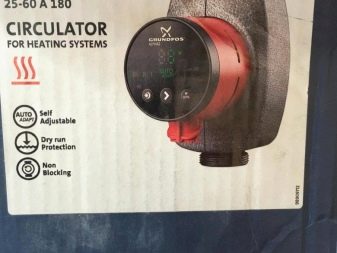

Advantages of Grundfos circulating pumps for home heating and gardening

During the design of the heating system, hot water supply or underfloor heating, it is important to achieve an optimal indicator of water circulation. Grundfos pumps designed to circulate heat carrier are often used to solve this problem. Brand equipment is distinguished by decent quality and reliable performance, which many users have already appreciated.

Specifications

A well-known Danish company manufactures various pumping equipment. The main difference between the products of this company is considered to be a specially developed modification of circulation pumps for use in certain areas. Pumps of this type are small and lightweight.These factors greatly facilitate the installation of equipment in the system.

The main task of this type of device is the forced circulation of the heat carrier through the installed system. The pump creates a certain pressure, due to which the coolant is constantly moving. The main characteristics of these products can be considered silent operation and cost-effective consumption of electrical energy.

Most models can be installed independently. During installation, there are usually no complications. If you have questions, you can watch the video and photo material with instructions for installing the product. After installation, the Grundfos pump can be used immediately, for which it is only necessary to connect it to the power supply.

Adjustment of the correct operation of the circulating pump is carried out in automatic mode. Therefore, the owner does not need to constantly monitor the equipment and adjust his work under the system.

In order to choose the right device of this type for your case, you need to know the water temperature in the system or clarify the characteristics of the liquid that replaces water and becomes the coolant.

Benefits

Grundfos pumps are quite popular because have several advantages.

- High performance with low power. Everyone knows that the performance of the circulating equipment is not affected by the distance, since the liquid returns to its initial position.

- With the use of equipment of this type the coolant practically does not lose its thermal energy. This is because this device circulates using the friction force in the system.

- Economy of electricity consumption. Savings are due to the fact that the pump can operate in autonomous mode. At the same time, he constantly maintains the temperature of the fluid in the heating system.

- Ability to set a certain temperature. This type of equipment has a special regulator with which you can adjust the temperature of the liquid. The set temperature will be maintained automatically. If the temperature level in the system is already suitable, but you have just installed the pump, it will adjust to this level automatically and will support it in the future.

- The pumps of this particular manufacturer have a fairly simple design. Due to this factor, you can install the device yourself, without the help of specialists.

- There is a choice of devices for individual heating system. The cost of such equipment will depend on the required configuration for a particular system. Due to this, you can save on the purchase.

- Products of this type, as well as other products of the brand, are made of quality materials. This means that they are reliable and practical. Since the devices must operate continuously and automatically, high demands are placed on the products. In addition, they do not have unnecessary functions and components. This not only reduces the cost of vehicles, but also makes them more durable.

- The benefits can be attributed to the warranty period of operation, which is 2 years after the purchase of the device, as well as the availability of detailed instructions for self-installation and use.

Popular models

Among the pumping equipment for heating systems supplied by the company to the market, there are models thatwhich are most popular with consumers. Let us consider in more detail their features and characteristics.

ALPHA2 L

This model has 7 modes of operation. Such devices are used for single-circuit and double-circuit heating systems, as well as for arranging underfloor heating. This pump has a motor with permanent magnets and a set of settings for the desired pressure in the system.

If air accidentally gets into such a device, it will be displayed automatically. To do this, you must set the 3 mode of operation. After removing the air, the mode required for normal operation should be reset.

In addition, this view has 2 additional settings for certain modes with possible pressure drops in the system. Such additional installations make it possible to constantly maintain a uniform pressure in the heating system, regardless of its fluctuations.

ALPHA2

This version of the circulation pump is considered more functional and interesting. It is equipped with 3 main modes of operation, 3 modes for operation with pressure drops in the system and 3 modes of proportional adjustment.Due to the number of modes, this model is considered universal.

In addition, the device is equipped with 2 additional functions. The first is a summer mode of operation, and the second is a night economy mode.

In the country of the manufacturer (in Denmark) such devices are very popular. The main advantage of this type is the possibility of night savings. For example, if there are no people in a building at night, at that time it is possible not to heat it. This allows you to significantly reduce costs.

Another feature is the versatility of the device. Due to this, the device can be used with modern boilers, which do not have the function of forced circulation of coolant in the heating system or in the system of warm floors.

ALPHA3

This model can not "boast" a large number of different modes, but it has the ability to automatically balance the system. Such ground heating devices for home heating are often referred to as “cold medicine”.

The set of such equipment includes Reader. This additional device is installed and connected to the electrical unit.It transmits information about the operation of the pump to any gadget (smartphone or other device). Also, this model makes it possible to find out what the flow rate of the coolant in the system.

Different variations of Grundfos circulation pumps allow you to choose the right fit for any occasion. The choice of model will not be so difficult if you familiarize yourself with the recommendations for the purchase of equipment of this type.

The nuances of choice

Before choosing a device, you need to familiarize yourself with the flow rate of the heat carrier in the heating system. Such a recommendation is substantiated by the fact that the indicators of the amount of heat carrier required for the optimal operation of the installation depend on the flow properties of the pump.

To determine the flow rate in your heating system, you need to know a few basic indicators:

- the amount of heat demand, taking into account one kilowatt per square of the room (the value is denoted by W);

- temperature difference indicators (on return pipe - T2, on feed - T1);

- specific heat carrier heat capacity, which is 1164 watts per 1 cubic meter.

After collecting all the necessary data, calculations should be made using the formula R = W / C (T1-T2). As a result, you get the number B, which should be measured in liters for one hour. The resulting number should be converted to cubes. According to such data, you need to select a suitable pump.

According to experts, when choosing a pump for the heating system, you should not forget that Grundfos devices are capable of operating in 3 established modes. This means that the transfer rate of devices is different. When choosing, it is necessary to focus attention on the second mode.

It is also advisable to carefully study the labeling of all types of pumps. For example, the UPS 20-60 pump is able to work optimally on a heating system, whose pipe diameter is about 2 cm, and its height is not more than 600 cm.

Installation

Installation of the pump should be carried out on the return, but preferably before entering the heating equipment. In this case, he will begin to move the cold coolant, which has already passed a circle through the heating system. If the pump of forced circulation is installed on the supply pipe, then in this case it will contact with the hot coolant and thereby damage the sealing elements of its case.

Installation of this type of pumps is carried out in a threaded manner on the so-called American. The shaft in this case should be located strictly in a horizontal position. If it is installed in a vertical position, it will lose about 30% of the efficiency.

At installation you should not forget about the need to pre-install the filter for the mechanical cleaning of the coolant. On both sides should be located check valves.

If two pumps are installed at once on one heating system, then a ball valve must also be installed at each connection.

During installation, it is necessary to take into account that the device case should not be subjected to loads and deformation pressure. Therefore, it is necessary to monitor the abrasion of the nozzles of the system in order to have an idea about the degree of wear. If the system often accumulates air, then in its design it is necessary to include automatic air vent.

If you are installing a closed-circuit heating system, an expansion tank must be installed with the pump. The latter will divert possible hydraulic shocks and eliminate pressure drops in the system.

You will learn more about the installation stages of the Grundfos circulating pump by watching the following video.