Varieties of borehole pumps Grundfos

With a wide range of borehole pump models, Grundfos is the leader in sales in most countries of the world. Grundfos equipment belongs to the expensive segment, since its cost is 1.5–2 times higher than similar equipment from other manufacturers. However, its price is justified by excellent quality, because Grundfos borehole pumps are characterized by durability and reliability.

Special features

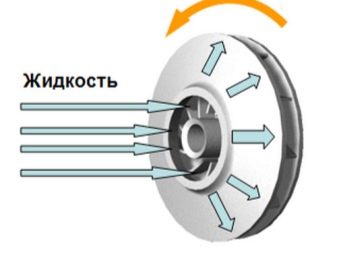

Grundfos downhole pumps allow pumping fluid from wells with different diameters. The principle of the pump is based on the laws of centrifugal force. Normal operation of pumping equipment is possible only after filling the working chamber with liquid and immersing directly in the water column.The electric motor with which each borehole pump is equipped ensures the rotation of the impeller.

The curved blades of the wheel during rotation take water and transport it to the outlet of the pump with maximum force and speed. In the area of the impeller, a vacuum - pressure drop occurs, due to which the inlet valve opens and the liquid enters the equipment from the outside. Regulation of the pump by using the control unit.

Grundfos borehole pumps feature the following positive features:

- high quality materials for the manufacture of pumps that are resistant to corrosive wear;

- a wide range of models, among which there are options with high performance up to 470 liters per minute and head up to 650 meters;

- compactness, which reduces the cost of the pump and simplify its installation;

- easy disassembly when performing repair work or sanding;

- high efficiency at operation both in vertical, and in horizontal position;

- low noise level;

- low costs, as Grundfos pumps do not require frequent maintenance;

- large hydraulic machine management resources.As a result of the use of innovative control units, submersible units quickly react to changes in operating conditions, which allows to increase the service life;

- the use of food rubber for the manufacture of power cables, so that the pump can pump drinking water;

- reliability. All parts and assemblies of pumping equipment are made of stainless steel, and bearings are made of high-strength composite materials;

- "Floating" impellers allow you to pump liquid when it contains solid fine particles;

- protection from work at idle, which provides for automatic shutdown of the pump while reducing the minimum amount of water. This avoids breakage of the pumping equipment and the well itself;

- soft start system avoids water hammer, mechanical abrasion and high voltages;

- the presence of the inlet auger ensures regular lubrication of the pump with the pumped liquid and additional protection against cavitation;

- the presence of the stop ring protects the pump from damage during its transportation;

- the presence of the filter element on the suction pipe prevents solid particles from entering the pump;

- innovative bearings with special channels for sand provide lubrication of pump components pumped liquid;

- a check valve prevents fluid from returning when the well equipment is stopped, thereby reducing the risk of water hammer;

- efficient cooling of the engine through special channels.

The only drawback of manufactured models of well pumps is the possibility of functioning only in one position: either in the horizontal or in the vertical. As a result, there is a need for careful selection of equipment based on operating conditions.

Kinds

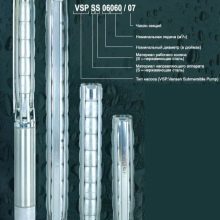

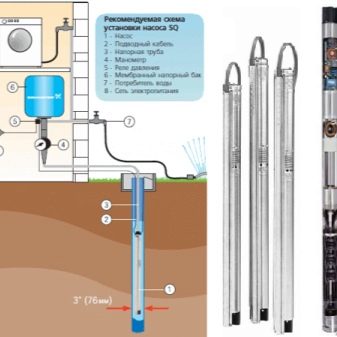

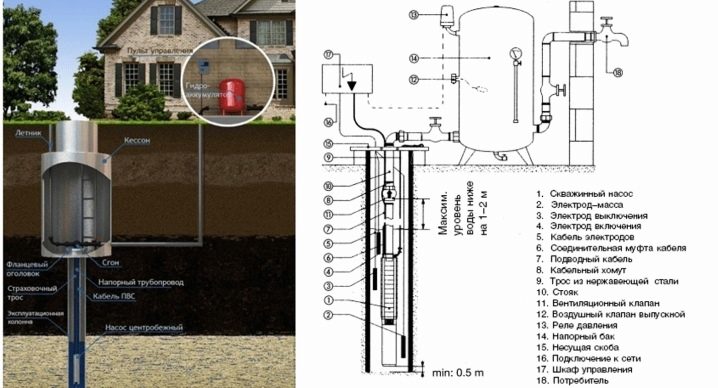

Submersible pumping units are presented in two series - SP and SQ, which are able to pump only clean liquid. By design, they are no different, since they are deep-seated devices for working both in horizontal and in vertical positions. Standard well pumps consist of a steel casing with a single-phase or three-phase motor., and also with the driving wheel from polyamide material.Water intake is carried out at the bottom of the pump.

SQ Series

This series is represented by devices with single-phase electric motor MS 3. The marking of the pump is carried out as follows. For example, a pump for an SQ 3-105 well has a capacity of 3 m³ / hour and a liquid lift to a height of 105 meters. Currently available devices with installed power cable or without it. The first ones are more convenient due to the fact that there is no need to search for a product with a specific cross section and an independent connection with pumping equipment.

The range of pumps of this series is presented by a big variety of models with the different technical characteristics. Therefore, depending on the scale of the water supply system, it is possible to choose a device with optimal parameters. Due to the wide range of technical characteristics, these devices have found application in domestic water supply. The parameter ranges are as follows:

- power is 0.7–1.85 kW;

- liquid rise - 21–238 meters;

- productivity - 1,7–9 m³ / hour;

- weight - 4.5–7 kg.

It is worth considering the most popular models of the SQ series.

- Pump equipment SQ 1-65 It is installed in wells with an internal diameter of more than 7.6 cm. It is resistant to wear and has protection against the dry running of the pump. This option is suitable for pumping drinking, hot, saline and seawater. The pump has the option of a smooth start, which is designed to prevent water hammer, and a check valve that prevents the flow of fluid. SQ 1-65 is made of stainless steel and protected with an anti-corrosion layer. The equipment has been used in everyday life, in drainage systems, as well as in irrigation systems and industrial circulation.

- Pumps SQ 3-45 AW Made of stainless steel and other anti-corrosion materials. The equipment is equipped with a system of protection against dry running, voltage drops and overheating of bearings. It has a long service life. Its capacity is 3 m³ / h, weight - 5 kg and pressure - up to 45 m. The pump can only be used for pumping clean water.

- Unit SQ 2-70 it is applied in systems of water supply in life and industry. It is equipped with an automatic cooling system for bearings, has a high efficiency.Regulation of the pump unit is carried out using a temperature sensor, which is installed in the electronic unit. Its capacity is 2 m³ / hour, power - 1.15 kW, pressure - 70 meters and weight - 6 kg.

The pump for a well of the SQE series represents the equipment similar to the SQ series.

Models have the same shapes, dimensions and design features, but they have one distinguishing feature. SQE series models have frequency converters that perform the function of pressure stabilization in the entire water supply system. This feature allows you to install pumps for water supply cottage plots.

You will learn more about the SQE series borehole pumps by watching the following video.

SP Series

Water pumps of the SP series have more serious technical characteristics. They are equipped with a three-phase electric motor, which makes them truly powerful. All components that are in contact with the pumped water are made of stainless steel, and the bearings are made of food rubber. The pump has a multi-stage impeller, thereby increasing productivity. It is used for large diameter wells.Fluid can be pumped at temperatures up to +60 degrees.

SP series models are characterized by the following ranges of parameters:

- power ranges from 0.37 to 15 kW;

- the rise of the fluid is 50–520 meters;

- productivity - 1.4–7 m³ / hour.

Due to such essential characteristics, the devices can be installed for pumping liquids with the presence of various impurities. The most famous model in this series is the SP 9-16 weighing 30.5 kg. It is made of steel with a chromium-nickel alloy, which allows it to withstand the harmful effects of corrosion. The pump capacity is 9 m³ / h, the head is up to 85 meters, the maximum temperature of the pumped liquid lies in the range from 0 to +55 degrees, it pumps liquid with solids content up to 115 g / m³.

Other equally popular models of well pumps include the following:

- SBA 3-35 A has a motor with a capacity of 1 kW, performance 4.5 m³ / hour, lifting of the liquid to a height of up to 35 meters. The pump in place of the water intake is equipped with a metal grill and float switch to prevent idle operation;

- SB 95 4N designed for pumping raw water, for lowering the level of groundwater and increasing the pressure of a clean, non-aggressive and non-viscous liquid medium.The device is completely made of stainless steel, equipped with a check valve.

Scope of application

Grundfos borehole pumps are used in the following areas:

- transfer of water from wells and wells to summer cottages, water supply systems and irrigation systems of low power;

- transfer of various liquid media to industrial tanks;

- increased pressure in the water supply system;

- use as work cycles in garages and gas stations;

- for sampling and recovery for environmental purposes;

- Well submersible pumps of the SQ and SQE series are used to transfer water from wells and boreholes, open sources to residential sectors and irrigation systems.

Reviews

As a rule, with proper selection of a well pump and proper installation in accordance with its purpose, the equipment will last for several decades. Grundfos product reviews are mostly positive.

After a long operation of the pump, customers concluded that the device was working without any complaints and comments. But, buyers also mention the high cost of Grundfos pumping equipment, which is 2 times higher when compared with similar equipment from other manufacturers. But once risking, they did not regret the money spent.In addition, the Grundfos pump has a power cable that simplifies the installation of equipment.

The pump is also excellent at cleaning the sewage system, and can also be used for watering the garden.

Tips

It is necessary to treat the choice of the borehole pump with all responsibility. To do this, you need to know all the information about the well itself, which is presented in its passport. In particular, you need to pay attention to such values as:

- well debit - this is her performance. This value indicates how much power can be used to pump fluid from a given source;

- borehole diameter - This is an important parameter when selecting a submersible unit. To date, there are three standard diameters: 15.2, 13.3 and 10 cm;

- dynamic fluid level shows the depth at which the equipment must be installed;

- additional loads: distance of the pump to the storage tank, pressure level in the accumulator and others.

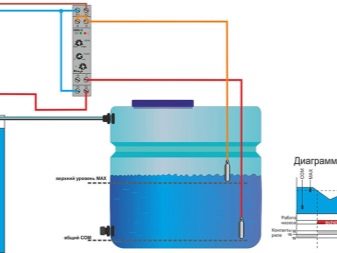

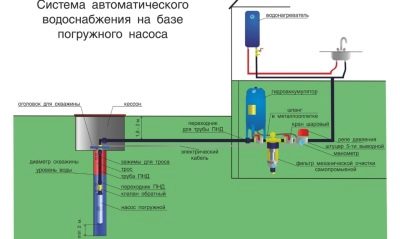

The following items are included in the package of pumping equipment:

- downhole pump with cable connector in an impermeable sheath and the flat cable itself;

- Control block;

- pressure gauge for measuring pressure in the range from 0 to 10 bar;

- pressure tank with a capacity of 8 liters;

- pressure meter;

- stopcock;

- cable clips.

The range of Grundfos submersible units is presented in a wide range, so you can choose the best pump for any water supply system.

To make the right choice in favor of a particular device, it is recommended to consult with a specialist.

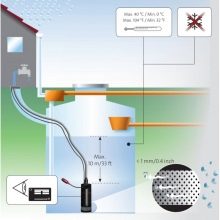

Installation of pumping equipment should begin with a check of geometrical parameters. The most important rule of installation is the observance of the orientation of the apparatus vertically. Possible defects can be detected by clarifying the straightness and matching the diameter of the well with pump sizes. You can use special templates - these are elements of a pipe with a diameter larger than the dimensions of the pump unit, to determine possible curvatures by lowering the template into the well.

During the installation of the Grundfos downhole tool, the following tools are required:

- special means for lifting the pump from the well;

- fittings;

- electrical wires and clamps;

- set of tools.

Initially, you need to attach the electrical wire, clean the ends of the cable and fix it with solder. At the edges of the electric motor are the sleeves where the cable is inserted, the joints are treated with solder. Before loading the pump into the well, it is necessary to familiarize yourself with the equipment installation instructions.

The manufacturer recommends to pre-fill the engine with fluid. The best option is filtered water to eliminate the possibility of plaque formation.

If you do not fill the motor with water, the pump can only be started a few hours after it is immersed in water. The pump is connected to the yoke in a strictly upright position and dipped into the water column. The function of the clamp is to ensure the hanging position of the structure. The other end of the pipe is attached to the second clamp, continuing to dive. After starting the submersible pump, it is necessary to observe the operation of the equipment in order to timely eliminate possible errors.