumps with a built-in float switch are divided according to the variant of their location - they distinguish immersion and surface instruments.

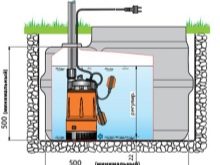

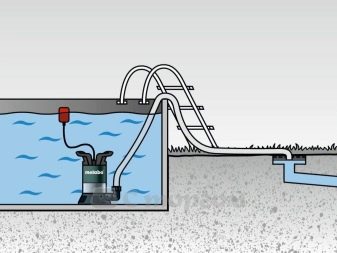

- Submersible - it is equipped with a hermetic case, thanks to which it can work even with full immersion in water.Differs in a big power, during functioning practically does not emit noise. It is also worth noting the high efficiency and versatility. But if the case is damaged, it is difficult to repair it, in some cases it is even impossible. The pump is quickly contaminated, so it must be cleaned often.

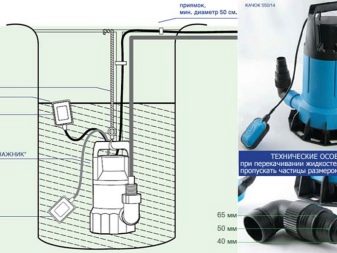

- Equipment with internal float - the device includes a rubber hose or PVC pipe, which is immersed in the waste liquid, but the casing remains on the ground surface. The advantage of the tool is simple installation and maintenance. But during the transfer of fluid, such a pump makes a lot of noise.

- Fecal pumps - are intended for pumping out of liquid from septic tanks and cesspools. The benefits include high power. In the device there is an additional detail - the grid, crushing large waste. There is a submersible and surface pump.

- Vertical models - equipped with a vertical float switch that performs automatic pumping of fluid from confined spaces. Often, such equipment is used to drain broken pipelines. They can also be used as ordinary drainage systems.

The connection scheme of each equipment is different, before operation it is recommended to study the instruction or consult with a specialist.

Criterias of choice

In order to choose a high-quality drainage pump that will meet your requirements and will be able to perform its work effectively, you must carefully consider the choice of equipment.

Consider the following nuances:

- You should not strive for too high power, it is reflected in the parameters of the instrument, power consumption and rapid heating of the equipment. As a rule, pumps of this class are designed for a normal network of 220 volts, and the power starts from 350 to 400 watts. Three-phase models are operated by individuals very rarely.

- It is especially important to consider the coefficient created at the outlet of the liquid head. It is measured in meters of water column, in technical atmospheres or bars. Pressure should be enough not only to raise the water, but also to overcome the hydraulic resistance of the horizontal elements of the pipe.

- Do not forget to know the maximum depth to which the equipment can fall.

- The higher the performance, the higher the rate of fluid transfer.

- Note that some pumps are not able to process solid large deposits. Choose a knife better than a cutting edge.

- Head and depth of immersion - the height of the pumped liquid depends on these indicators.

- It is worth exploring carefully the features of operation - how to take care of the equipment, how to change its elements and repair.

As a rule, cast iron and stainless steel together with other materials are used for the production of modern drainage pumps. which will be necessary for assembly of the case of the equipment and other accessories:

- stainless steel - high-quality durable material that will last for many years;

- cast iron - is highly durable, but weighs a lot and is expensive;

- plastic is a budget option that will last for a relatively short time.

Popular equipment, the body of which is plastic, and the steel wheel. This model ideally combines an affordable price and high quality. Not so long ago, such models with polymer working blades appeared on the market, they are cheaper than their technological counterparts.Differ in the long term of operation, durability and reliability.

Float

Drainage pumps with float switches operate in automatic mode, which prevents the accumulation tank from overflowing and prevents the engine from running if there is no water. A float is a special sensor that is built into the body or is installed separately; it is easier to use equipment with it. Stand-alone float switches are divided into light and heavy depending on the density of the wastewater. Depending on the pump model, the floats are equipped with cables of 2–10 meters long.

If the equipment does not work or its specific parts have failed, for example, a float, it must be disassembled. Repair it yourself is easy. To turn the device off on time, you need to make adjustments. The minimum shutdown level is better to set above 0.5 cm. This indicator will prevent overheating of the equipment in an unforeseen situation.

What does the quantity depend on?

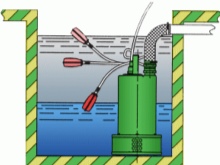

The number of operated floats is affected by the installed control panel and pump model.Also to a large extent the number of additional parts and the number of switches. To make the work of the equipment more efficient, experts advise to mount additional bars, on which the performance of the tool depends. The places of their installation and quantity are fixed in the design decision or are determined in the course of installation.

When is it applied?

The float switch is designed for the following purposes:

- the float connected to the pump for filling the tank, turns off during the ascent and connects when the lower limit of the equipment is reached;

- for an automatic station, switching on when the upper limit of the water level is reached and off at the lower;

- servo-operated valves - the switch signals closing when the tank is full and opening when the tank is nearly empty;

- control room - control of excess and lack of water.

The option of connecting two pumps to one float is allowed. One pump will fill the tank when the float is at the bottom, the second will pump out the water when the float rises.This method will show a good result only if water is supplied to the tank without failures.

Principles of operation and installation

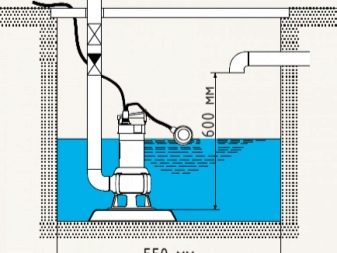

Installation of equipment should, first of all, begin with measuring the current level, it should be below the allowable. Experts advise to mount the float in the recess.

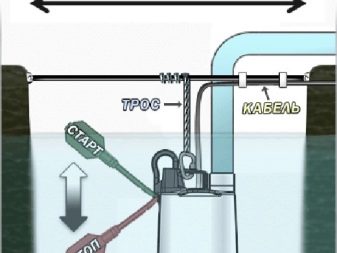

To install, you will need a cable and a small weight, which is in the set:

- the load is strung on the cord, after which the course of the float is determined;

- the latch will fix the weight;

- cable is fixed from the outside;

- The switch is connected to the pump.

You can install the float yourself only if the equipment does not freeze inside the tank. If several floats are installed at the same time, they are placed in a special rod. To do this, use a plastic tube. For proper installation, you must set the float yourself, adjust it, set it so that the radius of the floats does not touch, fix the cables with cable ties.

The apparatus mounted in the system can join the float in two ways:

- if the power is less than 1.2 kV, then it is connected directly through the network wire;

- if the power is higher than 1.2 kV, the connection is made via an electromagnetic relay or other switching link.

The float switch works as follows:

- A pump with a built-in float when filling the tank turns off the switch when ascending, when the tank is completely filled with water. When lowering to the bottom, the equipment will turn on when the tank is empty.

- If the tank is completely filled, the float switch will be on the surface, the equipment functions automatically. When the tank is empty, the device will stop its work.

- The switch gives a command and the valve closes when raised to the surface. In such a situation, the tank is filled. When it reaches the bottom, the valve opens and the container is emptied.

Service and Repair

Often the float fails, due to the fact that it is clogged with dirt. Repair the float with their own hands is easy. To do this, pass a stream of pure liquid through the float. If after these procedures, the part did not become operational, and that no damage is visible, it is easier to replace the mechanism with a new one. Because the complex, as a rule, is expensive.

An overview of the Wilo TM 327 drainage pump with float switch, see the video below.