Rules for selecting a pump for a well

Wells are designed to provide people with at least technical water. As a maximum - it must be tasty and meet all sanitary requirements. But to raise the liquid manually, buckets somehow not very convenient, and therefore requires careful selection of pumping equipment.

Special features

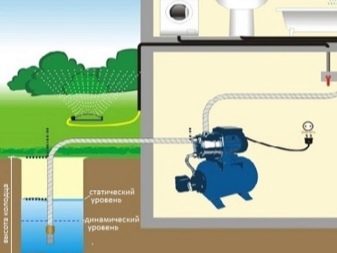

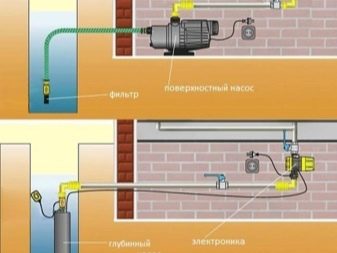

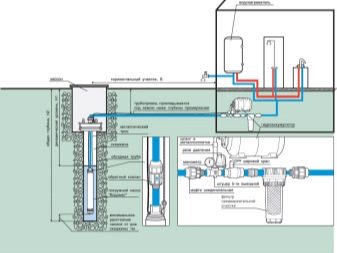

A well pump is almost always a submersible device. Only occasionally is it allowed to use surface systems, because they cannot fully cope with the pumping of liquid. It is unreasonable to choose a surface apparatus also in those cases when the water source itself is removed from the house (regardless of the height of the water mirror).The submersible pump is so named not by chance: it should be dredged into the water at least 1 meter. If the liquid level is significantly reduced, it can no longer cool the electric motor, and therefore there is a risk of its failure.

In country wells they install the same pumps as in wells:

- screw;

- centrifugal performance;

- whirling;

- vibration type.

Vibration-free systems that do not have blades or other structures that require mandatory lubrication and that threaten to overheat from friction.

The system operates at the expense of electromagnetic forces, then attracting pistons and rods, then disconnected by automatics. As a result, a pressure change occurs, and the fluid moves along the contour. The widely known “Brooks”, “Aquarius” are just vibratory pumps. Soft prices and long-term use are somewhat overshadowed by the suction of various types of dirt, if the pump inadvertently approaches the bottom by more than 1 meter.

Kinds

It is already clear that the well pump can be very different in type, power, that it is calculated on a certain water pressure and other parameters.

In assessing the properties of a particular type of pump, the following are taken into account:

- for what water will be used and in what quantity;

- how deep it lies;

- how far you need to feed the liquid from the well;

- whether the equipment will be used continuously or periodically only.

The general rule is that the more productive the installation should be, and the more actively it will be used, the more important the equipment is automatic. Then, at least one of the constant worries in the life of gardeners and gardeners will occur less frequently. Vibration devices are suitable for farms that consume relatively little water. Surface apparatuses are permissible only for lifting liquid from a depth of not more than 9 m, but are distinguished by insufficient suction height. Therefore it is necessary to bring the device closer to the well or to put pipes of increased section.

For a private house, centrifugal immersion devices are often used. Externally, they are a cylinder of stainless steel, in which the drive is placed. For pulling water up applied so-called impeller. Equipment with a float is needed to eliminate the situation when the device would extend all available water. Sometimes, instead of a float mounted automatic controller.

The centrifugal machine consumes a lot of lubricating oil. If the casing is damaged, or the tube is depressurized, the water in the well will have a film that is extremely difficult to remove. It is necessary to use either another pump or special reagents. In the first case, an additional device must be prepared. In the second - there is a risk to degrade the quality of water.

Submersible pumps in the wells are also drainage. They are designed to eliminate the accumulation of polluted water. The advantage of this design is that it is able to pull out dirt in other places, even in the basement or in the drain hole. Performance is very high, although the pressure and height of the water column are relatively small. External devices work with water of different contamination, but they create considerable noise. Knowing all these moments, it is easy to understand the properties of a particular pump, focusing on its type.

But it is important to get acquainted with two more of them. First of all, the multistage type. The purpose of its use is to extract water that does not contain sediment. Such liquid can be used in irrigation, water supply.Every detail in contact with water is made of non-corrosive materials: either stainless steels or special plastic (noril).

Warning: multistage pumps are not able to provide continuous water supply.

Any device, no matter what type it belongs to, is recommended to stop after 120 minutes of work. Break time - until the device cools to a temperature that is a maximum of 2 degrees higher than the ambient temperature. Breaking this rule, one may face the premature exhaustion of a resource.

Hydraulic shock pump unit works as follows:

- flow is introduced into the suction line;

- as soon as it reaches a certain speed, the accelerating valve stops;

- head pressure opens up the main channel;

- pumped passes into the drive.

Once he finally stops, the pulling unit closes, but at the same time, the passage for the new portion opens immediately. A pressurized air stream bursts into the tank, pushing the fluid into the receiving path. Cyclic action occurs with a pulsating pressure level, but in a water circuit, where water flows to the final consumer,it is already stable. The hydraulic pump is able to operate only on terrain with a significant bias. But he does not consume electrical energy and works for a very long time.

Surface

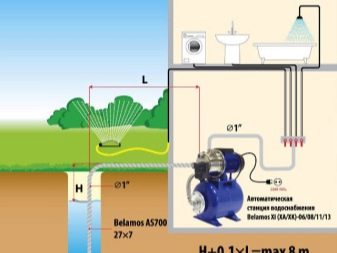

In addition to the type of drive, it is worth considering the depth at which the pump can take water. A surface pump in close proximity to it inevitably creates cavitation. It simultaneously increases its productivity and at the same time accelerates the breakdown. Manufacturers, to avoid lawsuits and fines, guarantee the rise of water from a depth of 8 m. Individual wells of greater depth can also be serviced by surface pumps, but such cases automatically remove all warranty obligations.

Note that we are talking about injection devices. The use of a deep ejector allows you to pump out a liquid from 40 m. Be sure to install two pipes at once (you will not be able to do one of them). Negative feature is inevitably decreasing performance. The injection unit is able to deliver up to 4 cubic meters in 60 minutes. m of water, and the ejector - does not pump even half of this amount.

Deep

Its peculiarity is that the raising of water is carried out in the simplest way.As a result, the system performance is higher than that of surface models of even the highest quality. Up to 16 cu. m of liquid, the magnitude of the pressure ranges from 150 to 200 m. But comparing solely in performance is not very reasonable, there are still a number of other significant indicators. So, the flow rate of 1.8 cubic meters. m per hour with a pressure of 30 m can not be achieved using a pump that consumes less than 900 W of electricity (surface) or 750 W (submersible type).

The reason is simple: immersed systems do not spend a certain part of the energy consumed to retract, they only form a head. The difference is even more pronounced when comparing submersible apparatuses with ejector units remaining on the surface. To achieve the characteristics of the water supply just mentioned, they have to absorb more than 2 kW per hour. In addition, the submersible equipment creates less noise, since there are no blades forcedly cooled by the air flow. But reliability depends not so much on the type, but on the selection for specific conditions and on the literacy of operation.

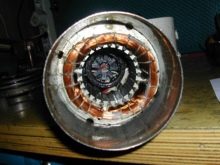

Device

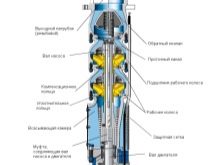

It is impossible to disassemble the device of all existing pumps in one article.It is useful to dwell on such a popular model as the “Water Cannon” - especially since this brand has created a whole niche of submersible pumping equipment.

It is different:

- soft prices;

- high performance;

- ease of repair and service work.

"Dzhileks Vodomet" 60/52 proved to be very good thanks to a carefully thought-out standardized design. The body is a cylindrical metal block that hides the engine. The shaft serves to attach the impeller, but it does not come into contact with the engine compartment, since it is separated from it by the liner. The winged part has a complex internal structure (it includes a set of disks). After the white part with the outer blades put a black washer of the same diameter.

Next is the "cup", the second blade disc, washer. After them:

- white disk with blades;

- glass;

- washer;

- disk;

- glass;

- washer;

- glass;

- washer;

- white cap with a hole in the middle;

- the cover is black with the same hole;

- a shortened cylinder with a grid placed above it.

The role of the last detail is to filter the water.Only the fluid that passes through the mesh is fed into the hose or into the pipeline. This pattern of alternation of components is characteristic of any model of this series, be it intended for a depth of 5 m, or designed to work in wells dug to 20-40 m. The task of the washers is to reduce friction. Polyamide is used for the production of discs, washers and glasses.

This design means that a breakdown can be caused:

- or contact of the impeller with sludge;

- or the destruction of the network cable;

- or a malfunction of the electric motor.

When the pump is removed and the shaft is spinning during a test run, the problem is caused by silting. The inability to start the machine requires you to check the cable with a tester.

Attention: you should not eliminate the defect by twisting or using a soldering iron. This will break the tightness of the shell with all the ensuing consequences. Having rejected these two assumptions, it remains to repair and sort out the engine compartment; disassembling it in the reverse order.

Manufacturers

It is very important to focus not only on purely technical points and general descriptions, but also to take into account the characteristics of specific manufacturers.Among Russian companies it is better to choose brand products. "Dzhileks"who have long established themselves on the positive side. Significant positions in various ratings are occupied by Makita products. For example, submersible pumps for clean water PF0300, 0800.

The body of the two models is made of sturdy plastic, and a double layer of rubber in the gasket increases the service life of the motor. The float is controlled by an adjustable lever. The handle with which you need to carry the pump, not only strong, but also convenient for people. Liquid outlet pipe is made in size 1 ½. Protection against water ingress is IPX8 compliant.

Both pumps are connected through a 10 m supply cable and can pump water containing suspended solids no larger than 0.5 cm. The permissible heating of the liquid is 35 degrees maximum, the depth of loading into the water does not exceed 5 m. For the devices to work quietly and not to spoil, water mirror from 2 cm thick. Modification of PF0403 / 1100 differs significantly from the products described above. The difference is already expressed in the fact that the body is made of steel, and the outlet pipe has a diameter of 1.

A conversation about Italian well pumps cannot ignore such a popular brand as Pedrollo. NK version can serve up to 7.2 cu.m of water per hour (in other words, 120 liters in 60 seconds). The created pressure reaches 80 m.

It is necessary to take into account that the device cannot be used:

- at a liquid temperature of 41 degrees;

- when the concentration of sand is more than 0.05 kg per 1 cub. m;

- if necessary, lower the device 20 m below the surface of the water;

- for continuous extraction of fluid.

The company is ready to order to complete the pump with various electrical cables. Individual reconfiguration to non-standard mains voltage or to a frequency of 60 Hz is also allowed. By default, the delivery comes with a wire length of 20 m, the warranty period is 24 months. Another company model is Top Multi-Tech It can also supply 120 liters of water in 1 minute, but creates a pressure only in 42 m. At a pressure of 1.5 bar, a restart occurs.

The power cable has a length of 10 m. An electronic device is built into the system that allows you to automatically open and block the water supply. Pumps of this type can pump only clean water, high efficiency and reliability allow for comfort. Do not immerse the pumping unit deeper than 10 m from the highest point of analysis. It is acceptable to have solid particles (suspension) not more than 0.13 cm in diameter.

How to choose?

It is easy to see that there is a huge variety of technical systems that allow the use of a well for water supply at home. The difference in technical performance, characteristics can be misleading or even compel to buy the first available device. But such a practice can hardly be considered a reasonable solution. The main thing is to take into account the characteristics of a particular water source.

Even the most experienced engineers and salespeople will not be able to give sensible recommendations if they do not know:

- how far is the introductory point from the well bottom;

- what is the static level of the water mirror;

- how big is the dynamic level;

- how much water should be obtained, and how much can be extracted outside.

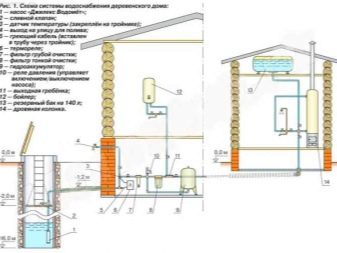

Collecting and disassembling water pipelines in country houses are measured, counting the distance between the bottom of the wells and the upper limit of the tips. If the pipeline is operating continuously, the entry point into the wall is a reference point. Independently measure the height of the water mirror can be, if you use the simplest devices. The total height of the well, which is calculated as the sum of the width of the rings used, is also taken into account.Of course, if the rings were not used, you will have to solve the problem differently.

The next step in the selection is the measurement of the distance between the water intake point and the points of its receipt. Here you can get by the scheme drawn up by the owners of the plot, but the distance should be measured accurately. It is necessarily estimated how clean the liquid is (and if there is a suspension in it, set the diameter). When there is no full confidence in the chemical inertness of water, it is worth ordering the analysis in the laboratory. They will say which materials will be stable when in contact with the liquid, and which will quickly decompose.

But it is important not to forget: all these moments only precede the present choice, and do not allow to make it definitively. When it is planned to supply water in the summer months, an inexpensive surface pump is enough. But if you need to supply the cottage or a country house with water all year round, there will already need deep equipment. To reduce the risk of clogging and deformation of the motor, it is necessary to leave at least 1 m of water up and down from the bottom of the well to the submersible pump. Theoretically, a well pump can also be installed in a well, but it is better still specialized, it is easy to recognize it even simply by name.

Do not install submersible pumps in old water sources. If the need for this still arises, it is necessary to thoroughly strengthen the walls and bottom (after pumping water). Universal surface pump is advisable to use in the summer water supply. When a well reveals the horizon of the upper layer, and it is planned to use a liquid for technical needs, surface equipment is the best choice. It so happens that the production has a rapidly changing volume of water - then you should mount modifications with signal floats.

Such floats stop the pumping of fluid, if its level does not reach the technically justified limit. It is recommended when choosing carefully to read the technical data sheet for a particular model. It is impossible to purchase pumping systems with excess capacity, since the apparatus switched to the dry run mode will lose performance. The flow rate of the well is more important in the event of an unstable water supply than its flow. Another thing to consider is feedback from consumers who have previously purchased one or another model.

Often there is a need for pumping dirty water.

It can fall into the wells:

- for integrity violations;

- when illiterate exploitation;

- due to errors in the design and construction.

The sand removal pump can be cantilevered or single stage in performance.

Such a device is capable of removing:

- sand and abrasive hydraulic mixtures;

- water mixed with clay;

- ore dressing products;

- silt

It is useful to bear in mind that pumps for pumping sand must work with strictly defined parameters. The liquid normally has a temperature of 5 - 60 degrees, the density is not higher than 1300 kg per 1 cubic meter. m. Although the pump is called sand, it can not cope with a concentration of solid particles of more than 25%. The device is also useless in the case when the size of inclusions exceeds 1 cm. These parameters allow you to save the working qualities of the system as long as possible.

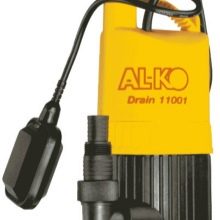

Drainage pump for supplying dirty water is desirable to have at any cottage. Such equipment is useful both before disinfection (chlorination) of the water supply source, and before repairing it. Low-power devices are not able to solve a similar problem, because the liquid will flow from below with the same or even with even greater speed.According to the professionals, Ergus Drenaggio 400F can be used for drainage works. The Italian mechanism will be able to extract 7500 l of water in 60 minutes, the pumping depth is 5 m, the allowable size of durable impregnations is 35 mm.

Russian products (“Vortex DN-400”) can pump up water from a depth of 8 m. And about 11 tons of liquid rise in an hour. Despite the increased productivity, such a system can only pump over a suspension with particles with a maximum section of 5 mm. Conclusion - "Whirlwind" is intended primarily for wells filled with sand, and the release of the well from dirt for it is a secondary function. Alternative - AL-KO Drain 11001, produced in Germany.

German equipment allows you to pull a large amount of water from a depth of up to 950 cm - a maximum of 12 tons. It uses a relatively weak power system, it consumes a maximum of 850 watts of electricity. The recommended width of solids is 30 mm. "Dzhileks Drainage 110/6" demonstrates that Russian products can be no worse. True, it can only be immersed at 5 m, lifting up to 6.6 tons of liquid per hour.

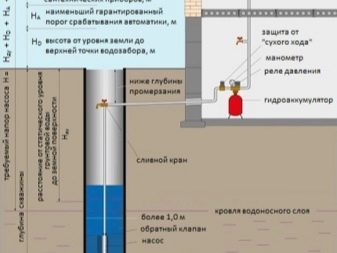

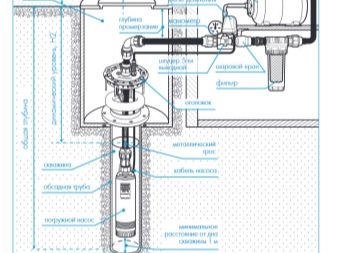

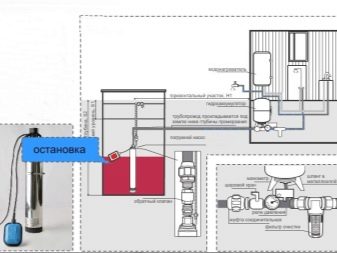

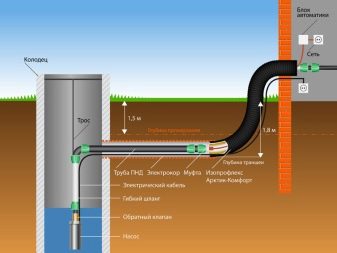

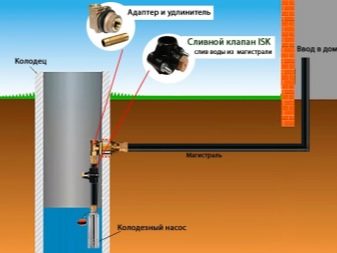

Installation

When a pump is selected, it is necessary to carefully install it. Submersible devices are mounted starting with digging a trench.Then in the basement of the house are preparing holes for pipelines and cables. When the pump is lowered to the source, you can install the relay, batteries, cable. In advance form the scheme of installation and select carefully suitable material.

Experts advise if possible to lay the pipeline in a straight section, where it will not be necessary to make bends.

The advantages of this solution are obvious:

- reduction of the volume of work performed;

- pressure increase in the pipeline;

- reduction in the number of connections;

- minimal risk of water leakage.

The trench should be 50 cm wide and 100–150 cm deep. 100–200 mm of sand are poured, then a sheet of geological textiles is laid. It will help to wrap the pipe. For the construction of the pipeline using the design of stainless steel or polypropylene. Replacing full pipes with rubber hoses is permissible only in summer water supply systems.

It is recommended to warm the channels through which water will be pumped. The sleeve that holds the pipe outlet to the well is fixed with the help of concrete and its tightness is carefully ensured. To protect against chaotic liquid distribution, waterproofing is being prepared.The end of the pipes are inserted 250 mm deep into the liner; they are necessarily equipped with a tap for emergency water drainage. Submersible pumps are lowered, hanging on a cable made of nylon or galvanized steel.

Even the strongest ferrous metal cables initially deteriorate quickly in such conditions. The hold of the cables is made of strong steel frames, which are prepared by taking the so-called corners. Pumps that are not equipped with check valves should be placed on the outlets. If there is a valve, a coupling is attached to it first, and only then a pipe. The cables are fastened on an insulating tape or clamps, the wiring should be fixed firmly, but without stretching to the level of the string.

The most crucial moment - the descent of the pump inside the casing. It is associated with tee sanitary paste. Having removed the cable through the trench, it is brought inside the house with the pipe through a hole prepared in advance. If the pump breaks down or needs to be removed for another reason, this should be done with caution. Excessive rush will inevitably lead to problems.

Tips

Even the most reliable and well-designed well can have mud deposits.But for cleaning in any case, ordinary water pumps are unacceptable, you should use only specialized units. Do not violate the rules prescribed by the manufacturer for the depth of laying under water, the height of the water column, the duration of continuous action, and so on. Filters are a very useful thing, even if they are not included, it is recommended to buy such equipment in addition. When you have to put the pump near the house, it is desirable to choose options with a cast-iron or plastic casing, they are less noisy than steel.

Recommends purchasing accessories compatible with it only with a pump:

- hydraulic accumulators;

- backflow valves;

- automatic against dry running;

- Surge Protectors;

- relays and gauges.

How to choose a well pump, see the following video.