Thermal insulation of air ducts: how is it arranged and what is it necessary for?

On the Internet you can find a lot of materials devoted to the weatherization of walls and ceilings, the floor and foundation, residential and industrial buildings. But not a single dwelling, not a single institution, workshop or trade pavilion can be operated without ventilation. Therefore, it is very important to minimize the heat leaving through it.

Special features

Thermal insulation of ducts effectively solves such three main tasks at once, if it is done correctly, like:

- condensation is prevented;

- reduced heating costs;

- reduced noise operation of ventilation equipment.

The air flow thrown on the street in winter is inevitably warmer than the outside. Where the duct goes through heated rooms, it is safe.But all areas in the cold zone without proper protection will be frozen outside and covered with hoarfrost. As the temperature difference increases, the effect is only stronger. As a result, the lumen of the ventilation channel can sharply narrow. During long frosty winters, the air duct can stop working altogether.

The reduction of heat loss is especially important for complexes of heated ventilation. Insulation helps to avoid cooling the air in the gap from the point of heating to the conclusion of the room. Such a move is even more important with a large length of the ventilation duct or its laying through unheated rooms. As for sound insulation, in quiet places the noise of the ventilation systems can be very unpleasant.

Materials

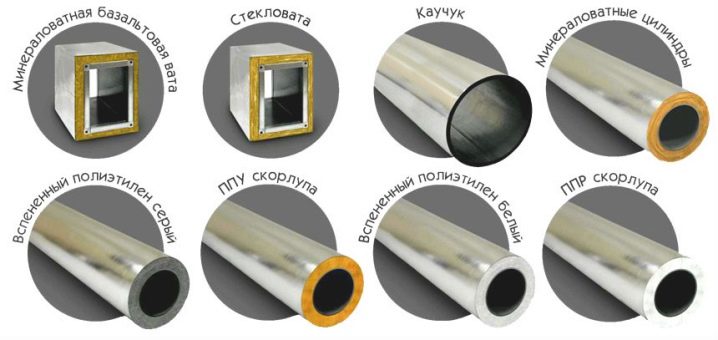

The following materials can be used for ventilation ducts:

- rolled material;

- cylindrical shells;

- sheet products, if the duct is rectangular or square.

Even for quadrangular systems, sheet heat insulation options are rarely used. Installation is very difficult and time consuming. In addition, we have to do a lot of joints, inevitably weakening the structure as a whole.An excellent substitute is roll insulation. For the most part, insulation is achieved in rolls of mineral wool with a total thickness of 40 to 80 mm.

The most popular format is 50 mm. Only occasionally they apply a mineral wool thicker than 8 cm, it is necessary for large-panel housing construction, but not for the construction of a private residential building. Mineral wool with an outer layer of foil makes the structure more efficient and protects it purely mechanically.

But in any case, it will be necessary to take into account that cotton wool gradually collapses, and will begin to crumble, and when working with it care is required.

Polyethylene foam is cheaper because its thermal efficiency is lower. Due to the small thickness of the insulation wrap the pipe will need several times. Similar in its characteristics and foamed rubber. Therefore, among the rolled options mineral wool insulation should still be considered as a priority. The shell is made from such components as:

- mineral wool, rubber or polyethylene;

- foam plastic;

- extruded polystyrene;

- PPU

It is formed either monolithic - strung on pipes during ventilation installation, or collapsible - suitable for installation on ready-made existing ventilation systems.Insulation shells helps out very much in places where the pipe is led through the wall. It is easy to imagine what difficulties arise there when winding a simple rolled insulation. Quite good results are achieved on even open areas. But the point where the duct turns, close the outside of the cylinder will not work. Only insulating mats will fit there.

Both in supply and exhaust ventilation systems, there is a lot of noise during operation. The larger the cross section of the pipe, the higher the throughput, but at the same time the resistance will also increase. The role of interior decoration is to create the smoothest possible surface, which would least inhibit the air flow.

Combined insulation solutions are now used relatively rarely, since there are more practical ways. Noise can be reduced with the help of silencers.

In addition to mineral wool, glass wool can also be practiced for warming, which is covered with reinforced aluminum in the outdoor version and fiberglass with impregnated surface in the inner version. The use of foam elastomers is attractive,as they fade out and do not sustain combustion. In addition, such substances have the following features:

- they do not allow mold colonies to develop;

- harmful to microorganisms;

- miss a lot of steam without harm to themselves;

- absorb significant amounts of moisture.

Along with polyurethane and polyethylene, polyisocyanate, polystyrene and polyvinyl chloride are considered completely non-combustible. These materials are supplied in the form of blocks, tubular sectors and plates. The main scope of application is an internal heat-shielding of air ducts. Phenol-based expanded resins are not only fireproof, but also consistently tolerate microbiological aggression. For this reason, they are often put into the air ducts of industrial refrigerators.

Choosing the right material for the duct's thermal protection is quite complicated; you will have to take into account the following:

- the location of the pipe on the street or in the room;

- thickness;

- main construction material;

- diameter.

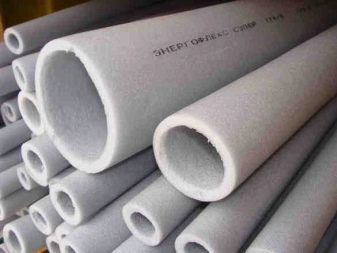

All these subtleties can be revealed as it should only with the help of specialists. Household ventilation is usually insulated with polyethylene foam.It is made at the factory fully finished shell, taking the form of pipes and insulating them from hypothermia. The advantage is the absence of harmful substances in the composition of this material.

If at the same time it is planned to insulate the pipes of the ventilation and the gas pipeline, then the best solution is simple mineral wool.

Device

Air ducts abroad heated premises, output through the wall, insulated from the point of withdrawal to the deflector. The ventilation pipe going through the attic and through the roof should be insulated throughout the attic. Similar requirements apply to the entire area passing through unheated rooms. The inlet heated system is equipped with thermal protection throughout. In attics often resort to the use of boxes (enclosures) of polyethylene foam.

The advantage of this design can be considered an affordable price and the ability to purchase the right product anywhere. The casing should fit exactly to the size of the pipe. It should be noted that the foamed polyethylene easily deteriorates under the action of ultraviolet radiation. To prevent this negative effect, it is necessary to cover the structure with kitchen aluminum foil on the outside. The sequence of work is as follows:

- measured diameter and height of the duct outside;

- preparing the casing of the required size;

- the umbrella is removed if it is delivered;

- the casing is tensioned to the base of the pipeline;

- the umbrella returns to its former place;

- foil is wound onto the system from bottom to top, which will help to increase the service life;

- winding fastening is made of stainless or copper clamps.

For the middle zone of the Russian Federation, this solution is very well manifested. In a more severe climatic zone, reinforced insulators are needed, such as mineral wool. It works equally well on domestic and industrial ventilated channels. If desired, it can be used even from the inside, even from the outside. A typical example (the other options differ slightly) is the use of Izover coating.

The work will require the following tools:

- spatula with rubber working part;

- stapler ;;

- sharp-cut construction knife;

- aluminum scotch with a strip of 7.5 cm;

- gon

- metal tape;

- ruler;

- marker for marking.

When calculating the desired width before cutting it is worth repelling from the diameter of the pipe.The doubled thickness of the chosen insulation is added to it, and the amount is increased by 3.14 times - this will be the desired indicator. When the figure is received, the roll is unwound and the necessary distance is measured on it. Of course, the measurement should be done so that the cotton is not soaked. If it is raining outside, even a little, it is better to postpone the preparation for later than to lose a very expensive product.

After an incision on the surface, gently separate the cotton layer to the foil itself. Cutting the roll along the prepared mark, wrap the pipe in it, ensuring that the foil of the connecting seam closes on top. Every 10 cm you need to fix this seam with a stapler and glue the joined section with aluminum tape tape. Immediately after that, the tape is taken with a rubber trowel, then the glue will grab onto the foil surface exactly.

The pipes supplying the house with air should be protected from heat leaks also at the joints.

This problem is solved simply: by cutting curvilinear pieces. Their length is selected in strict accordance with the pre-calculated values. The fragments are exposed so that they completely duplicate the problem bend.Places of joining pieces again should be blocked with aluminum tape, which is aligned with a spatula. It is easier than with other types of insulation to work with the shell, it is only applied to the right place and snapped in the manner provided by the designers.

Serious problems are often caused by thermal insulation of air separation. In industrial installations where such systems are present, only materials that are guaranteed to exclude burning or detonation under standard conditions are necessarily used. But the sensitivity to shock, by contrast, is not significant. Important: open air duct areas will not be able to be insulated with assembly foam.

Even if you do not take into account the high price of such a cover, it will be unreliable and will not be able to solve the problem. It is better to contact the professionals with the right equipment and get a quality service.

Tips and tricks

You can often find statements that only air ducts in the coldest areas are warmed. But this is nothing more than a myth: it is not so much the peak temperature that is decisive as its daily variation.Even with a positive value, if the air at night is much colder than during the day, a large amount of condensate inevitably appears. When working with mineral wool, it is recommended to always wear protective clothing and be extremely careful. Fastening of foiled insulation can be made not only with specialized elements, but also with ordinary wire.

It is believed that the duct with external insulation is better protected from fire than the outdoor option. But it would be better to take care of additional security guarantees. They are provided by the use of fire valves installed immediately after the ventilation systems. Quite good results, judging by the reviews, are given by the use of izolon and foil-coated K-Flex.

But penofol is not recommended to use, it will cease to stick after a while.

If any material with a foil layer is used, it should be turned outwards. This will help and improve the thermal quality of the structure, as well as facilitate the fixing of the product on the pipes. Insulation hoods located in the thickness of the walls, rarely practiced.But to increase their tightness with 4-5 cm foam will be easy. At the same time, a vapor barrier is installed in advance inside the house and its contour is attached to the channel so that the foam does not get wet from water vapor.

It is recommended to equip intake systems with heat-insulated ventilation valves. Such a mechanism will not precisely freeze even in the most severe frosts and will prevent the ingress of excessively cold air inside. The role of heating elements is not in the heating of the premises, but only in preventing the formation of ice on the valve leaflets.

Essential to the design and calculations is the dew point. Focusing on it, you can determine the exact boundaries of the insulated area. But professionals recommend that it is better to cover a longer area with thermal insulation than follows from the calculations.

Records of negative temperatures and daily weather changes can be beaten at any time, and it is worth preparing in advance for such events. If mineral wool is used, you must be ready to replace it every 24–36 months due to the loss of heat. When insulating square pipes, the plate breaks are laid with pieces of insulation and sealed from above.Metal ducts do not necessarily cover the vapor barrier, but the liquid hydrophobic layer is very useful.

If there is a serious limitation in the means, it is recommended to replace the branded rolled insulation with universal mineral wool: in two turns it is wound onto a channel and pressed with clamps. All open areas must be outside to overlay roofing material or more modern waterproofing using bitumen and polymers. In some cases, it is acceptable to use PIR type ventilation plates. But this decision is very responsible, because the material is relatively new and quite expensive.

It is better to make a choice only after consulting with qualified engineers.

Important: where there are crows or seagulls, all open areas of the air ducts after thermal insulation should be covered with metal. Only this will give at least the minimum guarantee of lasting peace of mind. It does not really matter what material is located below under galvanization - it can be K-Flex, foam glass, wool or other means. In the domestic environment there is no special sense to give preference to liquid insulation.They are expensive, and require special equipment, and can not be applied everywhere, and almost every air duct has hard-to-reach areas.

Suppressing noise due to insulation materials will be much more efficient if you set the correct settings for ventilation equipment. In addition, in the place where the air duct and the fan dock, it is advisable to put a damping gasket so that it dampens other sounds. Signs of poor-quality work of the ventilation duct, motivating to urgently engage in its thermal insulation, are diverse. Reasons for alarm are the following:

- violation of the tightness of the ventilation system;

- the appearance of traces of rust on the pipes;

- reduced air flow;

- detection of moisture accumulations inside walls and floors.

Selecting the internal or external insulation of the duct is not as easy as it seems. Thus, the complexity of creating thermal protection from the inside pays off reliable protection from temperature extremes and from mechanical damage. But, reducing the useful internal diameter will require expanding the design with the same characteristics.This is not always possible both for technical and purely economic reasons. If it is difficult to make a final decision, then you should consult with the experts so that they understand the specific circumstances.

Polystyrene shells can incise with a knife or saw. When overlaying the pipe, it is quite permissible to move its fragments by 20 mm in order to ensure an optimal imposition. Cold bridges are a big problem in many cases. It is possible to prevent their occurrence only with the strictest observance of technological standards.

Maximum attention is always paid to the insulation of the joints between the ventilation ducts and the main building structures. Depressurization of these joints will instantly devalue the rest of the work.

You can learn more about how to heat the ventilation pipes in the garage with your own hands.