Noise isolation ventilation: features of the device and installation methods

Noise isolation ventilation ducts is a necessity, since ventilation is a serious and significant source of constant noise. If there is no proper sound insulation, then you can hear how the fan functions. This noise can lead to insomnia, unstable pressure, as well as noise has a negative impact on human health - that is why you need to create high-quality sound insulation of ventilation, protecting yourself and the residents of the house from this irritant.

Noise sources

Noises, which are provoked by the operation of ventilation, may have different characters of origin. All of them can be divided into several types, including:

- Airborne noise It implies the movement of air flows through the ventilation channels. The speed of movement of such air is quite high, because of what it happens with a certain noise. The presence of sounds is inevitable, but it is possible to reduce their level, albeit only slightly.

- Vibrational noise It occurs if the ventilation parts were not securely fixed. It is the poor-quality installation of the system that causes the vibrating hum to pass along the walls of the ventilation shafts. Particular attention should be paid to the fixture elements in the installation site of the fans.

- Generating type of noise. Occurs if there are complex turns in the ventilation system. Such noise occurs when we are dealing with a non-standard design. In this case, quite often it becomes a strong irritant.

In any apartment ventilation chambers must be installed correctly. Noise absorber and ventkanal in a residential building can be mounted with your own hands in the shortest possible time, if you follow all the recommendations presented. In some cases, this will require only self-adhesive tape.Its successful application is proved by positive feedback from consumers.

Installation errors

Most of the provoked noise is due to the fact that the ventilation system is poorly installed. Therefore, noise can be avoided by proper installation. In the case when the occurrence of noise is unavoidable, it can be significantly reduced by sound insulation. But you need to understand that there is no completely silent ventilation. Regardless of the measures, the minimum hum will always be present.

Below is a definite list of actions due to which errors can be avoided when designing and installing a ventilation system. Thanks to them, most of the provoked noise can be avoided.

- It is not necessary to use the recirculation system of air without the presence of certain branches. Such an error usually occurs when the space between the ceiling and the false ceiling is involved. In this case, the movement of air occurs arbitrarily, so he chooses the most convenient for him flow - this is what provokes the occurrence of unwanted noise.

- It is not necessary to lay noisy air ducts over those rooms in which noise is undesirable. This parameter must be considered at the design stage. The ventilation system is best laid above non-residential premises. Correcting such an error can lead to large financial costs, but it is an excellent way out of preventing noise.

If it is not possible to pave the ventilation in any other way, then it is worthwhile to take care of the use of special structures that can reduce the noise level.

- It is necessary to lay the duct along the corridor with its further ramification in the desired direction. This approach will be optimal in the situation of a single duct with adjacent rooms.

- Need to use vibration isolationthat will significantly reduce vibration noise. By alternating flexible and rigid air, you can completely eliminate vibration. In this situation, the sound will be lost along the way.

- Control the speed of movement of air flow in the system. It is necessary to calculate the amount of air passing through the ventilation channels. The data obtained allow you to select the optimal diameter of the duct,so that the flow rate can be reduced and, therefore, reduced noise.

Ways to fight

It is possible to reduce the spread of noise through noise insulation of the ventilation system. You can implement it by the following methods:

- The implementation of competent design. If you make a thorough analysis and laying of the route in the ventilation, it is possible to prevent various noises. It is necessary to avoid the presence of sharp bends in the system.

You should stop your choice on the option that is accompanied by the least amount of transitions from one channel size to another. Using this approach, you can prevent the occurrence of self-generated noise and minimize the number of places of their possible occurrence.

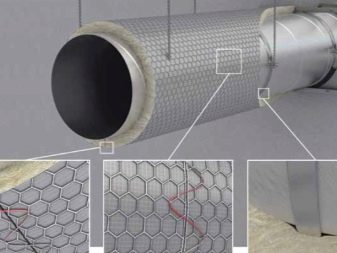

- Installing a silencer in problem areas. Such a device is usually mounted near a working installation or its nodes. They take over the air currents and absorb their vibrations. There are plate, which are installed inside a rectangular ducts, and tubular options, focused on installation in round-shaped ducts.

- By applying soundproof material to the channels. This method allows to avoid friction of parts and assemblies in their connections. The layer can be applied both to the inner and to the outer surface.

- Installation of flexible gaskets or joints - An additional way to reduce the amount of noise.

Materials

The effectiveness of sound insulation of the ventilation system is related to how correctly this or that material will be selected and used. It is necessary to take into account the structure of the material, its ability to absorb sounds, cost and, directly, quality. When choosing, you must also be based on the features of installation.

Weak points in the air ducts are transitions and knees - it is in these places that noise usually begins to occur. The used insulation in these places is rather quickly deformed and decreases, so it is necessary to apply an extra extra layer of insulation or use lamellar mats in order to add an additional noise absorber. The unique structure of the material allows the fibers to resist deformation.

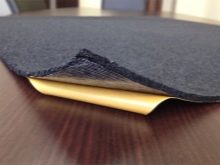

Often used technology is the spraying of the surface of pipes with polymeric materials.The use of izolon or self-adhesive izolonapep is popular. With the help of spraying, you can cope with the reduction of external noise, however, in more vibrating areas, it amplifies oscillations during fan operation.

The best effect can be achieved if the materials for sound insulation repeat the configuration in the ducts, correspond to the material of which the duct is made, and its parameters.

That is why the methods for noise suppression should be selected at the stage of designing a house and developing a ventilation system.

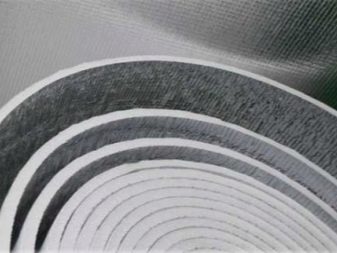

It is important to note that the ventilation system, which has a round sectional shape, is characterized by greater noiselessness. This is achieved through a flexible duct, which is able to more effectively suppress sound vibrations than a rigid duct.

It is recommended to use mats made of polyethylene and rubber, which are used in the form of an outer insulator. With their help, it is possible to reduce the vibration of the walls of the sleeve during the operation of the fan and reduce aerodynamic noise.

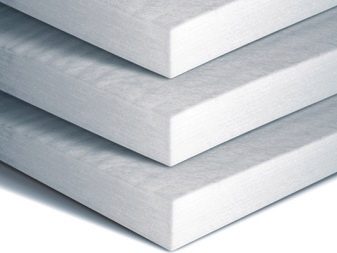

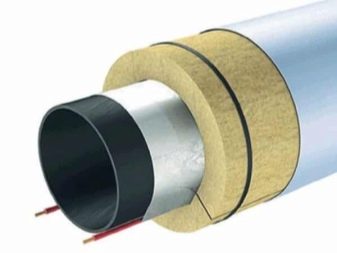

The most common material for the thermal and sound insulation of ducts is mineral wool andpolyethylene foam. Minwat is much more common.

Insulation procedure is as follows:

- Initially, it is required to clean the pipes from existing contaminants.

- Then it is necessary to wind the pipes with a layer of mineral wool.

- The overlay foiled insulation, the thickness of which is equal to 4 mm. This is required so that the cold does not penetrate inside and the heat does not go outside.

- There is a sealing of seams by means of an aluminum adhesive tape.

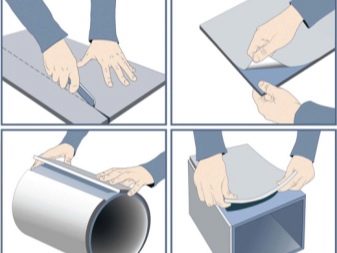

Polyethylene foam also leads in frequency of installation. The installation process is extremely simple: you first need to measure, after which the sheath of polyethylene is opened along the seams and attached around the pipe. At the end of the work, it is necessary to seal up the existing seams and joints with adhesive or tape.

Soundproofing do it yourself

Make noise insulation, which will reduce the level of aerodynamic noise, you can do it yourself, without resorting to the services of specialists. To do this, use polymer and rubber plates for insulation, which are able to reduce the low-frequency noise, which is the most dangerous to humans.They are characterized by ease of processing and easily take the form of a surface that is insulated. They are applied a sticky layer, so that they are firmly and comfortably fixed. These plates are an effective and organic fiber.

To carry out work on the box is easy. To do this, you must perform the following actions:

- It is necessary to purchase plates with polyethylene foam.

- If there is no adhesive surface, apply acrylic glue.

- You will need a knife, spatulas and a brush.

- The box is cleaned of all kinds of pollution.

- Places that are difficult to access, it is necessary to glue the foam polyethylene. Its reflective surface must face out.

- Work on the box body should be performed overlap without gluing.

To learn how to make noise insulation of ventilation ducts, see the following video.