How to choose and install a pump "Gnome"?

Pumps "Gnome" are widely demanded not only at home, but also in other industries, such as construction, metallurgy, energy, oil and gas, rural and mining. They effectively perform their function in virtually any working environment. These units are characterized by impeccable quality, ease of use and practicality, as well as well proven in all applicable areas. To know how to choose and install the pump "Gnome", you need to familiarize yourself with the features and varieties of these units.

Special features

Production of sediment "Gnome" is carried out in Russia. This equipment is characterized by wide functionality, wear resistance and ease of operation. Each such unit is designed for pumping out both clean and polluted liquids.As for pumping fecal waste, for this purpose special models with individual technical characteristics are provided.

The main advantages of the "Gnome" pumps include:

- a large assortment;

- excellent quality;

- wear resistance;

- ease of repair and maintenance;

- durability;

- affordable cost.

The disadvantage is the possibility of overheating models without a casing.

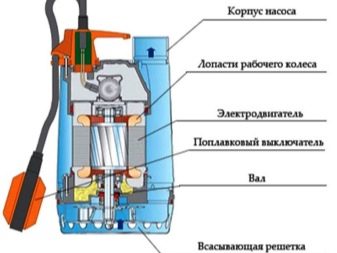

Each pump "Gnome" is designed for full or partial immersion in liquid. These devices operate according to the centrifugal principle, made in an elongated form with a vertically installed type of nodes in the inner part of the body. The process of pumping liquids is carried out under the influence of centrifugal forces that occur during engine operation.

Pumps "Gnome" have the following technical features:

- the level of productivity depending on the type of the unit may be in the range of 7-600 m3 / hour;

- the permissible temperature of the liquid during pumping can reach +60 degrees;

- impurity concentration can be up to 10%;

- head of pumped liquid is at the level of 7-25 m;

- the power of the mechanism for each instance is individual, its maximum indicator is 11 kW;

- the mass of devices is within 112 kg;

- the shaft and the impeller of the device are made of durable steel, and the outlet is made of high-quality plastic.

The manufacturer claims that all these features allow the use of “Gnome” pumps for solving a variety of tasks both in domestic conditions and in large enterprises.

They are mainly used for such purposes as:

- drainage of basements flooded during floods;

- drainage of ditches;

- pumping fluid in factories and enterprises;

- rural irrigation;

- pumping waste from different systems and electrical engineering;

- neutralization of the consequences of accidents.

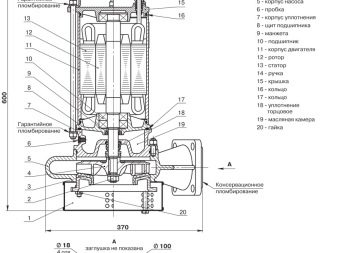

The design of the pumps "Gnome" is made of two parts - pump and motor department, which are harmoniously combined into one unit. The engine is cooled directly when pumping fluid, and its seal on the shaft is provided by the end seal. Inside is filled with oil, which cools and lubricates the bearings of the device, ensuring their full working condition.

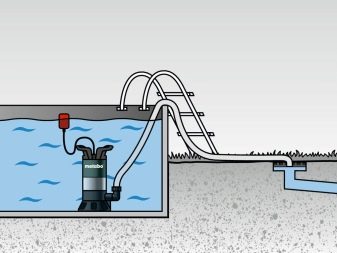

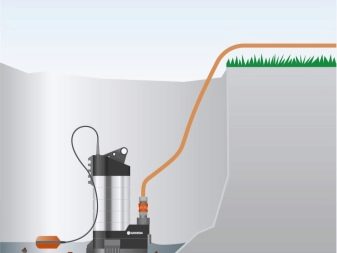

It must be remembered that immediately before switching on the unit must be in the liquid at a level of at least 50 cm. After starting the device, the pumped out fluid is sucked through the additional mesh into the inside of the case, from where it is pushed out of the pump compartment under pressure.

Kinds

All Gnome pumps are available in four varieties:

- Household. Submersible device, which is characterized by an average level of power and performance. Mainly used at home for pumping dirty water. Their productivity does not exceed 10-25 m3 / hour.

- High pressure. They belong to the category of industrial machinery, as they differ in impressive performance, which can reach 50 m3 / hour. The power of such models is up to 45 kW.

- Explosion proof. Professional devices that are marked with the EX marking. Actively used in industrial production and large objects. In comparison with a mud copy, it is characterized by higher cost and power.

- Self-cooled. Used not only for full, but also for partial immersion. Such a drainage unit is equipped with a special cooling jacket, which is responsible for the level of cooling in the process of pumping out dirt or other aqueous liquid. Technical characteristics of this device allow to operate it in those places where there is no possibility to immerse the product in water.

It is worth noting that all types of pumps "Dwarf" are very simple and quick disassembly of the main components. This feature makes the process of cleaning and repair as easy and affordable as possible. In the bearing shield there is a special plug in which the oil is poured. The manufacturer recommends careful monitoring of the quality and level of oil used, since the full functionality of these mechanisms depends on this. Its timely topping up and replacement will allow the device to maintain its excellent working condition during the entire period of operation.

Devices that can be operated not only separately, but also in conjunction with other units, are pumps "Gnome" 25/20. They are a portable system of the submersible type with the presence of an electric motor. The tightness of the internal part of the electric motor is ensured by the assembly on which the mechanical seal is located. Such models are used for pumping groundwater, drainage of ditches, swamps, basements, as well as are an integral technique at construction sites and hazardous production.

The vibration type of the “Gnome” pumps remains quite relevant. In relation to other options, such devices are considered to be much more economical in terms of energy consumption and are distinguished by affordable pricing policies. Their range allows you to choose the best option that will best meet the requirements.

The fecal type of pumps “Dwarf” is in wide demand, which is used not only for pumping fecal effluents, but also for irrigation in agriculture or for pumping water from pools. These units are characterized by increased resistance to negative impact factors and perfectly retain their original qualities throughout the entire period of operation.

Pumping water mixtures with high density of solid particles, the level of which is about 2500 kg / m3, is capable of providing a “Gnome” slurry pump. Technical characteristics of these models fully contribute to this.

Each of the varieties of pumps "Gnome" has its own individual purpose, which allows you to use it for those or other purposes.Therefore, in the selection process, it is necessary to take into account exactly where this unit will be applied and whether it will meet the requirements imposed on it.

Subtleties of installation and repair

Pumps "Gnome" are represented on the world market in the form of monoblocks, consisting of two parts: an electric motor and a pump part. The unit is driven by a starting device, which is located on the cord. For maximum convenience, the Gnome products are equipped with special capacitors and circuit breakers that serve as protection against engine overheating. Immediately before turning on the device, it is completely or partially immersed in water. Without water it is allowed to operate the unit no more than 15 minutes.

When preparing the “Dwarf” pump for operation, it is necessary to inspect the device for the presence of body damage.that may occur not only on the case, but also on the power cable. Be sure to check the presence of oil in the appropriate chamber. After that, you need to remove the cap from the nozzle, connect the device to a flexible hose, which is fixed on both sides with special clamps.The size of the hose is chosen individually for each model of the pump, taking into account the parameters of its discharge port.

In the process of immersion of the pump “Dwarf” with the help of a cable into the pit, it must have an exclusively vertical position with a tolerance of no more than 10 degrees. It is necessary to provide a full discharge from the hose, preventing the appearance of bends and fractures on it. Installing the unit on a sandy or muddy bottom, it is necessary to lay the substrate in the form of a rubberized mat at the installation site. Such a measure will allow you to create a stable and anti-slip base on the installation of the device. After adjustment of the pump and compliance with all rules of operation, you can start.

It should be noted that all types of Gnome pumps are easily repaired due to the simplicity of their design.

The main causes of problems and their solutions are:

- Lack of power. The most common cause of such a problem is connected with a cable break or engine failure. To eliminate it, it is necessary to check the voltage level, as well as inspect the cable for damage and neutralize them.If the engine itself fails, additional assistance from qualified craftsmen will be required.

- Inability to pump water. Such a cause occurs when there is no water in the source or the hose is not properly connected.

- The appearance of increased vibration and noise. Occurs due to bearing failure. Its replacement can be made independently or contact the service center.

- Head loss Occurs when a line is leaking or due to a decrease in voltage in the network. In some cases, the cause may be clogged pump debris. Then the device is subject to disassembly, followed by cleaning and washing the pump chamber.

All these features must be taken into account during installation, operation and during repairs. After all, even the most minor problem can cause serious repair of the entire unit.

Tips and tricks

Multifunctional pumps “Gnome” occupy high positions in the popularity rating among other brands. Deciphering the name of these units speaks for itself and sounds like this - Mudwater Pump One-stage Monoblock.Well-established production ensures the creation of high-quality devices that are actively used in various industries.

In the process of acquiring the pump company "Gnome" must take into account many important factors.which are directly related to the further use of the product. First of all, it is necessary to determine the future mission of the unit, after which you can proceed to the choice of a model with a suitable power and performance.

With regular operation of the device “Gnome” it is recommended to perform technical inspection in a timely manner, fixing records in a special passport. Manufacturers recommend maintenance maintenance units on a monthly basis to increase their service life and timely troubleshooting.

Maintenance involves the following actions:

- oil control;

- checking the integrity of the electric cord, as well as the elimination of deformations on the hose;

- inspection and repair of damage;

- measure the level of security isolation.

It is recommended to fill the oil every 250 working hours or if foreign liquids and elements get into it.For this, the “Dwarf” unit is installed on a flat surface, the plug is removed in the bearing shield, after which the oil is added or changed. Full replacement requires a volume of 300 ml. Suitable as a special oil, designed exclusively for pumps, and the usual technical version with medium or low viscosity.

After using the unit for the purpose of pumping liquid with mud impurities, it is worthwhile to start the device for pumping clean waterto clean the internal elements of the structure. When the mechanism has not been used for a long time, it is necessary to check the degree of rotation of the impeller before switching it on. Compliance with these rules and recommendations will help to preserve the original quality of products for a long time, as well as extend their service life.

Numerous reviews indicate that the pumps "Gnome" practically have no analogues. Due to its impeccable quality, functionality and reasonable cost, these products are widely demanded in the global market. They are actively used not only at home, but also in large industrial facilities.A well-established production process, as well as the use of the most modern technologies and materials make the devices of this brand really in demand, because each model harmoniously combines only the best characteristics.

In the next video, see the review on the pump "Gnome" 25-20.