Hand pumps for water: where to use and how to make?

Pumps for water, working on manual technology, are very often found in summer cottages and other locations. This device has become indispensable for many users. But in order to choose a suitable unit, it is necessary to get acquainted in advance with all the features, applications and types of devices for pumping water. These questions will be discussed in detail in this article.

Purpose: where does it apply?

Manual pump designs used to be very common not only in private territories, but also on the streets of the city. They were also called water columns. But with the advent of more modernized electrical technologies for pumping water, mechanical devices began to occur less and less. However, in some areas and locations, hand pumps are still popular.

First of all, the device can be seen on the territories of country houses. Their main function is the transfer of water from a common source to various points on the site. These points can serve as a garage, house, greenhouse, sauna, and even garden beds or lawn.

Wells, artificial reservoirs, wells and various other structures can be used as sources.

Features of the application depend on the mode of visiting by the owners of their summer cottage. There are three types of territories.

- Plot for permanent residence. In this area, in most cases, an electric pump is installed, but the manual design is also available as a backup device. A mechanical pump is also used as a reserve if the site is visited seasonally, for example, if it is lived only in summer and spring.Such use is explained by the fact that electricity was conducted in such cases in the country house, and there is no need to use a hand pump regularly.

- But in private houses of periodic residence, when the electricity is not carried out, a manual unit is very necessary for pumping water. Such a device will be used for watering beds, beds or lawns. With the help of pumps, garden sprays work, which are often used in the overall garden areas.

- Sometimes hand pumps are used in the suburban areas, if it is impossible to carry out the connection of the electrical analog to the power source.

- Piston set in order to pump out water from the well. For the same purpose, pumps are used by fire brigades. Previously, pumps of this type were used on ships for pumping water. Sometimes these devices perform a decorative function, as they are successfully combined with various styles of landscape design.

- Winged type of pumping structures used for the transfer of viscous liquids. With their help, shallow wells are cleaned.

- Membrane The devices are mainly used for technical purposes. Using them, they often carry out the transfer of liquid products, as well as fuel and lubricants from one vessel to another. For domestic purposes, this unit is useful for pumping out water from rooms whose level is below ground level, for example, basements.

- Rod pump structures are used for pumping water in mines of direct and vertical type.

- To pump water or oil from small tanks, usually apply slide valves mechanical pumps.

- And also for pumping oily liquids or viscous compounds can be used. rotary hand pumps.

- When the depth of the well exceeds 10 m, then apply special designs for manual pumping - deep pumps.

Types and device

There are various types of pumps, each of which has its own principle of operation. Let us consider in more detail the main types.

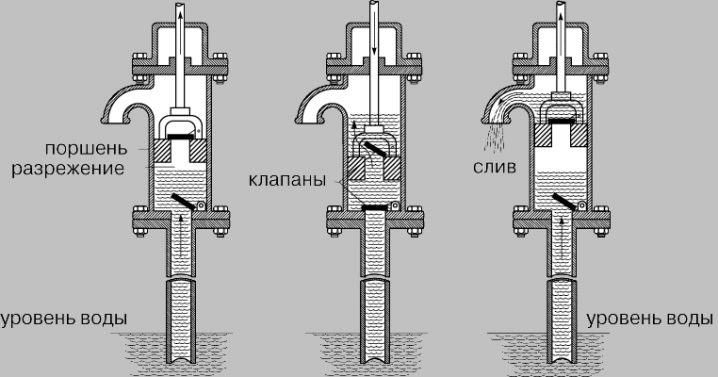

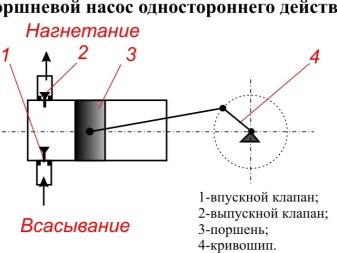

Piston

The design is based on the sleeve, which is a cylindrical body. This part can be made of the following materials:

- cast iron;

- polymers;

- stainless steel.

Another component is the spout, there is also a rocker arm,which is fixed on the axis with the help of hinges, it is connected with a vertical rod, it goes directly into the depth of the pump.

The piston itself is located in the housing. In the piston are seals that are adjacent to the walls of the housing. Above there is a strong connection with the rod, which is also connected with the lever of the rocker arm. In the upper part of the housing there is a pipe or a hole for unobstructed exit of the pumped water into the chute or pipe. The lower part of the pump is connected to a pipe located in the well. Before installing the pump on the pipe must be placed a check valve.

Hose

Such designs are used for more convenient watering of beds. Hoses of various materials can be connected to the pump design. They can be nylon, polyurethane, rubber and have increased strength.

The length of the hose can also vary depending on the distance that the objects for irrigation are located from the source.

Winged

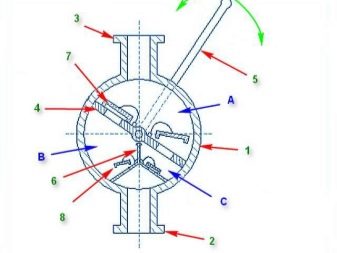

Such pumps are more compact equipment. They are made of metal casing, two nozzles have different types of connection: coupling or flange.The suction pipe passes water through itself, and the pressure head connects to the disassembly point. Instead of a piston mechanism in this design uses the impeller. It represents the central axis along which two wings radially move opposite each other.

The wings are connected with the handle of the central stock axis. When a person presses on the handle with effort, the wings start moving, carrying out the work of the pump. The lower cavity of the device is divided in two by a special jumper.

An important element are the valves, which are located both on the wings and in the lower part of the device. They work opposite to each other.

Types and features

Some types of pumps have a special design that carries out the pumping of water.

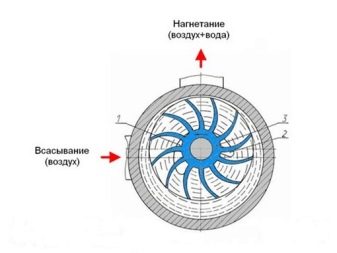

Rotary

As can be seen from the name of the device, the principle of its work is the movement of a special mechanism - the rotor. It is equipped with special longitudinal slots. Thin plate scrapers are pressed against this mechanism. This process is due to the impact of special centrifugal force.

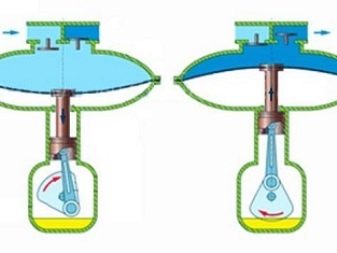

Membrane

Mechanical diaphragm pumps are different from other types in that the basis of their work is not friction processes. The units are endowed with special ball valves.These elements contribute to the regular self-cleaning of the structure, as well as prevent the mechanisms from sticking.

Deep

The hand pump is a standard type with a piston in the center. But the stock, which contributes to the work of the pump, is connected to the exhaust pipe.

Both of these parts are long enough to plunge into fairly deep wells.

For bottled water

There are special pumps for bottled water. It is often used in the domestic sphere to pump out water from large plastic bottles. In such a mechanism, the liquid rises through a special pipe under the action of a vacuum, and then goes through a special valve into a substituted container.

Advantages and disadvantages

Water pumps that work in manual mode have a number of positive and negative qualities. The advantages of designs include several characteristics.

- Compared to electrical models, mechanical devices have a significantly lower cost.

- If electropumps can be stolen in the event of a site being exposed, then it is much more difficult to remove mechanical structures from the site.

- The manual construction rarely breaks. Such a product is very durable in service life.

- The mechanical pump can be installed almost anywhere in the area, since the device is unpretentious to the location.

- This unit may well work offline.

- Manual designs can be easily repaired in case of breakage. This will help to avoid additional costs for the services of specialists.

- Mechanical pumps save energy.

Among the main disadvantages of mechanical units can be identified:

- the need for physical work for the implementation of water supply;

- there is no possibility of continuous fluid supply.

It is also worth paying attention to the positive and negative qualities of specific models.

- A significant advantage of the impeller pump is the continuous flow of water, the direction of movement of the working handle does not play a special role. But the disadvantage of the device is a low level of efficiency. And also similar pumps cannot be used for the polluted water.

- The advantage of the membrane design is the simplicity of its device.Weakness - a high degree of wear of the membrane. But this problem can be solved quite easily, because diaphragm pumps can be easily repaired. To do this, simply purchase a spare membrane, or immediately buy it complete with the device.

- Rod models have rather intensive absorption of water due to the presence of a vacuum in the structure.

But among the minuses of the devices can be noted their cumbersome and high risk that during operation the hose can break. And also the installation of such a unit may not be carried out in all places, for example, it is not recommended to have such equipment on slopes.

How to choose the right one?

To choose the right hand pump for pumping water, you must rely on a number of criteria.

- The key indicator is the well parameters and dimensions of the pump itself. Most of the proposed models are designed for a depth of 6 to 8 meters. Sometimes the permissible depth may exceed 10 meters.

- Consider the performance - the amount of fluid that the device can pump in a minute under heavy load.

- Consider the diameter of the casing.If the conditional bypass of the bypass pipe is 10 cm or more, then any type of pump can be purchased. But in the case of narrower parameters of the nozzle, it is recommended to refrain from choosing a sucker-rod pump.

- It is important to consider the degree of contamination of the water in the well. Not all devices can pass contaminated liquid.

- Rate the comfort of the device. It should be convenient to work with all family members.

- Consider the method of installation when choosing a design. This criterion may be affected by the mass of the selected hand pump. For installation, special platforms, welded metal frames, brackets and mounting holes may be attached to the device.

- The season of use of the unit is important. If the device will be operated in the summer, it is permissible to purchase plastic structures with a light weight.

- For many, the external features of the device are also important if the site owners plan to make the pump not only functional, but also a decorative element of the landscape.

Review of existing options

Based on the advantages and disadvantages of all types of models of manual pumps,You can choose the finished equipment in the store or make a similar design with your own hands.

Ready models

Among the ready-made options are several models.

- Borehole hand pump NR-3M. Such a model is made of impact-resistant polymers, and it also contains parts made of rubber and primed steel. For the full cycle the device produces 1500 ml of liquid. The depth of the well for such a pump can be from two to five meters (in the latter case it is necessary to install a check valve at the lower end). The mass of the device is 4600 grams, and its cost is only 2500 rubles.

- Pump design PH-01 NZH. Its body is made of stainless steel, other parts of brass, as well as primed and painted steel. The depth of the well can be from 6 to 9 meters. Productivity per cycle is 1000 ml. The device weighs 8 kg and costs 6500 rubles.

- Special variety - cast iron pump type BSD. It has an open spout design, made in the form of a gutter. Permissible well depth is from 6 to 9 meters. In one cycle, the pump drives 500 ml of water. Its mass is 7 kg, and the cost is 3200 rubles.

Craftsmanship: ways

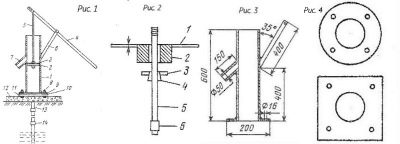

There are a number of artisan techniques that allow you to make a homemade hand pump.In order for any of the methods to be implemented correctly, it is recommended to prepare drawings for the future construction in advance. There are several methods of handicraft production.

First option

The product for pumping the well is made of casing and is used as a backup option when disconnecting electricity. To cut metal parts, you should use a grinder, you will also need a drill to drill holes for fasteners. The metal part for the frame should have a cylindrical shape, for example, a part of the sedimentary tube will fit.

This type of work can be performed only by those who have experience in welding.

The structure, in addition to the sediment pipe, must be equipped with the following elements:

- bottom cover;

- two check valves on the nozzles;

- rubber gasket;

- piston mounted on the rod;

- round cap (for cylinder);

- lever made of metal, coupled with the cover;

- connecting studs made of metal.

To install the structure on the ground, a special construction of metal pipes is used, providing the equipment with a strong position.

Second option

It is possible to create a pump using a used fire extinguisher as a pump tank. Such a device will be indispensable for cleaning wells from dirty water and can be installed at a rather great depth - up to 15 meters.

To make a device, you also need to use a welding machine and a tool for cutting metal. Using a fire extinguisher as a body and other spare parts, it is necessary to build a structure with all the elements:

- special bed to install the pump in the ground;

- branch pipe (at the top of the housing);

- driving on the spout for water supply;

- driving on the water intake;

- handle with which to drag the design;

- special seal located between the body and the bed;

- a rod on which the case fastens.

To protect metal parts from corrosion, they are covered with a layer of primer. To improve the level of protection, a layer of special paint on metal is applied over the primer. On average, a single click on the lever pumped a couple of liters of water. To fill the bucket you need to turn the lever 3-4 times.

Well Construction

Before installing a hand pump in the country,care must be taken to build a well from which water will flow. Well it is possible to do it yourself.

The most suitable type of well - “abyssinka” implies special attention to each layer of soil when digging a dimple. The first layer of soil, saturated with water, is under the fertile, clay and sandy layers. But the water here is rather polluted and not suitable for use. At a depth of 5 - 8 meters under the layer of impermeable clay is water-bearing sand containing moisture, filtered better.

A thin tube with a filter in the walls can be immersed in this layer, if it is sufficiently saturated with water. The length of the pipe, which is 1.2 m, is equipped with a special metal needle, which has a solid construction. This end of the pipe is driven into the well. Next, you need to carry out a number of commissioning operations, and after them - install the pump from the other end of the pipe.

The most difficult stage of this process is the drilling of a well. To implement this work, it is recommended to invite specialists with the necessary equipment.

To learn how to make a hand pump for water do it yourself, see the next video.