The process of manufacturing a boiler indirect heating

An indirect heating device is a special accumulation apparatus that heats water without using other power sources. The boiler without the slightest effort heats large volumes of water and maintains the required temperature by supplying a hot stream. This method of obtaining hot water minimizes the cost of the owner.

Special features

The appearance of this type of heater resembles a barrel, however, models of rectangular and cubic forms began to appear. Boilers, by their nature, are unique equipment, as they are suitable for apartments and houses, regardless of the area.

Electrode boilers or, as they are also called electric boilers, make it possible to save on electricity, providing relatively quick heating of the heating water in the heating system.For heating private houses use a device with a power supply of 220 watts or 380 volt electric boiler.

You should know that the price of a double-circuit boiler will be much higher than the cost of an appliance that heats only a house.

The water heater of layer-by-layer heating has a high rate of performance, because the heating of the liquid in the boiler takes place in a flowing manner, and the container accumulates water. Layer-by-layer heating has several advantages over indirect, namely:

- performance is twice as high;

- entry level performance is also superior;

- there is only a small loss of heat.

This device for the purpose of use is similar to a water heater, however, there are differences.

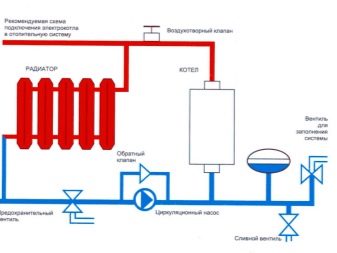

Indirect heating boiler uses the energy of the coolant, which heats the building. The system of borrowing energy is simple: a heat exchanger is introduced into the storage tank, passing through which the heating medium heats not only the room, but also water. Such a boiler is not only super economical, but also safer than a water heater. Thus, you can not only protect yourself and your family from burns and scalding, but also save a lot of money, and most importantly, you can make and install the device with your own hands.

The positive sides of the indirect heating boiler are the following:

- the heat exchanger can be connected to both central heating and to any type of boiler;

- water heating does not require electricity, gas and other fuels, which reduces the cost of operation and installation of equipment;

- the stability of the water temperature without the slightest jumps, which allows you to safely take a shower or wash dishes at any time of the day;

- safety during operation without installing expensive automation;

- the simplicity of the design and installation considerably saves money, allowing you to independently make and install a boiler.

But there are also disadvantages of indirect heating devices. These include the following:

- rather large dimensions and weight of the boiler compared to storage water heaters;

- use only in the heating season, for use in summer it is necessary to equip the boiler with a tubular electric heater;

- a decrease in the temperature of the coolant with long-term heating of the water, which affects the heating of the room;

- regular cleaning and maintenance of the coil in connection with the deposition of salts, which is a rather labor-intensive process.

Blueprints

An indirect water heater consists of a storage tank connected to the boiler by a pipe system. Inside is a coil with a coolant circulating in it that heats the water. Due to the constant movement of the heating source, the water in the tank remains hot. Water consumption and the addition of a new almost do not affect the temperature, because in a matter of minutes, the water reaches the conditioned temperature. This factor is a super-economic advantage of this device.

Before you make the device yourself, you should consider the main three types of boilers, such as:

- indirect heating boiler with a coil, through which the coolant moves;

- a device with pipes located along the walls (the principle of heat exchange resembles the first type of boilers);

- two vessels - large and small. Water is poured into the small one, the coolant circulates in the large one.

The primitive scheme of a homemade heater gives a huge scope to creativity. Having understood the principle of work, you can easily come up with your own design of your product. For a storage tank, you can use absolutely any container of the required size,resistant to temperature changes and protected from corrosion, for example, from a stainless steel, most often from copper.

The ideal option can be considered an old gas cylinder, which has a high degree of strength. But do not use enameled containers to collect the tank. Continuous contact with water will destroy the walls of the vessel and in a year (at best, after a year and a half) will have to build a boiler again.

How to do?

Today, in specialized stores you can purchase an electric, wood, magnetic or water boiler. However, this is all a costly matter both in time and financially. You can choose an economical option - create a high-quality water heating device yourself. Before you make the boiler yourself, you need to calculate the minimum volume of the tank and the length of the heat exchanger.

To provide the necessary amount of water, you should approximately calculate its daily consumption. It is considered that a permanent tenant consumes 50–80 liters of hot water per day. This amount is enough to take a shower, a bath and spend on household needs.In this case, a family of 3-4 people will need a 200-liter boiler.

Selected tank tank should have five holes: two at the side for mounting the coil, one at the bottom for the flow of running water, one at the top for getting hot and one at the bottom for the drain valve. A hole is also made to install the tubular electric heater. Valves or ball valves are attached to the holes. The coil is made of a spiral-shaped metal pipe or in the form of an internal mini-tank.

The material from which the coil will be made must have high heat transfer and rust resistance, such a metal can be copper. On average, ten liters should be calculated 1.5 kW thermal capacity of the coil. To give a spiral shape, you can use a log or a pipe of a larger size.

Winding the coil requires care, you should pay attention to the following points:

- to improve the effect upon contact with water, the coils should not touch each other, which will allow for more rapid heating;

- you should not be zealous in coiling the coil, because then it will be simply impossible to remove it from the rim;

- it is necessary to count the number of turns, starting from the volume and height of the tank.

The size and number of turns is determined by calculations using the formula l = P / (n • d • T), where:

- P is the heat output of the coil, which is 1.5 kW for every 10 liters of the tank volume;

- d is the diameter of the pipe chosen for the manufacture of the coil, which is presented in meters;

- l is the total length of the pipe in meters;

- T is the temperature difference before and after heating (usually for preliminary calculations take the difference of 65 degrees).

To facilitate calculations, you should pay attention to the calculations for some tanks:

Volume of boiler tank (l) | Coil Thermal Power (kW) | Coil length (m) | Diameter of boiler tank (m) | Diameter of coil loop (m) | Number of coil turns |

200 | 30 | 15 | 0,5 | 0,4 | 12 |

150 | 22,5 | 11 | 0,5 | 0,4 | 9 |

100 | 15 | 7,5 | 0,4 | 0,3 | 8 |

50 | 7,5 | 4 | 0,4 | 0,3 | 5 |

As mentioned above, one of the drawbacks of the boiler is the lack of operation in the warm season. There are two ways to solve this problem, such as:

- install a short closed loop from the boiler;

- install a tubular electric heater in the boiler tank itself.

The first method is too wasteful, because it is based on fuel, for example, wood or diesel fuel. And if the fuel is coal, it will entail soot and soot. In addition, time will be lost for maintenance, cleaning and loading. As for the installation of a tubular electric heater in the tank itself, this will allow the water to be heated in the warm season in the normal mode of the water heater. To save electricity, water can be heated at night or connected to a solar collector system. The power of the tubular electric heater must correspond to the volume of the tank device. So, for 50 liters of power should be 1.5–1.8 kW, and for 200 liters - 5–6 kW.

In the structure of the boiler, heat insulation is simply necessary, since it plays the role of a kind of incubator. It enhances and retains heat inside the device.

For insulation can be suitable for any material insulation, applicable to repair. You can opt for mounting foam or mineral wool, which is attached with wire, ties or glue. To add aesthetics, the body is covered with thin sheet metal or foil insulation.Such plating not only retains heat, but also accelerates the heating process.

To assemble the boiler yourself, you must first prepare all the elements of the future homemade, and then proceed to the following steps:

- Inside the tank of indirect heating, the coil is first mounted - in the center or along the walls. Next, the pipes are soldered to the inlet and outlet pipes;

- if the boiler will stand upright, supports should be welded to the bottom; if the device will hang - the hinges (the so-called ears), which it will be attached to the wall;

- the installation of a tubular electric heater should be carried out if there is a desire to use the device not only in the cold season, but also in the summer;

- after completing the installation of the viscera, close the device tightly with a lid;

- now it is necessary to connect the boiler with external elements, connect the coil to the contour of the heating system;

- connect the inlet and outlet pipes for hot and running water;

- it is now necessary to dilute the pipes in the kitchen or in the bathroom at the point of dismantling.

Tips

In conclusion, it is necessary to dwell on the advice from experts who will help both in assembling a self-made construction, and in choosing a suitable indirect heating boiler.

- Indirect heating boilers are divided into four groups: vertical, horizontal, wall and floor. For a country private house, the floor device would be ideal. The volume of heated water varies from 100 to 300 liters, this amount is more than enough for a large family.

- You need to understand that you need about 50 liters of water for a shower, and 30 liters for a dishwasher. During the day, a family consisting of four family members spends up to 50 liters of water on washing, up to 90 liters on household needs (washing dishes, for example), and about 300 liters per shower. And also do not forget about the other needs of water sales in the house. It is for this reason that the family, which includes three people, must purchase a boiler for 100 liters and no less.

- To avoid violations during the operation of the boiler, a part of the device must be insulated with a special layer of expanded polystyrene, mineral wool or polyurethane foam, in other words, the so-called thermal insulation.

- It is worth remembering that in no case can you use enameled objects to create a boiler tank, since the design process will take a lot of time and effort, and after a year the device of indirect heating will have to be redone.

How the Drazice boiler is made, see the following video.