Varieties and principle of operation of pumps for pressure testing of the heating system

The pump for pressure testing of the heating system serves to identify violations and defects in the tightness of the pipeline. The principle of operation of this device is to create a high pressure at the moment when water is poured into the pipes. Such a device indicates various leaks and damages in heating systems; therefore, a pressure pump is a very convenient device when carrying out maintenance work on heating systems.

When to use?

It is advisable to use this device immediately after the installation of the heating system.or other pipelines, which will allow to check the quality of work and immediately identify deficiencies for their elimination. Typically, the pressure of the pressure pump should exceed the performance by 2-3 times. When the required pressure is established at all parts of the system, it is necessary to follow the pressure gauge at the pump. If the arrow stably stays in one place without significant deviations - the heating system is working properly and there are no leaks. But if the pressure reading starts to drop sharply - it means that there is a defect in the system that needs to be fixed. After that, the system must be crimped again.

Before carrying out inspections of heating systems and the use of an opressovoe pump, it is recommended that you familiarize yourself with special regulations, which regulate the conduct of such work:

- “Rules of technical operation of thermal power plants” No. 115, approved by order of the Ministry of Energy of the Russian Federation dated March 24, 2003;

- construction norms and rules of the Russian Federation "Heating, ventilation and air conditioning";

- construction norms and rules of the Russian Federation "Internal sanitary systems".

Kinds

The classification of the pressing devices is represented by such basic types as:

- manual pump;

- electric pump.

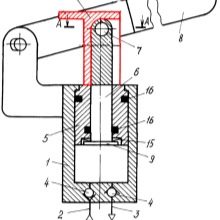

The manual pump is a fully mechanical device. The great advantage of such a device is its low cost, as well as ease of operation and not fastidiousness. Typically, mechanical devices are composed immediately all the necessary components - hoses, pressure gauge and tank. From the negative sides it is worth noting the low level of performance. When using this device on its own, it will be necessary to make great efforts to carry out quality system verification work.

Based on the description of the pump with a manual drive, we can distinguish the following positive aspects:

- low cost;

- ease of use;

- high mobility;

- does not require power supplies.

Electrically operated devices are more expensive and more cumbersome, but efforts to use them are minimized. Such a hydraulic pump can provide virtually any level of pressure in the system. In many cases, these electrical devices are used by professionals when pressure testing must be carried out frequently and at large sites.Electrical devices allow you to check the heating equipment, sanitary standards of technical devices, cooling and pneumatic devices.

The disadvantage of such equipment is the high cost, although there are many more advantages:

- full automation;

- possibility of use on large objects;

- saving time and own strength;

- high level of performance.

How to choose?

When choosing a pump for crimping, you should consider two main factors, such as:

- capacity of the heating system in which the pump will be used;

- How often will be crimped.

If a system check will take place in a small residential area and the frequency of checks will be rare, then it is not at all necessary to spend money on an electric pump. In this case, a hand pump will be fine. But if the test involves pressure testing the system in a large room, then the power of the hand-held device may not be enough, so it is advisable to purchase an electric compression pump. Quite a lot of positive feedback is received by models not with a plastic case, but with an iron one, most often from steel.And also in many devices there is a special valve that prevents high pressure in the system during the work. This aspect also needs to be considered when choosing a pump.

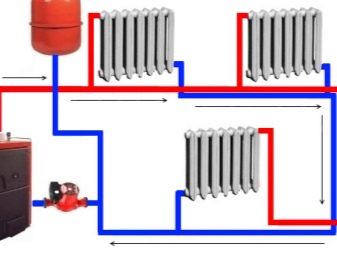

Connection

Before you carry out work on checking the system, as well as connecting the pumping station to it, it is recommended that you carefully read the wiring diagram and take into account the design of the heating system itself. First, the system must be filled with water with a temperature above 5 degrees. Then, with the help of a hose, a crimping device is connected to it. Commonly used threaded connection. In no case can not eliminate defects in the system with a working opressovschik. Also, for safety reasons, it is not recommended to install too high pressure, which can adversely affect the heating system and lead to its breakdown.

Models

Modern manufacturers offer a wide variety of models of crimping pumps.

Among the most famous, there are several options.

- NIR-25. This model of compression molding pump is intended for pressure testing and hydrotesting of heating systems.Such a device has a manual drive and it is recommended to use it for work with small objects. The pump is compact and lightweight. This device is perfect for personal use when conducting tests in a private home.

- Compact-50. This model is made in Italy. Its advantages are contained in the title itself - it has small dimensions and low weight. This pump has a complete set of tank up to 12 liters, hoses and pressure gauge.

- OIG-1. Another of the most commonly used models of pressure pumps. Such a device allows to carry out qualitative tests of the heating system and is suitable for performing various tasks. UGI-1 has a 20-liter tank in the configuration.

How to make yourself?

If you can not buy a pump for crimping, then it can be made by hand. The main parts that will be needed for self-manufacturing of the pump are the old jack and the cylinder capacity. In this container holes are made for the measuring device and the hose for draining the liquid. But even for a homemade device, you will have to purchase a pressure gauge to trackindications.

What can replace the pump for pressing the heating system, see the following video:

Recommendations

In many heating systems it is recommended to use not only water, but also antifreeze. It is extremely important to get rid of the air in the system after crimping, otherwise its operation may become unstable. The coolant must be poured into the circuit from the bottom, so that the air in the system is forced out by these fluids.

Inspection of heating systems is one of the main stages before the start of their operation. The pumping station for pressing operations will help to identify various defects and leaks in the system and eradicate them in time. It is advisable to purchase a pump if these checks are carried out frequently. In isolated cases it is better to turn to professionals who will do everything quickly and efficiently, because working with heating systems is a rather important process that requires certain skills.