Insulation for pipes made of polyethylene foam: features and characteristics

Outside pipes are freezing in winter. To prevent the liquid from turning into ice and rupture of communications, the pipes must be insulated. Installation work on laying pipelines for various purposes is combined with thermal insulation. Mineral wool and polymer insulation are used for thermal protection. The most popular insulation is polyethylene foam.

What it is?

Polyethylene foam is an artificial elastic material consisting of bubbles filled with gas. Production takes place on special extruded lines, where polyethylene granules are mixed with reagents. In the process, the composition is heated to +140 degrees - a chemical reaction occurs, as a result of which the volume increases 20 times and the material acquires a cellular structure.

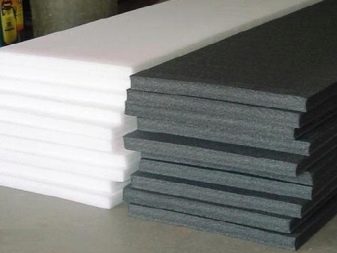

Not cooled down mix can be formed for receiving various types of thermal insulation:

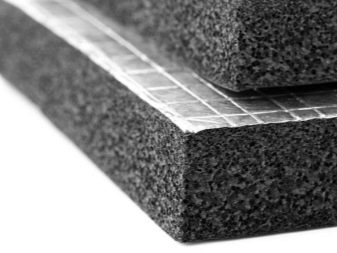

- sheets, coiled, for insulation of building structures and packaging;

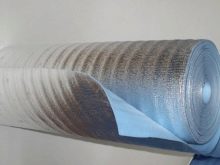

- reflective foil sheets;

- harnesses for sealing joints;

- mats for various purposes;

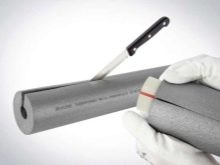

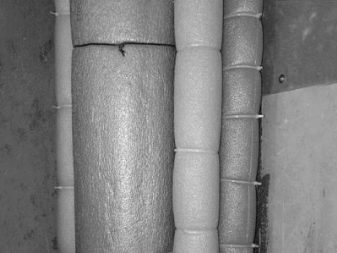

- hollow cylinders for pipe insulation.

To increase the strength of products made of polyethylene foam, chemical or mechanical cross-linking is carried out in order to enhance molecular bonds.

The size of closed bubbles does not exceed 1 mm, which increases the density and technical characteristics of the material. Insulation for pipes produced from cross-linked and unstitched polyethylene.

Polyethylene foam is inert to various materials and mortars. Therefore, pipe insulation can be carried out under the ground and in the open access. PE foam insulation is suitable for thermal insulation of pipes made of polypropylene, steel, cast iron, metal-plastic, polyvinyl chloride.It is used in industrial engineering systems, urban communications and in private pipelines.

Properties of thermal insulation raw materials

Pipe insulation performs a protective function for pipelines. Polyethylene foam is used for various engineering communications:

- heating lines;

- pipelines for cold and hot water supply;

- sewage;

- air conditioning systems;

- ventilation in ventilation.

For pipes of heating and hot water supply, insulation is needed to reduce heat losses in the coolant and to level the thermal expansion of the material. For cold water pipes, the heat insulator serves as protection against freezing and condensation on the surface. PE foam protects sewer channels from freezing and reduces noise. Ventilation and air conditioning pipes are protected from ice and condensate.

Polyethylene performs insulating functions due to its technical characteristics:

- thermal conductivity coefficient is 0.03-0.04 W / m * K;

- product density varies from different manufacturers from 25 to 40 kg / m3;

- water absorption - not higher than 2%;

- fire resistance class G2 in accordance with GOST 30244 (refers to a moderately combustible material);

- application temperature - from -60 to +90 degrees;

- vapor permeability of 0.001 mg / m * h * Pa allows material to be referred to as fully vapor proof;

- the minimum lifetime is 20 years, the maximum is 80 years;

- strength is expressed in tensile strength at rupture up to 0.3 MPa and elastic moduli in dynamics up to 0.7 MPa;

- depending on the layer of insulation sound absorption coefficient from 25 to 55%;

- resistance to aggressive chemical attack.

High insulation performance demonstrate the characteristics of insulation for pipelines for various purposes. Low thermal conductivity allows to reduce the thickness of the insulator, without changing the efficiency. PE foam exhibits waterproofing properties, protects metal pipes from corrosion. The material does not rot, has high hygienic indicators, fungi and bacteria do not breed on the surface.

The disadvantages of the insulator are flammability at a temperature of more than 300 degrees, spontaneous combustion at 400 degrees. In addition, the material is unstable to ultraviolet.

Due to the elasticity of the material is resistant to deformation, but it can be damaged with sharp objects.Low cost and ease of installation allows the use of polyethylene foam in industrial facilities and in private engineering systems.

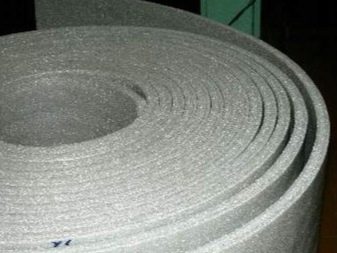

Dimensions

Sheet and pipe versions of polyethylene are used for insulating pipes of various diameters. Rolls from 60 to 120 cm wide produce sheets up to 5 cm thick. They are used to install thermal insulation on pipes with a diameter of more than 16 cm. The length in a roll depends on the layer thickness and can be from 2 to 30 meters. The sheet may have a foil layer on one side of the material.

Foamed polyethylene is supplied in the form of tubes of different caliber for continuous installation of a small diameter pipeline. The dimensions of the tubes vary in length - from 1 to 10 meters. The thickness of the insulation walls can be: 6, 9, 12, 20, 25 and 32 mm. Internal diameter corresponds to the external caliber of pipes, varies from 6 to 160 mm.

In addition, the polyethylene tube can have an outer polymer layer of 1–2 mm, which gives it mechanical resistance and protects against UV light.

Overview of manufacturers

In the heat insulation market, Russian manufacturers are widely represented, producing artificial materials for insulating pipelines. The plants produce foamed polyethylene on foreign equipment, which accounts for the high quality and long service life (over 30 years).

- JSC "Nelidovo Plastics Plant" produces foamed polyethylene under the brand name "Izonel" for the insulation of pipelines for hot and cold water supply, gas and air ducts. Modern German extrusion lines provide high quality polyethylene foam. Two brands of pipe shells "Izonel" are produced: ППЭОТ and ППЭОТ-Г with fire extinguishing agents. Products are gray in color with wall thicknesses from 6 to 20 mm, internal diameter for pipes is from 10 to 89 mm.

- Company "Polifas" It is engaged in the production of insulation materials of the “Stenoflex” and “Stenofon” brands. In the assortment there is foam polyethylene insulation for pipes “Stenoflex 400” in the form of shells of various sizes: wall thickness is from 6 to 30 mm, internal diameter is from 6 to 160 mm, external diameter is from 18 to 200 mm.

- CJSC "Plant of Information Technologies LIT" manufactures products from foamed polyethylene under the brand "Penofol" and "Tilit". Tilit Super pipes with a length of 2 meters and an inner diameter of 15 to 160 mm are used for pipe insulation in heating, water supply and sewage systems.Pipe insulation "Tilit Super Protect" with a polymer coating of red and blue has high resistance to mechanical stress and resistance to destructive environmental conditions. It is supplied in coils with a length of 10 m and 2 m for pipes with a cross section of 15 to 35 mm.

The supplier of heat-insulated pipes and heat-insulating materials for pipeline systems is the company "Thermaflex.

A wide range of products from physically foamed polyethylene is represented by the following brands:

- for household water distribution systems a series has been created "TermaSmart Pro";

- pipe insulation with polymer coating brand "Ultra-M" used in pharmaceutical and food industries;

- insulating tubes "Thermocompact" with an external protective layer designed for pipelines laid in floors and walls;

- universal insulation for pipes with a diameter of 12 to 114 mm "Thermaflex FRZ" designed for new and reconstructed heating systems, water supply and sanitation;

- under the brand "Flexalen" produce heat-insulated pipes of different diameters with a flexible corrugated casing and semi-flexible structures with a diameter of 160–225 mm.

- Polymer processing is engaged in OAO Izhevsk Plastics Plant. For insulation of plumbing systems, flexible foam polyethylene mats of Izolon 500 brand with a thickness of 1 to 5 cm are used. Etiol LLC produces pipes made of high and low pressure polyethylene. The wall thickness is up to 20 mm for pipes with a diameter of 1 to 20 cm. The length of the segments varies from 1.5 to 4.5 m.

- A well-known manufacturer of heat insulation for engineering communications is the firm. Rols Isomarket, which produces technical insulation of foamed polyethylene under the brand Energoflex. The Energoflex Super series is manufactured in the form of tubes with a diameter of up to 5 cm and a length of 1 m, 2 m and 11 m. In the form of rolls, the material is intended to protect large-section pipes.

- Izolin LLC It produces insulation from mineral wool, foam glass, polyethylene, polyurethane. The assortment includes polyethylene pipes of the Izolin PE TUBE brand in the standard version: 2 m long, with a layer thickness of 6, 9, 13, 20 mm, with a diameter of 15 to 110 mm for the pipe.

How to choose?

When choosing insulation for pipes, it is necessary to take into account such parameters as:

- tightness;

- the size;

- ease of installation;

- pipe placement;

- density.

To ensure the tightness of the heat-insulating layer, the foamed polyethylene must completely cover the surface without gaps and deformation.

All joints are glued and fixed with construction tape. In order for the heat-insulating material to fit snugly to the pipe, it is necessary to accurately calculate the size of the internal diameter of the tube, which depends on the dimensions of the pipeline.

The thickness of the insulation walls is calculated taking into account the temperature in the coolant and the lower temperature value in the environment. Also taken into account the purpose of insulation - to prevent freezing, the elimination of condensate on the surface, providing the desired temperature parameter on the floor.

With self-installation of insulation on pipes, the determining factor is ease of installation. In pipe insulation, a cut is provided along the wall, which is convenient for insulating the finished pipeline. When laying new channels, polyethylene foam insulation is put on the pipe section in advance.

The location of the pipeline determines the type of material used. If the plumbing system is visible, located in the free access of the sun's rays, the insulation is selected with an outer protective layer.Polymer shell will protect polyethylene from UV exposure and external damage.

High-quality insulation should be of high density: the durability and efficiency of insulation depend on it.

High density polyethylene withstand heavy loads without deforming and without reducing the thickness of the insulating layer. Also pay attention to the volume of closed cells in the material: the smaller the size of the cells, the higher the insulating properties.

Instructions for use

It is quick and easy to install foamed polyethylene in the form of hollow cylinders and rolls. When applied to a new pipeline or to insulate an existing pipeline, the procedure does not differ.

First of all, the heating and plumbing systems must be turned off. And also before installing the insulation, prepare the surface of the pipes: clean it from dirt and debris, clean it from rust.

When installing on a new engineering system, the polyethylene foam tube can be fastened at the stage of assembly of the structure or upon completion of the connection of the complex. If the installation takes place during the pipeline connection, then an insulating box is put on the pipe section previously.If the insulation is mounted on the mounted hydraulic system, the cylinder opens on one side and is mounted on the finished pipe.

Technical joint seam is fixed with adhesive tape or sealed with plastic clips. The incision can also be glued with glue of the marks “Neoprene”, “Akrol” or rubber 88-NP.

The longitudinal joint between the pieces of insulation is fixed with foil tape. The space between the pipe and polyurethane foam is not glued so that in case of repair it is possible to dismantle the insulation and reuse it.

When the pipeline section has joints and tie-ins with a larger diameter than the main one, then thermal insulation of different sizes may be necessary. First, insulate the main segment. A wider joint between the pipes is insulated with a material with a large internal caliber, which is placed overlapping in both directions. If there are bends and bends of the pipeline, then the corners also need thermal insulation.

For the installation of large caliber pipes, it is advisable to use a sheet version of polyethylene foam.

To do this, a fragment that is equal to the diameter of the pipe is cut from the roll, a section is wrapped with insulation, the joint is fixed with adhesive tape.Installation work continues throughout the area until the pipeline is complete.

Pro tips

- Foam polyethylene insulation may be used. for insulation of various pipes. The wall thickness of 6 mm is used in a limited space for passing communications. Often these pipelines are located indoors and are mounted on walls or floor screed. The thickness of the insulation layer of 9 mm protects cold water pipes from freezing. To reduce heat losses in the heating system and for the pipeline with hot water, polyethylene foam is used with a thickness of 13 and 20 mm.

- The design of the pipeline can be made of different materials. When choosing the inner diameter of the insulation, it is necessary to take into account the coefficient of expansion when heating the coolant. If the pipes are polypropylene, then they select the size of the inner channel of insulation 2 mm larger than the diameter of the pipe. For steel pipes, an internal insulator gauge is 5–10 mm larger than a metal pipe.

- Sizing transverse and longitudinal seams will help to achieve complete tightness in thermal insulationat. Proper installation will prevent condensation from accumulating under the insulation.Glue consumption is small: 6–8 square meters of roll material can be glued with 1 liter of glue. If you count the adhesive flow to the heater in the form of a tube, then 9 mm thick can be glued 1500 meters of seams, 12 mm thick - 600 meters, for a layer of 20 mm - 380 meters of joints. High-quality and reliable adhesive joint can be obtained during installation work at temperatures above +15 degrees and humidity below 70%.

- During operation, the polyethylene foam shrinks. HIf there are no gaps in the longitudinal seams, the material is mounted on the material. On straight sections of the pipeline joints tightly pressed to each other. In the case of installation on heating pipes located on the street, polyethylene foam needs to be protected from ultraviolet radiation and premature wear: a covering material, PVC sheath, fiberglass coating, metal or plastic casing are installed on top of the insulation.

Insulation made of polyethylene foam is shown in the following video.