How to choose a pump for the well?

The flow of water from a well, unlike a well, cannot be ensured with the help of buckets. Be sure to have to use specialized equipment - the pump. What he should be, you should know any gardener, gardener, the owner of the garden.

Special features

A pump for a well, by definition, must be more efficient than a pump installed in a heating or sewage system. After all, it works even for a relatively short time in most cases, but it should provide a powerful peak load. The height of raising the water column becomes a critical characteristic.

One more thing: you will definitely have to supplement the device with a filter, since even the best and most well-prepared well can become clogged.

Kinds

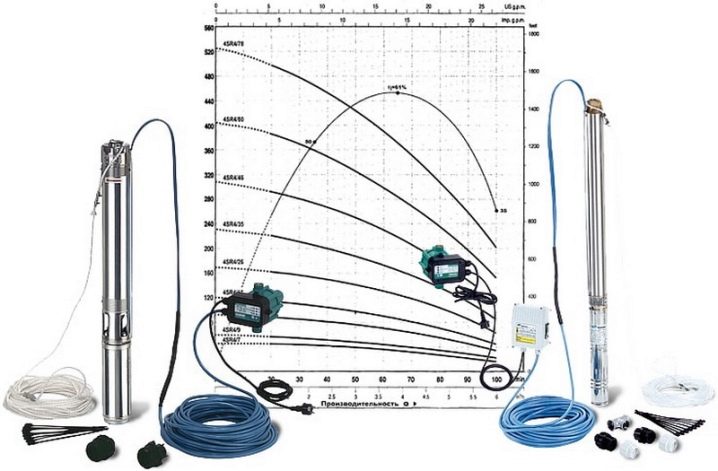

Engineers were able to develop a number of options for borehole pumps, among them there are even deep ones, raising the water by 50 meters or more. Of course, the greater the height of the water column provided, the greater should be the capacity of the installation. Submersible systems are suitable for taking liquids from any kind of reservoir. Of course, the developers care about the anticorrosion properties and high strength of all the materials used. There is a smaller division.

Thus, the vibrating submersible pump is characterized by simplicity of design and minimal maintenance requirements. Equally important for consumers is the affordable price, as well as the exclusion of any rotating parts that are the most fragile and sensitive. The scheme of work is as follows:

- electric current is applied to the coil;

- passing through the winding, it gives a magnetic field;

- under the influence of a magnetic field the core is pulled in;

- behind the core the attached rod connected with a rubber diaphragm stretches;

- it bends, forms in the middle part of the pump the area of low pressure;

- water is sucked into the chamber;

- the springs at this point force the diaphragm to return to its original position;

- the consumer receives water after closing the valve under the action of overpressure.

It is not surprising that such a device is widely used in gardens and kitchen gardens, it is used to drain flooded basements and cellars. The centrifugal scheme, however, also has certain advantages. It provides extraction of water of various temperatures. This pump works quietly with oil and acid solutions. The engine is connected through the shaft to the impeller, and holes are made in the wheel, through which water can flow in and be directed in the right direction. Inside the body, the fluid draws in under the action of the same pressure differential, only it is created by centrifugal force.

This option allows you to provide a very high pressure column, even with ordinary performance. The centrifugal self-priming pump is equipped with a horizontal casing and begins to operate only after the air intake hose is 100% filled.

Normally, the suction unit is also pre-filled, but with water. A multistage type can develop a stronger head than a single stage, but the total performance will not change. In summer houses, surface units can also be used, which also provide good water to homes.

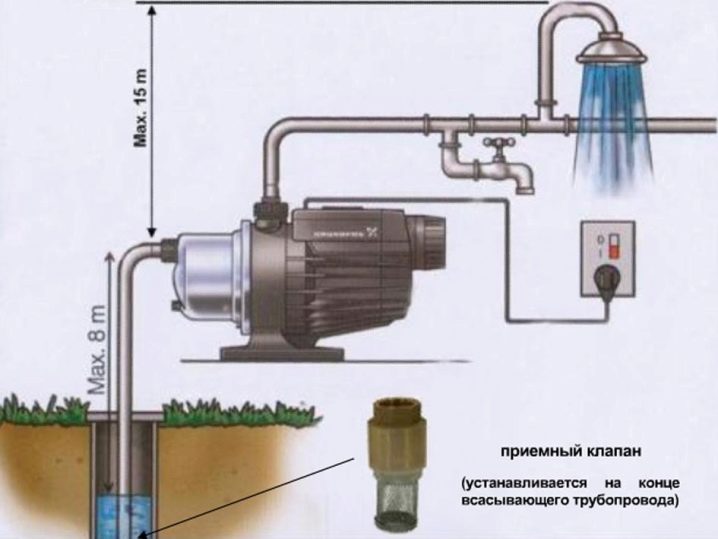

The difference lies in the fact that surface-type devices “get along” extremely poorly, even with minor fluid blockages. The pump itself does not sink into the wells and the wells, only a flexible hose is placed there. The greatest depth of water intake is 9 m. If this is not enough, you will have to additionally buy ejectors. Before starting, the pump must be filled with water; Automatic systems are preferable because they consume less current and are equipped with overheating protection.

Manual models can also lift water up to 9 m. If necessary, they can be removed and used to move other fluids without abrasive inclusions. The highest temperature of transported substances is limited to 80 degrees. The wing rotates under the action of the forces imparted by the hand lever.Each side is involved in the absorption or ejection of water, because the movement of fluid is theoretically infinite.

The minimum practiced pump diameter for wells is 3 inches (sometimes 4). The fact is that it is not possible to place a sufficiently powerful “stuffing” for pumping out water from a depth of more than 7-9 m into smaller bodies. And this greatly limits the water supply capacity on polluted soils. And even if the surface is relatively clean, the roofing is rarely suitable for technical needs, not to mention domestic purposes.

You can not use pumps, the body of which is closely related to the walls of the casing. The smallest gap is 0.4 cm.

Rod pumps are well represented by anyone who has ever seen on a television screen installation, swinging "black gold". Water is lifted to the top, of course, not such mechanized devices, but simple manual counterparts. They allow you to work with layers that are at a depth of over 7 m (which is inaccessible to piston devices). The limit of availability is 30 m depth. Shiberny equipment for work with wells is not suitable, it is applicable only on open reservoirs.

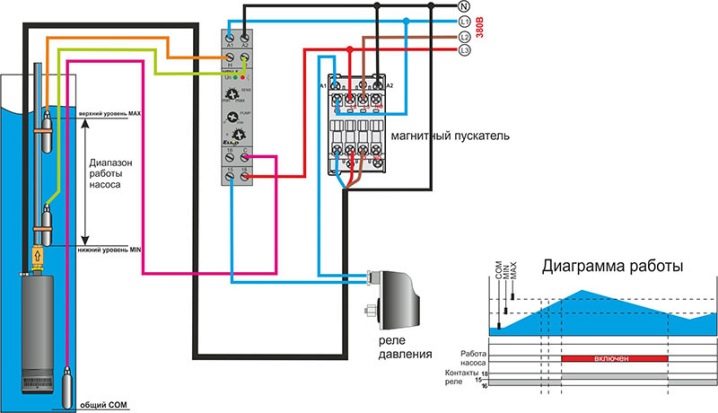

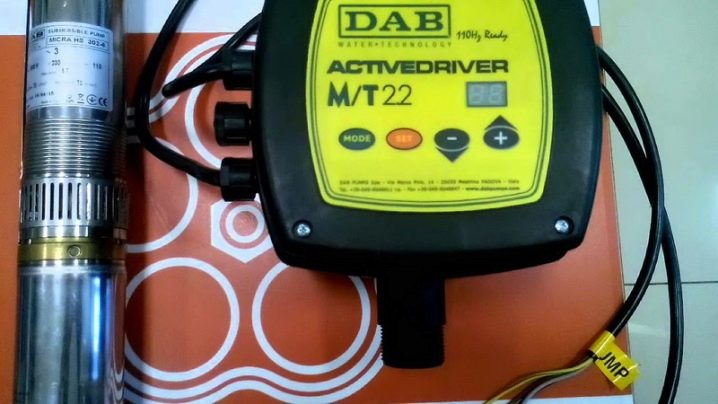

Submersible pumps do not care from which regulatory depth to lift a liquid, whether it is 20 m or 50. But a pumping system with a single-phase motor that is not equipped with a condenser must have a starting protection. ROM can either be bundled or purchased by the consumer. But in either case, it is connected independently. The advantage of the remote ROM is that replacing the condenser does not require removing the pump itself from the well.

It is necessary to choose this unit, being guided by the general electric capacity and on rated starting current of the thermal relay. It exceeds the rated motor current by about 20%. Choosing a start-up device, it is not necessary to use models of the same brand as the pump itself, the main thing is that the capacity coincides.

In order to get to work soon, without resorting to the help of specialists, and not having difficulties during the pumping of water, it is advisable to purchase a system with wiring performed in an industrial environment.

Device

Of great importance for the outboard pump in the well is the cable with which it is installed. An incorrectly mounted fastener may break at any time and you will need to buy a new one along with a replaceable pump.It is practically impossible to extract the loss from a narrow deep well, and this will not affect the quality of the water in the best way. The main value when choosing a cable is the mass that it is able to hold, along with the water covering the pump.

The load in some cases exceeds 80 kg, but do not be afraid - professional equipment will withstand several times greater severity.

If you need to save money, it is recommended to choose cables based on synthetic materials. But even cheapness and corrosion resistance do not make them the ideal solution. After all, synthetic fiber is gradually stretched, and therefore the load will affect more and more pipes. It is possible to increase the consumer characteristics of any cable by folding it in half or in four layers. Steel retaining elements, even in very clean water, will last for about a year; zinc coating increases this period, but only slightly.

A more perfect option is a polymer tube around steel. For its manufacture used polyvinyl chloride. If to mount the device in due form, the period of service will be long enough.But PVC at the point of attachment to the pump inevitably frays with time and there comes a time when the cable will rust and break. An alternative can be considered the use of stainless steel cables. The problem is only one: the high price of a similar design, approaching the prices of pumps of the budget category.

Some people use iron chains with a small link or rope for climbers to fasten pumping equipment. It is better not to conduct such experiments, because no one will give a firm guarantee of their success. In any performance it is impossible to apply even the smallest load to the network cable, this is extremely dangerous. In many cases it is better to use not the plug-in motor, but the external apparatus But this imposes certain restrictions on the hoses used.

In any case, you should not buy a hose that is suitable only for one watering. It will only help in the warm season of the year, providing:

- washing the car (motorcycle, bike, tracks and sidewalks);

- Actually, watering;

- filling tanks;

- water supply of the country house.

The rigidity of the water intake hoses is very important. It can be achieved by a thickening of the walls, the introduction of reinforcing parts, the creation of a corrugated structure.Hoses that are reinforced with steel spirals are considered the most advanced option. They will endure considerable pressure as long as possible. For hoses that will be used year-round, frost resistance is of particular importance.

Flattening and deterioration under negative temperatures are absolutely unacceptable. When it is known that water will be taken for drinking, any rubber hoses become unacceptable. The liquid passing through them not only acquires a bad smell, it gradually becomes unsafe for the health and even the lives of consumers. Therefore, drinking water can only be pumped through the silicone and polyvinyl chloride channels. Silicone is exactly suitable for food use, serves for a long time and does not give a negative smell.

The objective disadvantage of this material is its unsatisfactory strength and the risk of destruction at the joints with other sections of the railway, with the equipment. PVC in this regard is better and is relatively inexpensive. Regardless of the material of the hose, it is recommended to buy it in a large department store, and even better - in a company outlet.No one can guarantee the safety of water that has passed through a hose purchased on the market or in an underground passage. The same applies to fittings and fasteners.

Payment

Determining the exact characteristics of the pump that must be ensured in any case is very important. In the calculation are taken into account:

- real parameters of water sources;

- distance between water intake and consumer (consumers);

- required amount of water intake.

Now there is no special need to use sophisticated formulas or use the help of experts. Online calculators come to the rescue, in which you only need to specify a few basic variables for the calculation. But still, it would be much more accurate to use both calculation methods at once to make the result as accurate as possible. Professional formulas are especially important when the need for water supply of a large residential building with a farm is calculated.

An error that occurred at the height of the field season can be very serious in its consequences.

Manufacturers: review and reviews

Russian pumping stations enjoy a well-deserved prestige and demand, and this is not only a matter of patriotic feelings.For example, the products of the brand "Dzhileks", now represented in the sector of well pumps with the series "Vodomet". Model 40/50 allows immersion in the water column to a depth of 30 m, while in a minute the device will lift up to 40 liters of liquid.

Consumers invariably point out that “Jilex” products are better than offers from any other Russian company. Due to a special technological measure, the device version 55/75 can give the owners about 3 cu. m of water per hour, and even from sand-filled wells.

The undoubted advantage of any domestic products is that they are initially designed taking into account the climatic features of the country. Significant positions in all major ratings invariably occupy German-made products.

Grundfos represents borehole pumps primarily in the SQ series. All of them are made using highly durable steel, treated in a special way to impart anti-corrosion properties. The engineers took care of protection against abrasive particles and other important points; a problem for the consumer can only be a solid price.

Products Unipump Eco not bad cope with the work in wells, fairly clogged with sand.The corrosion-proof case hiding the single-phase motor - a fine combination for the solution of the majority of practical tasks. The use of "floating" construction wheels can significantly reduce the risk of damage to the working parts contained in the water suspended. Disadvantages - the impossibility of pumping fluid containing long fibers, as well as sensitivity to hard water. Consumers say that these pumps perform well in wells up to 15 m.

In search of guaranteed quality, you can buy any Italian pump. So, the products of the Pedrollo series “6FK” have a power of 4 to 30 kW, equipped with a power wire up to 4 m long. The devices can be started up to 20 times per hour, making regular technological pauses at the same time. The electric motor will require the supply of a three-phase current of 400 V. The Speroni company is also among the leaders of the Russian market.

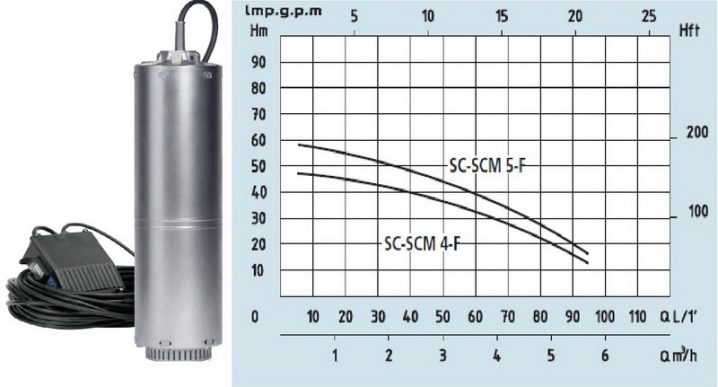

The downhole multistage SCM 4 / S-F pump is highly appreciated by consumers. It can be immersed up to 30 m in water containing up to 0.1 kg of sand particles per 1 cubic meter. m, and run to work 40 times in 60 minutes. Solid overload protection and a built-in capacitor are a great help when using the system. Graphite elements are used as the end seal.All main parts are made of stainless steel, only the main working wheel is made of brass.

How to choose?

In order to correctly select the well pump, it is desirable to focus on the bottom of the bottom mark, on the dynamic water level. The first digit should be indicated by all construction organizations in the technical passports to the wells. The dynamic level is the gap from the ground level to the water surface during pump operation. When there is still a lot of water left after ½ hour after starting the car, this at the same time testifies to a good debit and a competent choice of equipment.

You should also pay attention to the static water level, that is, the distance between the top point of the well and water; for maximum accuracy, the liquid is not pumped out for some time.

Subtracting from the total depth of the static level, you can determine the height of the water column of the well. The diameter of the pipe is measured in an elementary way, just like any other diameters. For obvious reasons, submersible structures have a diameter limit (18–20 cm). Larger systems simply will not be able to be lowered into the casing.The outer casing of the mass-produced pumps is made from alloys based on aluminum, only the most expensive versions are equipped with steel casings.

Vortex pumps are similar to centrifugal, but they also have specific features. They are larger and can give up more water than simpler devices. It is not possible to force out centrifugal devices due to objective weaknesses - complicated construction and increased price. Screw scheme differs by the type of device for forcing fluid. As his engineers choose a screw, visually similar to the screw.

The overwhelming majority of models on the market can pump out 20–200 l per minute from a well; it should be remembered that it is undesirable to take the device, working for wear to cover the basic needs.

There is no need to save money for another reason: equipment produced by well-known manufacturers breaks less often and works more stable. So, together with the cost of repairs and maintenance, customers are only in the black.

The pressure of the water column must ensure the passage of fluid through each vertical and horizontal section of the pipeline.In this case, the minimum pressure at any point should be done from 2.5 atm. In places with a high level of criminal danger and in the dacha cooperatives, it is desirable to install surface pumps, since their protection in the booths will be higher.

Those wells that are obtained on their own or with the help of informal teams, do not have accompanying documents indicating the characteristics. Moreover, after prolonged use even of official water sources, their properties may vary widely. All the necessary parameters are easily refined using the simplest available tools.

The static level is measured by a rope with a small weight attached to it in the format of a cylinder or with no bottom cone or just a plastic tube.

Before starting the measurement, it is worth at least an hour not to lift water from the well. Usually this is enough to lift the liquid to the maximum natural level.

Of course, it strongly depends on the degree of depletion of aquifers. Recognizing the touch of a tied load on the surface of the water is easy by the characteristic sound. Immediately mark the point on the rope, and after lifting it is measured in any convenient way.For your information: if the dynamic and static levels coincide or are very close, this indicates a good well condition. It is important to remember that The limit of underground water sources in different seasons of the year and, depending on the prevailing weather conditions, may vary considerably.

An excessively powerful pump only seems like a good acquisition: yes, at first it will pump up quite a lot of liquid, but working without water in a dried well will very quickly fail. 3-4 liters of water per day is enough for 3-4 consumers (excluding irrigation of gardens and technical consumption). It is very important to think about how the pump will pull the water up.

A simple rubber hose is not very practical, because the rarefaction of the air in it causes the walls to collapse and stop pumping. The solution is to supplement the pump with plastic parts of suitable size.

It is not necessary to acquire surface pumps if the distance between the ground and the water mirror exceeds 8 m. Because for filtration and artesian wells, in contrast to the Abyssinian wells, this technique is unsuitable. With a lifting height of 40 m, you will need to give preference to a higher power installation.Considering the noise of any water pumping unit and its sensitivity to various contaminants, it is advisable to buy or make an external box with your own hands. Important: when selecting pumps in depth it is worth to reserve a certain stock.

Thus, the device, declared by the manufacturer for lifting fluid from 60 m, will ideally feel in the well 50 m deep. Continuous action at the limit of the possible load leads to a reduction in working life and accelerated wear. A very important circumstance is the availability of protection from work in the dry mode. It is impossible to foresee in advance all the situations when it may arise, it will not work and to constantly manually control the water level. Having entrusted this work to automation, the site owners will be reliably protected from various incidents.

Despite the wide popularity of vibration pumps, qualified specialists do not tire of warning about their adverse effects on wells. Even if such an effect is not detected at first, they say, anyway, destruction will occur over time. In addition to the choice of pumping unit for these parameters, you need to consider:

- the complexity of the repair;

- the possibility of obtaining parts;

- warranty duration;

- reviews on a specific model;

- water quality in the well;

- frequency and intensity of use of the system.

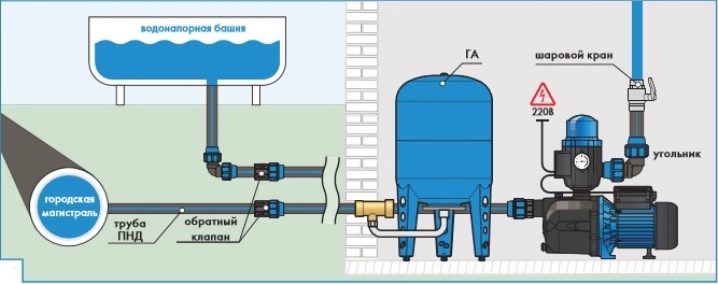

Wiring diagram

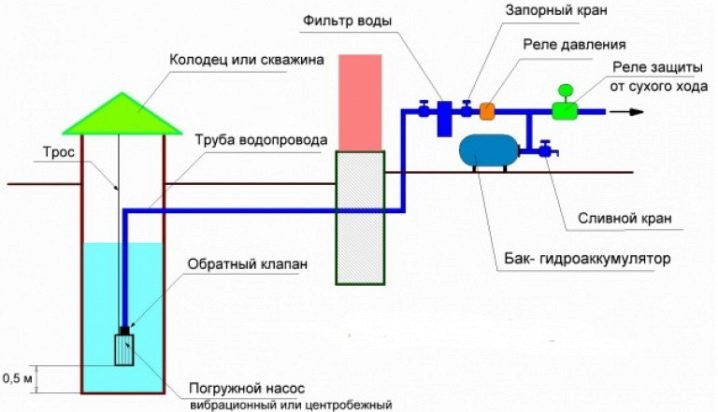

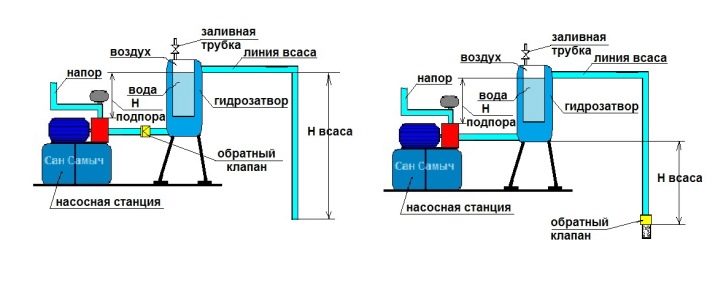

Even the best and flawlessly selected pump is required to be connected according to a special scheme. Only if this condition is met can a stable water flow of the required volume be guaranteed. Before installation, surface pumps are placed on a flat platform and fixed to avoid the slightest displacement. You can attach them to the well using a pipe or a rigid hose with a diameter of 2.5-3.2 cm. One of the ends of the pickup circuit must be immersed in water at least 0.3 m.

Important: before descending into the well at this end attach a check valve. The section taken from the pump must be inclined towards the water source. The sealing of the joints is carried out in the same way as in other plumbing systems. It is possible to fill the pump with water (along with the line connected to it) through the filler plug or outlet.

Hurry up with this work categorically impossible, it is necessary to ensure that all the air left the system.

Important: it is necessary to open the water tap and look at the readings of the pressure gauge. If the obtained figures differ from those contained in the documentation, the technician needs additional adjustment. The minimum volume of the accumulator should be 100 liters. Capacities less than this value do not justify the space occupied on the site. For the ligament between the pump and the water reservoir, a so-called pyternik is used. As for automation, it should include at least a pressure gauge and a relay.

Next, connect the device to the pressure lines. The filling hole must be blocked, all parts of the equipment are tied together and divorced around the house or site. Be sure to check what the air pressure in the storage, sometimes it needs to be pumped additionally. Everything, now it is possible to connect the pump to the power supply network. As soon as the pressure in the system, including the accumulator, reaches the required value, the machine will stop.

To ensure the longest possible operation of the automation unit is possible only when it is connected via a contactor. Cost reduction is achieved by connecting via a pressure switch. As soon as the pressure in the storage tank reaches the highest stipulated value, the pump is automatically disconnected from the supply line. Important: pressure thresholds must be measured inside the tank itself.

Installing a simplified protection relay instead of a full-fledged automatic device saves money, but then you have to restart the system every time you turn it off.

How to install?

Installing the pump in the right way is the best guarantee that it will not need repair for a long time. It is unacceptable to put the device on the very bottom of the well or to bring more than 0.3 m closer to the lower edge of the pipe. This will end up filling the pump with sludge, and it will almost immediately burn out. Estimating the maximum permitted depth of the apparatus, it is necessary to focus on the length of the sump (a special filtered tank that blocks the intake of dirt inside). It also takes into account the thickness of the water-containing layer.

Determining the correct depth of the pump into the well, exceeding substantially 15 m, is impossible with the help of ordinary improvised means. But such deep mines are drilled only after geological exploration and the calculation of the necessary indicators using special formulas. In relatively shallow mines, the ends of the cables are equipped with shock-absorbing springs, which should damp the resulting vibrations.

Having connected this end with the pump, connect the branch pipes, control whether the socket for connection to the electrical network is sealed. The equipment is lowered into the mine using a manual or mechanical winch.

Having lowered the pump, fix a cable on an ogolovka and do the first trial start. If there is a difference in power from the calculated one (in both directions), it is recommended to check whether all the connections are tight. Additionally, the pump itself is lifted to ascertain whether various impurities have appeared in it. Repeated descent and consolidation are all produced by the same algorithm.

The cable for installation is selected individually for each model, while taking into account the highest levels of permitted loads.

Working with your own hands or checking the actions of specialists, we must not forget about the tightness of the place where the cable is connected to the pump. Often, a shrink sleeve is used for this purpose, and the ends are cut and degreased. The conductors need to be connected and pressed with clips, small details of the couplings are strung on each individual core. When this is completed, the connection is covered with the case, it is heated with a hairdryer or a soldering iron.The hot coupling shrinks and tightly covers the ends of the cable.

The advantage of this solution can be considered the ability to immediately launch the entire circuit into operation. The filling type of couplings is characterized in that the tightness is ensured by the use of a polymeric compound. In terms of cost, both solutions are identical, but you need to wait at least 24 hours before switching on. Attention: contact connectors are primarily intended for surface pumps. For deep equipment they are not reliable enough.

Accelerated wear prevention is usually done with a frequency inverter that lowers the amplitude of the supply voltage. But it is important to consider that such measures are mainly applied to powerful equipment options. Adding a converter to a circuit with a 300-400 W pump will only lead to excessive heating of the motor. But filters that cut off the ultrahigh voltage level are very useful in any variant.

The transducer, if it is still installed, should be tuned to a certain minimum frequency.

The inverter must be connected to the flow meter, which is also set to the minimum value.The reason is simple - it ensures stable and uniform operation of the pump. As a result, the motor does not operate in idle mode and its life is extended. Frequently, control over current frequencies helps to avoid the use of storage tanks. More importantly, it prevents hydraulic shocks and unnecessary surges in the dynamic level of the well.

In some places, the power supply is unstable or completely absent. And even in general, a normal power grid sometimes for several reasons will not be able to provide pumping equipment with current. You can fix this problem using a gasoline generator. For most models of such sources of electricity acceptable conditions of use will be:

- atmospheric humidity maximum 60%;

- heating the environment no more than 30 degrees;

- location above sea level - up to 150 m.

Tips

When choosing the appropriate version of the pumping system, it is necessary to take into account that intensively working filters may slightly lower the generated head. Professionals recommend paying special attention to the joints that appear during normal operation under water.It is at these points that the most problems arise even with a small manufacturing defect or violation of the principles of operation.

The bulk of the pumps are now being designed for four-inch casing. Too frequent launches of household pumps are considered to be turning them on more than once within 120 seconds.

Sometimes pumps get stuck in wells, and a solution to this problem is usually not possible. As a result, both the device itself and the well are lost for the owner. It is much better to take care of the exclusion of such a situation in principle. Electrical cables should be strapped to the pipes or hoses. Yes, you have to cut them for a few minutes and re-mount them every time you run the pump, but this is economically viable.

It so happens that you have to pull the pump by the pipe, hose or even the cable. Then it is required to carefully control that all these three elements rise evenly and there are no weak points anywhere.

It is not allowed to snap the cable to the cables and hoses. Having noticed a dangerous weakening, one should not panic or speed up work. It is better to push the pump a little deeper, holding the hose or pipe.

If it is not possible to move the pump down this way, you can improvise (tying a scrap on a rope and so on). But even with a favorable outcome of the "experiment", no one will vouch for the safety of the case and the performance of the system. If the sludge after a long inactivity of the well has risen above the pump, it remains only to try to rock the latter, but without excessive enthusiasm.

When it is impossible to achieve the appearance of a lumen between the body and the well, then, alas, you have to accept the loss. The flow rate of the water source will sharply decrease even with complete success (if it can be called such), and the quality may fall.

To prevent silting back and pump sticking associated with it, it is possible, if not lowering it more than 10 m below the dynamic line and at least once every 60 months, to the surface. If this situation nevertheless arose, you can try to pull the device, swinging it. It is advisable to make such an attempt with the pump on. This will help lift up the particles of crushed sludge.

When it is not possible to pull the device out with simple methods, you need to immediately turn to professionals.For your information: even the use of the latest equipment allows to solve only about 70% of problems with a jam, aggravated by “innovative approaches”.

Do not use spliced hoses and cables. Each such compound increases the risk of seizure. An additional prevention of it is a fairly wide gap between the unit and the walls. The amount of drilling at once a very wide well is fully justified compared to the payment of technical assistance services or the preparation of a new channel. You should also spend money on the tip, which will prevent the clogging of the water source with various objects.

Maintenance work and inspections on borehole pumps are recommended in the spring and with the approach of cold weather. To reduce the likelihood of interruptions and the occurrence of extraneous noise, it is required to regularly change the lubricant. Experts advise during the maintenance to assess the condition of the hoses or pipes attached to the pumps. It is not recommended to run the system more often than necessary, it will inevitably end in an emergency breakdown.

Only minor damage can be repaired by yourself.while any significant defects are eliminated only by professionals.

Removing the pump for maintenance or repair, you must first de-energize it. Pulling the device is better with assistants and without sudden movements. Mount the serviceable device in the reverse order. Be sure to test run, even if there is no practical need. Before the first maintenance, it is recommended to once again study the technical documentation.

How to choose a pump for the well, see the following video.