Izolon PES: properties, advantages and scope of the material

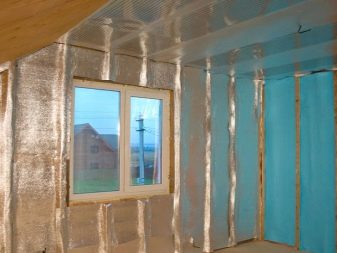

When carrying out construction and repair work can not do without quality materials. Universal tools are especially appreciated by professionals, which include Izolon PES. It is widely used as a noise, moisture, vibration and vapor barrier, is an excellent insulation, and can also be used in the device walls, roof and floor.

What is it and where is it produced?

Izolon is a universal material that has won not only the Russian, but also the foreign market. Abroad, it is represented by the brand Isolon 500, which supplies Russia. Produced at the Izhevsk plastics plant.

Consider the technology of the process of obtaining this building material:

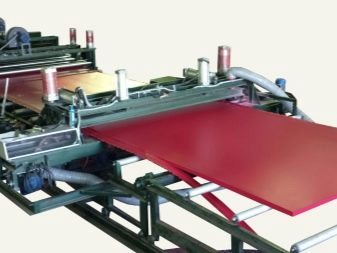

- Polymer sheets are processed by a special composition - extrusion.

- In a special horizontal furnace, the workpieces are fused using an accelerator of radiation particles. After this treatment, the molecular structure of the web changes, and it acquires a foam structure that provides high thermal conductivity and durability.

- Some types of isolon are made in vertical furnaces, which allows to achieve the required thickness and volume.

When baking in a furnace, the structure of the material changes, becoming cellular.

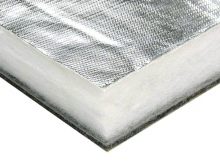

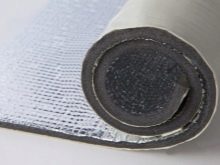

For extra strength, the isolon can be reinforced with a special mesh and covered with foil on one or two sides.

Isolon 500 is the most popular of the entire group of foamed polyethylene. The abbreviation PPE stands for polyethylene foam. Since the 1980s, Japanese equipment Sekisui Chemical CO., LTD has been installed at the Izhevsk plant. This allows you to produce high quality products that meet all international standards and safety.

In 2013, Isolon changed its name to Latin. This is due to the traditionally large export volumes of this material.

Characteristics and brands

The versatility of this building material is related to the intricacies of the manufacturing process.Specifications vary depending on the number of foaming cycles, as well as on the use of additional processing. So, the greater the number of cycles that the isolon goes through, the higher the water absorption, thermal conductivity, sound absorption and strength it acquires.

Here are the main technical specifications of Isolon products:

- nominal ρ - 25-46 kg / m²;

- reflective effect - 97%;

- water absorption - ≤0.1%;

- compressive strength - 0.036-0.33 MPa;

- elasticity - from 130 to 250%;

- temperature range from -60 to + 125 ° C;

- thermal capacity - 1.80-1.95 kJ / kg * s;

- thermal conductivity — 0.031 W / mK;

- vapor permeability - 0.001 mg / mchPa;

- flammability class - G2-G4 (according to GOST 30244);

- sound absorption - reduces noise by 20 dB.

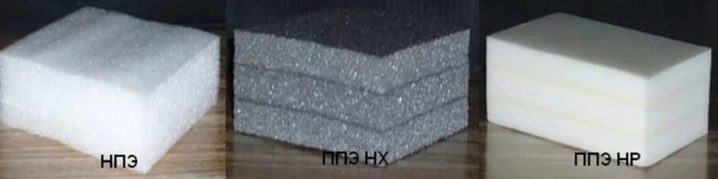

The manufacturer produces several types of isolon:

- Square or rectangular sheets 15-100 mm thick. They are dense and elastic to the touch, and their nominal density is 33 kg per square meter. At the same time, the weight of the ППЭ-Л is insignificant, which simplifies the work and transportation of the material.

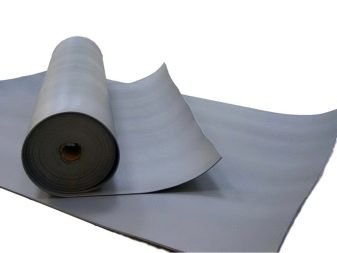

- Rolled isolon with a width of 800 to 1500 mm and a length of 10 to 200 meters. The thickness of the material is from 3 mm to 10 mm. Versions - ППЭ 3003, ПЭЭ 3005, ППЭ Л 3010.

- Stamps with foil-coated. Available in sheets and in rolls.The foil in this material can be represented by a thin film of aluminum or reinforced metal mesh. The reflective layer is applied by lamination, which allows to achieve high adhesion of the foiled part with the isolon itself.

- Izolonape - material from polyolefin with adhesive sides. Usually produced in rolls. It is very convenient to lay. Some manufacturers offer such izolon with 2 sides, one of which is foil, and the other - self-adhesive.

- Series "EcoHit" it is presented as substrates for wallpapers and floor coverings, as well as a “warm floor” system.

Izolon 500 can have a variety of colors: ranging from gray and ending with bright colors - orange and red. And also the outer surface of the material can be embossed with five kinds of patterns.

It is possible to apply laser engravings and logos on the material.

Advantages and disadvantages

Any material has strengths and weaknesses and isolon, despite all its versatility, is no exception.

Its advantages include:

- high strength and resistance to mechanical stress;

- long service life - about 90 years;

- a wide range of applications ranging from the construction industry and ending with automotive and rocket production;

- resistance to aggressive chemicals;

- resistance to ultraviolet and adverse weather conditions is high, so the material can be safely used for the device of external insulation;

- fire resistance, isolon when exposed to fire and temperature does not burn, and decomposes into carbon dioxide and water;

- foamed PES has a small weight, which simplifies both its installation and transportation;

- high elasticity, so that the material easily takes any desired shape;

- good elasticity allows the material to quickly restore the original look and size;

- excellent performance of heat, sound and vapor barrier;

- Isolon practically does not absorb moisture;

- resistant to biological organisms - mold and fungus, does not rot;

- simple and convenient installation in a variety of ways ranging from glue and ending with self-tapping screws or staples of a construction stapler;

- environmental safety and the absence of toxic substances for humans or animals in the composition;

- savings on heating when using isolon can be up to 35%.

The disadvantages include only a few points:

- the relatively high cost of the material, especially foil stamps;

- the need to be careful when installing to avoid material damage;

- You should not “load” the isolon when installing on the wall with additional layers, as this can lead to deformation and lagging behind the wall insulation.

All the disadvantages are rather the features of Isolon, which can be easily overcome, and its low cost is more than offset by the advantages of this material.

How to choose?

The way in which the PES is preferred depends primarily on the purpose for which it is planned to be used.

Experts give recommendations on the choice of isolon, depending on the area of its application.

- As the substrate for the laminate used isolon 2-5 mm. Laying foil material is possible.

- For insulation and insulation of floors made of concrete and wood, a material with a thickness of 8-10 mm is perfect.

- Thin Isolon (up to 3 mm) should be purchased for the device "warm floor".

- As insulation for pipes running underground, PES is used with a thickness of 15-45 mm.

- The overlap between the floors is soundproofed by an isolon of 8-10 mm. If a high level of noise is expected in one of the rooms, then it makes sense to use a thicker version of the material.

- For dry screed and pipe insulation it is better to purchase Isolon foil. Wet screed is performed using izolona, foil on both sides.

- Brand 1508 is used as a lining lag. They are characterized by high density and good noise absorption.

Thus, the choice is directly dependent on what work with the help of PES is planned.

Where does it apply?

The widespread use of Isolon is due to its unique technical characteristics.

This material is actively used:

- in the repair and construction of houses, apartments and cottages as a universal insulation with excellent moisture, noise, and vapor protection;

- in the automotive industry as a heater and noise insulation, as well as tuning the car;

- on ships and ships as insulation;

- in industrial engineering;

- as packaging material;

- as packing and laying in the food industry;

- in the medical industry as a material for the manufacture of orthopedic products, for example, special insoles;

- in the shoe industry;

- in the oil and gas industry;

- in the leather and haberdashery industry as parts of products, a reflective element of cooler bags and other temperature-keeping objects;

- in the sports industry as an elastic base for mats, boxing paws and other equipment;

- in sports, tourism and recreation, like carpets and tatami;

- in the production of toys like hygienic puzzles, prefabricated toys, designers, and so on;

- in needlework, for example, as the basis for the manufacture of large flowers, volumetric decorative figures for celebrations and much more;

- in rocket science.

Izolon is so available in every hardware store that it is not difficult to purchase it and use it at your discretion. Due to the wide range, this unique material can be used in almost any household, industrial, decorative, advertising and other purposes.

It keeps its shape perfectly, does not sink, insulates and is not afraid of moisture, besides it is beautifully decorated.

These are the main reasons that its popularity and scope are constantly expanding.

You will learn more about the fields of application of the isolon by watching the following video.