Drainage pumps: application features and tips for choosing

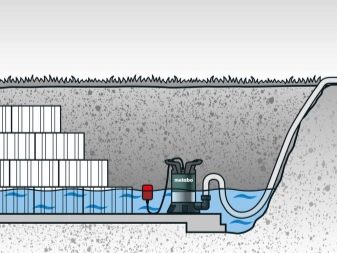

Drainage sediments are designed for pumping water from the territory of private ownership. Each owner of a suburban site should study the features of the application and tips on choosing this device before buying. Drainage sediment is suitable for pumping water from pools, ponds, as well as basements and cellars.

What it is?

A drainage pump was made to pump fluid from flooded basements. In the future, the expansion of the device application area was observed.Modern pumps are designed for pumping lightly contaminated fluid from wells, pools and trenches, as well as to pump and clean the well. Some pumps are operated in production. Many models can carry out the transfer of fluid in which there are impurities up to 10 mm in size.

A drainage pump is a special device that is manufactured for specific actions. It is not allowed to use a non-intended application. Although the drainage is operated when cleaning a shallow well and a well of a mine type, such devices are not suitable for continuous interaction.

It is not allowed to operate the equipment as a fecal pump, although many users try to ignore the rules.

Drains have the following advantages:

- The equipment can be mounted offline or in stationary mode.

- The device has a float-type switch, which is responsible for controlling the filling of the liquid.

- The devices are made of durable materials that do not corrode and other irritants from the external environment.

- Drainage pumps have a small size and weight. Due to the compactness of the device is considered mobile.

- Devices can pump out liquids that contain solids. Some models are characterized by the processing of fiber and some chemical components of non-aggressive type.

- The equipment is characterized by high efficiency indicators along with a maximum immersion depth and high technical properties.

- Drain pump does not require special care.

The disadvantages include one item, which is dependent on electricity. Equipment cannot operate without power supply.

Specifications

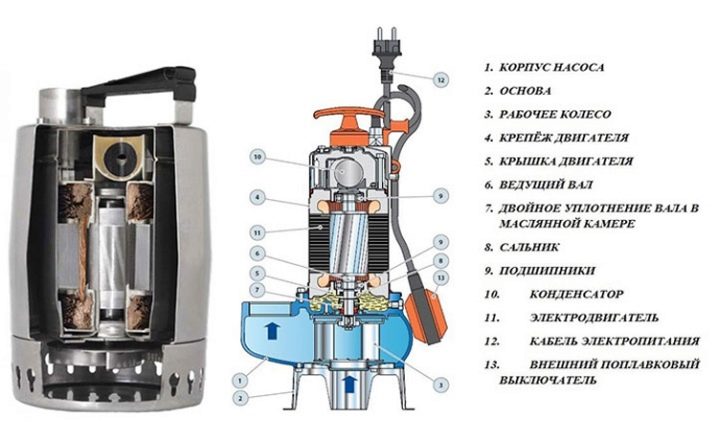

Simplified designs consist of the following parts:

- Electric motor

- Shaft with impeller. It can be directly on the motor or separately. The purpose of the part does not change from its placement: it is responsible for the movement of water inside the equipment. Component is made of stainless steel type.

- Pump unit equipped with intake manifold. Water penetrates the pump through its holes.Using the diameter of the holes, the dimensions of the particles to be passed are determined.

- Cabinet part. Household pumping station is made of plastic or steel. Thanks to such materials, the device is characterized by mobility and convenient use. Plastic has a high sensitivity to the interaction with solid particles, so these pumps often break down and need repair.

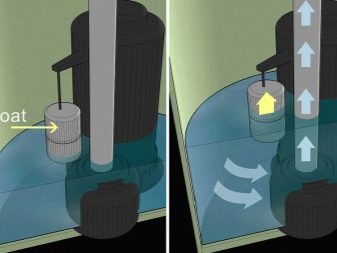

- Switch float type. It prevents flooding and the work of the product "dry", as it automatically turns on and off depending on the amount of water.

The scheme of the pump is quite simple: when the device is activated, an electric motor starts, which rotates the shaft with the impeller. A zone with discharged air appears around the rotating blades, due to which the pressure in the chamber decreases. Water is drawn into the nozzles with holes and moves inside the pump. Due to the action of centrifugal force, the liquid moves to the outlet and goes into the discharge hose.

In order for the pump to function properly, it is necessary to observe the rule that the total number of solid impurities that are in the chamber does not exceed 10% of its volume.

Traditional drainage pumps are not suitable for interaction with hot liquids. They can operate with high temperatures for a short period of time, as the motor cools, giving off thermal energy to the liquid. If a pump is required for continuous transfer of hot liquids, you will need to purchase a special type of model.

The material from which the pump is made has an effect on product reliability. According to GOST, immersion models can be made from composite raw materials combined with stainless steel. There are also models that are completely made of stainless steel.

Dimensions of particles filtered by submersible pumps are considered an important indicator. Some models of devices can interact only with the smallest particles, the size of which does not exceed 10 mm. They are designed for pumping conditionally clean liquid (water after washing machine, washing unit, shower).

Other models can work with larger particles, the size of which is 12.35.50 mm. With the help of such equipment it is allowed to pump more dirty waters with a high content of sand.

Flow-quality is also an important characteristic.It includes flow and pressure indicators of the fluid. Household products have a maximum flow rate that does not exceed 14 cubic meters per hour, the pressure of the devices reaches 10.9 cubic meters.

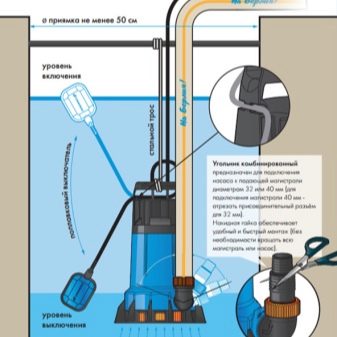

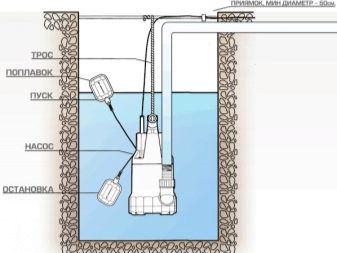

Drainage pumps have manual or automatic control. Automation is considered more convenient and reliable. In such products a float switch is provided that reacts to the water level and is located exactly on the surface. If the float is lowered, the equipment automatically turns off. When raising the float, the system turns on.

More advanced models are controlled by a special control cabinet.

Orientation of pressure nozzles: there are horizontal or vertical models. Selection of the desired orientation is considered an important task, especially if the pump is integrated into an already ready drainage system.

If the orientation does not match, a flexible hose will be required to connect to the wiring.

Principle of operation

A drainage pump is needed for pumping fluid from filled reservoirs (from a well, pool, well) or flooded rooms to a nearby drainage system.The pumped water moves into the working chamber, after which it enters the outlet nozzle. Due to the structure of the majority of drainage systems, according to which the impeller has a semi-open view, the equipment can transfer a large amount of groundwater and other water in a short time.

Since the equipment cannot generate a lot of pressure, it is not capable of pumping and lifting water over considerable distances. The pumped water also allows the engine to cool. Due to this quality, the risk of overheating of the water pump after long-term operation is minimized. Therefore, there is a limit on the maximum temperatures of the pumped liquids. For most models, the value does not exceed 50 degrees.

Manufacturers offer devices that can be used in non-standard areas and in hot environments. However, the cost of such equipment is much higher compared to traditional varieties. Drains can effectively function in an environment that has varying degrees of contamination. All units are divided into three types:

- For clean liquid or water with a low degree of contamination. They can pump water in which there are impurities whose size does not exceed 5 mm. They are used as water intakes for the water-lowering well, pools.

- For medium contaminated liquids. The size of solid particles in the fluid being moved should not exceed 25 mm. The equipment is used to collect water from storm drains, wells.

- For dirty water, in which there are inclusions up to 38 mm in size. Pumps are used for pumping liquids from the accumulation water trap, pumping flood water during flooding.

The efficiency of equipment that is designed to interact with clean water is 83-230 l / min. Indicators of the flow of pumped fluid reaches 5-12 meters. Such data is sufficient for the full functioning of fountains and water supply systems, the use of products for irrigation.

For pumping out of dirty waters, in which there is gravel and other particles with a size of 10-15 mm, products are used whose efficiency is 37-450 l / min. They provide water to a height of 5-22 meters.Industrial drains are designed to work with sewage. They are able to recycle particles whose size reaches 120 mm.

Drainage installations differ from borehole in that they pump out water, which contains various impurities. Drains can also interact with only the minimum content of solid particles in the liquid. In faecal pumps, there are shredders that effectively cope with dirty liquids that contain solid waste.

Varieties at the place of installation

There are two types of drainage pumps, which differ in the place of installation. There are surface and submersible drainage systems.

Surface pumps

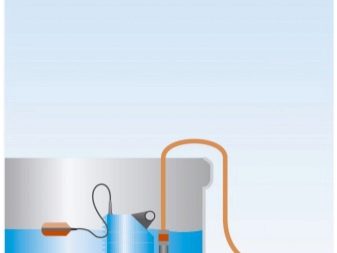

The surface or self-priming pump is located on the edge of the tank from which the pumping is performed. Such products are distinguished by compact size and mobility. There are vertical or horizontal devices.

The inlet is lowered to the bottom of the tank, from where it begins to suck up the liquid with impurities. The equipment can operate independently, without human assistance, as it is equipped with a float mechanism that reacts to the fluid level.When the water rises, the float rises and the water pump starts working. When the level drops, the pumping system automatically shuts down.

Surface equipment is easy to maintain and transport. Each unit node is available, so the repair will not be difficult. Most instruments have average power ratings.

They can be operated in a pumping station that interacts with wells and boreholes.

Submersible pumps

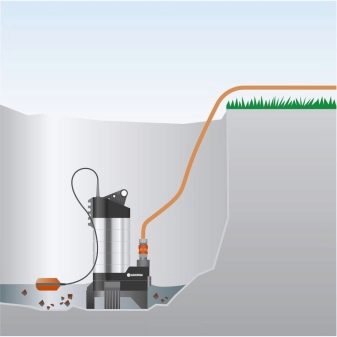

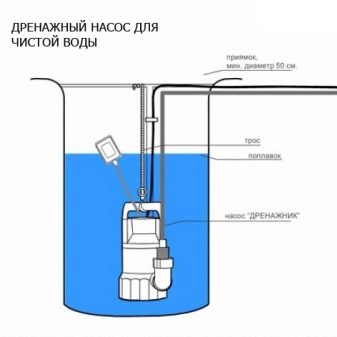

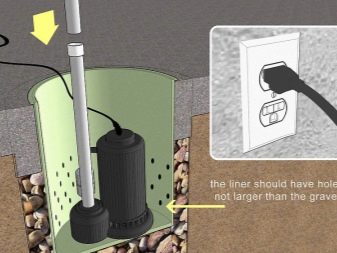

Submersible drainage pump is designed to work directly in the pumped liquid, so the product is completely immersed in the tank. There is no suction nozzle in the equipment. Water enters the pump through special holes that are located in the bottom of the pump. To provide protection against large particles, a mesh-type filter is used in the design.

Since the submersible equipment works directly in the pumped water, its body part must be leakproof and durable. Products operate in automatic mode, manual control type is not provided. The pump has enhanced electrical insulation, thanks to which the product can work in liquid media. Submersible pumps are characterized by high power levels, performance, quiet operation, long and safe operation.

Power varieties

Based on indicators of power and scope of use, drainage pumping equipment can be divided into two categories: domestic and industrial.

Household

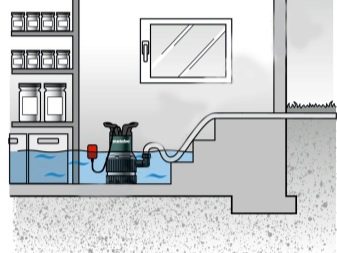

Drains designed for use in the domestic sphere, have a wide range of uses. They can be used for pumping fluids from flooded cellars, technical wells, pools and natural reservoirs.

The equipment is often used in irrigation systems, as well as for the rapid supply of water to the fountains. The body part of the product is made of stainless steel. It is also allowed to use for these purposes reinforced polymer. The devices are capable of pumping liquids with solid impurities up to 10 mm in size.

Industrial

Industrial drainage systems have a high level of power and efficiency. Motor-pumping and diesel-pumping apparatus is often used by public utilities, construction organizations and the Ministry of Emergency Situations. With the help of such pumps the following actions are performed:

- pumping fluid from the sewer tank, clogged pipeline;

- elimination of emergency flooding;

- industrial drainage;

- pumping water from the reservoir pit and other structures.

In industrial drainage pumps used electric motor, which is located in a cast iron housing. A radiator with increased power ensures efficiency in heat dissipation. Thanks to the cast-iron case, the device is protected from deformation due to heat generation.

Which to choose?

The selection of drainage pumps is based on operating conditions. To purchase equipment that meets all requirements, you should pay attention to several indicators.

Although drains have good performance, their operation can be accompanied by difficulties if solid particles are present in the pumped liquid. Given this quality, it can be concluded that the pump is ideal for pumping out liquid from flooded rooms.

To make the drainage of the reservoir, under the apparatus will need to equip a solid and level base.For use on the construction site need fecal pumps with a grinder.

When calculating the required power, the following formulas should be used: the required power of one meter of depth is identical to ten meters in the horizontal plane. For example, for pumping liquid from a pit, the depth of which is 50 meters, you should prepare a hose 50 meters long. It should be borne in mind that the pumping speed will be small, as there is a length of the outlet that goes over the soil. If, with correct calculations, a small head is still present, an additional length of three meters will be required. Efficiency indicators are directly dependent on the power level, so attention should be paid to this factor.

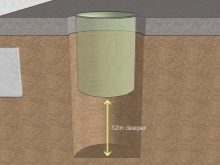

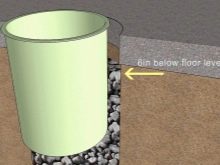

Selection of the desired model depends on several factors. First of all, you should pay attention to the installation site. Experts advise installing a hand pump without a float in a small recess (about 0.5 meters). This step eliminates the leakage of fluid to the surface. If automatic equipment is used, the floor will always remain dry, as automation is considered the most reliable system.If the installation site has a length and width of more than 50 cm, use any float pump. If a full drainage of the tank is required, the use of surface products without a float is permitted.

The lifetime of drainage pumps depends on the material from which the parts are made. Body part can be plastic or metal. The first models have a lower cost, but plastic does not have a sufficient level of resistance to mechanical stress. Therefore, the plastic case can be deformed and crack. Experts recommend to purchase products with a metal casing, as they have sufficient strength and can be repaired. The longest service life of pumps are stainless steel and cast iron.

The blades of the equipment can be made of stainless steel or special technical polymers. The latter option is considered to be optimal, since special impurities are present in the polymers, due to which the parts become resistant to aggressive effects. But such parts are not subject to repair.

Metal blades wear out quickly compared to plastic ones, so their price is lower.

Most modern models are equipped with automatics, which triggers a mechanism to achieve a certain level of fluid. The following devices exist:

- Electronic embedded. They are complex and expensive nodes operating on the basis of an electronic control unit.

- Float. These are simple and reliable items.

Automated switches of both types do not allow the device to function "dry", therefore, ensure smooth operation.

By capacity is meant the amount of liquid in cubic meters that the pump pumps in 60 minutes. The efficiency is indicated in the technical data sheet for the pump. To determine the performance required for the work, it will be necessary to divide the volume of the pumped tank by the expected period of operation.

As a rule, for home operation there is enough device with an efficiency of 10 cu. m / h For industrial facilities, it is necessary to choose a more powerful pump whose capacity exceeds 100 cubic meters. m / h

The pressure depends on the type of pump and is 5-50 m.Consider the distance to which the fluid is discharged, and the height of the pumped water. All characteristics are recorded in the technical passport and indicated in the ratio of 1:10.

If the technical documentation states that the pump is capable of raising water to a height of five meters, then the transfer of fluid can be carried out for a length of 50 meters. These are average values that do not take into account other characteristics (for example, the diameter of the hose).

To ensure maximum efficiency of the pump, you will need to choose the right size pipe. Models with a small diameter of 0.5-1.5 inches are suitable for pumping water. To interact with contaminated liquid, choose a diameter of 8 inches.

On sale there are branch pipes in vertical or horizontal execution. You should also pay attention to the diameter of the hose, which should coincide with the pipe. Portable and lightweight products are suitable for domestic use. They differ in mobility and convenience in operation.

If you need to pump out "dry", you should choose a model that leaves no more than 2 mm of water.

Popular manufacturers

There are many manufacturers that offer different models of drainage pumps. Each brand offers models that attract customers with its functionality and technical characteristics.

To make the right choice, it is recommended to study the rating, which contains the best manufacturers of drainage equipment. Customer reviews will allow you to learn more about the proposed models.

Grundfos

This is a Danish brand, which is engaged in the release of drainage pumps. In addition to the units, customers can purchase electric motors and components. The manufacturer offers a wide range of immersion and surface products that can function in different environments.

There are products that can work in a dirty liquid, and also developed special pumps for hot water. Buyers speak of this brand as reliable, as all components are made from high quality raw materials. Pumps run smoothly and are characterized by a long service life.

However, some people leave negative comments about the cost.equipment, as the brand is considered expensive.

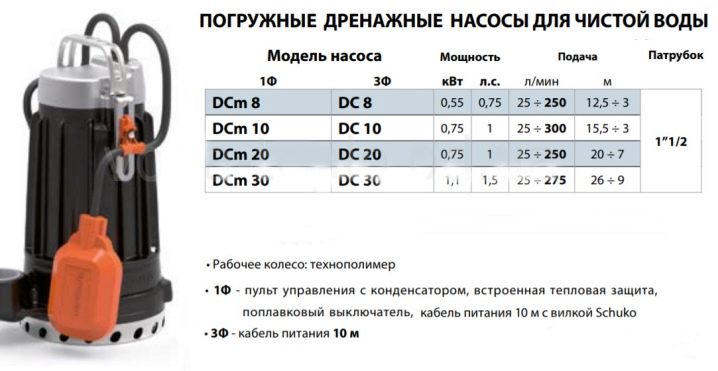

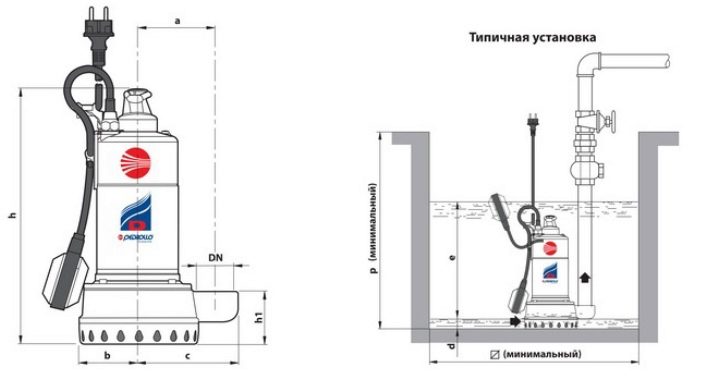

Perdollo

Italian drainage pumps Perdollo are in great demand. The manufacturer sells new generation equipment. Buyers have access to a wide range of models, which differ in their functionality, design and technical parameters. Drainage pumps of this brand have a high level of resistance to wear and mechanical damage.

Buyers from different parts of the globe leave positive feedback on purchased products. Despite the fact that the drainage systems of this brand have a high price tag, the products have shown themselves to be high-quality and reliable units with a long service life.

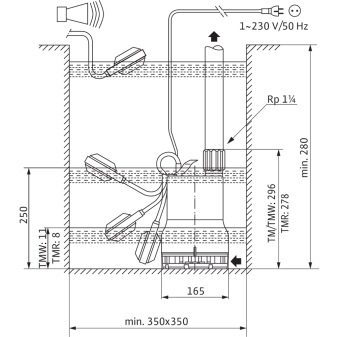

Wilo

A popular brand from Germany, which has been providing the Russian market with high-quality and modern drainage equipment for more than 20 years. The manufacturer offers new technologies and attractive design. Each pump produced at the Wilo plant is of high quality. The manufacturer is confident of the reliability of its products, since there is a multistage quality control at the production facilities.

Reviews of Wilo drainage pumps confirm the words of the manufacturer. Buyers report that the pump has been running smoothly for a long time and there are very few reviews of equipment breakdowns. Modern design and advanced technologies attract a wide audience.

"Dzhileks"

This is a popular Russian brand. Drainage pumps are produced since 1993. To date, "Dzhileks" is a leading manufacturer in its field. Products are distinguished by reliability, the ability for a long time to operate in difficult conditions. The manufacturer is constantly working to improve its models and offers new solutions to the audience.

Customers are attracted by the reliability of products, a wide range in which you can choose a pump that is suitable for solving tasks. Affordable cost makes the product the most attractive. Users report that drainage pumps are of high quality, which can be compared with foreign counterparts.

Tsurumi

Tsurumi is a Japanese manufacturer that is considered the world leader in the manufacture of drainage pumps.The company offers reliable products that can cope even with highly contaminated liquids.

The brand has been known since 1924 and is currently in demand around the world. Buyers are willing to pay a high price, as investments will be justified. Drainage pumps of this brand have numerous advantages that allow to operate the products in the harsh Russian conditions.

In bilge pumps there is a bimetallic sensor, which is located on top of the electric motor. Such a device eliminates overheating or failure due to increased pressure in the system. Measurement of resistance can be carried out from the far cable in such a way that it will not be necessary to remove the case cover.

Installation rules

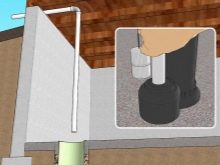

Each person can install the drainage pump with his own hands. No special connection is required for the submersible device. This pump just needs to be immersed in the tank and plugged into the network.

Surface products should be fixed on a clean and dry area, attach hoses to them under the liquid outlet and start the mechanism.

Experts recommend to observe the following rules in installation:

- For the drainage device will need to equip the ground. This is due to the fact that the pump works with the help of electricity and is located in wet conditions.

- If the electrical network does not contain modern devices and sockets and grounding, you will need to create a "ground" with your own hands.

- The diameter of the exhaust valves is large, so standard irrigation hoses are not suitable for connection. Together with the pump, you will need to purchase hoses of the desired length and diameter.

- The method of connection of the nozzle for discharge of fluid should be considered. It may have a vertical or horizontal position. The selection is based on the characteristics of the site.

Installation of a drainage pump is possible for every person, since this event does not require special skills or knowledge. If an immersion device is purchased, do not immerse it in the bottom. You need to select a site higher. Such an arrangement can prolong the life of the equipment, since it does not need to be constantly removed and washed from contamination.

Troubleshooting

The most common malfunctions that require prompt intervention and repair work include:

- the pump hums and does not pump fluid;

- during the start-up of the device, the automatic power switch is “flying out” or knocks out traffic jams;

- vibration is observed or the pump overheats;

- low level of water pressure at the outlet;

- pressure switch or hydraulic accumulator malfunction.

In order to understand what the main causes of failure are related to, it is necessary to analyze each option in more detail.

Many owners of drainage pumps are faced with a situation where the equipment does not pump liquid and buzzes loudly. Water pressure may be weak or not present at all. The most common causes of failure include the following factors:

- low level of pumped liquid;

- short circuit between the turns of the electric motor;

- failure associated with the mechanical component of the device;

- breakdown of the air valve.

If an immersion type of device is used, it must be placed in water. To exclude the operation of equipment without liquid, installation of auxiliary protection, which is a float switch, will be required.This element works automatically and shuts off the pump when the water level becomes too low. Disconnection is made using the ball, which is located in the float.

When the water level changes, the ball changes its position in the float, closing or opening the contact. Sometimes you may notice that the pump is buzzing or running, but pumping fluid is not performed. Breakdown may be due to cavitation mode.

Cavitation is created when the equipment has a high power level, which is why the liquid does not have time to penetrate the impeller blades. To eliminate this situation, you will need to place the equipment deeper.

Also, a similar fault may relate to inter-turn closures. It is easy to identify the defect: when turned on, the motor starts to buzz and the cable heats up. The closure between the coils is formed if the pump runs dry.

The motor is cooled due to the pumped liquid. Without water, the power unit begins to function at idle, overheats and there is a violation of insulation in the winding.

The failure of a mechanical character manifests itself during the operation of the engine: the engine starts, but does not spin and hums. The fault may be hidden in the blades of the impeller.Broken parts wedge the rotating shaft. Also, this factor can disrupt the operation of the bearing system. Long work in this mode leads to inter-turn circuit, due to which disassembly of the pump is required.

To detect a malfunction, you must unplug the machine from the mains and remove it from the water. Then you need to rotate the impeller on the shaft. If scrolling fails, proceed with disassembling the pump. On some models, a special valve is installed that is responsible for the descent of air. The ball in the valve may stick. The situation arises because of operation in difficult environments and at hit of liquid with solid particles in the pump.

The sticking of the ball contributes to the violation of the constant removal of accumulated air masses, and the motor begins to function at idle. To restore activity, temporary operation of equipment in a clean liquid can help. With this method, the valve is cleaned of dirt and plaque.

When starting the electric motor, there may be a knockout of plugs or a disconnection of the circuit breaker.This action is observed due to jamming of the bearing shaft or from the combustion of the motor.

If there is a second option, you can smell the burning.

The malfunction of the float switch is associated with an illiterate connection and the wrong network selection. For example, the voltage is 380 V instead of 220 V. Experts do not advise you to disassemble the pump with your own hands, since in the future it will be necessary to rewind the armature windings, which only a professional can handle. To verify that the cause of the breakdown is in the winding, it is possible to measure the insulation resistance. The minimum value should be equal to 0.2 Mom.

On some modern models there is a thermal relay, which is responsible for shutting down the pump when overheating. If such a part is missing, it will be necessary to control that the equipment does not work without water.

Due to continuous dry running, the body part will begin to warm up, which will cause the magnet to move, which will lead to seizure of the piston.

After the magnet has peeled off, internal vibration with a chain reaction will appear throughout the pump design.In the end, the event will disable all mechanical and electronic components of the product. Professionals report that after such a malfunction, further repair of the pump is inappropriate.

To repair the drainage pump, first of all, you need to completely disassemble the equipment and remove the magnet. Then it should be applied to the body with a magnet longitudinal notches and glass sealant. All worn parts are replaced and the pump is assembled in the reverse order.

During operation of submersible or surface drainage systems, one may encounter the fact that there is a slight pressure at the outlet. Most often, the cause of the fault lies in clogging the filter.

The pressure of the pumped water through the hose may drop sharply or disappear completely. Among the main "symptoms" are engine overheating or loud noise during operation. At the surface of the pump during wear and tear, the sleeve may be damaged or the clamp, which secures the mounting on the sleeve, may be loosened. This defect leads to the suction of unwanted air flow into the system, which prevents pumping.

To eliminate the problem, you will need to examine all the connecting elements on the nozzles and clamps. If no defects are found, the reason may be hidden in the short course of the vibrator.To solve the problem, you will need to disassemble the device and adjust the auxiliary washer with a vibrating rod. Also checked sealing elements with membranes.

Not all the defects described can be eliminated by hand. At home, you can strengthen the weakened dampers, change the floats and restore the mechanical damage, due to which there was a wedge of the impeller. Each user will be able to independently replace the cable. The easiest way to fix the shock absorber. To do this, you need to make a wound body and tighten the loose nuts. The top nut must be fixed so that it does not loosen in the future.

In order to replace the wires, it will take some time. You can change the condenser only on some types of drainage devices. Other types of faults cannot be repaired without the help of a service center. For example, if the stock is broken, it will be easier to buy a new pump than to try to rebuild the equipment. Valve replacement is also considered an unprofitable event if you do it yourself. Burnt winding can be restored only in the service center.

Maintenance and Care Tips

Proper use of the drainage pump is the key to a long service life and uninterrupted operation of the product. To ensure proper progress, you will need to follow simple rules:

- Water is used as a coolant for submersible drainage pumps. The temperature of the surface products should be monitored independently or select models equipped with thermal relays.

- The use of float protection is considered mandatory. When operating the pump in a small amount of liquid, there is a risk of failure.

- When buying, you should study the performance of the device. For household use, a pump with a capacity of up to 180 l / min is suitable. This volume is enough to work with heavy flooding and pumping of groundwater. If there is no risk of a large rise in water, small pumps with a capacity of 80-85 l / min can be purchased.

Before buying the device is recommended to consult with experts. They will help organize a proper irrigation or pumping scheme. In some cases, irrigation of a vegetable garden from a natural reservoir is possible.Experienced professionals will assist in the selection of products that are suitable for the task.

Proper selection of the pump will eliminate the formation of breakdowns in the operation of the device.

Review and unpack the drainage pump, see below.